Professional Documents

Culture Documents

HeliCoil Titanium Inserts

Uploaded by

Ace Industrial SuppliesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HeliCoil Titanium Inserts

Uploaded by

Ace Industrial SuppliesCopyright:

Available Formats

Titanium inserts offer the lightweight, high strength properties needed in todays aerospace applications.

Due to their low coefficient of thermal expansion and increased material stability, Titanium inserts can be utilized in satellites and any other application where inserts must withstand temperatures from subzero to 600 Fahrenheit.

As with Heli-Coil standard stainless steel inserts, Titanium inserts provide stronger assemblies, eliminate stress in the parent material, reduce thread wear and are also corrosion resistant.

sa l

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

Features & Benefits:

Meets Aerospace Standards

Titanium Inserts

Decrease material weight for greater efficiencies

Significant weight reduction without compromising assembly strength Ideal for corrosive environments Low coefficient of thermal expansion

emhart.com

Titanium Inserts

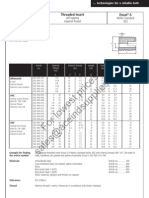

Assembly Tensile Strength Comparison

12000 10000 Tensile Strength (lbs.) 8000 6000 4000 Titanium Stainless Steel

sa l

As shown in the chart above, Titanium inserts weigh significantly less than 300 series stainless steel. Weight reduction is a significant concern in Aerospace applications, where fuel consumption and efficiencies are a priority.

Titanium inserts can also be utilized in applications such as gyros, compasses, radar systems, environmental controls and medical systems. Heli-Coil Titanium inserts are available in both free-running and screw-lock designs.

emhart.com

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

0 #4-40 #6-32 #10-32 1/4-28 5/16-24 Thread Size

Americas Emhart Teknologies P.O. Box 859 50 Shelton Technology Center Shelton, CT 06484 USA Tel: (877) EMHART-1 Fax: (800) 225-5614 Canada: (514) 351-0330 Brazil: + 55 11 3871-6460 Mxico: + 52-55-5326-7100

2011 Emhart Teknologies HC1021 Rev.2 (06/11)

2000

You might also like

- Ati c-200-250-300-350 Tds En2 v1Document10 pagesAti c-200-250-300-350 Tds En2 v1spibluNo ratings yet

- Titanium Alloy GuideDocument48 pagesTitanium Alloy GuidePatrick DominguezNo ratings yet

- BpweldtiDocument36 pagesBpweldtiBivashNo ratings yet

- A330 PylonsDocument21 pagesA330 Pylonsosamoz100% (2)

- Titanium For Automotive Engine ApplicationsDocument5 pagesTitanium For Automotive Engine ApplicationsBg AnoopNo ratings yet

- Application of Titanium & Its Alloys For Automobile Parts PDFDocument6 pagesApplication of Titanium & Its Alloys For Automobile Parts PDFAhmadreza AminianNo ratings yet

- High Perf Metals Brochure v1Document5 pagesHigh Perf Metals Brochure v1arianaseriNo ratings yet

- Applying Titanium Alloys in Drilling and Offshore Production SystemsDocument3 pagesApplying Titanium Alloys in Drilling and Offshore Production SystemsrandyooiscribdNo ratings yet

- Sapa Alloy 6005-6105Document2 pagesSapa Alloy 6005-6105Bob LoblawNo ratings yet

- Titanium Grades PDFDocument7 pagesTitanium Grades PDFMatt AgonyaNo ratings yet

- Grades 6056 Comparison Vs 6061 2024 7075Document2 pagesGrades 6056 Comparison Vs 6061 2024 7075Vinoth Kumar100% (1)

- lt300 ShearbeamloadcellDocument2 pageslt300 ShearbeamloadcellJohan ConradieNo ratings yet

- TitaniumDocument2 pagesTitaniumFenicottero BluNo ratings yet

- Application and Features of Titanium For The Aerospace IndustryDocument6 pagesApplication and Features of Titanium For The Aerospace IndustryCláudiaCardosoNo ratings yet

- Ati 302™/ati 304™/ati 304l™/ati 305™Document11 pagesAti 302™/ati 304™/ati 304l™/ati 305™Vivek JainNo ratings yet

- Titanium Grade Overview PDFDocument6 pagesTitanium Grade Overview PDFAhmadreza AminianNo ratings yet

