Professional Documents

Culture Documents

Abstract For Fabrication of Aqua Silencer

Uploaded by

Jithin AsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abstract For Fabrication of Aqua Silencer

Uploaded by

Jithin AsCopyright:

Available Formats

ABSTRACT FOR FABRICATION OF AQUA SILENCER

FABRICATION OF AQUA SILENCER

SYNOPSIS This project is an attempt to reduce the toxic content of dieselexhaust, before it is emitted to the atmosphere. This system can be safely used for diesel power packs which could be used in inflammable atmospheres, such as refineries, chemicalsprocessing industries, open cost mines and other confined areas, which demands the need for diesel power packs.

WORKING PRINCIPLE The aqua silencer is more effective in the reduction of emission gases from the engine exhaust gas using perforatedtube. By using perforated tube the back pressure will remain constant and the sound level is reduced. Using the perforated tube the fuel consumption remains same as conventional system. By using water as a medium the sound can be lowered and also by using activated charcoal in water. We can control the exhaust emission to a grater level. The water contamination is found to be negligible in aqua silencer, because the amount of acidity level in aqua silencer is expected to be below the dangerous acidity. It is smokeless and

pollution free emission and also very cheap.

The aqua silencers

performance is almost equivalent to the conventional silencer.

ADVANTAGES Diesel engines are playing a vital role in Road and sea transport, Agriculture, mining and many other industries. Considering the available fuel resources and the present technological development, Diesel fuel is evidently indispensable In general, the consumption of fuel is an index for finding out the economic strength of any country.

DISADVANTAGE Need to alter the silencer which may increase the total weight of the vehicle.

APPLICATION For achieving this toxic gases are to be reduced to acceptable limits before they are emitted out of this atmosphere, which otherwise will be hazardous and prone to accidents.

You might also like

- Aqua Silencer: SynopsisDocument3 pagesAqua Silencer: Synopsismythos mechNo ratings yet

- Aqua SilencerDocument4 pagesAqua SilencerPrabhat GuptaNo ratings yet

- Aqua SilencerDocument4 pagesAqua SilencerSubash0% (1)

- Emission Test For Co2Document4 pagesEmission Test For Co2ieee4mybusinessonlyNo ratings yet

- Emission Control of Diesel Engine: SynopsisDocument4 pagesEmission Control of Diesel Engine: SynopsisShruti BiradarNo ratings yet

- Adblue PresintationDocument12 pagesAdblue Presintationapi-718247816No ratings yet

- Aqua SilencerDocument6 pagesAqua SilencerJayaseelan100% (1)

- Reduce Toxic Diesel Exhaust EmissionsDocument4 pagesReduce Toxic Diesel Exhaust EmissionsParamesh WaranNo ratings yet

- Aqua Silencer PDFDocument28 pagesAqua Silencer PDFAniketGunjal89% (44)

- Reduction of Pollutants in CI Engine Using Emulsion Fuels To Reduce Overall Traffic-Induced EmissionsDocument7 pagesReduction of Pollutants in CI Engine Using Emulsion Fuels To Reduce Overall Traffic-Induced Emissionsdipali2229No ratings yet

- So2 To So3 To So4Document2 pagesSo2 To So3 To So4Marlon CarrilloNo ratings yet

- h2s Scavenging BRDocument12 pagesh2s Scavenging BROmid LarkiNo ratings yet

- Outstanding H S Removal: Reduce Risk. Increase ReturnDocument12 pagesOutstanding H S Removal: Reduce Risk. Increase ReturnQaiser HafeezNo ratings yet

- Synopsis: Aqua Silencer Is A Concept Which Is Designed To Replace Conventional Single UnitDocument11 pagesSynopsis: Aqua Silencer Is A Concept Which Is Designed To Replace Conventional Single UnitRohit KumarNo ratings yet

- Seminar Report 123 (Reference Copy) 123Document22 pagesSeminar Report 123 (Reference Copy) 123Ajith RajagopalanNo ratings yet

- Design and Analysis of Hydro Silencer For Two Wheeler and Calculating The EmissionDocument19 pagesDesign and Analysis of Hydro Silencer For Two Wheeler and Calculating The EmissionAnonymous qRAAcePNo ratings yet

- Developement and Experimental Test For Aqua Silencer For Air Pollution Control For Diesel EngineDocument2 pagesDevelopement and Experimental Test For Aqua Silencer For Air Pollution Control For Diesel Enginejyani hiteshNo ratings yet

- Green TechnologiesDocument3 pagesGreen TechnologiesPriyanka GopinathanNo ratings yet

