Professional Documents

Culture Documents

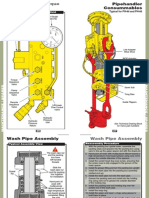

Washpipe Packing Assemblies

Uploaded by

John HoldingOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Washpipe Packing Assemblies

Uploaded by

John HoldingCopyright:

Available Formats

Release

Product Bulletin No.: TDS-04-05 Top Drive Drilling Systems

Date: April 8, 2004

Subject: Performance Update on Washpipe Assemblies Product: All Varco Top Drive Drilling Systems Affected: Varco Washpipe Assemblies Objective: Update Users of Revised Washpipe Assembly, Operation and Maintenance Procedures, Pressure Ratings and Release of Washpipe Service Manual Problem: The main factors that affect washpipe life are standpipe pressure, TDS rpm, the washpipe diameter and mud temperature. Pressure, rpm and washpipe diameter affect how much heat the seals generate while operating, and the mud temperature affects how the seal is cooled. Too much heat can result in rapid seal wear and premature failure of the Washpipe Assembly. Solution: Varco has been working on numerous initiatives to improve performance of the Washpipe Assemblies. While the main focus has been the large bore (4-inch) assemblies (Ref: Product Bulletin TDS-01-02), benefits have been realized on all Varco Washpipe Assemblies. In most cases, operating hours consistently exceeding 400 rotating hours for large bore Washpipe Assemblies and up to 2,000 hours with small bore (3-inch) assemblies is are obtainable by following the latest Varco recommended practices.

2004 Varco All Rights Reserved

TDS-04-05 Page 1 of 3

Grease Requirements for Washpipe Assemblies Because of the high temperatures that can be developed in a Washpipe Assembly, a high temperature, lithium based grease should always be used. Varco recommends Shell Cyprina RA (P/N 56005-1) because of its resistance to washing. All new Washpipe Assemblies are packed with Shell Cyprina RA when assembled. Before substituting grease from an alternative manufacturer, be sure to verify that it has properties compatible with Shell Cyprina RA. Greasing frequency has proven to have a minor affect on seal life. Customers have followed schedules as rigorous as greasing their washpipes once every stand to never greasing assemblies at all after initial installation. Greasing with greater frequency has shown an improvement in seal life of approximately 20% over a washpipe that has never been greased. Varcos recommendation is to grease the units twice a day, or once every 10 rotating hours. Washpipe Service Manual Revisions Varco has developed a Washpipe Assembly supplement to the TDS Service Manual. The Washpipe Assembly Service Manual (P/N SM01053), provides detailed washpipe maintenance and troubleshooting procedures and an illustrated part list for both the standard and hammerless Washpipe Assembly. This service manual may be obtained by contacting your local Varco Service Center. Seal Packing All Varco packing has been redesigned for improved performance. It has been observed that the previous standard seal packing design provided approximately twice the life of high pressure seal packings when drilling pressures were low (< 5,000 psi). Improvements have been made to Varcos standard packing so that it no longer experiences a rapid drop in performance when used at high pressures (>5,000 psi). Consequently, extensive factory testing and feedback from users has confirmed that the best overall seal packing life will be achieved when using the standard pressure washpipe packing. Varcos standard Washpipe Assembly has been proof load tested to 11,250 psi to increase the pressure rating to 7,500 psi. Varco now offers only standard pressure packing for washpipe operating pressures up to 7,500 psi. Consult the Washpipe Assembly Service Manual for the latest part number configurations.

2004 Varco All Rights Reserved

TDS-04-05 Page 2 of 3

Washpipe Standard pressure washpipes will typically groove with use, and should not be reused after a packing change, as this will significantly reduce the life of the assembly. High pressure washpipes (P/N 30123438-TC for large bore, P/N 30123289-TC for small bore), should also not be reused after a packing change. High pressure washpipes may be used with either high or standard pressure packing. Eventually, the high pressure (Tungsten carbide-coated) washpipes and high pressure packings will no longer be available and will be replaced by standard components. Varco now uses only non-Tungsten carbide coated washpipes as standard in all Washpipe Assemblies shipped with new Top Drives. Large to Small Bore Washpipe Conversions For rigs with large bore systems, washpipe life can be improved by installing the Large to Small Bore Washpipe Installation Kit (P/N 30157539-X) **. The increased pressure drop across the small bore vs. the large bore washpipe is equivalent to less than one stand of 5 ID drill pipe. When used in non HTHP (High Temperature High Pressure) applications, this substitution results in approximately a 30% improvement in washpipe life. Life improvement while operating with HTHP conditions can be as much as 10 times, as compared to an otherwise equivalent large bore assembly. The large to small bore washpipe is now standard on all Varco large bore top drives. Kit Number is dependent upon TDS model and if a gooseneck replacement is required. Note: A modification to the gooseneck to add a counterbore for the stem liners is necessary when converting to the large to small bore washpipe and if not done, a replacement gooseneck is required. Consult your Varco Service Center. Ongoing Development Varco is continuing the effort to develop new and improved sealing technologies. We will provide updates to this product bulletin to advise our users as future developments arise related to washpipe design. Please contact your local Varco Service Center if you have any questions regarding this product bulletin.

**

2004 Varco All Rights Reserved

TDS-04-05 Page 3 of 3

NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49

SAFETY REV TITLE ALERT Counterbalance System Adjustment A B A A F A A GE Motor Lubrication EMD Motor Lubrication Field Welding of Service Loop Bracket Gearbox Lubrication Schedule Blower Impeller Loosening Gearbox Sight Gauge Installation Saver Sub Thread Recut Make-Up Torques Safety Valve Actuator Cylinder Locking Safety Valve Actuator Assembly Waterproofing Driller's Controls Pipehandler Cylinder Clevis Loosening IBOP Actuator - Pipehandler Kits Torque Wrench Operation Adjustment Dual IBOP Valve Kit Field Welding, Bail Pin Lock Tabs Rotating Pipehandler, Inst. /Oper. Oil Pump Shaft Retention GE Motor/Main Shaft Housing Rework Blower Motor Lubrication Solid Body Elevator Ear IBOP Actuator Sleeve Link Tilt Improvement Kit Pipehandler/Torque Arrestor Pins Pipehandler Speed-Up Kit Bearing Shield Installation IBOP Actuator Arm Replacement I.S. Cable Slack Hydraulic Pressure Filter Installation Solid Body Elevator Plate Short and Long Term Storage IBOP Valve Corrosion Upper Safety Valve Lubrication Safety Valve Actuator Installation Load Carrying Component Replacement Dolly Link Adjustment Load Carring Component Care Drilling Motor & Cooling System Maint. Closed Loop Cooling System Air Req. STUMP Wiring Changes Guide Rail Installation Tolerances Closed Loop Cooling System Water Supply Shunt Motor Field Coil Maintenance 500 Ton System Upgrade Motor Alignment Cylinder Torque Wrench Body Chamfer Exhaust Cleaning, Overtemp Protection Active vs Passive Shunt Field Supply

