Professional Documents

Culture Documents

Installation Ipasolink 1000

Uploaded by

Nikang Praises JamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Ipasolink 1000

Uploaded by

Nikang Praises JamCopyright:

Available Formats

i

iPASOLINK 1000

CHAPTER I INSTALLATION

CONTENTS

iPASOLINK 1000: INSTALLATION NWD-118789-04E

December, 2011

1. OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. COMPOSITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 IDU and ODU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.2 Pole Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.3 iPASOLINK 1000 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.4 IDU and ODU for 1+0 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.1.5 IDU and ODU for 1+1 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2 iPASOLINK 1000 IDU Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.1 Cards for Universal Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.1.1MODEM-A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.1.2STM-1A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.1.316E1-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.1.4GbE-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.1.5AUX-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.1.6MSE-A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.1.7CWDMFA/CWDMFB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.2 Fundamental Cards for iPASOLINK 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.2.2.1MC-M (Main Card). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.2.2.2PS-M (Power Supply) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.2.2.3TERM-M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.2.3 CWDM Filter Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2.3.1CWDMFA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2.3.2CWDMFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3. UNPACKING IDU and ODU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

4. MOUNTING IDU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Mount IDU / CWDM Filter Box Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Replace FAN Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 Replace MODEM-A/(*)-A Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4 Replace MC-M Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.5 Replace CLK2M-C Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

ii CONTENTS

NWD-118789-04E iPASOLINK 1000: INSTALLATION

4.6 Replace PS-M Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.7 Replace PS-M Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.8 Replace TERM-M Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.9 CWDM Filter Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.9.1IDU and Filter Box Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.9.2Mount CWDMF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.10 Mount SFP Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.10.1SFP Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.10.2Colored SFP Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

5. MOUNTING ODU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Antenna Direct Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.1 Basic Installation for Antenna & ODU. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.2 With Hybrid/Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.1.3 With TX Span Attenuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

5.1.4 With Ortho-Mode Transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

5.2 Feeder Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

5.2.1 For Coaxial Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

5.2.2 For Waveguide Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

5.2.3 For Waveguide Connection with Hybrid . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

5.3 Other Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

5.3.1 Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

5.3.2 Rack Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

5.4 Hybrid Combiner Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

6. ADJUSTING CABLE ENDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 5D Coaxial Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.2 8D Coaxial Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

6.3 Other Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

7. WIRING and FORMING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2.1 Connector Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2.2 Connect I/F Cable with L-angle Plug to IDU . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.3 Rout Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.3.1 Grounding Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.3.2 IF Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

CONTENTS iii

iPASOLINK 1000: INSTALLATION NWD-118789-04E

7.3.3 Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.3.4 16E1, STM-1, GbE and AUX Signal Cables . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.3.5 XIF Coaxial Cables (XPIC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.3.5.1Connection for XPIC 1+0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.3.5.2Connection for XPIC 1+1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7.3.6 Cables Using CWDM Filter Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

7.3.6.1Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

7.3.6.2For CWDMF on IDU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.3.6.3For CWDM on Filter Box Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.4 Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.4.1 MC-M Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.4.2 TERM-M Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.4.3 PS-M Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

7.4.4 AUX-A Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7.4.5 16E1-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

8. GROUNDING THE FRAME. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

9. WATERPROOFING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

10. START-UP and SHUT-DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.1 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.2 Shut-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.3 System #2 #4 ODU Expansion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

11. ORIENTING ANTENNA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

iv /END CONTENTS

NWD-118789-04E iPASOLINK 1000: INSTALLATION

This page is intentionally left blank.

OVERVIEW 1-1

iPASOLINK 1000: INSTALLATION NWD-118789-04E

1. OVERVIEW

The standard installation is summarized in this section. Following shows the typical

installation work flow and guides to IDU installation, ODU installation, Antenna

(ANT) installation, waveguide connection and coaxial cable connections. The

installation flow chart is shown below.

This product is a part of the radio link system, and is intended to be connected with a

external antenna.

This product should be installed and operated by skilled personnel.

After the installation, the system should be ensured to comply with the relevant limits

for general public exposure specified as basic restrictions or reference levels in the

council Recommendation 1999/519/EC.

Figure 1-1 Typical Installation Flow Diagram

Unpacking IDU

(see Section 3.)

Unpacking ODU

(see Section 3.)

Mounting ODU

(see Section 5.)

Mounting IDU

(see Section 4.)

Grounding

the Frame

(see Section 8.)

Terminating Cables

(see Section 6.)

Waterproofing

(see Section 9.)

Wiring and Forming

(see Section 7.)

Orienting Antenna

(see Section 11.)

1-2/END OVERVIEW

NWD-118789-04E iPASOLINK 1000: INSTALLATION

This page is intentionally left blank.

COMPOSITIONS 2-1

iPASOLINK 1000: INSTALLATION NWD-118789-04E

2. COMPOSITIONS

2.1 Overview

Each unpacked component of the [ ] GHz [ ] MB digital radio system must be

checked as shown below:

Contents List Subsection

IDU and ODU 2.1.1 IDU and ODU

Mounting Bracket 2.1.2 Pole Mounting Bracket

iPASOLINK 1000 Composition 2.1.3 iPASOLINK 1000 Composition

Installation Kit 2.1.4 IDU and ODU for 1+0 System

2.1.5 IDU and ODU for 1+1 System

2.2.1 Cards for Universal Slots

2.2.2 Fundamental Cards for iPASOLINK 1000

2.2.3 CWDM Filter Box

2-2 COMPOSITIONS

NWD-118789-04E iPASOLINK 1000: INSTALLATION

2.1.1 IDU and ODU

Note*: Two spare fuses are provided in the IDU packing box.

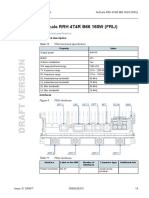

Figure 2-1 Contents of Cards

No. Description

1 TRP-( )G-1D (ODU)

2 MDP-400MB-1BB (IDU)

3 O-Ring (Attached to the waveguide type ODU)

4 Power Connector [Housing (AMP: 1-178288-8 (x1 ea)) or DK-3100S-10R (x1 ea) and

Socket Contacts (AMP: 1-175218-2 (x10 ea))]

5 Cylindrical Fuse (ES1-12500 (250 V/12.5 AH))*

3

1

5

4

(13-42 GHz)

(6-11 GHz)

2

COMPOSITIONS 2-3

iPASOLINK 1000: INSTALLATION NWD-118789-04E

2.1.2 Pole Mounting Bracket

Figure 2-2 Pole Mounting Bracket

2.1.3 iPASOLINK 1000 Composition

Figure 2-3 iPASOLINK 1000 Composition

No. Description

1 Pole Mounting Bracket for Coaxial Cable (6/7/8 GHz)/Waveguide Connection Type

2 Pole Mounting Bracket for Antenna direct Mounting Type

(Supplied with Antenna)

2

1

Universal Slot #1 Universal Slot #2 Universal Slot #3 Universal Slot #4

Universal Slot #5 Universal Slot #6 Universal Slot #7 Universal Slot #8

Universal Slot #9

Universal Slot #10

MAIN CARD 1

TERM PS 1

FAN1

FAN2

Main Card Slot #2

Universal Slot #11 Universal Slot #12 Universal Slot #13 Universal Slot #14

PS Slot #2

Slot #

Slots for fundamental cards that must be mounted.

Slots for option cards, which can be left vacant.

PS Power Supply

Main Card Slot #1

2-4 COMPOSITIONS

NWD-118789-04E iPASOLINK 1000: INSTALLATION

2.1.4 IDU and ODU for 1+0 System

Figure 2-4 IDU and ODU to be Installed for 1+0 System

ODU (13-42 GHz)

N-P connector N-P connector

ODU (6-11 GHz)

Earth Screw

(FG)

TNCP Connector

Earth Screw (FG)

Earth Screw

(FG)

COMPOSITIONS 2-5

iPASOLINK 1000: INSTALLATION NWD-118789-04E

2.1.5 IDU and ODU for 1+1 System

Figure 2-5 IDU and ODU to be Installed for 1+1 System

ODU (6-11 GHz) ODU (6-11 GHz)

N-P connector

TNCP connector

N-P connector

ODU (13-42 GHz)

N-P connector

TNCP connector

N-P connector

Earth Screw Earth Screw

ODU (13-42 GHz)

Earth Screw Earth Screw Earth Screw Earth Screw

(FG)

(FG) (FG) (FG) (FG)

(FG)

2-6 COMPOSITIONS

NWD-118789-04E iPASOLINK 1000: INSTALLATION

2.2 iPASOLINK 1000 IDU Components

2.2.1 Cards for Universal Slots

2.2.1.1 MODEM-A

2.2.1.2 STM-1A

2.2.1.3 16E1-A

TNC Connector

Earth Screw XIF Connectors MD/ODU PWR Switch

SFP Module Ports

CLASS 1 LASER PRODUCT

MDR Connector

COMPOSITIONS 2-7

iPASOLINK 1000: INSTALLATION NWD-118789-04E

2.2.1.4 GbE-A

2.2.1.5 AUX-A

2.2.1.6 MSE-A

2.2.1.7 CWDMFA/CWDMFB

See 2.2.3 CWDM Filter Box.