- Process - Desanding HydrocyclonesDocument4 pagesProcess - Desanding HydrocyclonesgshdavidNo ratings yet

- Alderley PWT BrochureDocument8 pagesAlderley PWT BrochurechirinoslaaNo ratings yet

- SREENIDHI INSTITUTE OF SCIENCE AND TECHNOLOGY AQUA SILENCERDocument9 pagesSREENIDHI INSTITUTE OF SCIENCE AND TECHNOLOGY AQUA SILENCERRahul rathanNo ratings yet

- DuPont Oil Well Productivity GlicolicoDocument12 pagesDuPont Oil Well Productivity GlicolicoFederico ArqueroNo ratings yet

- Anaer ObiDocument4 pagesAnaer ObiLTE002No ratings yet

- Design and Fabrication of Aqua Silencer. (Report)Document82 pagesDesign and Fabrication of Aqua Silencer. (Report)mkkfakes100% (2)

- Wartsila ScrubbersDocument8 pagesWartsila ScrubbersKalezic NebojsaNo ratings yet

- Design and Development of Aqua Silencer: ISO 9001:2008 CertifiedDocument7 pagesDesign and Development of Aqua Silencer: ISO 9001:2008 CertifiedrassNo ratings yet

- Seawater Flue Gas DesulphurisationDocument2 pagesSeawater Flue Gas DesulphurisationNestramiNo ratings yet

- Wartsila O IG Moss Inert Gas Generator For Tankers PDFDocument4 pagesWartsila O IG Moss Inert Gas Generator For Tankers PDFvcharlesNo ratings yet

- Product and Technical Data - FUEL DOCTOR DescriptionDocument2 pagesProduct and Technical Data - FUEL DOCTOR DescriptionScott FullerNo ratings yet

- Drilling ThesisDocument8 pagesDrilling ThesisShery TentionNo ratings yet

- Drilling Fluids and Drilling Waste Management PDFDocument8 pagesDrilling Fluids and Drilling Waste Management PDFkenny haekaseNo ratings yet

- 01condensate Polisher Systems - Degremont Technologies - Worldwide Water and Wastewater Treatment SpecialistsDocument2 pages01condensate Polisher Systems - Degremont Technologies - Worldwide Water and Wastewater Treatment SpecialistsJAGADEESHNo ratings yet

- Rentar Fuel Catalyst BrochureDocument4 pagesRentar Fuel Catalyst BrochureMuhammad Asim ShabbirNo ratings yet

- New De-Oiling Hydrocyclone OutperformsDocument17 pagesNew De-Oiling Hydrocyclone OutperformsUci SianiparNo ratings yet

- Measures in Air Pollution ReductionDocument61 pagesMeasures in Air Pollution ReductionPamela MendozaNo ratings yet

- Group Members: Andile Sibanda Donovan Moyo Takunda Chikohwa Lebani Dube Byron MawoyoDocument18 pagesGroup Members: Andile Sibanda Donovan Moyo Takunda Chikohwa Lebani Dube Byron MawoyoSambiri PisiraiNo ratings yet

- OGV+ VSA - Oxygen GeneratorDocument18 pagesOGV+ VSA - Oxygen GeneratorAljamali AlhofashiNo ratings yet

- JETIRES06095Document6 pagesJETIRES06095karthickeyan250No ratings yet

- Evolution Long Life SAE 5W30: DescriptionDocument2 pagesEvolution Long Life SAE 5W30: DescriptionGiga KekaNo ratings yet

- TO, Shri. Naveen Patnaik, The Honorable Cheif Minister of Odisha, Naveen Niwas, Bhubaneshwar, OdishaDocument2 pagesTO, Shri. Naveen Patnaik, The Honorable Cheif Minister of Odisha, Naveen Niwas, Bhubaneshwar, OdishaAfrin MemonNo ratings yet

- Oil & GasDocument18 pagesOil & GasYesika Eka Swasti ApsariNo ratings yet

- OGV+ VPSA BrochureDocument18 pagesOGV+ VPSA Brochurenicolas.lelorrainNo ratings yet

- DISORBDocument6 pagesDISORBThe Sur StudioNo ratings yet

- How To Choose The Right ScrubberDocument5 pagesHow To Choose The Right ScrubberKamelia CleantechNo ratings yet

- The Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Document9 pagesThe Challenge of Filtering Heavy Feed Stocks - Article From Filtration News - October 2011Eaton FiltrationNo ratings yet

