Professional Documents

Culture Documents

Machine Tool Gearbox Design.

Uploaded by

Mohamed OsamaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Tool Gearbox Design.

Uploaded by

Mohamed OsamaCopyright:

Available Formats

UNTUK RUJUKAN SAHAJA. JANGAN MENIRU. JADILAH UMAT YANG SUKA BERFIKIR UNTUK KEBAIKAN DAN KEKUATAN ISLAM.

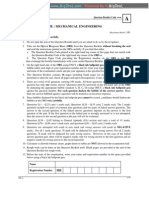

KJM 561: Sessional Assignment 1 EM220 / 7M2 Date: 9/4/2005 UiTM Shah Alam

TITLE: MACHINE TOOL GEARBOX DESIGN.

This gearbox design is actually the interpretation of the available gearbox configuration of a cutting machine. The arrangement of the gearbox gears was taken from a catalogue at UiTM machine shop. For my case of study, I have chosen the eight speeds Cholchester 5 in. (140 mm) Bantam Lathe. The diagram of the machine is shown in the Appendix. Figure 1 shows the gearbox layout of the lathe

machine. It consists of three major shafts with the input or driving shaft denoted by C. As shaft C act as the input shaft, it consists of four gears for speed changing mechanism with number of teeth of 12, 30, 14 and 24 respectively. On the intermediate shaft, denoted as D, four gears mounted on it. Each gears having number of teeth of 30, 13, 28, and 20 respectively. On the output shaft A, two major gears acting on it which have number of teeth of 44 and 51 respectively. Shaft B and E act as reversing shafts for the system. Furthermore the arrangement speeds of the gearbox is in 4.2 (i.e.; four C

different

produced

intermediately

between

shaft

and D whilst two different speeds between shaft D and A). As a summary, number of teeth of the gears involve in the mechanism can be categorized as follows:

Shaft C: N11 = 12 (= a) N12 = 14 (= c) N13 = 24 (= e) N14 = 30 (= g) Shaft D: N21 = 30 (= b) N22 = 28 (= d) N23 = 20 (= f) N24 = 13 (= h) Shaft A: N31 = 51 (= i) N32 = 44 (= k)

From Figure 1, the first stage transmission ratio has four combinations:

uI1 = N11/ N21 (= 12/30) = 0.4 uI2 = N12/ N22 (= 14/28) = 0.5 uI3 = N13/ N23 (= 24/20) = 1.2 uI4 = N14/ N24 (= 30/13) = 2.3

Figure 1: Gearbox layout of 8 speeds Cholchester Bantam Lathe.

The

second

stage

transmission

ratio

then

has

two

combinations which are:

uII1 = N23/ N31 (= 20/51) = 0.39 uII2 = N22/ N32 (= 28/44) = 0.64

The speed layout or the Ray Diagram of the gearbox is shown in Figure 2.

Figure 2: Speed layout of eight speeds gearbox.

The step ratio of the gearbox can be calculated as follows: B = speed range z nH nL B = step ratio = number of speed = the highest speed = the lowest speed

(z-1)

= nH/ nL = 800/36 = 22.222 = 22.2221/7

= 1.56

which give the speeds as follows : n1 = 36 rpm n2 = 36 () (= 56.16 rpm) n3 = 36 (2) (= 87.61 rpm)

n4 = 36 (3) (= 136.67 rpm) n5 = 36 (4) (= 213.21 rpm) n6 = 36 (5) (= 332.60 rpm) n7 = 36 (6) (= 518.86 rpm) n8 = 36 (7) (= 800.00 rpm) Speeds of shaft D by each gear as referred to Figure 2 are: nII1 = n1 + (n2-n1)/2 = 46 rpm

nII2 = n3 + (n4-n5)/2 = 112 rpm

nII3 = n5 + (n6-n5)/2 = 273 rpm

nII4 = n7 + (n8-n7)/2 = 659 rpm

Speed of the input gear on shaft C as referred to Figure 2 is: nI1 = n4 + (n5-n4)/2 = 175 rpm

Because

of

the

space

requirement,

we

can

see

that

the

gearbox designed is very simple rather than because of its number of speeds is only eight. The gearbox also using the sliding gears as the type of speed changing mechanism.