DATE REL. 1/3/84 2/2/84 1/5/84 1/5/84 6/5/84 2/9/84 2/29/84 2/24/84 2/24/84 2/29/84 2/29/84 3/29/84 4/6/84 8/2/84 4/6/84 8/29/84 9/24/84 11/2/84 12/21/84 1/29/85 1/30/86 10/31/85 11/19/85 12/13/85 12/2/85 1/31/86 1/29/86 2/6/86 2/5/86 2/13/86 3/11/86 3/11/86 5/2/86 9/3/86 9/8/86 3/14/94 11/17/86 8/29/94 11/17/86 11/17/86 12/1/86 10/9/87 9/11/87 9/11/87 7/9/90 10/23/90 11/6/87 12/2/87 1/18/88

EFFECTIVITY Serial Numbers 1 Thru 31 Incorporated, See Sec. 8 of original Service Manual Incorporated, See Sec. 8 of original Service Manual Incorporated, See Sec. 2 of original Service Manual Incorporated, See Sec. 8 of original Service Manual Obsolete, See Sec. 3 of original Service Manual Obsolete, See Sec. 7 (Mtr/Housing Assy) of original Service Manual Obsolete, See Sec. 4 of original Service Manual Incorporated, See Sec. 4 of original Service Manual Incorporated, See Sec. 4 of original Service Manual Obsolete, See Sec. 4 of original Service Manual Serial Numbers 1 Thru 14 Serial Numbers 1 Thru 12 Incorporated, See Sec. 4 of original Service Manual Incorporated, See Sec. 4 of original Service Manual Incorporated, See Sec. 4 of original Service Manual Incorporated, See Sec. 2 of original Service Manual Incorporated, See Sec. 4 of original Service Manual Obsolete, See Sec. 3 & 7 of original Service Manual Serial Number 1 only Incorporated, See Sec. 8 of original Service Manual Serial Numbers 1 Thru 60 Serial Numbers 1 Thru 64 Serial Numbers 1 Thru 70 Serial Numbers 1 Thru 70 Serial Numbers 1 Thru 70 Serial Numbers 1 Thru 74 Serial Numbers 1 Thru 31 Serial Numbers 1 Thru 75 w/Expo Purge Serial Numbers 1 Thru 80 Serial Numbers 1 Thru 83 Serial Numbers 1 Thru 35 Serial Numbers 1 Thru 90 Serial Numbers 1 Thru 90 Serial Numbers 1 Thru 90 Serial Numbers 1 Thru 90 Serial Numbers 1 Thru 93(w/o 500 Ton Conversion) Serial Numbers 1 thru 90 Serial Numbers 1 Thru 90 Serial Numbers 1 Thru 90(w/Closed Loop Cooling) All Units to Date Equipped w/ STUMP All Units All Units w/Closed Loop Cooling All Units W/ Shunt Drilling Motor Serial Numbers 1 Thru 93 Serial Numbers 1 thru 93 Torque Wrench S/N 1 Thru 110 Serial Numbers 1 Thru 92 All Units Equipped w/ Shunt Drilling Motor

NO. 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 92 92.1 92.2 92.3 92.4 92.5 92.6 93-1 93.2

SAFETY REV TITLE ALERT Revised Operation Section Yes A A B A A Yes Yes A Yes Yes A B Yes Yes A Yes Yes Yes Yes A A Clevises on Link Tilt Assy.P/N 74967 IBOP Control Circuit Kit P/N 87235 Purge Air Oil Removal Filter P/N 86608 Torque Wrench Hinge Pin P/N 76532 Motor Frame Fatigue Cracking Solid Body Elevator Plate Interference Link Tilt Intermediate Stop Spring Fatigue Purge System Cycle Times High Torque Drilling Heavy Duty Guide Roller Lube Problems Motor Lubrication Changes Motor Bearing Lubrication TDS Torque Wrench Body Pins TDS IBOP Valve Assy Control Circuit, IBOP Actuator Shell EMD Bearing/Seal Replacement Operation Safety Notice Safety Notice/Pipe Handler Safety Notice/RBS Pipehandler Connections Varco/Best IBOP Seal Kit Elevator Floor Stand Bushing Replacement DOE Notice Safety Notice/Perforating Tools PH 60/85 Torque Readout Gauges Drill Collar Dolly P/M Trans. Oil Heat Exchanger Transmission Oil Selection Trans. Lube Pump Adjust. Swing Bolt Modification Not Released Safety Notice/IBOP Actuator Shell S/B Numbering System Change Varco BJ Internal Release Pipehandler Hinge Pins Inspect. of 500T Split Land. Collars&Equip Varco/Best Blow Out Preventers AR3000 Maintenance Safety RBS Position Indicator Post Jarring Inspection of Top Drives S/B Numbering System Change Compound Brg Thrust Ring Letter Bonnet Seals Letter VOID VOID Yes Transmission Oil Pumping & Cooling Sys Wireline Adapter

DATE REL. 1/19/88 9/30/88 9/30/88 9/30/88 10/19/88 6/9/89 6/13/89 1/17/91 8/21/89 10/23/90 8/21/89 6/11/91 10/19/89 10/24/89 12/13/89 7/5/90 7/5/90 6/1/90 9/19/90 11/20/90 1/17/91 10/23/90 1/17/91 1/17/91 3/5/91 3/5/91 3/5/91 4/18/91 4/4/91 4/4/91 4/4/91 6/11/91 7/8/92 4/14/92 7/8/92 5/30/92 8/21/92 10/8/92 5/14/03 2/22/93 1/25/93 1/19/93