- Motoare Diesel - PropulsieDocument24 pagesMotoare Diesel - PropulsieDan Aurelian Popa100% (1)

- DynaWave ScrubberDocument1 pageDynaWave ScrubberDave DumontNo ratings yet

- 2.5.1 - Separador Espuma 01Document15 pages2.5.1 - Separador Espuma 01lucianosilva75No ratings yet

- Hybrid Aqua SilencerDocument43 pagesHybrid Aqua SilencerNihar VsNo ratings yet

- QUADRICELLDocument2 pagesQUADRICELLGuido PerezNo ratings yet

- Fuel ManagementDocument3 pagesFuel ManagementShazmaniaNo ratings yet

- UOP Mercury Removal For Natural Gas Production BrochureDocument4 pagesUOP Mercury Removal For Natural Gas Production BrochurePherx Jhoss100% (1)

- CPipDusTreatEcomagination enDocument2 pagesCPipDusTreatEcomagination enlrbolNo ratings yet

- Diaphragm Metering PumpDocument4 pagesDiaphragm Metering Pumpmacarronm62016No ratings yet

- Wartsila SP B General.Document10 pagesWartsila SP B General.Uhrin ImreNo ratings yet

- Gas Treating Products and ServicesDocument16 pagesGas Treating Products and ServicesphantanthanhNo ratings yet

- Economical Chemical RecoveryDocument5 pagesEconomical Chemical Recoveryroohollah13No ratings yet

- 4.DOING Waste Oil Distillation Project ReportDocument24 pages4.DOING Waste Oil Distillation Project ReportPranav Tubaji100% (1)

- Prevention: Cutting DryersDocument5 pagesPrevention: Cutting DryersAljay ImperialNo ratings yet

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- AbstractDocument1 pageAbstractJithin AsNo ratings yet

- Revolutionizing Underwater Travel with SupercavitationDocument20 pagesRevolutionizing Underwater Travel with SupercavitationRoshan ThimmaiahNo ratings yet

- References: Application To Rotating Machinery. SpringerDocument1 pageReferences: Application To Rotating Machinery. SpringerJithin AsNo ratings yet

- Aqua SilencerDocument5 pagesAqua SilencerBaneeIshaqueKNo ratings yet

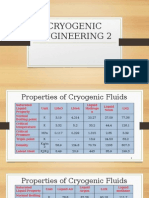

- Cryogenic Engineering Iii: Low Temperature Properties of MaterialsDocument19 pagesCryogenic Engineering Iii: Low Temperature Properties of MaterialsJithin AsNo ratings yet

- ReferenceDocument2 pagesReferenceJithin AsNo ratings yet

- Snmimtmaliankara: Mechanical Engineering Department SEMINAR REPORTS (2006-2010 Batch)Document2 pagesSnmimtmaliankara: Mechanical Engineering Department SEMINAR REPORTS (2006-2010 Batch)Jithin AsNo ratings yet

- Critical Components of A Liquefaction SystemDocument11 pagesCritical Components of A Liquefaction SystemJithin AsNo ratings yet

- ReferencesDocument2 pagesReferencesJithin AsNo ratings yet

- CryogenDocument49 pagesCryogenJithin AsNo ratings yet

- Pharmaceutical Pollution in WaterDocument3 pagesPharmaceutical Pollution in WaterJithin AsNo ratings yet

- Critical Components of A Liquefaction SystemDocument11 pagesCritical Components of A Liquefaction SystemJithin AsNo ratings yet

- Chapter 1Document4 pagesChapter 1Jithin AsNo ratings yet

- SolarDocument1 pageSolarJithin AsNo ratings yet

- AbstractDocument1 pageAbstractJithin AsNo ratings yet

- New Explosive FormingDocument24 pagesNew Explosive FormingJithin As33% (3)

- CRYOGENIC GRINDING BENEFITSDocument18 pagesCRYOGENIC GRINDING BENEFITSVivekavardhan RachakondaNo ratings yet

- Sativum, Orysa Sativa Are CollectedDocument3 pagesSativum, Orysa Sativa Are CollectedJithin AsNo ratings yet

- Title, Abstract, Introduction, Literature Review-BogaDocument20 pagesTitle, Abstract, Introduction, Literature Review-Bogaasheesh87No ratings yet

- Chapter 1Document4 pagesChapter 1Jithin AsNo ratings yet

- AbstractDocument1 pageAbstractJithin AsNo ratings yet

- Presentexplosive Formingation 1Document14 pagesPresentexplosive Formingation 1Jithin AsNo ratings yet