From Figure 2, The overall transmission ratio at stage 1 = 6 = 14.41

The overall transmission ratio at stage 2 = = 1.56

On

the

first

stage,

uI1 and

uI2 (i.e.

0.4

and

0.5)

are

relatively low, thus the differences between the torques which have to be transmitted is low but then uI3 and uI4 (i.e. 1.2 and 2.3) are relatively high, thus the required torque is also high. On the second stage, both

transmissions ratio are low (i.e. 0.39 and 0.64). The first speed of the gearbox is provided by the

combination of gear a.b and gear f.i. When switching to the second speed, second stage meshing gear is then changed to gear d.k. To change to the third speed, first stage meshing gear changed to the combination of gear c.d and gear f.i on the second stage while fourth speed is the combination of gear c.d and gear d.k. The next speeds are following the same sequence. It can be said that, to change the speed, the gear on the output shaft has to be changed every time, thus this will cause fast failure because of fatigue on the gear

teeth caused by the torque transmitted between gears on different shafts. This means that speed range is supplied by different set of gear set (i.e. to change the speed, gear set has to be changed at stage 1 and stage 2). The transmission ratio of the second stage is , and thus this is very preferable since it is low. The highest transmission ratio, i.e. the greatest speed change occurs in the first part drive. Therefore the gears for reduction uI1 must be strong enough.

Appendix

a. Eight speeds Cholchester 5 in. Bantam lathe machine

b. The assembly of the eight speeds gearbox of Cholchester 5 in. Bantam lathe

c. Separated parts drawing of eight speeds gearbox of Cholchester 5 in. Bantam lathe machine

You might also like

- Nine-Speed Gearbox Design for Motor Running at 720 RPMDocument14 pagesNine-Speed Gearbox Design for Motor Running at 720 RPMrip111176100% (1)

- Design and Analysis of GearDocument35 pagesDesign and Analysis of GearABnB InnovationsNo ratings yet

- Gear & Gear TrainDocument20 pagesGear & Gear Trainniaz kilamNo ratings yet

- CH 13Document27 pagesCH 13Sanjay KumarNo ratings yet

- The Indexing or Dividing Head For Milling MachineDocument4 pagesThe Indexing or Dividing Head For Milling MachineDion Adi PutraNo ratings yet

- Construction and Details of GearsDocument19 pagesConstruction and Details of GearsAkhil NairNo ratings yet

- Design of Machine Tool GBDocument39 pagesDesign of Machine Tool GBrahul bachuteNo ratings yet

- Machine Tool Gear Box DesignDocument38 pagesMachine Tool Gear Box DesignKarthikeyanRamanujam100% (1)

- Ray Diagram Kinematic LayoutDocument4 pagesRay Diagram Kinematic Layoutvijayakumar0% (1)

- Adaptive Design of Machine Tool GearboxesDocument9 pagesAdaptive Design of Machine Tool Gearboxesأحمد دعبسNo ratings yet

- Spur Gear Design ProcedureDocument11 pagesSpur Gear Design ProcedureRamji RaoNo ratings yet

- Rack and Pinion Steering DesigningDocument19 pagesRack and Pinion Steering DesigningAudrian Louven Realubit Sabado0% (2)

- Gear Selection and DesignDocument9 pagesGear Selection and DesignDarwin LimNo ratings yet

- 1 1 4 A PulleydrivessprocketsDocument4 pages1 1 4 A Pulleydrivessprocketsapi-30839565067% (3)

- Part 5 MT Drives and Mechanisms 1Document11 pagesPart 5 MT Drives and Mechanisms 1Zayed KhanNo ratings yet

- Flange Coupling Lab PDFDocument25 pagesFlange Coupling Lab PDFAli Raza MalikNo ratings yet

- Best Practice - How To Open Files Created in Newer Release, in Older Version of Creo ParametricDocument5 pagesBest Practice - How To Open Files Created in Newer Release, in Older Version of Creo ParametricAkshay JumleNo ratings yet