EFFECTIVITY Serial Numbers 1 Thru 97 Serial Numbers 109, 127-129 & 133-149 Serial Numbers 1 Thru 153 Serial Numbers 1 Thru 113 w/ Closed Loop Cooling Serial Numbers 1 Thru 117 & 119 Serial Numbers 1 Thru 174 per list Serial Numbers 1 Thru 172 Serial Numbers 1 Thru 172 Units w/ Expo Purge Sys. All Units Units w/ 80230 Rollers Units w/ G. E. Motors All TDS Units All TDS Before 10/89 Selected MFGs.10/88-89 TDS-3 Up Through Serial Number 25 All M89 VTS Mfg. up to 8/89 All Units All Units All TDS w/ RBS All TDS Units All Varco/Best Style Valves All Units All U.K. Customers All Units All Unit w/ PH 60-85 All Units w/ Drill Collar Dolly All TDS 4 & 4H Units All TDS Units All TDS Units All TDS Units All TDS Units using PH60 Service Bulletin No. 92 (Admin. only) PH-60 Pipehandler All 500T IDS or IDS Pipehandlers Mfg. w/ provisions for installation of a mud saver All AR3000 units All Raised Backup Systems All TDS Models Administrative Only TDS-4H/4S Owners All S-Model Top Drive Owners

TDS-93-1 TDS-93-2 TDS-93-3 TDS-93-4

2/25/93 2/24/93

All TDS-3S, -4H & -4S Top Drives All Model Top Drives

NO. TDS-93-5 TDS-93-6 TDS-93-7 TDS-93-8 TDS-93-9 TDS-93-10 TDS-93-11 TDS-93-12 TDS-93-13 TDS-93-14 TDS-93-15 TDS-93-16 TDS-93-17 TDS-93-18 TDS-93-19 TDS-93-20 TDS-93-21 TDS-93-22 TDS-93-23 TDS-93-24 TDS-93-25 TDS-93-26 TDS-94-01 TDS-94-02 TDS-94-03 TDS-94-04 TDS-94-05 TDS-94-06 TDS-95-01 TDS-95-02 TDS-95-03 TDS-95-04 TDS-95-05 TDS-95-06 TDS-95-07 TDS-95-08 TDS-95-09 TDS-96-01 TDS-96-2 TDS-97-01 TDS-97-02 TDS-98-01 TDS-98-02 TDS-98-03 TDS-98-04

SAFETY REV TITLE ALERT A Upper IBOP Valve A A A A A Yes Yes Yes Yes Yes Yes B A Yes Yes Yes Yes Yes Yes A A B Yes Yes B B B A B B Air Brake Quick Exhaust Valve Elimination Servicing of Air filters/regulators/lubricators Lower IBOP Valves Maint. & Improve. on Pipe Handlers, PH-60&PH-80 TDS Torque Arrestors Varco BJ 350Ton BNC Elevator TDS-5 Gear Box Oil Capacities Link Tilt Adjustment Locking Device Hydraulic Quick Disconnect Pre-Charging the C'balance System TDS Pipehandler PH-60 Pinion Gear and Drive Train Life Varco/Best Upper IBOP Valves Top Drive Rotating Head Locking Handle Upper IBOP Valve Crank Actuator Inspection TDS-4 Gearshift Maintenance Electrical Service Loop Handling TDS Pipehandler Booster Kit Air Operated Elev. used w/TDS or IDS TDS Split Landing Collar TDS DC Motor Exhaust Duct Covers TDS Mainshaft Wear Allowances 500T Landing Collar Up Grade Installation of Elevator Links on TDS Link Adapter C'Bal Cylinders Accumulator Nitrogen Precharge Model Upper Bonnet Seal Lubrication Top Drive Pipehandler Make-up Torque TDS Lube Oil Filter TDS Work Platform Latch Elevator Link Retainers TDS Link Tilt Stop Adjustment Pipe Handler Torque Tube Access Holes TDS Parking Brake Lock Tabs on TDS Pressure & Temp. Switches Retractable Guide Dollies Well Control Stripping Operations TDS-9S Carriage Roller Contacting Guide Beam Hinge Pin TDS Inline Orifice Bearing Filter Kit TDS Retract Dolly Stops TDS-3S, -4S, -6S & -7S Upper Bearing Seal Retrofit Kit TDS-9S Guide Beam, Slide Type (Non-roller) TDS-9S Hydraulic Manifold Hose Retrofit Falling Crank from PH-85 Upper 7-5/8 IBOP TDS-9S Connector Label & Lockwire Kit

DATE REL. 12/9/94 3/10/93 3/10/93 3/10/93 3/10/93 3/10/93 3/3/93 3/10/93 3/26/93 4/5/93 4/5/93 4/5/93 4/13/93 4/7/93 4/5/93 4/7/93 4/8/93 6/8/93 9/8/93 9/9/93 6/21/93 8/25/93 3/14/94 5/10/94 5/17/94 12/9/94 11/15/94 12/6/94 3/2/95 5/18/95 4/6/95 7/7/03 6/15/95 7/19/95 7/21/95 9/1/95 11/13/95 2/9/96 3/15/96 4/28/97 2/15/00 7/8/98 5/29/98 6/12/98 6/9/98

EFFECTIVITY Varco/Best IBOPs mfg. w/provisions for Mud Saver All Top Drives w/Air Brakes Immediately, on all Top Drives IBOP Valves w/lip seals on spring loaded seat All TDS Models, PH-60 & PH-85 All TDS Users All TDS Units All TDS-5 Units All Top Drives w/PH-60 or PH-85 Pipehandlers TDS Pipehandlers PH-60 & PH-85 All TDS Units All PH-60 Pipehandlers All TDS Units All Varco/Best Type Upper IBOP Valves TDS w/PH-60 & Ph-85 & IDS w/PH-60 Pipehandlers All TDS Units All TDS-4 Units All TDS Units All Booster Kits All Air Operated Elev. used w/TDS or IDS TDS w/Landing Collar Load Pickup Device TDS w/Local or Remote Cooling Sys All TDS-3, 4, 5 & 6 Units All 500T TDS w/Landing Collars All TDS All TDS All TDS-3S, 4S, 6S, 7S Units All PH-60 and PH-85 Pipehandlers All TDS TDS-3, -4, -5, -3H & -4H, 5H All TDS All TDS w/link tilt stops TDS/IDS w/PH-60 & PH-80 Pipe Handlers All Top Drives Baseefa/European TDS 7 IDS All TDS All TDS All TDS-9S Units with Guide Beam All TDS-3S & 4S models TDS Retract Dolly W/Rubber Stops All TDS-3S, -4S, -6S & -7S with 3 and 4 Bore Wash Pipe TDS-9S w/Slide Type Carriages TDS-9S Units All PH-85 Upper 7-5/8 IBOP All TDS-9S Units

