Professional Documents

Culture Documents

Combined Gusset Plate Design

Uploaded by

kalpanaadhiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Combined Gusset Plate Design

Uploaded by

kalpanaadhiCopyright:

Available Formats

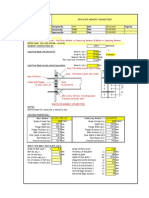

EVERSENDAI ENGINEERING L.L.

C

PROJECT GTC-11-141 - NAKILAT - SUPERYACHT HALL SUBJECT DESIGN OF GUSSET CONNECTION Job no 21006 Date 7/10/2013 Reference BS 5950-1:2000

Sheet 1 of 3 Designed by SKB Checked by KMK Approved by BNR

Member profile Properties of the Section Diameter Thickness Member profile Properties of the Section Diameter Thickness Member profile Properties of the Section Diameter Thickness

(M1) NO MEMBER (No Member) D t (M2) PIPE 168X6.3 = = 0 0 mm mm

Tie Beam Details UC 254X254X73 D = 254 mm B = 255 mm d' = 226 mm Tw = 9 mm Tf = 14 mm

D t (M3) PIPE 219X6.3

= =

168 6.3

mm mm

Utilization Percentage Summary:

Stress Ratio 0.71 0.63 0.94 0.64 0.60 0.48

Block shear capacity Tension capacity of plate Check for Weld Shear Capacity of Gusset Plate

D t

= =

219 6.3

mm mm

Design Input Grade of bolt Shear strength of bolt Bearing strength of bolt Bearing strength of plate Dia of bolt Dia of bolt hole No of bolt Column (Vertical) No of bolt Rows (Horizontal) End distance in the connected plate in CHS Pitch distance in the connected plate in CHS Total no bolts No of members connected to the Gusset Thickness of Gusset plate Thickness of splice plate No of shear plane (M1) No of shear plane (M2) No of shear plane (M3) Total thickness of splice plate

Compression Capacity of Gusset Plate Moment Capacity of Gusset Plate M1 M2 M3

59

ps pbb pbs d dbh nc nr e p nt tg tc np np np Ttp

= = = = = = = = = = = = = = = = = = = = = = =

8.8 375 1000 550 24 26 2 3 50 70 6 2 20 0 1 1 1 N.A N.A 250 80.83 500 20

N/mm2 N/mm2 N/mm2 mm mm Nos Nos mm mm Nos mm mm

32

Height of the Gusset plate(for comp check) L width of the Gusset plate (whitmore section) w Actual width of gusset plate Wa size of the weld for chord to gusset plate s Member Forces Member profile (M1) Compressive Force Tensile Force Member profile (M2) Compressive Force Tensile Force Member profile (M3) Compressive Force Tensile Force

mm (conservatively) mm mm (Approx) mm

NO MEMBER C = T = PIPE 168X6.3 C = T = PIPE 219X6.3 C = T =

0 0

kN kN

780 780

kN kN

780 780

kN kN

Max Tension and Compression Forces to check Gusset plate Max compressive Force Max Tensile Force C T = = 780 780 kN kN

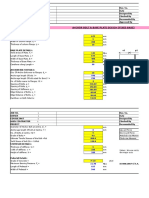

EVERSENDAI ENGINEERING L.L.C

PROJECT GTC-11-141 - NAKILAT - SUPERYACHT HALL SUBJECT DESIGN OF GUSSET CONNECTION Job no 21006 Date 7/10/2013 Reference BS 5950-1:2000

Sheet 1 of 3 Designed by SKB Checked by KMK Approved by BNR

780 Check for Gusset plate Block shear capacity (Local check) (cl 6.2.4) Block shear capacity of gusset plate Pr = 0.6*py*t*[Lv+(Ke*Lt)] Coefficient for single or two line of bolt k = 2.5 Effective net area coefficient Ke = 1.1 (Grade S355) Length of shear face Lv = 2*(70+50) (Enter Manually) = 240 mm Length of tension face Lt = 70+70-((3-1)*26) (Enter Manually) = 88 mm py = 345 N/mm2 = 0.6*345*20[240+1.1(88-2.5*26)] 780 kN Pr = 1098.34 kN > stress ratio = 0.71 Compresssion capacity of gusset plate Compresssion capacity of gusset plate un supported Length (between base of gusset to C/L of top most bolt) Effective Length Slenderness ratio Radius of gyration (cl 4.7.4) Pc = pc*Ac L = 250 Leff = Leff = = rmin = = = C = = pc = w = w = Ac = = = Pc = = 70+70 50 70

kN

(Enter Manually)