RJ45 Modular Ports

CLASS 1 LASER PRODUCT

SFP Module Ports

Hi-Density D-Sub (44) Connector

2-8 COMPOSITIONS

NWD-118789-04E iPASOLINK 1000: INSTALLATION

2.2.2 Fundamental Cards for iPASOLINK 1000

2.2.2.1 MC-M (Main Card)

2.2.2.2 PS-M (Power Supply)

2.2.2.3 TERM-M

Protection Switch

OW Outlet

CALL Push Button

USB Port

R45 Modular Ports

SFP Module Ports

High-Density D-Sub 44-pin Connector

CLASS 1 LASER PRODUCT

Power Supply Connector

R45 Modular Ports

High-Density D-Sub 15-pin Connector

COMPOSITIONS 2-9

iPASOLINK 1000: INSTALLATION NWD-118789-04E

2.2.3 CWDM Filter Box

NOTE: CWDM Fitter Box (CWDMF) is not a managed object within IDU. Thus,

retrieving the information of status, inventory, etc., regarding the CWDMF is

not available. However, the inventory information for the Colored SFP only

can be retrieved.

2.2.3.1 CWDMFA

2.2.3.2 CWDMFB

SFP Module Ports

LC Connector Port

CLASS 1 LASER PRODUCT

CLASS 1M LASER PRODUCT

SFP Module Ports

LC Connector Port

CLASS 1M LASER PRODUCT

CLASS 1 LASER PRODUCT

2-10/END COMPOSITIONS

NWD-118789-04E iPASOLINK 1000: INSTALLATION

This page is intentionally left blank.

UNPACKING IDU and ODU 3-1

iPASOLINK 1000: INSTALLATION NWD-118789-04E

3. UNPACKING IDU and ODU

Procedures for unpacking IDU and ODU are shown in following chart.

IDU: Procedure 3-1

ODU: Procedure 3-2

Note When conveying the IDU or ODU to another place, the original packing

should be used to avoid damage.

Procedure 3-1 Method of Unpacking IDU

1 Open the container box.

Shipping Tag / Packing Slip

(with bar-code)

3-2 UNPACKING IDU and ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

2 Unbox the contents. The contents are boxed as shown below:

3 Remove the polyethylene sheet from IDU.

4 Inspect IDU.

Top Pad

(Accessories are taped on the top pad.)

SFP

SFP

FUSE

FUSE

(Desiccant)

IDU

Polyethylene Sheet

Bottom Pad

Container Box

UNPACKING IDU and ODU 3-3

iPASOLINK 1000: INSTALLATION NWD-118789-04E

Procedure 3-2 Method of Unpacking ODU

1 Remove the top cover of the packing box.

Recycle Mark

Package Label

Package Label

or

Recycle Mark

Care Label

Care Label

3-4/END UNPACKING IDU and ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

2 Unbox ODU, cushioning materials (pads) and polyethylene sheet:

3 Remove the polyethylene sheet from ODU.

4 Inspect ODU.

Top Pad

Polyethylene Sheet

Bottom Pad

Container Box

MOUNTING IDU 4-1

iPASOLINK 1000: INSTALLATION NWD-118789-04E

4. MOUNTING IDU

4.1 Mount IDU / CWDM Filter Box Mount

NOTE: Procedure below uses IDU for example.

Procedure 4-1 Methods of Mounting IDU

1 Supporting brackets are attached on the front of IDU.

2 Mount IDU onto the 19-inch Rack. Example below uses EIA 310-D [IEC-60297]

Rack:

Attach and half-tighten two screws (with spring and flat washers) for the bottom

side (or for the upper side if the rack is IEC-60917) of the shelf.

Hook the bottom-side (or upper-side if the rack is IEC-60917) keyholes of the

flanges onto these screws ().

Secure all four screws (with spring and flat washers) including half-tightened

screws ().

Front Side

Rear View

Screw

Spring Washer

Flat Washer

Keyhole

Screw Hole

4-2 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

3 Since the forced-air cooling fans are built in, IDU does not require spaces for the

heat dissipation on its top, bottom and rear when installing onto a 19-inch Rack.

However, to install cables, the space of about 1U [1.75 inches; 44.45 mm] each

above and below the IDU is required.

IDU

1U

1U

(wall)

1U = 1.75 inches / 44.45 mm

1U

(side view)

MOUNTING IDU 4-3

iPASOLINK 1000: INSTALLATION NWD-118789-04E

4.2 Replace FAN Unit

Notes

1. NEC recommends that FAN unit be replaced approximately every three

years, regardless of its condition.

2. If a FAN alarm occurs, replace the FAN unit immediately.

3. The FAN unit is hot-swappable, which allows the replacement without

shutting down the system.

4. When replacing a FAN, a new FAN unit to be mounted should be

prepared near.

Procedure 4-2 Replace FAN Unit

1 Dismount the defective FAN

Proceed with the illustrated steps in reverse:

Step 2: Using the screwdriver, loosen the screw.

Step 1: Holding the screw, pull the unit out.

2 Mount a new FAN

Proceed with the illustrated steps in a regular order:

Step 1: Insert the new FAN unit.

Step 2: Using the screwdriver, tighten the screw.

4-4 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Step 1

Step 2

FAN Unit

Screw (on lower FAN)

Screw (on upper FAN)

MOUNTING IDU 4-5

iPASOLINK 1000: INSTALLATION NWD-118789-04E

4.3 Replace MODEM-A/(*)-A Card

Note (*)-A: STM1-A, 16E1-A, GbE-A, MSE-A and AUX-A cards; the

procedures for replacing these cards are the same as that for MODEM-A

card, except for the PWR switch that only MODEM-A has.

Procedure 4-3 Replace MODEM-A/(*)-A Cards

1 Set the MD PWR switch on the MODEM-A card to OFF position.

2 Dismount the defective MODEM-A(*) card as shown below:

Using the screwdriver, loosen two screws.

Screw

Screw

4-6 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Holding the screws, pull the MODEM-A off from the slot.

3 Mount a new MODEM-A(*) card as shown below:

Place the card on the card slot guides of the chassis, then carefully push the

card till it is fully engaged to the chassis backboard.

MOUNTING IDU 4-7

iPASOLINK 1000: INSTALLATION NWD-118789-04E

Ensure not to touch any interfacing parts, carefully insert the card further into

the slot.

Using the screwdriver, secure the card by tighten the screws.

Warning: Ensure not to touch electrical devices on the card.

Screw

Screw

4-8 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

4.4 Replace MC-M Card

Procedure 4-4 Replace MC-M Card

NOTE: Before starting the procedure, check if the MC-M Card to be removed has its

associated MC-M:

If the MC-M Card to be removed is unprotected, or is protected but the last remaining of

the two, turn off the power of MODEM-A Card before starting the procedure.

If the MC-M Card has its associated MC-M configuring the protection group, ensure that

the MC-M to be removed is on the Standby mode, and in the OOS status.

1 Dismount the defective MC-M card:

Using the screwdriver, loosen two screws.

Pull two ejectors on the card outward.

Ejector

Ejector

Screw

Screw

MOUNTING IDU 4-9

iPASOLINK 1000: INSTALLATION NWD-118789-04E

2 Pull the card out from the slot.

3 Install a new MC-M card:

Place the card on the card slot guides of the chassis.

Carefully insert the card further till it is fully engaged, and press the two

ejectors on the card to lock them.

4-10 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

(1) Using the screwdriver, tighten the screws.

Warning: Ensure not to touch electrical devices on the card.

Screw

Screw

MOUNTING IDU 4-11

iPASOLINK 1000: INSTALLATION NWD-118789-04E

4.5 Replace CLK2M-C Card

To replace the defective CLK2M-C Card on the MC-M Card, proceed with the

following:

Procedure 4-5 Replace CLK2M-C Card

1 Dismount MC-M Card following Procedure 4-4 Replace MC-M Card.

2 Dismount CLK2M-C Card:

Remove the screw that secures the CLK2M-C Card on MC-M Card.

Warning: Ensure not to touch electrical devices on the card.

Screw

securing CLK2M-C Card

4-12 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Refering to the illustration below, remove the screw that secures the spacer

from the rear surface.

Dismount CLM2M-C Card.

