Professional Documents

Culture Documents

Lycra Heat Setting

Uploaded by

Kushagradhi DebnathOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lycra Heat Setting

Uploaded by

Kushagradhi DebnathCopyright:

Available Formats

www.fibre2fashion.

com

Lycra Heat Setting

By: Swapnil M. Patil, P.P.Raichurkar,Akhilesh Shukla, Ramkesh Yadav, S.Tharakeshwari & Pranjali Chandurkar

www.fibre2fashion.com

Lycra Heat Setting

By: Swapnil M. Patil, P.P.Raichurkar,Akhilesh Shukla, Ramkesh Yadav, S.Tharakeshwari & Pranjali Chandurkar

Abstract

In this project the optimum heat setting for the Lycra knitted fabric is studied. Achieving best heat setting means perfect dimensional stability of the knitted fabric. During heat setting process the fabric is passed through heated chambers of 200C for achieving the desired property of the Lycra knitted fabric. If the parameters like over feed, temperature, speed etc. suddenly changed, the fabric quality like GSM, width, Dimensional stability of the knitted fabric also change, thus resulting in variation between and within fabrics.

Key Points: Heat setting of Lycra, over feed, Temperature, Speed for Heat setting etc.

Introduction

Lycra blended fabric heat setting is a critical process. During heat setting process, the fabric runs continuously in the stenter machine. Any minute changes in the machine parameters will result in fabric quality variation. Lycra is a registered trademark used for DuPont's elastane fillament. Elastane is a generic term, like polyamide or polyester. It defines a manmade fiber in which the fiber-forming substance is a synthetic chain polymer containing at least 85% segmented polyurethane. Lycra filament is knitted or woven under tension along with other yarns. When relaxed, it tends to compact the fabric length and width to a jam point. The hard fiber buckles when the fabric is jammed, and it limits the extension of the fabric when it is being stretched. Elastic fabrics are very often appears wider and lighter, than their width and weight at Jam point.

www.fibre2fashion.com

Heat setting is a term used in the textile industry to describe a thermal process taking place mostly in either a steam atmosphere or a dry heat environment. The effect of the process gives fibers, yarns or fabric dimensional stability and, very often, other desirable attributes like higher volume, wrinkle resistance or temperature resistance.

Object of heat setting: 1) Improve the dimensional stability of fabric. 2) Improve the dye uptake of fabric. 3) Improve the crease resistance of fabric 4) Improve resistance to pilling 5) Remove creases formed during earlier processes.

Lycra yarn has outstanding elastic properties - very high stretch and recovery as well as high power at stretch. Its other important characteristic includes good abrasion resistance, long wear life, and strength.

The most fabrics which contain fine Lycra elastane filament, particularly in knitted fabrics, needs heat setting to impart an adequate Dimensional stability and flatness at a given fabrics GSM and Width.

Grey fabrics have to be heat-set in stretched condition, if their width is less than the desired finished width. Fabric should be heat set prior to hot wet processing in order to reduce shrinkage, control curling and prevent discoloration of goods. Setting after the wet process yields fabrics which can less stable, more curly and less white than the preset ones. Therefore, it is advisable to preset fabrics with Lycra.

Excessive heat exposure will over set the fabric whilst too little heat will leave it under set. Under setting of a fabric may lead to more shrinkage and curling, higher weight and narrower width than expected, whereas oversetting ma discolor it, reduce its power too much or impair the dye uniformity of companion hard fibers.

www.fibre2fashion.com

Method & material:a) Material

1) QUALITY

- 34*20 CT /LY S/J Elason extra soft - 30/28 - 3.0 - 230 - 4.3

Design no.AK13789 - 35 - 68 - 180

DIA/GG S.L G.GSM Lycra %

G.WIDTH F.WIDTH F.GSM

b) Method Heat setting dyeing finishing

During heat setting process continuous running fabric on stenter machine any minute change in the only one parameter (like, change overfeed) and result in vast variation in fabric quality. Then fabric passes through the dyeing& finally finishing.