NO. TDS-98-05 TDS-98-06 TDS-98-07 TDS-98-08 TDS-99-01 TDS-99-02 TDS-99-03 TDS-99-04 TDS-99-05 TDS-99-06 TDS-99-07

SAFETY REV TITLE ALERT TDS-9S Upper Seal Kit (P/N 119227) Yes Yes Yes Yes Yes Yes Yes B A API Torque Specifications in relation to the use of Large Bore Saver Subs to Smaller ID Drill Pipe TDS-10S Sight Gages on Oil Reservoir TDS-9S Guide Beam Hoisting Hook Failure Improved Terminal Blocks Available For TDS-9S, TDS-10S and TDS-11S Motors Availability of Retrofit Kit for Lubricating Vents for TDS Counterbalance Chain Connecting Link P/N 80392 Falling Object Incident of a TDS Pressure Filter (P/N 82747) PH-100 Pipehandler IBOP Actuator Inspection Guidelines for Retract Dollies Removal of U-Cup Seal (P/N 65260490 or P/N

DATE REL. 6/9/98 10/22/99 9/29/98 10/13/98 3/16/99 8/16/00 5/6/99 7/1/99 5/18/99 5/26/99 6/4/99

EFFECTIVITY TDS-9S w/ S/N TDS9SXXXX39 & under All Varco Customers with Large Bore Top Drive All TDS-10S Units w/Serial Number TDS10SXXXX39 & Under All TDS-9S, -11S Portable Top Drives All AC Motors P/N 108235 built before January 1999 All TDS-4, TDS-6, TDS-8 Units All Top Drive Models TDS-3, -3H, -3S, TDS-4, -4H, -4S, TDS-5, -5H, TDS-7S & TDS-8SA All Top Drives All PH-100 Pipehandlers All TDS and Block Retract Dollies All Rebuilt Large Bore Lower IBOP Valves using Repair Kits (P/N 95385-1 to 3) issued before August 1998

109209) in Large Bore Lower IBOP Valve Repair Kits and Rebuilt Valves

TDS-99-08 TDS-99-09 TDS-99-10 TDS-99-11 TDS-99-12 TDS-99-13 Yes Yes Yes Yes A B A Falling TDS-10S Wear Pads Wear Pad Kit (P/N 128406) HPU Breather Obstruction Implementation of Helical Gears in Varco Top Drives Blower Motor Inspection / Lock wire of Impeller PH-60 Single Crank, Upper 6-5/8 IBOP Falling Crank Top Drive Hydraulic Link Tilt Bolt Failure 6/9/99 6/9/99 6/14/99 9/21/99 11/8/01 6/15/01

All TDS-10S Top Drives All Hydraulic Power Units (HPUs) All Top Drives All Portable AC Top Drives (TDS-9S, -10S & -11S All Single Crank, Upper 6-5/8 IBOPs, P/Ns 94099, 94100 & 94769 (Model #s 500, -501 & -502 All PH-85 Pipehandlers with Hydraulic Link Tilt Systems (Pipehandler Installation Kits #118992 on configurations) All Portable AC Top Drives (TDS-9S, -10S & -11S) All Top Drives with a PH-85 Pipehandler Early TDS-3S, -4H, -4S Top Drives, All Top Drives with P/N 91264 & 94767 Oil Cooler Assemblies (AKA Batwing Coolers) Used on Remote Air Cooled Drilling Systems PH-50 Pipehandlers Shipped before November 14, 1997. Used on TDS-9S Top Drives with Serial Nos. TDS9SM30D52 and Earlier All TDS-8SA Top Drives TDS-9S Top Drives With Two Double Rod Hydraulic Link Tilt Cylinders And Guide Beam With Recessed Lifting Pockets All PH-100 Pipehandlers, Tool Joint Clamp Assemblies All TDS-3, -3H and IDS Top Drives with Landing Collar and 500 Ton PH-85 Pipehandler and Elevator Support Split Plate Assembly P/N 97256 All PH-85 Pipehandlers All TDS-3, -3H -3S, -4, -4H, -4S, -5 and 5H with UL Electric Controls All TDS-4H and -4S Top Drive Drilling Systems All Top Drives with Dolly Retract Control Systems Equipped with Accumulators

TDS-99-14 TDS-99-15 TDS-99-16

A -

Potting Inspection of AC Top Drive Connectors New PH-85 Upper IBOP Break Out Tool (P/N 127700-500) Oil Cooler Motor Shield Kit, P/N 126997

9/21/99 3/26/02 11/15/99

TDS-99-17

Yes

Falling Link Tilt Pin from PH-50 Pipehandler

3/15/01

TDS-99-18 TDS-00-01

Yes

TDS-8SA Motor Alignment Cylinder Link Tilt Cylinder Interference PH-100 Pipehandler Possible Interference Between Solid Body Elevator Support Guide Shoes and Upper IBOP Dropped PH-85 Pipehandler Die U. L. Instrument J-Box Cover Proper Method of Changing Transmission Speeds on TDS-4 Top Drives Top Drive Dolly Retract Systems Guard and Guide Beam

12/7/99 2/24/00

TDS-00-02 TDS-00-03

Yes

A -

12/3/01 5/9/00

TDS-00-04 TDS-00-05 TDS-00-06 TDS-00-07

Yes Yes Yes -

6/28/00 9/5/00 11/8/00 12/21/00

NO. TDS-01-01 TDS-01-02 TDS-01-03 TDS-01-04 TDS-01-05 TDS-01-06 TDS-01-07 TDS-01-08 TDS-01-09 TDS-01-10 TDS-01-11 TDS-01-12 TDS-01-13 TDS-01-14 TDS-01-15 TDS-01-16 TDS-01-17 TDS-01-18 TDS-01-19 TDS-01-20 TDS-02-01 TDS-02-02 TDS-02-03 TDS-02-04 TDS-02-05 TDS-02-06 TDS-02-07 TDS-02-08 TDS-02-09 TDS-02-10 TDS-02-11 TDS-02-12 TDS-02-13