Warning: Ensure not to touch electrical devices on the card.

3 Mount CLK2M-C Card:

Place the spacer on surface of the MC-M Card.

Spacer

CLK2M-C Card

Screw securing the spacer

MOUNTING IDU 4-13

iPASOLINK 1000: INSTALLATION NWD-118789-04E

Tighten the spacer using the screw from the rear surface of MC-M Card.

Set the CLK2M-C Card on the connector provided on the MC-M Card.

Secure the CLK2M-C card using the screwdriver and screw.

Spacer

CLK2M-C Card

4-14 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

4 Verify the installed CLK2M-C Card.

Warning: Ensure not to touch electrical devices on the card.

5 Mount MC-M Card following Procedure 4-4 Replace MC-M Card.

CLK2M-C Card

MOUNTING IDU 4-15

iPASOLINK 1000: INSTALLATION NWD-118789-04E

4.6 Replace PS-M Card

Procedure 4-6 Replace PS-M Card

1 Power off the equipment:

Disconnect the power cable(s) from PS-M Card(s).

Confirm that the PWR LED lamp(s) is/are off.

2 Dismount the defective PS-M card:

Using the screwdriver, loosen the screws.

Power Cable port

PWR LED

on PS-M Card 1

Power Cable port

on PS-M Card 2

PWR LED

Screw

Screw

4-16 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Holding the screws, pull the card out from the slot.

3 Mount a new PS-M card:

Place the card on the card slot guides of the chassis.

MOUNTING IDU 4-17

iPASOLINK 1000: INSTALLATION NWD-118789-04E

Suspend the screws by pulling them outward.

Ensure not to touch interface parts, insert the card further till it is fully engaged

with the chassis backboard.

Using the screwdriver, tighten the screw.

Warning: Ensure not to touch electrical devices on the card.

4 Connect the Power Cable to turn on the power.

Screw

Screw

4-18 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

4.7 Replace PS-M Fuse

Procedure 4-7 Replace PS-M Fuses

1 Dismount the PS-M card following Procedure 4-6 Replace PS-M Card.

2 Remove the defective Fuse:

Remove the protective cover of the fuse.

Remove the fuse.

3 Set a new fuse.

4 Set the protective cover.

Warning: Ensure not to touch electrical devices on the card.

MOUNTING IDU 4-19

iPASOLINK 1000: INSTALLATION NWD-118789-04E

4.8 Replace TERM-M Card

Procedure 4-8 Replace TERM-M Card

1 Power off the equipment:

Disconnect the power cable(s) from PS-M Card(s).

Confirm that the PWR LED lamp(s) is/are off.

2 Dismount the defective TERM-M card:

Disconnect the cables if connected.

Using the screwdriver, loosen the screws.

Power Cable port

PWR LED

on PS-M Card 1

Power Cable port

on PS-M Card 2

PWR LED

TERM-M Card

Screw Screw

4-20 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Holding the screws, pull the card out from the slot.

3 Mount a new TERM-M card:

Place the card on the card slot guides of the chassis.

Suspend the screws by pulling them outward.

Ensure not to touch interface parts, insert the card further till it is fully engaged

with the chassis backboard.

MOUNTING IDU 4-21

iPASOLINK 1000: INSTALLATION NWD-118789-04E

Using the screwdriver, tighten the screws.

Warning: Ensure not to touch electrical devices on the card.

4 Connect cables back in place to TERM-M Card, if required.

5 Connect the Power Cable(s) to PS-M Card(s) to turn on the power.

Screw

Screw

4-22 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

4.9 CWDM Filter Box

Important:

Between the associated sites, a CWDM Filter Box A in one site, and CWDM Filter

Box B in the other site must be installed in pair for the use of designated IN and OUT

ports. See 7.3.6 Cables Using CWDM Filter Boxes for reference.

4.9.1 IDU and Filter Box Mount

CWDM Filter Box can be installed in to the Universal Slots, but it has no back pins to

connect with IDU. Thus, CWDM can also be placed out of the IDU using a Filter

Box Mount (a dedicated chassis for CWDM Filter Box) if no vacant slot is found in

the IDU.

CWDM Filter Boxes in IDU (Example)

CWDM Filter Boxes in Filter Box Mount

MOUNTING IDU 4-23

iPASOLINK 1000: INSTALLATION NWD-118789-04E

4.9.2 Mount CWDMF

Since CWDM Filter Box has no back pins, installing it either on IDU or Filter Box

Mount requires to secure the CWDM Filter Box using two screws only:

Insert the CWDMF into the Card Slot, and fasten two screws:

Screw

Screw

4-24 MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

4.10 Mount SFP Module

4.10.1 SFP Module

The Small Form-factor Pluggable (SFP) is a compact and hot-pluggable transceiver

designed to support Gigabit Ethernet (GbE) and/or SDH (STM-1) in the

iPASOLINK.

iPASOLINK offers the following five options for SFP modules:

1) Single Mode Fiber (SMF): This SFP complies with GbE along with SDH. The

SFP operates with the 1310 nm laser transmitter and has a duplex LC

connector.

2) Multi Mode Fiber (MMF): This SFP complies with 1.25 Gbps 1000 BASE-SX

Gigabit Ethernet. The SFP operates with the laser transmitter and has a duplex

LC connector.

3) Electrical SFP (RJ45): This SFP complies with 10/100/1000 BASE-T copper

interface.

Note SyncE function is not supported on Electrical SFP.

4) Electrical SFP (DIN 1.0/2.3): This SFP complies with STM-1e SDH interface.

5) Colored SFP: See 4.10.2 Colored SFP Module.

The SFP modules also accept LC fiber connectors with Polished Connector (LC-PC)

or Ultra Polished Connector (LC-UPC).

For the purpose of the use in iPASOLINK, it is recommended to use SFPs that are

designated and supplied by NEC.

SFP Module Ports [MC-M]

[SFP Module Ports when GbE-A Card(s) is/are mounted.]

SFP Module Ports [STM1-A on any Universal Slot]

MOUNTING IDU 4-25

iPASOLINK 1000: INSTALLATION NWD-118789-04E

4.10.2 Colored SFP Module

For the use of CWDM, following SFP are provided. Depending on the applicable

wavelength, a colored tape is applied on the extraction lever of each SFP:

Table 4-1 Types of SFP and Colors

Wavelength Color Indication on Extraction Lever

1470 nm Gray

1490 nm Violet

1510 nm Blue

1530 nm Green

1550 nm Yellow

1570 nm Orange

1590 nm Red

1610 nm Brown

EXTRACTION LEVER

4-26/END MOUNTING IDU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Procedure 4-9 Mount SFP Module (Example: IDU)

1 Mount an SFP module onto the SFP port till it clicks and is fully engaged:

SFP modules are mounted

MOUNTING ODU 5-1

iPASOLINK 1000: INSTALLATION NWD-118789-04E

5. MOUNTING ODU

The procedures for mounting and dismounting the ODU are described here. There are

two types of mounting for the Antenna Direct Mounting type and Feeder Connecting

type. The ODU should be installed in the radio station.

The tools for installation are listed in Table 5-1.

Caution

1. How to use small and large O-rings are shown in following table. Two

(small and large) O-rings are attached in 18 to 42 GHz band Andrew/RFS

direct mount antenna. 11/13/15 GHz band antenna does not have small O-

ring (Small O-ring is not used for Andrew/RFS direct mount antenna). If the

small O-ring is used for ODU direct mount installation, a gap may occur

between ODU and antenna for RF interface. Therefore it may happen

transmit or receive level down.

2. Do not apply silicon grease at O-ring.

Note 11/13/15 GHz antenna for direct mount is not possible to connect the

ordinary waveguide flanges.

Table 5-1 Tools

Tools

Wrench or Monkey Wrench

Screwdriver

Torque Wrench

System

Attachment Position of

O-ring (Between:)

O-ring

Remarks

Small Size Large Size

1+0 ANT ODU Not used Used Antenna direct mounting

ANT WG/ODU

(18 42 GHz BAND)

Used Not used Waveguide connection

1+1 ANT Hybrid/Coupler Not used Used Antenna direct mounting

ANT WG/Hybrid/Coupler

(18 42 GHz BAND)

Used Not used Waveguide connection

5-2 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Notes

1. Do not use both small O-ring and large O-ring simultaneously.

2. O-ring size is different with frequency band as follows:

Position of

large size

O-ring

Position of

small size

O-ring

For Waveguide Connection For Antenna Direct Mounting

ANDREW Antenna

Position of

large size

O-ring

Position of

small size

O-ring

RFS Antenna

For Waveguide Connection For Antenna Direct Mounting

3

2

m

m

3

5

m

m

Large Size O-ring for Antenna Direct Mounting

26-42 GHz Band

4

0

m

m

10-11 GHz Band 13-23 GHz Band

4

m

m

4

m

m

4

m

m

18/23 GHz Band 32/42 GHz Band

1

5

.