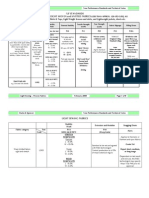

Study of different process parameter during heat setting and finishing process:

Parameter Overfeed (%) Temperature ( OC) Speed ( m/min) Nip Pressure ( bar) Expander width ( cm) Blower ( rpm) Before width ( cm) After width (cm) Before gsm After gsm

Ilsung Stenter 40

(H/S)

Ilsung Stenter S1( soft) 45 190 13 2 177 1500 164 179 171 -5.5*-1.5 0.5%

190 12-13 (70sec) 3 178 1800 165 182 195 215 L = 0.5* W= 0.2 2%

Shrinkage (%) Spirality (%)

www.fibre2fashion.com

� To study variation of temperature during heat setting process:-

QUALITY DIA/GG S.L G.GSM Lycra %

- 34*20 CT /LY S/J Elason extra soft - 30/28 - 3.0 - 230 - 4.3 G.WIDTH F.WIDTH F.GSM

Design no.AK13789 - 35 - 68 -180

Finishing process QUALITY DIA/GG G.GSM F.GSM - 34*20DLY S/J - 30/28 177 G.WIDTH F.WIDTH S.L - 32 - 65 - 2.20

- 180

Parameter Overfeed (%) Temperature ( OC) Speed ( m/min) Pressure ( bar) Expander width ( mm) Blower ( Rpm) Before width After width Before gsm After gsm

Stenter 40 190

(H/S)

Stenter(H/S) 40 180 13 2 177 1800 164 179 190

12-13 3 178 1800 165 182 195 215

www.fibre2fashion.com

� To study the variation of over feed during heat setting process:QUALITY DIA/GG S.L G.GSM Lycra % - 34*20 CT /LY S/J Elson extra soft - 30/28 - 3.0 - 230 - 4.3 G.WIDTH F.WIDTH F.GSM Design no.AK13789 - 35 - 68 -180

Parameter Overfeed (%) Temperature ( OC) Speed ( m/min) Pressure ( bar) Expander width ( mm) Fan (RPM) Before width After width Before gsm After gsm

Stenter 30 185 10 2 168

(H/S)

Stenter( H/S) 40 185 10 2 168 1700 164 180 225

1700 165 182 195 215

� To study the variation of speed during heat setting process

QUALITY DIA/GG S.L G.GSM Lycra % -

- 34*20 CT /LY S/J Elason extra soft 30/28 3.0 230 4.3 G.WIDTH F.WIDTH F.GSM - 35 - 68 - 180

Design no.AK13789

www.fibre2fashion.com

Parameter Overfeed (%) Temperature ( OC) Speed ( m/min) Pressure ( bar) Expander width ( mm) Fan (RPM) Before width After width Before gsm After gsm

Stenter 40 185 10 2 168

(H/S)

Stenter( H/S) 40 185 12 2 170 1700 163 179 190

1700 164 180 225

Result

Variation of overfeed during heat setting process

Overfeed GSM width

30 215 182

40 225 180

Variation of temperature during heat setting process

Temperature GSM width

190 215 182

180 190 179

Variation of Speed during heat setting process

Speed GSM Width ( MPM) 10 280 180 12 290 179

www.fibre2fashion.com

Conclusion

The Lycra heat setting is depends on the process parameter of the machine.

If any parameter (over feed, temperature, speed) will slightly change at the time of heat setting process then thats effect on the GSM, Shrinkage and Spirality of the fabric.

Effect on fabric property of heat-set temperature

Property Stability Shrinkage Whiteness Flatness Width Lubricant spots

Temp increase Increases Decreases Decreases Increases Increases Increases

References 1) S.V.Gokhle and J.R.Modi Process and quality control in chemical processing of textiles page no.52,53 2) Webcache.googleusercontent.com. 3) Technical Information Bulletin. L523, 24,25

The authors of the articles are associated with Centre for textile functions (CTF), NMIMS MPSTME Shirpur campus, shirpur, Maharashtra

You might also like

- Parameters of Finishing MachineDocument46 pagesParameters of Finishing MachineFathi Mustafa100% (2)

- Textil Testing Manual-Gihan RanganaDocument16 pagesTextil Testing Manual-Gihan RanganaGihan RanganaNo ratings yet

- Stenter Machine Operator CurriculumDocument5 pagesStenter Machine Operator CurriculumMohon KhanNo ratings yet