(Safe)

0 mm 780

kN 780 kN

1.2*L K=1.2 For Single Side 300 mm Support Leff/rmin

59.0 32.0

Total compressive force to gusset plate Compressive stress width of the Gusset plate Compressive area

Compresssion capacity of gusset plate stress ratio Tension capacity of gusset plate Total Tensile force Tension capacity of gusset plate C/S area Effective C/S area Effective area net area ke*Aeff Tension capacity of gusset plate stress ratio

t/sqrt(12) 5.77 51.96 780.00 780.00 kN 50 51.96 2 293.10 N/mm 52 140+80.83 220.83 mm w*t 220.83*20 4416.58 mm2 1294 kN > 780.00 kN (Safe) 0.60

pc 298 293

(cl 4.6.1) = 780.00 = 780.00 kN Pt = Aeff*py A = 4800 mm2 = 4800 mm2 Aeff = 3240 mm2 = 3240 mm2 mm2 Anet = 3564 Pt = 3564*345 = 1229.58 kN > = 0.63 T

20

50

140

50

(Distance B/w Extreme Bolts)

780 kN

(Safe)

EVERSENDAI ENGINEERING L.L.C

PROJECT GTC-11-141 - NAKILAT - SUPERYACHT HALL SUBJECT DESIGN OF GUSSET CONNECTION Job no 21006 Date 7/10/2013 Reference BS 5950-1:2000 (Cl 6.8.7) 780

Sheet 1 of 3 Designed by SKB Checked by KMK Approved by BNR 0 780

Check for weld between gusset plate and connected member Max Tension force Max shear force T V = = =

sin (90-59)*780+sin (90-32)*780 1063.21 kN cos (90-59)*780+cos (90-32)*780 1081.93 kN Wa*2 2*500 1000 1000 220

59.0 32.0

case -I (for Max Tension)

Length of gusset weld

L L

Design strength of weld

= = = L = pw =

780 mm mm N/mm2 Wa = 59.0 32.0

780 case -II (for Max Shear) mm

500

Directional Method

(Cl 6.8.7.3) FL FT e M Z fm fs fa Rf = = = = = = = = = 1081.93 kN 1063.21 kN 127 mm 137.40 kNm 83333.3 mm3/mm 1648.9 N/mm 1081.93 N/mm 1063.21 N/mm Sqrt((fa+fm)2+fs2) 2919.91 N/mm 18.77 mm

<

Longitudial Shear force Transverse Force Eccentricity of Beam Force Wrt to Weld Moment Induced in Weld Group Due to Eccentric Shear Force Section Modolus of Weld Group Max Stress in Weld due to moment Stress in Weld due to Shear Force Stress in Weld due to Axial Force Resultant Force in Gusset Plate Weld

Size of Gusset Plate Weld required

Sw =

20.00 mm (Safe)

Vertical Shear capacity of gusset plate Applied Shear Force from Brace to Gusset Plate Length of Gusset Plate Shear Capacity of Gusset Plate Fv Lv Pv = = = = Max(M1v,M2v,M3v) 661.48 kN 250.00 (Approximately) 1035.00 661.48 >

<

(Safe) (Safe)

= 0.64 Horizontal Shear capacity of gusset plate Applied Shear Force from Brace to Gusset Plate Length of Gusset Plate Shear Capacity of Gusset Plate Fh Wa Pv = 1081.93 kN

1.00

= 500.00 mm = 2070.00 kN > = 0.52

<

1081.93 1.00

(Safe) (Safe)