6

m

m

Small Size O-ring for Waveguide Connection

1

0

.

8

m

m

1

.

8

m

m

1

.

8

m

m

MOUNTING ODU 5-3

iPASOLINK 1000: INSTALLATION NWD-118789-04E

5.1 Antenna Direct Mounting

5.1.1 Basic Installation for Antenna & ODU

Note The details are referred to the installation manual which is attached to

the antenna.

Installation of Bracket

1 Install the bracket to the antenna pole,

2 Mount antenna to the bracket,

ANDREW pole mount bracket

for other reflector type

Washer

Note *: Tightening torque of 22 Nm for M10.

Three(3) screws*

(Apply screwtight to threads

before fitting to antenna)

Nut*

Protective cap

Lock washer

ANDREW pole mount bracket

for 1 or 2 ft reflector type

Lock washer

Washer

Nut

Clamp Bracket

5-4 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

RFS SB1 Type Bracket

MOUNTING ODU 5-5

iPASOLINK 1000: INSTALLATION NWD-118789-04E

Note The values in the following table are valid for screws and bolts which

have been greased according to the installation instructions.

Torques for RFS

Bolt M5 5 Nm

M6 8 Nm

M8 17 Nm

M10 35 Nm

M12 50 Nm

U-Bolt, V-Bolt (Pipe mount & safety collar) M10 20 Nm

Hexagonal brass nut of fine adjustment (Azimuth, Elevation) M8 5 Nm

M10 10 Nm

M12 17 Nm

Hexagonal socket stainless steel screws

(Feed systems install on aluminium mounting plate)

M3 0.2 Nm

M4 0.4 Nm

Exceptions

Fixing screw of the azimuth fine adjustment spindle M8 x 30 8 Nm

M12 x 55 17 Nm

Special application: NOT greased

Fixing screw of the plastic radome B4.2 3 Nm

5-6 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Pipe diameter: 48-114 mm

RFS C-Mount Type Bracket

Mount Assembly (RFS C-Mount Type)

MOUNTING ODU 5-7

iPASOLINK 1000: INSTALLATION NWD-118789-04E

RFS C-Mount Type Bracket

6

7

5-8 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

3 Fix the ODU to the bracket by tightening the M6 screws (four locations),

Notes

1. Being careful, tighten alternately and gradually four screws.

2. Figure shows V polarization.

3. Be careful not to damage the O-ring (Antenna).

4. The tightening torque is 4.0 Nm 10%.

O-ring

Hole for guide pin

ANDREW VHLP Type Bracket

ODU (6-11 GHz) ODU (13-42 GHz)

MOUNTING ODU 5-9

iPASOLINK 1000: INSTALLATION NWD-118789-04E

Notes

1. Figure shows V polarization.

2. Be careful not to damage the O-ring (Antenna).

3. The tightening torque is 4.0 Nm 10%.

RFS SB1 Type Bracket

O-ring

Hole for guide pin

ODU (6-11 GHz) ODU (13-42 GHz)

Note Set the ODU to the bracket after

polarization of the ODU is confirmed.

O-ring

RFS C-Mount Type Bracket

Hole for guide pin

ODU (6-11 GHz) ODU (13-42 GHz)

5-10 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

4 Insert guide pin on the hole of bracket to set the position of screws,

Caution Align flanges on antenna and ODU correctly, and fix the ODU

with four screws.

5 Fix the ODU to the bracket with four screws.

Note Tightening torque is 4.0 Nm 10%.

Guide pin

ODU

ODU flange

Antenna flange

Antenna

Screws

Screws

Screws

Screws

ODU (6-11 GHz)

ODU (13-42 GHz)

MOUNTING ODU 5-11

iPASOLINK 1000: INSTALLATION NWD-118789-04E

Note Antenna separation (S) is given by path calculation depending on the

system parameter.

1+1 SD System

Pole

(S)

Member of tower

1+0 System

Member of tower

Pole

No.1 ODU

No.2 ODU

ODU

ODU (6-11 GHz)

1+0 System

Member of tower

Pole

ODU

ODU (13-42 GHz)

1+1 SD System

ODU (6-11 GHz)

ODU (13-42 GHz)

Pole

(S)

Member of tower

No.2 ODU

No.1 ODU

5-12 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Procedure 5-1 Change of Polarization of Antenna

(1) ODU Direct Mounting Type Antenna (ANDREW Example #1)

Notes

1. The details are referred to the installation manual which is attached to

the antenna. The installation or removal of the antenna requires qualified

experienced personnel.

2. The antenna is set to V-polarization when shipped from the factory.

1 Keep the antenna stand horizontally,

2 If you change to H polarization, loosen the four screws with the hexagonal key

wrench and then rotate the Transition hub of feed, keeping the antenna stand

horizontal,

Note Do not remove the screw complete from the screw hole.

Hold the feed horn with hand.

Transition hub

2 screws

2 screws

MOUNTING ODU 5-13

iPASOLINK 1000: INSTALLATION NWD-118789-04E

3 Holding the feed with hand, rotate the feed 90 degrees,

Check that the aperture part of the Transition hub is rotated 90 degrees, then fix it

with the screws that were loosened in Step 2,

4 Check that the aperture part of the Transition hub is rotated 90 degrees, then fix it

with the screws that were loosened in Step 2.

Note When a large and a small gasket are included in the antenna package.

Please use the large one. (The small gasket is not used in antenna

mount.)

(2) ODU Direct Mounting Type Antenna (ANDREW Example #2)

Notes

1. The details are referred to the installation manual which is attached to

the antenna. The installation or removal of the antenna requires qualified

experienced personnel.

2. The antenna is set to V-polarization when shipped from the factory.

1 Keep the antenna stand horizontally,

2 Loosen six screws with Allen wrench until transition can rotate freely,

Notes

1. Do not remove the screw complete from the screw hole.

2. Because of the screwtight is applied, the strength to loosen screw is

necessary.

Polarization

V

Polarization

H

Top Top

5-14 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

3 Rotate the transition hub 90 degrees until timing pin locates in timing concavity.

Tighten six screws when transition hub is located. (Tightening torque is 5.0 Nm

10%.)

(3) ODU Direct Mounting Type Antenna (RFS Example)

Notes

1. The details are referred to the installation manual which is attached to

the antenna. The installation or removal of the antenna requires qualified

experienced personnel.

2. The antenna is set to V-polarization when shipped from the factory.

Vertical Polarized Application Horizontally Polarized Application

Transition hub

Transition hub

Timing pin Transition hub

RFS SB1

1. Unscrew the 4 screws M3 at the refined

steel ring,

2. Hold the feed tightly at the waveguide,

3. Rotate carefully the feed 90 degrees,

4. Mount the feed to the refined steel ring

and lock the 4 screws M3.

1. Loosen the 4 screws M3,

2. Hold the feed tightly at the waveguide,

3. Rotate the casting plate carefully the

feed 90 degrees,

4. Lock the 4 screws M3.

RFS C-mount

Drain plug

Drain plug

MOUNTING ODU 5-15

iPASOLINK 1000: INSTALLATION NWD-118789-04E

4 screws (M3)

Polarization V Polarization H

Antenna top

Vertical

Horizontal

5-16 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Procedure 5-2 Change of Polarization of ODU

1 When vertical polarization is required, rotate the ODU so as to go up the lug

marked with V.

2 When horizontal polarization is required, remove the guide pin fixed on the lug

marked with V.

3 Screw in the guide pin removed in Step 2 to the screw hole of the lug marked

with H.

4 Rotate the ODU so as to go up the lug marked with H.

Notes

1. When the ODU is mounted on the NEC Hybrid/Coupler, only V

polarization is applied.

2. When the waveguide or coaxial cable is connected between the ODU

and antenna, the ODU in V polarization for up position is recommended

for installation.

Guide pin

V-marked Lug

Guide pin

H-marked Lug

V-marked Lug

UP

V Polarization

H-marked Lug

UP

H Polarization

FG

IFL MON

RX LEV

F

G

IF

L

M

O

N

R

X

L

E

V

V/H Polarization Conversion

6-11 GHz ODU

MOUNTING ODU 5-17

iPASOLINK 1000: INSTALLATION NWD-118789-04E

V Polarization

-

I R

V-marked Lug

Guide pin

UP

-

I

R

H-marked Lug Guide pin

UP

H Polarization

V/H Polarization Conversion

13-42 GHz ODU

5-18 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

5.1.2 With Hybrid/Coupler

This section explains the antenna direct mounting type ODU installation with

Hybrid/Coupler.