- Circular Knitted FabricsDocument16 pagesCircular Knitted Fabricsrdsekar7633% (3)

- Knitted Fabric Analysis CalculationDocument5 pagesKnitted Fabric Analysis Calculationmbstutextile75% (4)

- Dyeing and Printing TechniquesDocument37 pagesDyeing and Printing Techniquesagga1111100% (1)

- Textile DocumentDocument28 pagesTextile DocumentKhandaker Sakib FarhadNo ratings yet

- Stenter Machine: Mazadul Hasan Shishir, Southeast UniversityDocument20 pagesStenter Machine: Mazadul Hasan Shishir, Southeast UniversitySyed Salahuddin MunnaNo ratings yet

- Viyellatex Group Internship ReportDocument184 pagesViyellatex Group Internship ReportAlauddin Ahmed Jahan95% (20)

- Wet Processing of Polyester MicrofibresDocument12 pagesWet Processing of Polyester MicrofibresEdward Menezes100% (1)

- Dyeing Defects and Their RemediesDocument5 pagesDyeing Defects and Their RemediesMuhammad ImranNo ratings yet

- Textile Wet Processing PDFDocument63 pagesTextile Wet Processing PDFRAYMOND URASSA50% (2)

- Soptextilefinishing 170316114830Document73 pagesSoptextilefinishing 170316114830Mohammed Tanjil Morshed remonNo ratings yet

- Stenter MachineDocument9 pagesStenter MachineMd.Tipu Sultan100% (1)

- Industrial Attachment Report On Micro Fibre GroupDocument125 pagesIndustrial Attachment Report On Micro Fibre GroupDigonto Das50% (2)

- Textile FinishingDocument21 pagesTextile FinishinganowartexNo ratings yet

- Process Control in Wet ProcessingDocument23 pagesProcess Control in Wet ProcessingKirti Nagda75% (4)

- 4.knit Fabric Specification Consumption Yarn Consumption PDFDocument56 pages4.knit Fabric Specification Consumption Yarn Consumption PDFRifatNo ratings yet

- FM-1 SizingDocument18 pagesFM-1 SizingTextile Department Help Desk.Diu100% (1)

- Finishing TextilesDocument202 pagesFinishing TextilesvasilicapNo ratings yet

- StenterDocument2 pagesStenterMusa Eltayeb100% (2)

- Dyeing ProblemsDocument12 pagesDyeing ProblemsShivam Bajpai100% (1)

- Dyeing machines overviewDocument6 pagesDyeing machines overviewChaarvi SaranyaNo ratings yet

- SpiralityDocument9 pagesSpiralitySenthil KumarNo ratings yet

- Tinting or OverdyeingDocument4 pagesTinting or OverdyeingDelwar Hossain67% (3)

- Introduction To Wet ProcessingDocument84 pagesIntroduction To Wet Processingzynab123No ratings yet

- Fully FashionDocument30 pagesFully FashiondewNo ratings yet

- STDS'M&SDocument8 pagesSTDS'M&SSazid Rahman100% (1)

- Container Fabric Cost AnalysisDocument1 pageContainer Fabric Cost Analysissubhankhan45No ratings yet

- Parameters For Fabric CostingDocument34 pagesParameters For Fabric CostingAbhinav VermaNo ratings yet

- Shrinkage: Types and Control MethodsDocument54 pagesShrinkage: Types and Control MethodsRichardValenciaNo ratings yet

- Singeing Process: Introduction To Textile Chemical ProcessingDocument28 pagesSingeing Process: Introduction To Textile Chemical ProcessingrehanabbaciNo ratings yet

- Testing procedures for fabrics and trims performanceDocument48 pagesTesting procedures for fabrics and trims performanceshivanift100% (1)

- Dyeing of Knitted Fabrics PDFDocument7 pagesDyeing of Knitted Fabrics PDFAhmed AksarNo ratings yet

- Dyeing of Polyester and Cotton BlendDocument50 pagesDyeing of Polyester and Cotton BlendarafathosainNo ratings yet

- How To Calculate Dyeing Recipe in Textile Wet ProcessingDocument5 pagesHow To Calculate Dyeing Recipe in Textile Wet ProcessingMuhammad HamzaNo ratings yet