Moment Capacity Check for Gusset Plate (for eccentric shear of gusset plate) Length of Gusset Plate Moment Induced in Gusset Plate due Due to Axial Component of Tie Moment Capacity fo Gusset Plate Wa M Mgh = 500.00 mm = 137.40 kNm = Zx*py 287.5

kNm

>

137 kNm (Safe)

You might also like

- Gusset Plate Design for Cleveland Clinic Abu DhabiDocument4 pagesGusset Plate Design for Cleveland Clinic Abu Dhabikalpanaadhi75% (4)

- Moment Connection - Flush End Plate-19.01.06Document48 pagesMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- Purlin Cleat 220908Document24 pagesPurlin Cleat 220908kalpanaadhi100% (2)

- Moment Connection Beam Column IS & BS SECTION FOR IS800Document29 pagesMoment Connection Beam Column IS & BS SECTION FOR IS800pjuvvadi86% (7)

- BASE PLATE DESIGN OPTIMIZATIONDocument45 pagesBASE PLATE DESIGN OPTIMIZATIONMuhammed Ali60% (5)

- 321 Chapter 5 Splice DesignDocument91 pages321 Chapter 5 Splice DesignHemant Ramesh NarkarNo ratings yet

- End Plate ConnectionDocument10 pagesEnd Plate ConnectionMohamed Tahar Allagui100% (1)

- Base Plate DesignDocument32 pagesBase Plate DesignGautam Sharma50% (2)

- Design of Base Plate & Anchor BoltDocument2 pagesDesign of Base Plate & Anchor Boltrameshdorage12100% (8)

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- Typ-Base PlateDocument11 pagesTyp-Base PlateManoj Jaiswal100% (2)

- Shear Connection - Beam - Steel Column - Fin PlateDocument30 pagesShear Connection - Beam - Steel Column - Fin Platekalpanaadhi100% (3)

- Base PlateDocument12 pagesBase PlateD SRINIVAS100% (1)

- Pinned and fixed base plate design calculations for I-section and tube columnsDocument7 pagesPinned and fixed base plate design calculations for I-section and tube columnsabdul karee100% (6)

- Att-5 - End-Plate Shear ConnectionDocument7 pagesAtt-5 - End-Plate Shear Connectioncravikumar1971100% (3)

- Base Plate With Moment & Axial CompressionDocument2 pagesBase Plate With Moment & Axial CompressionAnonymous b3NKZUb100% (3)

- Moment Connection Portal FrameDocument18 pagesMoment Connection Portal Frametmssorin100% (1)

- Base Plate DesignDocument3 pagesBase Plate DesignrajarshiboseNo ratings yet

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryDocument25 pagesRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- FIN PLATE - Beam To BeamDocument71 pagesFIN PLATE - Beam To BeamHemant Ramesh Narkar100% (3)

- Base Plate Design Fixed RevisedDocument8 pagesBase Plate Design Fixed RevisedEngDbt80% (5)

- Weld ConnectionDocument70 pagesWeld ConnectionSudhakar KrishnamurthyNo ratings yet

- End Plate DesignDocument4 pagesEnd Plate DesignAgnon Fung100% (4)

- Bolted ConnectionDocument86 pagesBolted ConnectionPooja MistryNo ratings yet

- End Plate-Beam To Column Moment ConnectionDocument81 pagesEnd Plate-Beam To Column Moment ConnectionHemant Ramesh Narkar50% (6)

- Beam SpliceDocument17 pagesBeam SpliceBoddu Ramakrishna100% (1)

- Bolted Moment ConnectionDocument3 pagesBolted Moment Connectionprabhu81100% (3)

- 6-Bracing Connection - TDocument2 pages6-Bracing Connection - TMUTHUKKUMARAMNo ratings yet

- Double Angle Connection Design ChecksDocument13 pagesDouble Angle Connection Design ChecksrunkirNo ratings yet

- Calculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataDocument1 pageCalculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataLaurence Arcon Banal0% (1)

- Connection Design MomentDocument4 pagesConnection Design MomentAkshit Dhawan100% (1)