SAFETY REV TITLE ALERT Yes Falling Shim Report from Top Drive Dolly Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes YES Yes Yes Yes Yes B A D A A A A A Large Bore Washpipe Assemblies Falling Pin from PH-50 Pipehandler Link Tilt Adjustment Stop Mechanism Falling Outer Collar from PH-60 Pipehandler Dropped Jaw Pin on PH-85 Pipehandler TDS Rotating Head Assembly Locking Handle Link Tilt Assembly Pivot Pins Rotating Hook Adapter Bypass Check Valve Kit Link Tilt Clamp Base Failure and Chain Upgrade Falling Pin from Drill Pipe Elevator Link Clamp Clevis TDS-9S and 11S Guide Beams Cam Follower on 500 Ton Rotating Head Assy TDS-4 Maintenance Guides Rotating Hook Adapter Structural Modification Kit TDS IBOP Actuator Shell and Torque Arrestor Interference Operation of Link Tilt Assemblies Revised Make-Up Torque Values for AC Top Drive Drill String Load Carrying Components Falling Objects From PH-50 Pipehandler TDS Retract Dolly Stop Plates Screws Falling from PH-85 Pipehandler End Cap Falling from a Cam Follower Report of Sheared Gearcase to Main Body Fasteners on TDS-3S Damage to Hydraulic Link Tilt Operation of Hydraulic Link Tilt Systems Advise Users of Inspection Requirements Faulty Caliper Brake Pads Report of Falling Fasteners from PH-85 Pipehandler PH-100 Pipehandler Stabbing Guide Report of Falling Fastener from PH-50 Pipehandler Control Loop Attachment Links Temperature Alarm and Trip for TDS-8S with RTD Feedback Reliability of PH-100 Powered Rotating Link Adapter Assemblies

DATE REL. 2/12/01 2/27/01 10/15/02 4/2/01 4/25/01 5/2/01 5/11/01 9/26/01 7/12/01 12/04/01 5/29/03 10/3/01 11/8/01 11/15/01 11/16/01 11/16/01 11/20/01 12/5/01 12/6/01 12/21/01 3/13/02 5/27/03 4/26/02 5/17/02 10/25/02 5/31/02 6/20/02 7/7/03 7/3/02 8/2/02 9/3/02 10/3/02 10/10/02

EFFECTIVITY All Top Drives / Traveling Blocks with Retract Systems All Varco 4 Washpipe Assembly Users All Top Drive Drilling Systems with PH-50 Pipehandlers All Units with PH-60 or PH-85 Pipehandlers All Top Drive Drilling Systems with PH-60 Pipehandlers All Top Drive Drilling Systems with PH-85 Pipehandlers All Top Drive Drilling Systems w/PH-60, PH-85 & PH100 Pipe Handlers All Pneumatic Link Tilt Users Powered Rotating Hook Adapter (PRHA) All Top Drive Units with Standard (52) and Extended Reach (76) Link Tilt Assemblies All Top Drive Drilling Systems with PH-60 or PH-85 Pipehandlers All TDS-9S & -11S Top Drive Drilling Systems All Varco PH 60 & 85 Rotating Head Assemblies All TDS-4, -4H, and -4S Top Drive Drilling Systems All Powered Rotating Hook Adapter (PRHA) Assemblies All 650-Ton Top Drive Drilling Systems w/Landing Collar All Units with PH-60 or PH-85 Pipehandlers All AC Top Drive Drilling Systems with PH-50 and PH100 Pipehandlers All Top Drive Drilling Systems with PH-50 Pipehandlers All Top Drives with Retract Dollies All Top Drive Drilling Systems with PH-85 Pipehandlers All TDS-9S and TDS-11S Top Drives with Cam Follower Type Carriages All Top Drive Drilling Systems PH-50, Ph-75 and PH-100 Pipehandler Hydraulic Link Tilt Systems All Top Drive Drilling Systems w/ PH-50/55/75/100 Pipehandlers PH-50 and PH-75 Pipehandlers Hydraulic Link Tilt Systems TDS-9S, -10S and -11S Top Drives All Top Drive Drilling Systems w/ PH-85 Pipehandlers All PH-100 Pipehandlers All PH-50, -55, -60, -75, -85 and -100 Pipehandlers TDS with Auxiliary Electrical Service Loop Kit, Varco P/N 30157644 TDS-8S with GE Multilin RTD Monitor AC Top Drive Drilling Systems with PH-100 Pipehandlers (Refer to Table on Page 4)

NO. TDS-02-14 TDS-02-15 TDS-02-16

SAFETY REV TITLE ALERT Yes Report of Falling Dust Plug/Cap from TDS-11SA During Drilling Operations Yes Reported Interference between PH-85 Pipehandler Link Tilt Assembly and Monkeyboard Yes Report of Falling Stop Tube from PH-85 Pipehandler Yes PH-50 and PH-75 Pipehandler Unclamp Speed Improvements Report of Roller Assembly Falling from PH-60 Pipehandler IBOP Actuator Shell Proper Setup for Siemens DB Choppers

DATE REL. 10/25/05 11/4/02 11/14/02

EFFECTIVITY All TDS-9SA, -10SA and -11SA Top Drive Drilling Systems All PH-60 and PH-85 Pipehandlers with Link Tilt Assemblies All Top Drive Drilling Systems w/ PH-60 and PH-85 Pipehandlers All TDS-9SA, -11SAA and -11HP Top Drive Drilling Systems All Top Drive Drilling Systems w/ PH-60 Pipehandlers (Single Crank IBOP Design only All TDS-8SA, -9SA, -10SA & -11SA Top Drives with Varco Control Systems utilizing Siemens 70 series VFDs All Varco Becket Assemblies All Varco TDS-9SA, -10SA and -11SA Top Drive Drilling Systems w/ Type GG Drill Pipe Elevator Assemblies All TDS-4S Powered Rotating Head Assemblies All Varco IDS, TDS-9SA, -10SA and -11SA Top Drive Drilling Systems All Top Drive Drilling Systems with PH-50, -55, -60, 75, -85 and PH-100 Pipehandlers TDS-11HP Top Drive Drilling Systems All PH-60 Pipehandlers PH-50, PH-75 and PH-100 Pipehandlers All TDS-11SA Top Drive Drilling Systems PH-85 Pipe Handlers Using Upper IBOP Quick Change Systems (P/N 127700) PH-50 and -75 Pipe Handlers Used with TDS-9SA and -11SA Top Drive Systems TDS-9SA and 11SA Top Drive Systems PH-60/PH-85 Pipe Handlers TDS-3H, -3S, -4H, -4S, -5 and -6S Top Drive Drilling Systems Electrical Package, TDS-9SA, TDS-11SA and TDS11HP TDS-11SA and 11HP Top Drives with PH-50/75 Pipehandlers TDS-3, TDS-3H, TDS-4H and TDS-5H Top Drives All PH-50, -60, -75, -85 and PH-100 Pipehandlers All TDS-9SA, TDS-10SA, and TDS-11S Top Drive Drilling Systems w/PH-50 Pipehandlers TDS-4S Units with the Remote Counterbalance (P/N 122549-100) TDS-9SA and TDS-11SA Top Drive Drilling Systems Digital Encoder Assembly TDS-3, 4, 5, 7, 8SA, 9SA, 11SA, 11HP, IDS-1, IDS-3 and Top Drive Drilling Systems PH-50, 55, 60, 75, 85 and 100 Pipe Handlers All Varco Top Drive Primary Load Carrying Components All Varco Top Drive Drilling Systems TDS-4S and TDS-8SA Oil Circulating Kits