- Textile Printing (STYLE AND METHODS)Document40 pagesTextile Printing (STYLE AND METHODS)ARYAN RATHORE75% (4)

- Industrial Attachment.. Beximco Denims Ltd.Document100 pagesIndustrial Attachment.. Beximco Denims Ltd.Rakibul Alam67% (9)

- Study On TEXtile FinishingDocument8 pagesStudy On TEXtile FinishingZAyed0% (1)

- Calculate Nominal Production of A Fleece-Knitting Machine Per HourDocument3 pagesCalculate Nominal Production of A Fleece-Knitting Machine Per HourkhurshidNo ratings yet

- Working Process of Jigger Dyeing MachineDocument10 pagesWorking Process of Jigger Dyeing MachineKhushaLNo ratings yet

- YarnsDocument27 pagesYarnsnitishkohli75% (4)

- Colour FastnessDocument37 pagesColour FastnessSivakumar K100% (1)

- Textile Testing: Presented By: Nisha Sangle Ankita Desai Poonam Patil Gayathri RangnathanDocument23 pagesTextile Testing: Presented By: Nisha Sangle Ankita Desai Poonam Patil Gayathri RangnathanChaaya AaldarNo ratings yet

- Spreading and Cutting of Apparel ProductsDocument43 pagesSpreading and Cutting of Apparel ProductsDaniela JakimovaNo ratings yet

- Mercerization ParametersDocument2 pagesMercerization Parametersahmer adnanNo ratings yet

- Defects in The Knitted FabricsDocument17 pagesDefects in The Knitted Fabricstamanna88100% (1)

- Textile Pretreatment: Processes for Removing Impurities from Cotton FabricDocument23 pagesTextile Pretreatment: Processes for Removing Impurities from Cotton FabricAyman BrohiNo ratings yet

- Costing of Knit Garments PDFDocument5 pagesCosting of Knit Garments PDFNurlan0% (1)

- Textile Finishing TechniquesDocument75 pagesTextile Finishing TechniquesShubham TilaraNo ratings yet

- What Is Garment Wash? - Types of Garment Washing - Procedure of Garment WashingDocument5 pagesWhat Is Garment Wash? - Types of Garment Washing - Procedure of Garment WashingHumaun KabirNo ratings yet

- Wet Processing Pretreatment-LectureDocument28 pagesWet Processing Pretreatment-Lecturearafathosain100% (3)

- Dictionary of Textile Finishing: Deutsch/Englisch, English/GermanFrom EverandDictionary of Textile Finishing: Deutsch/Englisch, English/GermanRating: 1.5 out of 5 stars1.5/5 (3)

- Textile Processing and Properties: Preparation, Dyeing, Finishing and PerformanceFrom EverandTextile Processing and Properties: Preparation, Dyeing, Finishing and PerformanceRating: 5 out of 5 stars5/5 (5)

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- Barco Projection SystemDocument7 pagesBarco Projection SystemKushagradhi DebnathNo ratings yet

- DellDocument7 pagesDellKushagradhi DebnathNo ratings yet

- Catalyzation of Alkaline Hydrolysis of Polyester by Oxidizing Agents For Surface ModificationDocument21 pagesCatalyzation of Alkaline Hydrolysis of Polyester by Oxidizing Agents For Surface ModificationKushagradhi DebnathNo ratings yet

- 2017 Chemicals Industry Trends PDFDocument12 pages2017 Chemicals Industry Trends PDFKushagradhi DebnathNo ratings yet

- The Impact of 'Zero' Coming into Fashion: Zero Liquid Discharge Uptake and Socio-Technical Transitions in TirupurDocument23 pagesThe Impact of 'Zero' Coming into Fashion: Zero Liquid Discharge Uptake and Socio-Technical Transitions in TirupurKushagradhi DebnathNo ratings yet

- UNIQEMA HypermerPolymericSurfactantsDocument2 pagesUNIQEMA HypermerPolymericSurfactantsKushagradhi DebnathNo ratings yet

- Reactive Printing and Crease Resistance Finishing of Cotton Fabrics Part I - Study of Influential Factors by An Experimental Design ApproachDocument10 pagesReactive Printing and Crease Resistance Finishing of Cotton Fabrics Part I - Study of Influential Factors by An Experimental Design ApproachKushagradhi DebnathNo ratings yet