- Involute Spur Gear ProblemsDocument6 pagesInvolute Spur Gear ProblemsChiragJansari100% (1)

- Mechanical Drives Gear SelectionDocument46 pagesMechanical Drives Gear Selectionganga6013No ratings yet

- Rack and Pinion Gears InformationDocument6 pagesRack and Pinion Gears InformationifyNo ratings yet

- Gear Tester, Gear Measuring Machines, Gear Inspection MachinesDocument8 pagesGear Tester, Gear Measuring Machines, Gear Inspection MachinesPramod Patil100% (1)

- Design & Development of Multi-Evaporative Refrigeration SystemDocument4 pagesDesign & Development of Multi-Evaporative Refrigeration SystemAnonymous izrFWiQNo ratings yet

- Final ReportDocument45 pagesFinal ReportKuppu Raj100% (1)

- Design of Jigs Fixtures and Press ToolsDocument4 pagesDesign of Jigs Fixtures and Press ToolsKarthic EaswarNo ratings yet

- Gear Box DesignDocument74 pagesGear Box DesignRanjib BiswasNo ratings yet

- Static and Dynamic Analysis of HCR Spur Gear Drive UsingDocument54 pagesStatic and Dynamic Analysis of HCR Spur Gear Drive Usingjr-parshanthNo ratings yet

- Classification Of Machine Tools: Types And DrivesDocument7 pagesClassification Of Machine Tools: Types And DrivesglisoNo ratings yet

- Machine Tool Engineering DesignDocument34 pagesMachine Tool Engineering DesignAshok Kumar UppariNo ratings yet

- Design and Fabrication of Cycloidal Gear Box: A Project Report OnDocument25 pagesDesign and Fabrication of Cycloidal Gear Box: A Project Report OnAjay NishadNo ratings yet

- Power Skiving PDFDocument11 pagesPower Skiving PDFmadhavikNo ratings yet

- Gear CAD Model Tutorial: Problem: Given A Radius of The Pitch Circle, RDocument22 pagesGear CAD Model Tutorial: Problem: Given A Radius of The Pitch Circle, Rvatsalparikh191991No ratings yet

- Dynamic Force Analysis ProblemsDocument8 pagesDynamic Force Analysis Problemsa c s KumarNo ratings yet

- Minimization of Warpage and Sink Index in InjectionDocument6 pagesMinimization of Warpage and Sink Index in InjectionS-HafizNomanNo ratings yet

- GearsDocument14 pagesGearsZulhilmi Chik TakNo ratings yet

- Low Node DensityDocument22 pagesLow Node Densityanu swamiNo ratings yet

- Gear IntroductionDocument17 pagesGear Introductionpatel ketan100% (1)

- INVOLUTE SPUR GEARS TERMINOLOGY AND MESHINGDocument13 pagesINVOLUTE SPUR GEARS TERMINOLOGY AND MESHINGjiteshpaul100% (1)

- Departmental of Mechanical Engineering Me 213: Manufacturing Practicle Lab Notes On Gears and Gear CuttingDocument7 pagesDepartmental of Mechanical Engineering Me 213: Manufacturing Practicle Lab Notes On Gears and Gear Cuttingnisteelroy100% (1)

- Cam Lab 1Document40 pagesCam Lab 1Madhusudhan Rao KNo ratings yet

- 2 Stage GearboxDocument47 pages2 Stage GearboxSanad Shajahan0% (1)

- Material Selection in Gear DesignDocument6 pagesMaterial Selection in Gear DesignAndre Branco Gil0% (1)

- Machine Design Unit 1 Design PhilosophyDocument12 pagesMachine Design Unit 1 Design PhilosophyAnand Babu100% (3)

- A880gm-Ad3 V10Document78 pagesA880gm-Ad3 V10Pramu Jaya FirstwobandNo ratings yet

- L Gear TrainsDocument88 pagesL Gear TrainsAditya Shubham Garg100% (1)

- Precision Involute Gear Hob DesignDocument11 pagesPrecision Involute Gear Hob DesignKalyan ChakravarthyNo ratings yet