TDS-02-17 TDS-02-18 TDS-03-01

12/13/02 12/13/02 1/16/03

TDS-03-02 TDS-03-03

Yes Yes

Report of Falling End Plate on Becket Assembly Report of Damaged Elevator Drill Pipe Assembly Possible Dowel Pin and Bolt Failures on Powered Rotating Head Assemblies Report of Sheared Hinge Joint Pin on TDS-11SA Guide Beam Assembly Potential Dropped Object from Link Tilt Intermediate Stop Release Cable Bumped/Broken Directional Control Valve Handle Sheared Hinge Pin on PH-60 Pipehandler Report of Stabbing Guide Falling from PH-50 Pipehandlers Report of Broken Fasteners on TDS-11SA Motor Housing Guard All Operators of PH-85 Upper IBOP Quick Change Systems All Top Drive Operators with PH-50 and PH-75 Pipe Handlers All Operators of TDS-9SA and TDS-11SA Top Drive Drilling Systems All PH-60 and PH-85 Pipe Handler Operators To Advise DC Top Drive Users of Motor Inspection Following Jarring To Advise Users of Revised Lube Pressure Switch Settings To Advise Users of Proper Setup and Capabilities of Link Tilt Installation of Incorrect Parts in Swivel/Bail Pin/Swivel Link Assemblies Torque Values for TDS Drill String Load Carrying Components Damaged Lower Guide Beam Tieback Link During Saver Sub Break Out Counterbalance Mounting Bolts Falling from a Top Drive Damage to Attachment Bolts on TDS-11SA Carriage Assembly Operation of AC Top Drives in Encoder Bypass Mode Secondary Retention of Pins & Fasteners on Top Drive Drilling Systems

1/17/03 1/20/03

TDS-03-04 TDS-03-05 TDS-03-06 TDS-03-07 TDS-03-08 TDS-03-09 TDS-03-10 TDS-03-11 TDS-03-12 TDS-03-13 TDS-03-14 TDS-03-15 TDS-03-16 TDS-03-17 TDS-03-18 TDS-03-19 TDS-03-20 TDS-03-21 TDS-03-22 TDS-03-23 TDS-03-24

Yes Yes Yes Yes Yes Yes Yes Yes Yes -

A A A A A

1/20/03 2/27/04 2/5/03 2/7/03 2/18/03 2/19/03 3/3/03 3/21/03 3/27/03 3/28/03 3/28/03 4/3/03 4/10/03 4/15/03 5/12/03 5/16/03 6/3/03 6/19/03 12/16/03 6/22/03 11/18/03

TDS-03-25 TDS-03-26 TDS-03-27

Magnetic Particle Inspection (MPI) Requirements Maintenance of Hydraulic Piston Accumulators Upgrade of TDS-4S and TDS-8SA Oil Circulating Systems

10/17/03 10/20/03 10/27/03

TDS-03-28 TDS-03-29 TDS-04-01 TDS-04-02

Yes Yes Yes

A -

Periodic Lubrication of TDS-9SA and -11SA AC Drilling Motors Falling Extension Spring from PH-85 Pipe Handler Stabbing Guide Assembly Sheared Retaining Pin on Torque Arrestor Roller Assembly Failure Resulting in a Dropped Cam Follower from the IBOP External Crank Assembly Inductive Voltage Buildup on AC Top Drive Service Loops Falling Stabilizer Liner on PH-75 Pipehandler Performance Update on Washpipe Assemblies

11/21/03 12/2/03 2/20/04 2/20/04

TDS-9SA and -11SA Motor Housing Assemblies All Top Drive Drilling Systems with PH-85 Pipe Handlers TDS Torque Arrestor Assemblies (P/N 90471, 90471-1 and 90471-2) External Crank Assembly (P/N 98898)

TDS-04-03 TDS-04-04 TDS-04-05

Yes -

2/23/04 3/29/04 4/8/04

Power Service Loop Assemblies Clamp Cylinder Assembly, PH-75 (P/N 30157287) Varco Washpipe Assemblies

You might also like

- 3092834-Varco Bulletin On TDSDocument9 pages3092834-Varco Bulletin On TDSSushil GuptaNo ratings yet

- Varco Top Drive Washpipe Performance UpdateDocument10 pagesVarco Top Drive Washpipe Performance Updatesorangel_123No ratings yet

- Product Bulletin No.: TDS-03-16 Release Top Drive Drilling SystemDocument8 pagesProduct Bulletin No.: TDS-03-16 Release Top Drive Drilling Systemahmedsaid85No ratings yet

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingFrom EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingRating: 5 out of 5 stars5/5 (9)

- List Sparepart MI-SWACO Shale ShakerDocument23 pagesList Sparepart MI-SWACO Shale ShakerahnafNo ratings yet

- TDS-02-11-PIB Rev D PDFDocument5 pagesTDS-02-11-PIB Rev D PDFahmedsaid85No ratings yet

- Estrangulador SwacoDocument129 pagesEstrangulador SwacoKamilo Forero100% (5)

- Washpipe AssysDocument16 pagesWashpipe AssysMario Francisco Castaño Segura100% (1)

- SEC5 (1) WashpipeDocument22 pagesSEC5 (1) WashpipeCarlos Alberto PerdomoNo ratings yet

- Packard CatalogDocument22 pagesPackard Catalogcrni roko100% (1)