Mounting

Note The details are referred to the installation manual which is attached to

the antenna.

ANDREW VHLP Type Bracket

Mounting hole for

Hybrid/Coupler

Hole for guide pin

Note The tightening torque is 4.0 Nm 10%.

Be careful not to damage the O-ring (Antenna).

O-ring

Hole for guide pin

O-ring

RFS SB1 Type Bracket

RFS C-mount type bracket

Mounting hole for

Hybrid/Coupler

O-ring

Hole for guide pin

Mounting hole for

Hybrid/Coupler

Note The tightening torque is 4.0 Nm 10%.

Be careful not to damage the O-ring (Antenna).

MOUNTING ODU 5-19

iPASOLINK 1000: INSTALLATION NWD-118789-04E

[A] 10-42 GHz Hybrid/Coupler

1 Fix the bracket and handle to the Hybrid/Coupler,

Note Tightening torque is 3.0 Nm 10%.

2 Check the polarization and install the Hybrid/Coupler to the antenna by

tightening the M6 screws (four locations),

.

Notes

1. Be careful not to damage the O-ring.

2. Tightening torque is 4.0 Nm 10%.

Hybrid/Coupler

Handle

M5 head cap screw

M5x12 (10ea)

Bracket

PUSH

ANT

O-ring

Hybrid/Coupler

Flat washer M6 screw

Guide pin

Short plate

O-ring

ODU port

5-20 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

3 Insert the O-rings to the two ODU ports of the Hybrid/Coupler,

4 Install the two ODUs with hex screws (four locations) using the Allen key

wrench.

Note Be careful not to damage the O-rings (Hybrid/Coupler).

For 10/11 GHz ODU

Note Tightening torque is 4.0 Nm 10%.

O-ring

ODU

ODU

O-ring

ODU

MOUNTING ODU 5-21

iPASOLINK 1000: INSTALLATION NWD-118789-04E

For 26-42 GHz ODU

Note Tightening torque is 4.0 Nm 10%.

O-ring

ODU

O-ring

ODU

ODU

ODU

ODU

5-22 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Demounting from Hybrid/Coupler

1 Loosen the four (or six) bolts fixed the ODU,

2 Then demount the ODU.

Note When demounting the ODU from Hybrid/Coupler, mount the attached

SHORT PLATE to the demounted port of the Hybrid/Coupler to avoid RF

power leaking from the hybrid/coupler and for waterproofing.

Note Tightening torque is 3.0 Nm 10%.

Mounting short plate to the

ODU port

Mounting hole for

short plate

Short plate

MOUNTING ODU 5-23

iPASOLINK 1000: INSTALLATION NWD-118789-04E

Change of Polarization of Hybrid/Coupler

Note The hybrid/coupler is set to V-polarization when shipped from the

factory.

1 If you change the polarization from V to H, loosen two screws, rotate the

transition hub and put it to the Hybrid/Coupler,

Note There are two types Hybrid/Coupler. One uses two pieces transition

hubs and another uses one piece.

2 Then fix it with the two screws that were loosened in Step 1.

Transition

hub

V Polarization

Guide pin

Hybrid/Coupler

V Polarization H Polarization

Two Pieces Transition Hub Type

H Polarization

V Polarization

One Piece Transition Hub Type

Cross-recessed

head machine screw

M2.6 (2ea)

Cross-recessed

head machine screw

M2.6 (2ea)

5-24 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

[B] 7/8 GHz Hybrid

This Hybrid/coupler is designed to be attached to 0.6 to 1.8 m antennas with interface

for direct mounting of ODU.

1 Hybrid assembly

Note Tightening torque is 3.0 Nm 10%.

2 Polarization coarse alignment

Support

Spring washer M5 (8ea.)

Hexagon socket

head cap screw

M5 x 14 (8ea.)

Hybrid

V Polarization H Polarization

Cross-recessed

Head machine screw

M2.6 (2ea.)

(Shipment condition)

MOUNTING ODU 5-25

iPASOLINK 1000: INSTALLATION NWD-118789-04E

3 Installation to antenna

Note Tightening torque is 4.0 Nm 10%.

4 Attachment of main ODU

Note Tightening torque is 4.0 Nm 10%.

Flat washer M6 (4ea.)

Hexagon socket

head cap screw

M6 x 20 (4ea.)

Spring washer M6 (4ea.)

Short plate

In case of removing ODU,

attach this short plate to

the ODU port.

Attachment of Short Plate

Hybrid

Antenna

equally and carefully by

Tighten the each screw

wrench at diagonal

position.

O-ring

Packing (Supplied by antenna)

Connection Part Details

Top View

NEC ODU

(Main ODU)

Hexagon socket

head cap screw M6

(Supplied by NEC

O-ring

(Packing)

V direction of ODU

with ODU)

O-ring (Packing)

5-26 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

5 Attachment of standby ODU

SS: Stainless steel

Table 5-2 Hybrid Parts List

No. Parts Name Qty

1 Hybrid 1

2 Support 1

3 O-ring 2

4 M5 x 14 Hexagon Socket Head Cap Screw (SS) 8

5 M5 Spring Washer (SS) 8

6 M6 x 20 Hexagon Socket Head Cap Screw (SS) 4

7 M6 Flat Washer (SS) 4

8 M6 Spring Washer (SS) 4

V direction of ODU

NEC ODU

(Main ODU)

O-ring

(Packing)

NEC ODU

(Standby ODU)

Top View

MOUNTING ODU 5-27

iPASOLINK 1000: INSTALLATION NWD-118789-04E

[C] 7/8 GHz Coupler

This Hybrid/coupler is designed to be attached to 0.6 to 1.8 m antennas with interface

for direct mounting of ODU.

1 Coupler assembly,

Note Tightening torque is 3.0 Nm 10%.

2 Polarization coarse alignment

Support

Spring washer M5 (8ea.)

Hexagon socket

head cap screw

M5 x 14 (8ea.)

Coupler

V Polarization H Polarization

Cross-recessed

Head machine screw

M2.6 (2ea.)

(Shipment condition)

5-28 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

3 Installation to antenna

Note Tightening torque is 4.0 Nm 10%.

4 Attachment of main ODU

Note Tightening torque is 4.0 Nm 10%.

Packing (Supplied by antenna)

Flat washer M6 (4ea.)

Hexagon socket

head cap screw

M6 x 20 (4ea.)

Spring washer M6 (4ea.)

Short plate

In case of removing ODU,

attach this short plate t

the ODU port.

Attachment of Short Plate

Coupler

Antenna

equally and carefully by

Tighten the each screw

wrench at diagonal

position.

O-ring

Connection Part Details

Top View

NEC ODU

(Main ODU)

Hexagon socket

head cap screw M6

(Supplied by NEC

O-ring

(Packing)

V direction of ODU

with ODU)

O-ring (Packing)

MOUNTING ODU 5-29

iPASOLINK 1000: INSTALLATION NWD-118789-04E

5 Attachment of standby ODU

SS: Stainless steel

Table 5-3 Coupler Parts List

No. Parts Name Qty

1 Coupler 1

2 Support 1

3 O-ring 2

4 M5 x 14 Hexagon Socket Head Cap Screw (SS) 8

5 M5 Spring Washer (SS) 8

6 M6 x 20 Hexagon Socket Head Cap Screw (SS) 4

7 M6 Flat Washer (SS) 4

8 M6 Spring Washer (SS) 4

V direction of ODU

NEC ODU

(Main ODU)

O-ring

(Packing)

NEC ODU

(Standby ODU)

Top View

5-30 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

[D] 13/15 GHz Hybrid, 15 GHz Coupler

This Hybrid/coupler is designed to be attached to 0.2 to 1.8 m antennas with interface

for direct mounting of ODU.

1 Hybrid/Coupler assembly

Note Tightening torque is 3.0 Nm 10%.

2 Polarization coarse alignment

Support

Spring washer M5 (8ea.)

Hexagon socket

head cap screw

M5 x 12 (8ea.)

Hybrid/Coupler

V Polarization H Polarization

Cross-recessed

head machine screw

M2.6 (2ea.)

MOUNTING ODU 5-31

iPASOLINK 1000: INSTALLATION NWD-118789-04E

3 Installation to antenna

Note Tightening torque is 4.0 Nm 10%.

4 Attachment of main ODU

Note Tightening torque is 4.0 Nm 10%.

Packing (Supplied by Antenna)

Flat washer M6 (4ea.)

Hexagon socket

head cap screw

M6 x 20 (4ea.)

Spring washer M6 (4ea.)

Short plate

In case of removing ODU,

attach this short plate t

the ODU port.