- Use of Dividing HeadDocument20 pagesUse of Dividing Headajs_pto3117No ratings yet

- Gear Terminology: Pitch Circle: Addendum Circle: Dedendum Circle: ClearanceDocument11 pagesGear Terminology: Pitch Circle: Addendum Circle: Dedendum Circle: ClearanceFawad HassanNo ratings yet

- Input Parameters: Compartment With Thermally Thick/Thin BoundariesDocument3 pagesInput Parameters: Compartment With Thermally Thick/Thin BoundariesgfgfNo ratings yet

- DMS PPTDocument116 pagesDMS PPTAyush BhardwajNo ratings yet

- 2011/2012 S1 Singapore Polytechnic Mechanics ExamDocument10 pages2011/2012 S1 Singapore Polytechnic Mechanics ExamsubipuruNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument8 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Design Project 2 Auto TrannyDocument9 pagesDesign Project 2 Auto TrannyUnmil PatelNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument8 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- SINGAPORE POLYTECHNIC 2001/2002 EXAM PAPERDocument8 pagesSINGAPORE POLYTECHNIC 2001/2002 EXAM PAPERsubipuruNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- 2001/2002 SINGAPORE POLYTECHNIC SEMESTER ONE EXAMINATIONDocument9 pages2001/2002 SINGAPORE POLYTECHNIC SEMESTER ONE EXAMINATIONsubipuruNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument8 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Chapter 2 Discretization of The DomainDocument21 pagesChapter 2 Discretization of The DomainMohamed Osama100% (2)

- Composite Medium With Simultaneously Negative Permeability PDFDocument4 pagesComposite Medium With Simultaneously Negative Permeability PDFMohamed OsamaNo ratings yet

- Water Jet MachiningDocument24 pagesWater Jet MachiningKarthik BhuvaneshNo ratings yet

- Introduction To GearsDocument30 pagesIntroduction To GearsPrakash Joshi100% (5)

- Nontraditional Machining and Thermal Cutting ProcessesDocument6 pagesNontraditional Machining and Thermal Cutting Processesku2h_garongNo ratings yet

- ReferenceDocument3 pagesReferenceMohamed OsamaNo ratings yet

- Sheets - Sep 2013Document13 pagesSheets - Sep 2013Mohamed OsamaNo ratings yet

- Waterjet CuttingDocument2 pagesWaterjet CuttingMohamed OsamaNo ratings yet

- Supercedes BS 2874.: Brass Rods and SectionsDocument1 pageSupercedes BS 2874.: Brass Rods and SectionsMohamed OsamaNo ratings yet

- Ijset 8Document9 pagesIjset 8Mohamed OsamaNo ratings yet

- The Module of A Gear: (1) About GearsDocument1 pageThe Module of A Gear: (1) About GearsAnonymous rYwUkpNo ratings yet

- Lecture Seven Gears: Common Gear TypesDocument8 pagesLecture Seven Gears: Common Gear TypesShruti SharmaNo ratings yet

- Industrial Automation: David O'Sullivan WWW - Owl.ieDocument33 pagesIndustrial Automation: David O'Sullivan WWW - Owl.ieruby_evangelinNo ratings yet

- 527 - Applications of Microwave Engineering by Robin JamesDocument3 pages527 - Applications of Microwave Engineering by Robin JamesMohamed OsamaNo ratings yet

- Nano MaterialsDocument4 pagesNano MaterialsMohamed OsamaNo ratings yet

- Ergonomics Case Study Cleaning StationsDocument3 pagesErgonomics Case Study Cleaning StationsMohamed OsamaNo ratings yet

- Complex Manufacturing SystemsDocument23 pagesComplex Manufacturing SystemsMohamed OsamaNo ratings yet

- Specifications and color options for Toyota E TypeDocument2 pagesSpecifications and color options for Toyota E TypeAngga KusumahNo ratings yet

- MRP BajajDocument352 pagesMRP BajajRanesh Kumar0% (1)