- 1625 de Das 001Document7 pages1625 de Das 001Leonardo Alvarez100% (1)

- Blak-JAK 7500psi Washpipe CartridgeDocument2 pagesBlak-JAK 7500psi Washpipe CartridgeLuka Bardic100% (1)

- Washpipe Assembly Washpipe Assembly: Service ManualDocument60 pagesWashpipe Assembly Washpipe Assembly: Service ManualIvan Kawempy100% (4)

- Crown Block Saver ComponentsDocument6 pagesCrown Block Saver Componentsmohamed salemNo ratings yet

- Deadline AnchorDocument1 pageDeadline AnchorJesus Sanchez100% (2)

- SH Shaker-Brandt Mini CobraDocument92 pagesSH Shaker-Brandt Mini CobraKapil Tiwari100% (1)

- Oilfield Mud Pump Parts ListDocument6 pagesOilfield Mud Pump Parts Listsophiesaurabh0% (1)

- 7838 Brake Care and OperationDocument54 pages7838 Brake Care and OperationMarutpal Mukherjee100% (1)

- GX Annular BOP Training-One FileDocument80 pagesGX Annular BOP Training-One FileGoumidi MohamedNo ratings yet

- 3.1 Iron RoughneckDocument99 pages3.1 Iron Roughneckdanielra8567% (3)

- Top Drive Drilling System Parts ListDocument105 pagesTop Drive Drilling System Parts ListAjay Singh RathaurNo ratings yet

- Varco Tds 11sa顶驱新图2014年Document261 pagesVarco Tds 11sa顶驱新图2014年Baber824No ratings yet

- Um199015 eDocument158 pagesUm199015 eingcalderon100% (1)

- Cobra ManualDocument180 pagesCobra ManualJairo Puentes75% (4)

- Woodhouse International CAD Control Systems inventoryDocument21 pagesWoodhouse International CAD Control Systems inventoryJuan Ulin100% (1)

- Swaco Disc Choke Console Manual 9090080 (E) PDFDocument166 pagesSwaco Disc Choke Console Manual 9090080 (E) PDFguoss10673100% (1)

- BVM Catelogue New-2016 PDFDocument116 pagesBVM Catelogue New-2016 PDFOperation100% (1)

- Washpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)Document12 pagesWashpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)osvaldoNo ratings yet

- Top Drive Data SheetDocument11 pagesTop Drive Data SheetWagner Ramos100% (1)

- Hydril - GK BOP PDFDocument66 pagesHydril - GK BOP PDFBoris Zaslichko67% (3)

- Ezy Torq Operating ManualDocument28 pagesEzy Torq Operating ManualSyed Zain Ahmad100% (2)

- Canrig TM120 Carriage Parts Manual PDFDocument47 pagesCanrig TM120 Carriage Parts Manual PDFHenry Alfaro Bermudez100% (1)

- 611520-Y-BC-D Rev 009 - B+V Manual CL 150-1000Document56 pages611520-Y-BC-D Rev 009 - B+V Manual CL 150-1000Imed Hammouda100% (2)

- Master and Casing Bushing - ACEWELDocument8 pagesMaster and Casing Bushing - ACEWELcristinelb100% (1)

- Chiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFDocument2 pagesChiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFCikalong Yard100% (1)

- CanrigBJWPC ICO Manual PDFDocument42 pagesCanrigBJWPC ICO Manual PDFCarlos Patiño SuarezNo ratings yet

- Iron RoughneckDocument200 pagesIron RoughneckChris K100% (1)

- HC 26V Sm00478 PDFDocument47 pagesHC 26V Sm00478 PDFetuk2No ratings yet

- Torque TDS4 Pocket Guide-2 PDFDocument5 pagesTorque TDS4 Pocket Guide-2 PDFHaridev50% (2)

- HH-Rotary Table ZP175 - ZP205 PDFDocument3 pagesHH-Rotary Table ZP175 - ZP205 PDFYosed L SantosNo ratings yet

- Iron Roughneck ST-80CDocument145 pagesIron Roughneck ST-80CFlorin Stoica75% (8)

- Mud Pump Interview TechnicalDocument4 pagesMud Pump Interview TechnicalPremkamal .Olanchery.RavishankarNo ratings yet

- M5329-R0 Dead Line AnchorDocument26 pagesM5329-R0 Dead Line Anchorandrei20041100% (2)

- Power Slips - 2130 Generic1Document220 pagesPower Slips - 2130 Generic1Emanuela Sales50% (4)

- Installation and Trouble Shooting Manual: Top Drive Drilling EquipmentDocument48 pagesInstallation and Trouble Shooting Manual: Top Drive Drilling EquipmentAlejandro HernadezNo ratings yet

- SD B312 Bop B011 02 01Document39 pagesSD B312 Bop B011 02 01krishnsgkNo ratings yet

- Varco Ibop Valves PDFDocument50 pagesVarco Ibop Valves PDFAnonymous MxwCc4100% (3)

- Maintenance Manual - Varco ST-80 RoughneckDocument42 pagesMaintenance Manual - Varco ST-80 RoughneckCarlos Alberto Perdomo100% (2)

- Controll Cabin OEM PDFDocument47 pagesControll Cabin OEM PDFOvRrj AhmedNo ratings yet

- Spare Parts Catalogue for Triplex Mud PumpDocument89 pagesSpare Parts Catalogue for Triplex Mud PumpJerson serranoNo ratings yet

- Titan CG RelfDocument1 pageTitan CG RelfRuano Andreola StumpfNo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbFrom EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- 3119049Document10 pages3119049Sug E QalanderNo ratings yet

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- Texas Oil Tools: "EH34" 3.06" 10M Quad BOPDocument32 pagesTexas Oil Tools: "EH34" 3.06" 10M Quad BOPjose perozo100% (2)

- 20160531aa8900-Wet Area Construction Application Guide June 2016Document20 pages20160531aa8900-Wet Area Construction Application Guide June 2016John HoldingNo ratings yet

- Waterproofing PDFDocument8 pagesWaterproofing PDFJohn HoldingNo ratings yet

- Arc Reinforcement Handbook 6ed 2010Document78 pagesArc Reinforcement Handbook 6ed 2010Anthony L. FelderNo ratings yet