- DyStar India and Alok Industries Graduates 3rd AADTT Cohort - DyStarDocument4 pagesDyStar India and Alok Industries Graduates 3rd AADTT Cohort - DyStarKushagradhi DebnathNo ratings yet

- Medlist Updated May 2017 TMDocument8 pagesMedlist Updated May 2017 TMKushagradhi DebnathNo ratings yet

- Exam Papers 2012Document14 pagesExam Papers 2012Kushagradhi DebnathNo ratings yet

- Hydrosulfite Types: Technical InformationDocument8 pagesHydrosulfite Types: Technical InformationKushagradhi DebnathNo ratings yet

- Chemours Capstone For Textiles K25183-1Document1 pageChemours Capstone For Textiles K25183-1Kushagradhi DebnathNo ratings yet

- Essay 3 Greg James at Sun MicrosystemsDocument1 pageEssay 3 Greg James at Sun MicrosystemsKushagradhi DebnathNo ratings yet

- British BS 5867 Part 2 Type B and C PDFDocument1 pageBritish BS 5867 Part 2 Type B and C PDFKushagradhi DebnathNo ratings yet

- British BS 5867 Part 2 Type B and C PDFDocument1 pageBritish BS 5867 Part 2 Type B and C PDFKushagradhi Debnath100% (1)

- Molecules 19 03731Document13 pagesMolecules 19 03731Kushagradhi DebnathNo ratings yet

- Synthesis and Application of Cationic SoDocument5 pagesSynthesis and Application of Cationic SoKushagradhi DebnathNo ratings yet

- Bus StrategyDocument25 pagesBus StrategyChavan VirajNo ratings yet

- ISO 105-E01:2013 Textiles - Tests For Colour Fastness - Part E01: Colour Fastness To WaterDocument1 pageISO 105-E01:2013 Textiles - Tests For Colour Fastness - Part E01: Colour Fastness To WaterKushagradhi DebnathNo ratings yet

- Textile CoatingDocument3 pagesTextile Coatingnitin_dhoot2005@yahoo.comNo ratings yet

- NKC-910 Technical Data SheetDocument2 pagesNKC-910 Technical Data SheetKushagradhi DebnathNo ratings yet

- The+Sequestering+Properties+of+Copolymer+Containing+Acrylic+Acid+Derivatives 최민배 (공개)Document1 pageThe+Sequestering+Properties+of+Copolymer+Containing+Acrylic+Acid+Derivatives 최민배 (공개)Kushagradhi DebnathNo ratings yet

- Multifect Xylanase: Product InformationDocument2 pagesMultifect Xylanase: Product InformationKushagradhi Debnath100% (1)

- TSD 34 1997 2 PerformanceDocument6 pagesTSD 34 1997 2 PerformanceKushagradhi DebnathNo ratings yet

- New Chelating AgentsDocument33 pagesNew Chelating AgentsKushagradhi DebnathNo ratings yet

- Evaluation of Detergents and Washing ProcessesDocument14 pagesEvaluation of Detergents and Washing ProcessesKushagradhi DebnathNo ratings yet

- No Vo GADocument2 pagesNo Vo GAlongthNo ratings yet

- Soften Fibers With Basosoft N-APDocument7 pagesSoften Fibers With Basosoft N-APKushagradhi DebnathNo ratings yet

- Chemistry of Fatty AcidsDocument44 pagesChemistry of Fatty Acidshenry_madumere1365100% (3)

- FR PolyesterDocument9 pagesFR PolyesterKushagradhi DebnathNo ratings yet

- Intro To Fluid PropertiesDocument18 pagesIntro To Fluid PropertiesAngela Mae LopezNo ratings yet

- Unit 5 MCQSDocument27 pagesUnit 5 MCQSFiras Ahmad100% (2)

- Mobilith SHC Greases for Heavy Duty & High Temp ApplicationsDocument2 pagesMobilith SHC Greases for Heavy Duty & High Temp ApplicationsEmerson 2140No ratings yet

- Aipmt 1998-2011Document293 pagesAipmt 1998-2011VideoGamesNo ratings yet

- Alloys - Ferrous & Non-Ferrous MetalsDocument13 pagesAlloys - Ferrous & Non-Ferrous MetalsResta CafNo ratings yet

