Professional Documents

Culture Documents

APQP Timing Chart

Uploaded by

Balram Ji0 ratings0% found this document useful (0 votes)

30 views1 pagePerforma for typical Timing Plan for Part Development

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPerforma for typical Timing Plan for Part Development

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views1 pageAPQP Timing Chart

Uploaded by

Balram JiPerforma for typical Timing Plan for Part Development

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

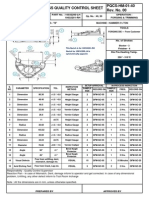

APQP TIMING CHART SUPPLIER NAME : Drawing No/Rev No: SN ACTIVITY DETAILS Part Number : Part Name: July'12

RESP DATE/NO. OF DAYS 1 4 7 10 13 16 19 22 25 28 30 1 4 7 Month ====> Aug'12 10 13 16 19 22 25 28 31 1 4 7 Sep'12 10 13 16 19 22 25 28 30

A- PHASE I - PRODUCT PROCESS INPUT DATA

1 2 3 Addmission avalution audit Input Data Sheet / 2D/3D & Relavent stds Hand over PQ6.2 /FQ2011 & other Std's. Plan Actual Plan Actual Plan Actual Plan Actual 5 Review Meeting Phase - I Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual Plan Actual

Feasibility of Mfg Processes

B. PHASE II - PRODUCT PROCESS & DEVELOPMENT

6 7 8 9 10 New Equipment & Facilities Requirement New Tooling Requirements New Gauges & Testing Equipment Requirements Team Feasibility Commitment Review Meeting Phase - 2

C. PHASE III - PROCESS DESIGN & DEVELOPMENT

11 12 13 14 15 16 17 18 Packaging Standards & Specifications Pre Launch Process Flow Chart Floor Plan Layout/If spl line for GTI PFMEA Pre Launch Control Plan Measurement System Plan Sample Submission Review Meeting Phase - 3

D. PHASE IV - PRODUCT & PROCESS VALIDATION

19 A B C D E F G H 20 21 22 23 24 25 Production Trial Run Cum PPAP Production Dimensional inspection report asper balloned drag minimum 05 samples(Layout Inspection) Material test reports Critical parameters inspection reporets 100 %pcs,if Reqd. Cut section reports if required. X ray reports if required Cleanlyness report as per QF 2011 Premeraly process study on critical parameters Packaging Standards Preperation Measurement System Evaluation Customer Feedback(Assembly/testing ),if Reqd. Production Control plan PPAP Document Submission Pilot Batch Submission Review Meeting Phase - 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Rework Record For Heat Treated Parts: Original Production DetailsDocument1 pageRework Record For Heat Treated Parts: Original Production DetailsBalram Ji100% (2)

- Chap-02 Pair ofDocument9 pagesChap-02 Pair ofBalram JiNo ratings yet

- Oerlikon Checklist 2012Document14 pagesOerlikon Checklist 2012Balram JiNo ratings yet

- Sae 1038 - Ø36Document1 pageSae 1038 - Ø36Balram JiNo ratings yet

- Micrometer Care and Use TechniquesDocument10 pagesMicrometer Care and Use TechniquesBalram JiNo ratings yet

- ABC SocialismDocument20 pagesABC SocialismsudamailNo ratings yet

- Tootan Wala KhoohDocument92 pagesTootan Wala KhoohBalram Ji100% (3)

- English Short StoriesDocument9 pagesEnglish Short StoriessharmasumittNo ratings yet

- Manav Kika HaniDocument19 pagesManav Kika HaniBalram JiNo ratings yet

- Stavax ESRDocument13 pagesStavax ESRBalram JiNo ratings yet

- Fundamentals of Heat Treating Ideal DiameterDocument2 pagesFundamentals of Heat Treating Ideal Diameterozkangurkal100% (1)

- Lea - 5SDocument1 pageLea - 5SallanjulesNo ratings yet

- VCIPL PQCS-HM-01-40 Process Quality Control Sheet for Forging & TrimmingDocument1 pageVCIPL PQCS-HM-01-40 Process Quality Control Sheet for Forging & TrimmingBalram JiNo ratings yet

- Touch Probe Fixtures enDocument7 pagesTouch Probe Fixtures enBalram JiNo ratings yet

- Ramya Balaji Alloy Pvt. Limited: Record No.: Date: Page 1 of 1 Title: Code of Conduct For Employees (Staff)Document1 pageRamya Balaji Alloy Pvt. Limited: Record No.: Date: Page 1 of 1 Title: Code of Conduct For Employees (Staff)Balram JiNo ratings yet

- Kmpnai Ko Inayama: Kma-Caari Ka Naama À Idpat-MaomtDocument1 pageKmpnai Ko Inayama: Kma-Caari Ka Naama À Idpat-MaomtBalram JiNo ratings yet

- Molygraph Graphol: Technical Data SheetDocument1 pageMolygraph Graphol: Technical Data SheetBalram JiNo ratings yet

- Billet Cutting Process Quality Control SheetDocument1 pageBillet Cutting Process Quality Control SheetBalram JiNo ratings yet

- Molygraph Graphol: Technical Data SheetDocument1 pageMolygraph Graphol: Technical Data SheetBalram JiNo ratings yet

- JG Ja0023Document1 pageJG Ja0023Balram JiNo ratings yet

- Technical Delivery Condition: Applicable To Parts: Ring WCFN0055Document4 pagesTechnical Delivery Condition: Applicable To Parts: Ring WCFN0055Balram JiNo ratings yet

- Jominy Formula SheetDocument2 pagesJominy Formula SheetBalram JiNo ratings yet

- METHOD SPOT TEST NICKEL STEELDocument2 pagesMETHOD SPOT TEST NICKEL STEELBalram JiNo ratings yet

- Shewhart Individuals Control ChartDocument2 pagesShewhart Individuals Control ChartBalram JiNo ratings yet

- Emissivity 2Document10 pagesEmissivity 2Les StroupfNo ratings yet

- Chapter 1Document1 pageChapter 1Balram JiNo ratings yet

- Why SpiritualityDocument37 pagesWhy SpiritualityBalram JiNo ratings yet

- How To Unprotect An Excel Sheet Without PasswordDocument6 pagesHow To Unprotect An Excel Sheet Without PasswordBalram JiNo ratings yet

- Preventive Maintenance PlanDocument3 pagesPreventive Maintenance PlanBalram Ji86% (7)

- Weight Standard FinalDocument1 pageWeight Standard FinalBalram JiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)