- Austral Wright Metals Incoloy 800 Product Data SheetDocument2 pagesAustral Wright Metals Incoloy 800 Product Data Sheetshashi_uit100% (1)

- Advance® Sections: CE Marked Structural Sections BS 5950 VersionDocument60 pagesAdvance® Sections: CE Marked Structural Sections BS 5950 VersionZsolt NagyNo ratings yet

- Tata Steel Advance Sections To BS5950 Nov12Document60 pagesTata Steel Advance Sections To BS5950 Nov12bryan.hesp5491No ratings yet

- Titanium 1Document12 pagesTitanium 1Farid AhmadiNo ratings yet

- Potential Applications of Titanium Alloys in Armor SystemsDocument49 pagesPotential Applications of Titanium Alloys in Armor SystemsJoséNo ratings yet

- Catalogo Nickel Alloys - Techalloy PDFDocument12 pagesCatalogo Nickel Alloys - Techalloy PDFCebrac ItatibaNo ratings yet

- rAJURI sTEEL COMPANY PROFILEDocument59 pagesrAJURI sTEEL COMPANY PROFILEpankajkapse100% (1)

- Gas Turbine MaterialsDocument15 pagesGas Turbine MaterialsTemesgen Debelo DesissaNo ratings yet

- Miller Welding TitaniumDocument20 pagesMiller Welding TitaniumrcpretoriusNo ratings yet

- The Use of Titanium in Family Automobiles: Current Trends: K. Faller and F.H. (Sam) FroesDocument2 pagesThe Use of Titanium in Family Automobiles: Current Trends: K. Faller and F.H. (Sam) FroesAmol HawaldarNo ratings yet

- Triten BrochureDocument8 pagesTriten Brochuredragon2065No ratings yet

- Arcelor Mittal HistarDocument32 pagesArcelor Mittal HistarAnonymous uNhWGqNzNo ratings yet

- Titanium alloy for high temperature jet enginesDocument1 pageTitanium alloy for high temperature jet enginesivanlawms6745No ratings yet

- Atlas Stainless Steel Data SheetsDocument57 pagesAtlas Stainless Steel Data Sheetszoksi67% (3)

- About Titanium WeldingDocument6 pagesAbout Titanium Weldingckkashyap0007No ratings yet

- Specialty HeatersDocument40 pagesSpecialty Heaterskvanps_kumarNo ratings yet

- Bollhoff Armstrong HeliCoilDocument28 pagesBollhoff Armstrong HeliCoilAce Industrial Supplies100% (1)

- WIDAC Abbreviated Foundation Coffman GolderDocument24 pagesWIDAC Abbreviated Foundation Coffman GolderKonstantinos KalemisNo ratings yet

- 106 04 PDFDocument6 pages106 04 PDFAbdul Aziz NasutionNo ratings yet

- Untitled Extract Pages (1)Document11 pagesUntitled Extract Pages (1)MohammedIrfanNo ratings yet

- Instrument Tubing Selection Guide: Bulletin 4200-TS Revised, June 2004Document4 pagesInstrument Tubing Selection Guide: Bulletin 4200-TS Revised, June 2004tedNo ratings yet

- 002 eDocument12 pages002 eFaizan Ahmed100% (1)

- Essar Steel Galvanised BrochureDocument9 pagesEssar Steel Galvanised BrochureSukanya Sen DuttaNo ratings yet

- Tedea-Huntleigh 355Document2 pagesTedea-Huntleigh 355jveraf_No ratings yet

- Tata Steel Cutting Edges GuideDocument2 pagesTata Steel Cutting Edges GuideKen SmithNo ratings yet

- RE TitanFeature FGDVBVBDocument2 pagesRE TitanFeature FGDVBVBStrawichDanielNo ratings yet

- Advance To BS5950 June 13-2Document60 pagesAdvance To BS5950 June 13-2Daniel WagnerNo ratings yet

- Shotcrete UKDocument8 pagesShotcrete UKAhirul YahyaNo ratings yet

- Stainless SteelDocument6 pagesStainless SteelNiko NištićNo ratings yet

- Design of Fit Between Die and InsertDocument4 pagesDesign of Fit Between Die and InsertInnovative Research PublicationsNo ratings yet

- Production of Titanium Alloys For Advanced AerospaDocument5 pagesProduction of Titanium Alloys For Advanced AerospaAkhil vNo ratings yet