- Baseplate Design Input DataDocument166 pagesBaseplate Design Input DataAnonymous ciKyr0t86% (7)

- Angle Brace ConnectionDocument20 pagesAngle Brace Connectionmaheshbandham100% (1)

- Design of I-Shape Column Base PlateDocument6 pagesDesign of I-Shape Column Base PlatebuildconNo ratings yet

- Base Plate Design for Bagging Tower SupportDocument9 pagesBase Plate Design for Bagging Tower SupportbuildconNo ratings yet

- Moment Connection Design-BS CODEDocument5 pagesMoment Connection Design-BS CODEMuthukumaran SivalingamNo ratings yet

- Design Base Plate for Platform 1 ColumnDocument93 pagesDesign Base Plate for Platform 1 ColumnAnand.5No ratings yet

- Anchor Bolt and Base Plate Design CheckDocument48 pagesAnchor Bolt and Base Plate Design CheckmaheshbandhamNo ratings yet

- Bracing Design for Asian Paints Phase III Expansion ProjectDocument2 pagesBracing Design for Asian Paints Phase III Expansion ProjectGopi GopinathanNo ratings yet

- Base Connection Design DetailsDocument11 pagesBase Connection Design DetailsmaheshbandhamNo ratings yet

- Base Plate Design for Column SupportDocument180 pagesBase Plate Design for Column Supportbuildcon62% (13)

- End Plate-Splice ConnectionDocument76 pagesEnd Plate-Splice ConnectionHemant Ramesh Narkar100% (6)

- DESIGN CALCULATION SHEET FOR SUPPORTING BEAMDocument29 pagesDESIGN CALCULATION SHEET FOR SUPPORTING BEAMTamkwokkwong86% (7)

- Beam To Beam Web - Shear ConnectionDocument2 pagesBeam To Beam Web - Shear ConnectionGautam SharmaNo ratings yet

- 4-Base Plate - Pin ConnectionDocument3 pages4-Base Plate - Pin ConnectionMUTHUKKUMARAMNo ratings yet

- Hollow Section Bracing Connetion - LRFDDocument5 pagesHollow Section Bracing Connetion - LRFDkalpanaadhiNo ratings yet

- Beam To Col. Pin Connection DesignDocument2 pagesBeam To Col. Pin Connection DesignmaheshbandhamNo ratings yet

- 1.0bolted Truss ConnectionDocument7 pages1.0bolted Truss ConnectionklynchelleNo ratings yet

- Column Base Plate (Fixed Type)Document11 pagesColumn Base Plate (Fixed Type)Ernest Navarro100% (2)

- Anchor Bolt DesignDocument2 pagesAnchor Bolt Designmail2meanwar7865No ratings yet

- Base Plate - FixedDocument4 pagesBase Plate - Fixedbhaskardharani80% (5)

- Base PlateDocument32 pagesBase PlateSunil SinghNo ratings yet

- Embed Design - Core WallDocument39 pagesEmbed Design - Core Wallkalpanaadhi100% (1)

- Design of Composite Steel Girder BridgeDocument10 pagesDesign of Composite Steel Girder BridgesorowareNo ratings yet

- Design of Headed Concrete AnchorDocument121 pagesDesign of Headed Concrete AnchorkalpanaadhiNo ratings yet

- Aashto Shear and TorsionDocument4 pagesAashto Shear and Torsion3cesNo ratings yet

- HAMTeK annexure 5.3a - Design of Base Plate and Anchor BoltsDocument7 pagesHAMTeK annexure 5.3a - Design of Base Plate and Anchor BoltsVenkatesha HebbarNo ratings yet

- 6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3Document8 pages6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3abdulNo ratings yet

- Pile Cap-4 PileDocument2 pagesPile Cap-4 Pilecnt_chanddanNo ratings yet

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- M. L. Gambhir - Fundamentals of Solid Mechanics-PHI Learning Private Limited (2009)Document934 pagesM. L. Gambhir - Fundamentals of Solid Mechanics-PHI Learning Private Limited (2009)shireenkatre100% (1)