Attachment of Short Plate

Hybrid/Coupler

Antenna

equally and carefully by

Tighten the each screw

wrench at diagonal

position.

O-ring

Connection part details

Top View

NEC ODU

(Main ODU)

Hexagon socket

head cap screw M6

(Supplied by NEC

O-ring

(Packing)

V direction of ODU

with ODU)

O-ring

(Packing)

5-32 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

5 Attachment of standby ODU

SS: Stainless steel

Table 5-4 Hybrid/Coupler Parts List

No. Parts Name Qty

1 Hybrid/Coupler 1

2 Support 1

3 O-ring 2

4 M5 x 12 Hexagon Socket Head Cap Screw (SS) 8

5 M5 Spring Washer (SS) 8

6 M6 x 20 Hexagon Socket Head Cap Screw (SS) 4

7 M6 Flat Washer (SS) 4

8 M6 Spring Washer (SS) 4

V direction of ODU

NEC ODU

(Main ODU)

O-ring

(Packing)

NEC ODU

(Standby ODU)

Top View

MOUNTING ODU 5-33

iPASOLINK 1000: INSTALLATION NWD-118789-04E

[E] 18/23 GHz Hybrid

This Hybrid is designed to be attached to 0.2 to 1.8 m antennas with interface for

direct mounting of ODU.

1 Hybrid assembly

Note Tightening torque is 3.0 Nm 10%

2 Polarization coarse alignment

Support

Spring washer M5 (8ea.)

Hexagon socket

head cap screw

M5 x 12 (8ea.)

Hybrid

V Polarization H Polarization

Cross-recessed

head machine screw

M2.6 (2ea.)

5-34 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

3 Installation to antenna

Note Tightening torque is 4.0 Nm 10%.

4 Attachment of main ODU

Note Tightening torque is 4.0 Nm 10%.

O-ring

Antenna

Packing (Supplied by Antenna)

Flat washer M6 (4ea.)

Hexagon socket

head cap screw

M6 x 20 (4ea.)

Spring washer M6 (4ea.)

Short plate

In case of removing ODU,

attach this short plate t

the ODU port.

Attachment of Short Plate

Hybrid

equally and carefully by

Tighten the each screw

wrench at diagonal

position.

O-ring (Packing)

Connection Part Details

Top View

NEC ODU

(Main ODU)

Hexagon socket

head cap screw M6

(Supplied by NEC

O-ring

(Packing)

V direction of ODU

with ODU)

MOUNTING ODU 5-35

iPASOLINK 1000: INSTALLATION NWD-118789-04E

5 Attachment of standby ODU

SS: Stainless steel

Table 5-5 Hybrid Parts List

No. Parts Name Qty

1 Hybrid 1

2 Support 1

3 O-ring 2

4 M5 x 12 Hexagon Socket Head Cap Screw (SS) 8

5 M5 Spring Washer (SS) 8

6 M6 x 20 Hexagon Socket Head Cap Screw (SS) 4

7 M6 Flat Washer (SS) 4

8 M6 Spring Washer (SS) 4

V direction of ODU

NEC ODU

(Main ODU)

O-ring

(Packing)

NEC ODU

(Standby ODU)

Top View

5-36 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

5.1.3 With TX Span Attenuator

This section explains the antenna direct mounting type ODU installation with TX

Span Attenuator (TX SPAN ATT).

Mounting

1 Check the polarization of the antenna connection unit of the TX ATT (Refer to

Change of Polarization of TX ATT to be hereinafter described.),

2 Fix the TX ATT to the antenna by tightening the M6 screws (four locations),

3 Insert the O-rings to port of the ODU,

4 Fix the ODU with hex screws (four locations) using the hexagonal key wrench.

Note Be careful not to damage the O-rings (TX ATT).

Antenna connection unit

TX ATT

Antenna

Guide pin

TX ATT

Flat washer M6 (4ea)

Packing (Supplied by antenna)

Installation to Antenna

1 2

3 4

Note Tightening torque (M6) is 4.0 Nm 10%.

Hexagon socket

head cap screw

M6 x 30 (4ea)

32/42 GHz Band ODU Mounting with TX SPAN ATT (1/2)

38A

Tighten the each

screw equally and

carefully by wrench

at diagonal position.

MOUNTING ODU 5-37

iPASOLINK 1000: INSTALLATION NWD-118789-04E

Attachment of ODU

Hexagon socket

head cap screw M6

(Supplied by NEC with ODU)

O-ring

(Packing)

O-ring

(Packing)

ODU connection unit

ODU

Top View

Side View

TX ATT

ODU

Antenna

TOP

TX ATT

ODU should be attached

by turning V up.

Note Tightening torque is 4.0 Nm 10%.

32/42 GHz Band ODU Mounting with TX SPAN ATT (2/2)

38A

5-38 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Change of Polarization of TX SPAN ATT

Note The TX ATT is set to V-polarization when shipped from the factory.

1 If you change to H polarization, loosen two screws, rotate the antenna connection

unit and put the TX ATT horizontally,

2 Check that aperture of the connection unit is rotated as shown below, then fix it

with the two screws that were loosened in Step 1.

TX ATT

Antenna

connection unit

V Polarization

Guide pin

Cross-recessed

Head machine screw

M2.6 (2ea)

Plate-1

H Polarization V Polarization

32/42 GHz Band TX SPAN ATT Polarization Change

Plate-2

MOUNTING ODU 5-39

iPASOLINK 1000: INSTALLATION NWD-118789-04E

5.1.4 With Ortho-Mode Transducer

This section explains the antenna direct mounting type ODU installation with Ortho-

Mode Transducer (OMT).

There are two types of O-rings for antenna mounting to the OMT depending on the

frequency band.

Caution Do not apply silicon grease to O-ring.

Note O-ring size is different with frequency band as follows:

Position of large size

O-ring

For Antenna Direct Mounting

RFS Antenna

Position of large size

O-ring

For Antenna Direct Mounting

ANDREW Antenna

3

2

m

m

3

5

m

m

Large Size O-ring for Antenna Direct Mounting

26-42 GHz Band 13-23 GHz Band

4

m

m

4

m

m

4

0

m

m

10-11 GHz Band

4

m

m

13-23 GHz Band 42 GHz Band

1

5

.

6

m

m

Small Size O-ring for Waveguide Connection

1

0

.

8

m

m

1

.

8

m

m

1

.

8

m

m

5-40 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

For the antenna direct mounting of the ODU, following OMT is used.

Cautions

1. For connecting the OMT to the antenna, the circular type waveguide flange

of the antenna is applied to the system. When the V/H flange is mounted to

the antenna, it must be changed to a circular type.

2. When mounting the ODU to the OMT, confirm the polarization for main

master and sub master ODU. The installation of the corresponding ODUs in

the opposite station must have the same polarization in order to make into

line main master and sub master MODEMs.

1 Fix the bracket and handle to the OMT,

Note Tightening torque is 3.0 Nm 10%.

Frequency

Band

Frequency

Range (GHz)

Interface WG Inner

Dia. (mm)

(ANT Side)

Interface

(ODU Side)

11 G 10.4 11.7 GHz 18.0 NEC Original

13 G 12.75 13.25 GHz 15.0

15 G 14.5 15.35 GHz 13.5

18 G 17.7 19.7 GHz 10.5

23 G 21.2 23.6 GHz 9.0

26 G 24.5 26.5 GHz 8.0

28 G 27.5 29.5 GHz 7.0

32 G 31.8 33.4 GHz 6.5

38 G 37 39.5 GHz 5.5

42 G 40.5 43.5 GHz 4.8

M5 head cap screw

MOUNTING ODU 5-41

iPASOLINK 1000: INSTALLATION NWD-118789-04E

2 Fix the OMT to the antenna by tightening them with M6 screws (four locations),

Notes

1. Be careful not to damage the O-ring.

2. Tightening torque is 4.0 Nm 10%.

3 Loosen the two screws and move the short plate if it is fixed to the ODU port (see

figure in Step 9),

4 Set the two ODUs to vertical polarization for OMT mounting. If the guide pin

behind the plate marked H is mounted, remove the guide pin,

Note The ODU should be attached by turning the plate marked V up position

for both main master ODU and sub master ODU.

5 Insert the guide pin removed in Step 4 behind the plate marked V,

Note Remove the protection metallic plate covering the waveguide hole on

ODU.