- Alemite Air PumpDocument1 pageAlemite Air PumpJohn HoldingNo ratings yet

- Heli-Transfer Quarentine Module - Exxon Mobil TestDocument4 pagesHeli-Transfer Quarentine Module - Exxon Mobil TestJohn HoldingNo ratings yet

- Australian Standard: 3959: FlooringDocument4 pagesAustralian Standard: 3959: FlooringJohn HoldingNo ratings yet

- Estrangulador SwacoDocument129 pagesEstrangulador SwacoKamilo Forero100% (5)

- As 1684.1-1999 Residential Timber-Framed Construction Design CriteriaDocument7 pagesAs 1684.1-1999 Residential Timber-Framed Construction Design CriteriaSAI Global - APACNo ratings yet

- Grease InterchangeDocument1 pageGrease InterchangeJohn HoldingNo ratings yet

- Pie Chart HelpDocument8 pagesPie Chart HelpJohn HoldingNo ratings yet

- Steel Technical CablesDocument37 pagesSteel Technical Cablesgreat2007No ratings yet

- Steel Technical CablesDocument37 pagesSteel Technical Cablesgreat2007No ratings yet

- BCA Classes of BuildingDocument1 pageBCA Classes of BuildingReesNo ratings yet

- Air Valve CatalogDocument58 pagesAir Valve CatalogJohn Holding100% (2)

- XE301P Service ManualDocument77 pagesXE301P Service ManualJohn Holding100% (1)

- UK CAA Cap 437Document91 pagesUK CAA Cap 437jaikay3198No ratings yet

- Beginners Guide To CorrosionDocument10 pagesBeginners Guide To Corrosionshamu081No ratings yet

- UK CAA Cap 437Document91 pagesUK CAA Cap 437jaikay3198No ratings yet

- Static Elect OilDocument23 pagesStatic Elect OilKudeep GargNo ratings yet

- NordLock Washers Product BrochureDocument16 pagesNordLock Washers Product BrochureAlex BaciuNo ratings yet

- TK70 Spare PartsDocument122 pagesTK70 Spare PartsPaul HernandezNo ratings yet

- Lesson-1-3 (CE 321C)Document81 pagesLesson-1-3 (CE 321C)Andjie LeeNo ratings yet

- Lindapter Catalogue Ancon New ZealandDocument80 pagesLindapter Catalogue Ancon New ZealandasdfzzzxxxcccvvvNo ratings yet

- MS - PV Module Installation On RoofDocument15 pagesMS - PV Module Installation On RoofIbrahim EsmatNo ratings yet

- Audi A1 Tdi 3 Cil (CUSB)Document335 pagesAudi A1 Tdi 3 Cil (CUSB)gume pesaNo ratings yet

- Recommendations For Structural Design Criteria For Low Head Slide GatesDocument30 pagesRecommendations For Structural Design Criteria For Low Head Slide GatesNaresh ANo ratings yet

- Tad1353 Work Shop ManualDocument338 pagesTad1353 Work Shop ManualMohamadNo ratings yet

- Boltec MC - 9851 2202 01fDocument4 pagesBoltec MC - 9851 2202 01fPablo Luis Pérez PostigoNo ratings yet

- Tightening Methods: Class Value of The K-FactorDocument6 pagesTightening Methods: Class Value of The K-FactorHACHEM-FATHINo ratings yet

- Final Design Work SheetDocument7 pagesFinal Design Work SheetKINDUNo ratings yet

- Structural steel design and bolted connection standards for SANS 10162-1Document7 pagesStructural steel design and bolted connection standards for SANS 10162-1Roelf MostertNo ratings yet

- High Strength Bolts - KulakDocument21 pagesHigh Strength Bolts - KulakalmeteckNo ratings yet

- Bolting & RivetingDocument17 pagesBolting & RivetingSulficker AliNo ratings yet

- Spontaneous Unfastening and Fatigue of Bolted Joints PDFDocument3 pagesSpontaneous Unfastening and Fatigue of Bolted Joints PDFIvan KlyuchkaNo ratings yet

- Equipment Component Stress and Leakage CalculationsDocument20 pagesEquipment Component Stress and Leakage CalculationsahmedalishNo ratings yet

- Self-Loosening of Threaded Fasteners: by Dr. Bill Eccles, Bolt ScienceDocument2 pagesSelf-Loosening of Threaded Fasteners: by Dr. Bill Eccles, Bolt ScienceElJeremiasNo ratings yet

- Shear Strength Analysis of Dissimilar Materials Bolted JointDocument4 pagesShear Strength Analysis of Dissimilar Materials Bolted JointSufyan Berinyuy WiysahnyuyNo ratings yet

- Bolted ConnectionsDocument135 pagesBolted ConnectionsDhruv patelNo ratings yet

- 6M33 Repair Manual Feb 2019 v3Document96 pages6M33 Repair Manual Feb 2019 v3Daniel Ardila100% (1)

- Bolt Clamping Load ChartsDocument1 pageBolt Clamping Load ChartssourajpatelNo ratings yet

- GEARBOX - ZF 5 S.270 / ZF 6 S.350: Renault V.IDocument34 pagesGEARBOX - ZF 5 S.270 / ZF 6 S.350: Renault V.IMax SamNo ratings yet

- Structural Bolting: Note That The ASTM Designation Is Indicated On The Head of The Bolts AboveDocument4 pagesStructural Bolting: Note That The ASTM Designation Is Indicated On The Head of The Bolts AboveRavi LoharNo ratings yet

- Finite Element Analysis of Fluid and Solid Mechanics Problems Using AnsysDocument59 pagesFinite Element Analysis of Fluid and Solid Mechanics Problems Using AnsysRebeca CruzNo ratings yet

- Polaris 2013 Service ManualDocument204 pagesPolaris 2013 Service ManualZalathiel VelazquezNo ratings yet

- Install Gas Separator 2.6Document3 pagesInstall Gas Separator 2.6Bombasticos FcNo ratings yet

- 201 Paper For Wind Turbine Bolt DesignDocument8 pages201 Paper For Wind Turbine Bolt DesignOvidiu LunguNo ratings yet

- ME311 Screws LectureDocument26 pagesME311 Screws LectureantoniodellisantiNo ratings yet

- Design of Seismic-Resistant Steel Building StructuresDocument107 pagesDesign of Seismic-Resistant Steel Building StructuresMario LimasNo ratings yet

- Aircraft Code Bolt2023r01Document14 pagesAircraft Code Bolt2023r01Dinesh GanapathyNo ratings yet