- Cyclo BBB PDFDocument124 pagesCyclo BBB PDFNguyenHuanNo ratings yet

- Klübersynth GH 6: Synthetic High-Performance Gear and High-Temperature Oil With Klübercomp Lube TechnologyDocument8 pagesKlübersynth GH 6: Synthetic High-Performance Gear and High-Temperature Oil With Klübercomp Lube TechnologyRangga120890No ratings yet

- Eickhoff Gearbox Operating ManualDocument83 pagesEickhoff Gearbox Operating Manualjjohnsco100% (5)

- Ackerman Angle CalculationsDocument17 pagesAckerman Angle CalculationsSiva Murugesan50% (2)

- R911266833 - 01-AC Main Spindle Drives With SERCOS InterfaceDocument72 pagesR911266833 - 01-AC Main Spindle Drives With SERCOS InterfaceVan Lap NguyenNo ratings yet

- SWARAJ ENGINEDocument30 pagesSWARAJ ENGINEKaran SinghNo ratings yet

- Alfa Laval GJ 4 - Product Leaflet - Ese03004 PDFDocument5 pagesAlfa Laval GJ 4 - Product Leaflet - Ese03004 PDFVils ArabadzhievaNo ratings yet

- Chaff CutterDocument9 pagesChaff CutterLuqman RasheedNo ratings yet

- Motorcycle Gearing Worksheet: (Enter ALL Figures in The Pink Column)Document8 pagesMotorcycle Gearing Worksheet: (Enter ALL Figures in The Pink Column)RobertYueNo ratings yet

- Improving Low Frequency Vibration AnalysisDocument21 pagesImproving Low Frequency Vibration AnalysisMohd Asiren Mohd SharifNo ratings yet

- Gear Cutter CalculationDocument6 pagesGear Cutter Calculationapek1No ratings yet

- CAT Simulator InformationDocument23 pagesCAT Simulator InformationnajafaliNo ratings yet

- Shark Screw Air Compressor: Installation, Maintenance and User ManualDocument43 pagesShark Screw Air Compressor: Installation, Maintenance and User ManualSatria Baru Perkasa RetesterNo ratings yet

- Conveyor Systems PDFDocument19 pagesConveyor Systems PDFJOHN UNIQUENo ratings yet

- Chapter-1: Remote Control GateDocument61 pagesChapter-1: Remote Control Gatevara prasadNo ratings yet

- Oki Data B6500 Spare Parts Chapter 5 Engine Parts ListDocument25 pagesOki Data B6500 Spare Parts Chapter 5 Engine Parts ListFlaco Depaulo CarlosNo ratings yet

- M&M Lab ManualDocument46 pagesM&M Lab Manualbharat_v79No ratings yet

- wx150 Shem Set - cgg0228400Document149 pageswx150 Shem Set - cgg0228400Николай НекрасовNo ratings yet

- Gear Ratios & TorqueDocument2 pagesGear Ratios & TorqueAjay GovindNo ratings yet

- Slotting MachineDocument32 pagesSlotting Machinesanaashraf91% (11)

- Premium Transmission - Profile CatalogueDocument8 pagesPremium Transmission - Profile CatalogueSanjib GhoshNo ratings yet

- TDI - Service Manual Model T100V Turbo Twin Engine Air StartDocument18 pagesTDI - Service Manual Model T100V Turbo Twin Engine Air StartJorge ContrerasNo ratings yet

- 09-Sundyne Presentation Fs ImprovementDocument39 pages09-Sundyne Presentation Fs Improvementjoseellargo100% (2)

- Procedure For Design of Bevel GearDocument4 pagesProcedure For Design of Bevel GearvijayakumarNo ratings yet

- 2.kinematics of MachineryDocument14 pages2.kinematics of MachineryJegan ParamasivamNo ratings yet

- Minimise CoggingDocument4 pagesMinimise CoggingRyn YahuFNo ratings yet

- A01100100-971 Normal Usage Manual SFBDocument33 pagesA01100100-971 Normal Usage Manual SFBVali GheorgheNo ratings yet

- Gate 2013 Question Paper With AnswerDocument16 pagesGate 2013 Question Paper With AnswerGurmail Singh GillNo ratings yet