- Wave Particle Duality and Heisenberg Principle, Schrodinger Wave Equation, Fermi-Dirac and Bose-Einstein DistributionsDocument17 pagesWave Particle Duality and Heisenberg Principle, Schrodinger Wave Equation, Fermi-Dirac and Bose-Einstein DistributionsmaniNo ratings yet

- MCQ's On Unit-1Document4 pagesMCQ's On Unit-1Online PaperNo ratings yet

- Determine Alcohol Content in Beer Using Back TitrationDocument5 pagesDetermine Alcohol Content in Beer Using Back Titrationemily100% (3)

- D 2938 - 95 Standar Test Mehod For Ucs Intact RockDocument3 pagesD 2938 - 95 Standar Test Mehod For Ucs Intact RockAnonymous 6WwThUVe8No ratings yet

- Guarsafe JK-303 - Hydroxypropyl GuarDocument1 pageGuarsafe JK-303 - Hydroxypropyl GuarJuanGuillermoCarmonaOcampoNo ratings yet

- ASTM C 309 Curing CompoundDocument3 pagesASTM C 309 Curing CompoundAlbert Ghobrial0% (1)

- G-6 - What Is Sci - Revised - (WS) 22-23Document5 pagesG-6 - What Is Sci - Revised - (WS) 22-23Arshaaqh BegumNo ratings yet

- TDS - Es-221Document2 pagesTDS - Es-221scribd8341No ratings yet

- FEEDING OF TILAPIA ON MICROBIAL FLOCSDocument16 pagesFEEDING OF TILAPIA ON MICROBIAL FLOCSJonathan Villamil Rodríguez50% (6)

- TEST-PENCIL VIEJO-Static 1-1-67KGDocument12 pagesTEST-PENCIL VIEJO-Static 1-1-67KGJoséMiguelSánchezGNo ratings yet

- Wrong Answered Questions: You MarkedDocument13 pagesWrong Answered Questions: You MarkedKhelan MehtaNo ratings yet

- Requirement For Crown Industrial ParkDocument1 pageRequirement For Crown Industrial ParkAbdul RafaeNo ratings yet

- Scenario For Effect of Leaching On NC and OC ClaysDocument4 pagesScenario For Effect of Leaching On NC and OC Claysshuri080No ratings yet

- PhenanthrolineDocument3 pagesPhenanthrolineRega PermanaNo ratings yet

- Biodegradable PlasticsDocument14 pagesBiodegradable PlasticsWieke SusilawatiNo ratings yet

- FFCR, Japan Monograph - Beet RedDocument2 pagesFFCR, Japan Monograph - Beet RedNur Hanisah MohtarNo ratings yet

- Digest JuneDocument15 pagesDigest Junetiquis_cat100% (3)

- Overview of Food Processing Equipment - Types, Applications, and Important AttributesDocument19 pagesOverview of Food Processing Equipment - Types, Applications, and Important Attributesphong viNo ratings yet

- Pharmaceutical Steam Generators and Water Distillation SystemsDocument12 pagesPharmaceutical Steam Generators and Water Distillation Systemssoajanii100% (2)

- Applications of The Reflux Classifier On SA CoalsDocument24 pagesApplications of The Reflux Classifier On SA CoalsSenthilkumar PragasamNo ratings yet

- Cambridge Assessment International Education: Chemistry 0620/63 October/November 2017Document5 pagesCambridge Assessment International Education: Chemistry 0620/63 October/November 2017Ain Husna ZaizakaraniNo ratings yet

- CALGAZ Test Gases Calibration Gas PDFDocument33 pagesCALGAZ Test Gases Calibration Gas PDFdavidjoe77No ratings yet

- RPT Science f2 DLP 2024Document27 pagesRPT Science f2 DLP 2024ruhaniNo ratings yet

- 0050 Goldenseal ApplicationNote PW PDFDocument5 pages0050 Goldenseal ApplicationNote PW PDFFábio Teixeira da SilvaNo ratings yet

- Ivanov Fundamentals of Physics Mir 1989 PDFDocument459 pagesIvanov Fundamentals of Physics Mir 1989 PDFkalpa_y100% (1)