ANT

Flat washer M6

Guide pin

O-ring

Short plate

O-ring

M6 screw

ODU port

Guide pin

Plate marked with V

5-42 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

6 Insert the O-rings to the two ODU ports of the OMT (see figure in Step 9),

7 Insert the guide pin into the hole of the OMT and set the position of screws,

8 Confirm which polarization is applied to the master ODU.

Check the indication of polarization on the upper side of OMT,

Main Master Sub Master

Plate marked with V

UP

FG

IFL MON

RX LEV

FG

IFL MON

RX LEV

ODU (10/11 GHz)

Main Master Sub Master

Plate marked with V

UP

-

I R

-

I R

ODU (13-42 GHz)

Guide pin

MOUNTING ODU 5-43

iPASOLINK 1000: INSTALLATION NWD-118789-04E

9 Fix the two ODUs with hex screws (four locations) using the hexagonal key

wrench.

Note Be careful not to damage the O-rings.

H Polarization side

V Polarization side

Note Tightening torque is 4.0 Nm 10%.

ODU (10/11 GHz)

O-ring

ODU

Note Tightening torque is 4.0 Nm 10%.

ODU (13-42 GHz)

Hex screw

Hex screw

Hex screw

ODU

ODU

ODU

Hex screw

O-ring

ODU

H Polarization side

V Polarization side

O-ring

ODU

O-ring

5-44 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Cautions

1. Tighten all screws with lighter torque at first, then full torque as specified.

2. When either ODU is demounting for ODU replacing or other reasons, fix the

attached short plate to the demounted port of the OMT to avoid leaking of

RF power from the OMT and for waterproof.

3. To avoid occurrence of bit errors due to microphonic properties, when

installing the sub master ODU, protect the main master ODU from

mechanical knocks.

Note Tightening torque is 3.0 Nm 10%.

Fixed short plate

to ODU port

Fixing hole for

short plate

Short plate

MOUNTING ODU 5-45

iPASOLINK 1000: INSTALLATION NWD-118789-04E

5.2 Feeder Connection

5.2.1 For Coaxial Cable Connection

6/7/8GHz ODU MOUNTING BRACKET INSTALLATION

This mounting bracket is designed in order to install 6/7/8 GHz ODU with N-type

connector or waveguide interface to a pole. The diameter of the pole is from 48.5 to

114.3 millimeters.

SS: Stainless steel

Note Tightening torque is 4 Nm 10% (M6 screw).

Tightening torque is 11 Nm 10% (M8 screw).

Table 5-6 Mounting Bracket Parts List

Item Description Qty

1 Bracket 1

2 Holder-1 (with Two M6 Taps) 2

3 Holder-2 2

4 M8 Stud Bolt (SS) 4

5 M8 Hexagon Nut (SS) 20

6 M8 Flat Washer (SS) 8

7 M616 Hexagon Socket Head Screw (SS) 4

8 M6 Spring lock Washer (SS) 4

9 M6 Flat Washer (SS) 4

10 Cap 4

11 Band (Cable Clamp) 2

Mounting Bracket

5-46 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

1 A nut is assembled to a stud bolt until a nut has come to a complete stop,

Standard Installation Reverse Installation

Stud bolt M8

Hexagon nut M8

Hexagon nut M8 (4 ea)

Stud bolt M8 (2 ea)

Fixed nut

Approx. 56 mm

Holder-1

Flat washer M8 (2 ea)

Note Tightening torque

is 11 Nm 10%.

Assembly of the Holder-1 (2 sets)

2 taps M6

MOUNTING ODU 5-47

iPASOLINK 1000: INSTALLATION NWD-118789-04E

2 Fix the two holder-1 to the bracket at four bolts,

3 Mount the bracket to the pole, point to the opposite station and tighten it with

four stud bolts,

Note Since a bolt projects from a holder when a pole diameter is small, please

attach the cap to a bolt end.

Assembly of the Bracket

Holder-1 assembly

Bracket

Flat washer M6 (4 ea)

Spring lock washer M6 (4 ea)

Hexagon socket head screw M616 (4 ea)

Note Tightening torque is 4

Nm 10%.

Pole (| 48.5 to 114.3 mm)

Note Tightening torque is

11 Nm 10%.

Holder-2 (2 ea)

A = B

A

B

Installation to the Pole

Holder

Bolt end

Cap (4 ea)

Hexagon nut M8 (8 ea)

Flat washer M8 (4 ea)

5-48 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

4 Mount the ODU on to the bracket and tighten four bolts (M6) at upper and lower

parts of the ODU,

5 Connect the coaxial cable to the RF IN/OUT connector of the ODU,

6 Install the coaxial cables between the antenna and the ODU.

Notes

1. Fix the coaxial cable to the pole or member with band (cable ties) after

antenna orientation has been completed.

2. Wrap the coaxial cable connection points with a self-bonding tape for

waterproof. (The self-bonding tape shall be prepared by customer.)

Hexagon socket head screw M6

Attachment of the ODU

Note Tightening torque is

4 Nm 10%.

Right angle side

Top View

Connection of the Coaxial Cable Example

N-type connector

Band

Coaxial

cable

Antenna

Coaxial cable

Pole

ODU

MOUNTING ODU 5-49

iPASOLINK 1000: INSTALLATION NWD-118789-04E

5.2.2 For Waveguide Connection

10-42 GHz ODU MOUNTING BRACKET INSTALLATION

This mounting bracket is designed in order to install 10-42 GHz ODU with antenna

direct mount interface to a pole. The diameter of the pole is from 48.5 to 114.3

millimeters.

SS: Stainless steel

Note Tightening torque is 4 Nm 10% (M6 screw).

Tightening torque is 11 Nm 10% (M8 screw).

Table 5-7 Mounting Bracket Parts List

Item Description Qty

1 Bracket (with Adapter) 1

2 Holder-1 (with two M6 taps) 2

3 Holder-2 2

4 M8 Stud Bolt (SS) 4

5 M8 Hexagon Nut (SS) 20

6 M8 Flat Washer (SS) 8

7 M616 Hexagon Socket Head Screw (SS) 4

8 M6 Spring Lock Washer (SS) 4

9 M6 Flat Washer (SS) 4

10 Cap 4

11 O-Ring (for ODU) 1

12 O-Ring (for Waveguide) 1

13 Screw of Waveguide Connecting

for 10/11 GHz M414 Hexagon Head Screw with Washer (SS)

for 13/15 GHz M412 Hexagon Head Screw with Washer (SS)

for 18/23/26/28/32/42 GHz M310 Hexagon Head

Screw with Washer (SS)

8

4

4

Mounting Bracket

5-50 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

1 A nut is assembled to a stud bolt until a nut has come to a complete stop,

Standard Installation Reverse Installation

Stud bolt M8

Hexagon nut M8

Hexagon nut M8 (4 ea)

Stud bolt M8 (2 ea)

Fixed nut

Approx. 56 mm

Holder-1

Flat washer M8 (2 ea)

Note Tightening torque is

12 Nm 10%.

Assembly of the Holder-1 (2 sets)

2 taps M6

MOUNTING ODU 5-51

iPASOLINK 1000: INSTALLATION NWD-118789-04E

2 Fix the two holder-1 to the bracket at four bolts,

3 Mount the bracket to the pole, point to the opposite station and tighten it with

four stud bolts,

Assembly of the Bracket

Holder-1 assembly

Bracket (with adapter)

Flat washer M6 (4 ea)

Spring lock washer M6 (4 ea)

Hexagon socket head screw M616 (4 ea)

Note Tightening torque is

4 Nm 10%.

Pole (| 48.5 to 114.3 mm)

Flat washer M8 (4 ea)

Hexagon nut M8 (8 ea)

Note Tightening torque is

12 Nm 10%.

Holder-2 (2 ea)

A = B

A

B

Installation to the Pole

Holder

Bolt end

Cap (4 ea)

5-52 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

Note Since a bolt projects from a Holder when a pole diameter is small, please

attach the cap to a bolt end.

4 Mount the ODU on to the bracket and tighten four bolts (M6) at upper and lower

parts of the ODU. Please equip the terminal area of ODU and adapter with O-

ring, and join together after that,

5 When the attachment screw of the ODU is hard, please loosen the fixed four

screw of adapter once,

6 Please adjust the position of adapter to compensate for attachment of ODU. Then

tighten four bolts (M6) of the ODU,

Hexagon socket head screw M6

Attachment of the ODU

Note Tightening torque is

4 Nm 10%.

Right angle side

Adapter

ODU

Adapter

O-ring (for ODU)

Top View

Loosen the fixed four screws Adapter

Bracket

MOUNTING ODU 5-53

iPASOLINK 1000: INSTALLATION NWD-118789-04E

7 Connect the waveguide to the adapter of the mounting bracket,

8 Install the waveguide between the antenna and the ODU.

Table 5-8 Waveguide Flange Type

Frequency Band Adapter Waveguide

10/11 GHz PDR100 PDR100

13 GHz PBR120 UBR120

13/15 GHz PBR140 UBR140

18/23 GHz PBR220 UBR220

26 GHz PBR260 UBR260

28/32/42 GHz PBR320 UBR320

Connection of the Waveguide Example

Flexible waveguide

Antenna

Pole

ODU

Flexible waveguide

Flexible waveguide O-ring (for waveguide)

Screw of waveguide

connecting

5-54 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

5.2.3 For Waveguide Connection with Hybrid

18/23 GHz Hybrid (FI)

This Hybrid is designed to be connect to waveguide with interface for direct

mounting of ODU. (Waveguide flange type: Hybrid side-PBR220, Waveguide side-

UBR220.)