- Structural Connections - KrishnarajuDocument11 pagesStructural Connections - KrishnarajukalpanaadhiNo ratings yet

- Bolt Capacity CalculationsDocument4 pagesBolt Capacity CalculationskalpanaadhiNo ratings yet

- Is 875 (Part 3) - 2015 Annex A As Per AmendmentDocument1 pageIs 875 (Part 3) - 2015 Annex A As Per AmendmentkalpanaadhiNo ratings yet

- Moody's ChartDocument100 pagesMoody's Chartbsk109100% (3)

- IS 1893 (PART 1) - 2016 Amedment No.2Document6 pagesIS 1893 (PART 1) - 2016 Amedment No.2kalpanaadhi0% (1)

- SP6 - 1 Gauge Distance in Legs of AnglesDocument1 pageSP6 - 1 Gauge Distance in Legs of AngleskalpanaadhiNo ratings yet

- Design Manual For Is 800 - 2007 - Compression MembersDocument6 pagesDesign Manual For Is 800 - 2007 - Compression MemberskalpanaadhiNo ratings yet

- Basics of Engineering DrawingDocument103 pagesBasics of Engineering DrawingkalpanaadhiNo ratings yet

- Helical Strakes DevelopmentDocument4 pagesHelical Strakes Developmentkalpanaadhi100% (1)

- ACE Civil Interview Questions - DSSDocument8 pagesACE Civil Interview Questions - DSSkalpanaadhiNo ratings yet

- Industrial Structures ListDocument2 pagesIndustrial Structures ListkalpanaadhiNo ratings yet

- Engg. MathsDocument46 pagesEngg. MathskalpanaadhiNo ratings yet

- IS 13920: 2016 Amedment No.2Document3 pagesIS 13920: 2016 Amedment No.2kalpanaadhiNo ratings yet

- Soil Basic TerminologyDocument1 pageSoil Basic TerminologykalpanaadhiNo ratings yet

- Soil Basic Terminology PDFDocument1 pageSoil Basic Terminology PDFkalpanaadhiNo ratings yet

- Hosts UmbrellaDocument1 pageHosts UmbrellaFabsor SoralNo ratings yet

- Assignment BeamDocument1 pageAssignment BeamkalpanaadhiNo ratings yet

- Green SkyscrapersDocument160 pagesGreen SkyscrapersMiti Agarwal100% (2)

- Concrete Structures (GATE)Document12 pagesConcrete Structures (GATE)kalpanaadhiNo ratings yet

- Is Drinking Milk EssentialDocument4 pagesIs Drinking Milk EssentialkalpanaadhiNo ratings yet

- Irregular PeriodsDocument2 pagesIrregular PeriodskalpanaadhiNo ratings yet

- Bayam Bayam BayamDocument1 pageBayam Bayam BayamkalpanaadhiNo ratings yet

- Put The Glass Down Today - Moral StoryDocument1 pagePut The Glass Down Today - Moral StorykalpanaadhiNo ratings yet

- Natural TreatmentDocument3 pagesNatural TreatmentkalpanaadhiNo ratings yet

- Free Span Elevated ConveyorsDocument1 pageFree Span Elevated ConveyorskalpanaadhiNo ratings yet

- Commitment Is CompulsoryDocument3 pagesCommitment Is CompulsorykalpanaadhiNo ratings yet

- Bed Wetting After 12 YearsDocument2 pagesBed Wetting After 12 YearskalpanaadhiNo ratings yet

- Awareness of Diseases in Rainy SeasonDocument4 pagesAwareness of Diseases in Rainy SeasonkalpanaadhiNo ratings yet

- CamSpan Trough ConveyorDocument2 pagesCamSpan Trough ConveyorkalpanaadhiNo ratings yet

- D 3878 - 02 Rdm4nzgtmdiDocument5 pagesD 3878 - 02 Rdm4nzgtmdiJuanNo ratings yet

- Es 13 Prob Set 1Document5 pagesEs 13 Prob Set 1Julian de LaraNo ratings yet

- Cubical DilationDocument5 pagesCubical DilationChintu Kishen KMNo ratings yet

- Mechanical Properties of PolymersDocument45 pagesMechanical Properties of PolymersJulian de Lara100% (3)