- Material Data Paper: TitaniumDocument1 pageMaterial Data Paper: TitaniumDanielle StephensNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Additive Manufacturing of Titanium Alloys: State of the Art, Challenges and OpportunitiesFrom EverandAdditive Manufacturing of Titanium Alloys: State of the Art, Challenges and OpportunitiesRating: 4.5 out of 5 stars4.5/5 (4)

- Friction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysFrom EverandFriction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- PowerCoil Screw Thread InsertsDocument103 pagesPowerCoil Screw Thread InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Product RangeDocument40 pagesHeliCoil Product RangeAce Industrial SuppliesNo ratings yet

- HeliCoil Stud-Lock InsertsDocument2 pagesHeliCoil Stud-Lock InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Pipe Thread Inserts NPT ANPT NPSCDocument8 pagesHeliCoil Pipe Thread Inserts NPT ANPT NPSCAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Kits Oxygen SensorDocument1 pageHeliCoil Aftermarket Kits Oxygen SensorAce Industrial SuppliesNo ratings yet

- HeliCoil Tangless ApplicationsDocument2 pagesHeliCoil Tangless ApplicationsAce Industrial SuppliesNo ratings yet

- HeliCoil Insert Specs MetricDocument1 pageHeliCoil Insert Specs MetricAce Industrial SuppliesNo ratings yet

- HeliCoil Stud-Lock ApplicationsDocument2 pagesHeliCoil Stud-Lock ApplicationsAce Industrial SuppliesNo ratings yet

- HeliCoil Self Tapping InsertsDocument4 pagesHeliCoil Self Tapping InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Insert Specs ImperialDocument1 pageHeliCoil Insert Specs ImperialAce Industrial SuppliesNo ratings yet

- HeliCoil Screw Thread InsertsDocument36 pagesHeliCoil Screw Thread InsertsAce Industrial Supplies0% (1)

- HeliCoil Serrated Spark Plug InsertsDocument4 pagesHeliCoil Serrated Spark Plug InsertsAce Industrial Supplies100% (1)

- HeliCoil Primer Free II ApplicationsDocument2 pagesHeliCoil Primer Free II ApplicationsAce Industrial SuppliesNo ratings yet

- HeliCoil NPT Inserts 8UNDocument4 pagesHeliCoil NPT Inserts 8UNAce Industrial SuppliesNo ratings yet

- HeliCoil Tangless Gall Resistant InsertsDocument2 pagesHeliCoil Tangless Gall Resistant InsertsAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 302 Series MetricDocument1 pageEnsat Self Tapping Inserts 302 Series MetricAce Industrial SuppliesNo ratings yet

- HeliCoil Gall Resistant InsertsDocument2 pagesHeliCoil Gall Resistant InsertsAce Industrial SuppliesNo ratings yet

- Bollhoff Rivkle RivnutsDocument52 pagesBollhoff Rivkle RivnutsAce Industrial SuppliesNo ratings yet

- Ripp Lock WashersDocument8 pagesRipp Lock WashersAce Industrial SuppliesNo ratings yet

- HeliCoil NPT Inserts 8UN 2Document2 pagesHeliCoil NPT Inserts 8UN 2Ace Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Catalogue 2Document24 pagesHeliCoil Aftermarket Catalogue 2Ace Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket KIts Sav-A-Thread HTDocument1 pageHeliCoil Aftermarket KIts Sav-A-Thread HTAce Industrial SuppliesNo ratings yet

- HeliCoil Primer Free II InsertsDocument2 pagesHeliCoil Primer Free II InsertsAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 302 Series ImperialDocument1 pageEnsat Self Tapping Inserts 302 Series ImperialAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 307 308 SeriesDocument1 pageEnsat Self Tapping Inserts 307 308 SeriesAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Kits Head Bolt Thread RepairDocument1 pageHeliCoil Aftermarket Kits Head Bolt Thread RepairAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket CatalogueDocument24 pagesHeliCoil Aftermarket CatalogueAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 303 SeriesDocument1 pageEnsat Self Tapping Inserts 303 SeriesAce Industrial SuppliesNo ratings yet

- RivclinchDocument28 pagesRivclinchAce Industrial SuppliesNo ratings yet

- Rivkle ElasticDocument12 pagesRivkle ElasticAce Industrial SuppliesNo ratings yet