1 Hybrid assembly

Tightening Torque

M3 0.6 Nm 10%

M5 3.0 Nm 10%

M6 4.0 Nm 10%

PUSH Handle

Hexagon socket

head cap screw

M5 12 (10 ea)

Bracket

Hybrid

MOUNTING ODU 5-55

iPASOLINK 1000: INSTALLATION NWD-118789-04E

2 Installation to pole mount

3 Attachment of main ODU

Hexagon head screw

M6 35 (4 ea)*

Case-1

Flat washer M6

(4 ea)*

Pole mount

Flat washer M6 (4 ea)*

Hexagon nut M6 (Double) (8 ea)*

Hybrid

Short plate

In case you remove ODU,

Please attach this Short plate

to the ODU port.

O-ring

Attachment of Short Plate

Note *: Supplied by pole mount.

ODU (Main ODU)

Pole mount

Hexagon socket head

cap screw M6

ODU should be attached by turning V up.

O-ring I/D |32

(Packing)

O-ring I/D |32

(Packing)

Connection Part Details

Top View

5-56 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

4 Attachment of standby ODU

5 Connection of waveguide

ODU (Main ODU)

O-ring I/D |32

(Packing)

ODU (Standby ODU)

Pole mount

ODU should be attached by turning V up.

Top View

Hybrid

Flexible waveguide

Flange type UBR220

Pole mount

O-ring I/D |32

(Packing)

Hexagon head screw

with washer M310 (4 ea)

Hybrid

Waveguide flange

Flange type PBR220

Do not remove.

*

Caution*: Please connect the flexible

waveguide in the same

direction as Hybrid.

MOUNTING ODU 5-57

iPASOLINK 1000: INSTALLATION NWD-118789-04E

Caution Be careful not to damage the Hybrid. Connection part will be

damaged if excessive power is applied to the Hybrid by

waveguide.

*: Supplied by pole mount.

SS: Stainless steel

6 Installation to mounting bracket

Table 5-9 Hybrid (Fl) Parts List (for Mounting Bracket)

No. Parts Name Qty

1 Hybrid (Waveguide Flange Interface Type) 1

2 Bracket 2

3 Handle 1

4 O-ring Inner Dia. |32 (for ODU) 2

5 O-ring Inner Dia. |15.6 (for Waveguide) 1

6 M5 12 Hexagon Socket Head Cap Screw (SS) 14 (4 part for spare.)

7 M3 10 Hexagon Head Screw With Washer (SS) 4

* M6 35 Hexagon Socket Head Cap Screw, Nut, Washer Set (SS) 4

Case-2

Mounting bracket

Short plate

In case you remove ODU,

Please attach this Short

plate to the ODU port.

O-ring

Attachment of short plate

Hybrid

Hexagon head screw M6 20 (4 ea)

Flat washer M6 (4 ea)

5-58 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

7 Attachment of main ODU

8 Attachment of standby ODU

Mounting bracket

O-ring I/D |32

(Packing)

Connection part details

ODU (Main ODU)

Hexagon socket head

cap screw M6

O-ring I/D |32

(Packing)

ODU should be attached

by turning V up.

Top View

Mounting bracket

ODU (Main ODU)

O-ring I/D |32

(Packing)

ODU (Standby ODU)

ODU should be attached by turning V up.

Top View

MOUNTING ODU 5-59

iPASOLINK 1000: INSTALLATION NWD-118789-04E

9 Connection of waveguide

SS: Stainless steel

Table 5-10 Hybrid (Fl) Parts List (for Mounting Bracket)

No. Parts Name Qty

1 Hybrid (Waveguide Flange Interface Type) 1

2 Bracket 2

3 Handle 1

4 O-ring Inner Dia. |32 (for ODU) 2

5 O-ring Inner Dia. |15.6 (for Waveguide) 1

6 M5 12 Hexagon Socket Head Cap Screw (SS) 14 (4 part for spare.)

7 M6 20 Hexagon Socket Head Cap Screw (SS) 4

8 M6 Flat Washer (SS) 4

9 M3 10 Hexagon Head Screw With Washer (SS) 4

Hybrid

Waveguide flange

Flange type PBR220

Do not remove.

*

Mounting bracket

O-ring I/D |15.6

(Packing)

Hexagon head screw

with washer M3 10

(4 ea)

Flexible waveguide

Flange type UBR220

Caution*: Please connect the flexible

waveguide in the same

direction as Hybrid.

5-60 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

5.3 Other Mounting

5.3.1 Wall Mounting

For the antenna direct mounting type ODU, wall mounting installation is explained in

following procedure.

1 Using a center punch and hammer, mark the drilling holes for the ODU wall

mount bracket. Dimensions are shown below,

2 Using an electric drill for concrete, drill the guide holes,

3 Change the concrete drill to enlarge the holes and drill the anchor bolt holes,

2

1

1

Unit: mm

Wall

L

L

D

M10

L

D

MOUNTING ODU 5-61

iPASOLINK 1000: INSTALLATION NWD-118789-04E

4 Remove debris from the specified hole and insert a plug-bolt into it,

5 Make sure to insert the plug-bolt fully,

6 Tighten hardly the bolt using a wrench or monkey wrench,

Note Anchor bolts of M10 bolt shall be prepared by the customer.

7 Loosen the bolt and remove it,

Anchor bolt

Bolt

Washer

5-62 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

8 Fix the ODU wall mounting bracket to the wall with the six bolts (M6) of the

anchor volt,

Note The bolt, flat washer and spring washer are the anchor bolt.

9 Mount the ODU onto the bracket and fix the ODU using the four bolts (M6) on

the ODU,

Note The tightening torque is 4.0 Nm 10%.

Flat washer*

Spring washer*

Bolt*

Flange adaptor

Guide pin

(V)

Transducer Transducer

Guide pin

(V)

ODU (13-42 GHz) ODU (10/11 GHz)

MOUNTING ODU 5-63

iPASOLINK 1000: INSTALLATION NWD-118789-04E

10 Connect the wave guide to the transducer for the ODU.

Notes

1. Tightening torque is 1.4 Nm 10% (up to 15 GHz).

Tightening torque is 0.6 Nm 10% (18 GHz or higher).

2. Be careful not to damage the O-ring.

Refer to 5.2.2 ODU Mounting for Waveguide Connection.

Washer

O-ring

Bolt (M4)

Spring washer

ODU 10/11 GHz)

Waveguide

A

Washer

O-ring

Bolt(M4)

Spring washer

ODU 13-42 GHz)

Waveguide

For 13-42 GHz

Details of A

For 10/11 GHz

A

5-64 MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

5.3.2 Rack Mounting

For the antenna direct mounting type ODU, rack mounting installation is explained in

following procedure.

1 Fix the ODU rack mounting bracket into the 19-inch rack using the six fixing

bolts,

2 Mount the ODU onto the bracket and tighten the four fixing bolts (M6) on the

ODU,

Note The tightening torque is 4.0 Nm 10%.

ODU mounting bracket

Bolt

Spring washer

Flat washer

19-inch rack

Flange adaptor

ODU

Guide pin

MOUNTING ODU 5-65

iPASOLINK 1000: INSTALLATION NWD-118789-04E

3 Connect the wave guide to the transducer for the ODU.

Notes

* M4: Up to 15 GHz.

M3: 18 GHz or higher.

1. Tightening torque is 1.4 Nm 10% (up to 15 GHz).

Tightening torque is 0.6 Nm 10% (18 GHz or higher).

2. Be careful not to damage the O-ring.

Refer to 5.2.2 ODU Mounting for Waveguide Connection.

Washer

O-ring

Waveguide

Bolt*

Spring washer

ODU

A

For 13-42 GHz

Details of A

For 10/11 GHz

5-66/END MOUNTING ODU

NWD-118789-04E iPASOLINK 1000: INSTALLATION

5.4 Hybrid Combiner Installation

When you attach two Hybrids to one dual pole antenna, for 1+1 or 2(1+1) system in

6/7/8 GHz rotate the antenna 90 degree counter clockwise, as shown below, to avoid