- Lubricants 07 00017 PDFDocument14 pagesLubricants 07 00017 PDFGabriel Ivan AviñaNo ratings yet

- Fundamentals of Rock Joint DeformationDocument20 pagesFundamentals of Rock Joint DeformationIgnasi AliguerNo ratings yet

- Mock Exam Paper - Mid Term - CIVE1108Document10 pagesMock Exam Paper - Mid Term - CIVE1108Dilshan JayasuriyaNo ratings yet

- Study On Pu SoleDocument4 pagesStudy On Pu Solesusan mishraNo ratings yet

- MOM Chapter 3-Mechanical Properties of MaterialsDocument22 pagesMOM Chapter 3-Mechanical Properties of MaterialsezoramajnunNo ratings yet

- S TN HNG 001 PDFDocument11 pagesS TN HNG 001 PDFIhab El AghouryNo ratings yet

- Geotechnical InvestigationDocument12 pagesGeotechnical InvestigationKaranjit SigotNo ratings yet

- Din 431 eDocument3 pagesDin 431 elokesh38No ratings yet

- StrainDocument50 pagesStrainilknurNo ratings yet

- En 795Document3 pagesEn 795Sayed Abbas0% (1)

- MEM1M Material Behavior and Failure CriteriaDocument19 pagesMEM1M Material Behavior and Failure CriteriaphantraNo ratings yet

- ThreeBond 1530b Moisture Curing Elasomeric AdhesiveDocument2 pagesThreeBond 1530b Moisture Curing Elasomeric AdhesiveAnderson MartinsNo ratings yet

- Neodyl PDFDocument2 pagesNeodyl PDFvranceanu.ovidiu-1No ratings yet

- Cardan Joints Efficiency PDFDocument6 pagesCardan Joints Efficiency PDFArmando Fdez McdoNo ratings yet

- Projek Solid Mechanics 1Document3 pagesProjek Solid Mechanics 1Shaktivell Letchumanan0% (1)

- 2004 Effect of Macrostructure and Microstructure On The Viscosity of The A356 Alloy in The Semi Solid StateDocument7 pages2004 Effect of Macrostructure and Microstructure On The Viscosity of The A356 Alloy in The Semi Solid StateAna RivasNo ratings yet

- Subsea Innovation Sealing SolutionsDocument7 pagesSubsea Innovation Sealing SolutionsanishsrNo ratings yet

- Jadavpur University: Faculty of Engineering & TechnologyDocument6 pagesJadavpur University: Faculty of Engineering & Technologysatyakidutta007No ratings yet

- PMMA Denture Base Material Enhancement: A Review of Fiber, Filler, and Nanofiller AdditionDocument12 pagesPMMA Denture Base Material Enhancement: A Review of Fiber, Filler, and Nanofiller AdditionPhoebe DavidNo ratings yet

- Biomaterials 2009 Fall Home Work No4Document2 pagesBiomaterials 2009 Fall Home Work No4_Ariane_Enaira_5613No ratings yet

- Fevitite Rapid and Clear Epoxy AdhesivesDocument2 pagesFevitite Rapid and Clear Epoxy AdhesivesSahil YOUSUFNo ratings yet

- Concrete Materials Laboratory SDN BHD, SelangorDocument4 pagesConcrete Materials Laboratory SDN BHD, SelangorAshwin RautNo ratings yet

- Reformer Tube Life Assessment ThepetrostreetDocument20 pagesReformer Tube Life Assessment Thepetrostreetksvvij100% (2)

- RCC Box Culvert - Methodology and Designs Including Computer MethodDocument31 pagesRCC Box Culvert - Methodology and Designs Including Computer MethodYoshua Yang0% (2)

- Drain DesignDocument106 pagesDrain DesignBilal Ahmed Barbhuiya100% (2)

- Thesis On Fibre Reinforced ConcreteDocument4 pagesThesis On Fibre Reinforced Concretefjfsyk5w100% (1)