Professional Documents

Culture Documents

Azeotropic Mass Balance

Uploaded by

sowjanyaavkCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Azeotropic Mass Balance

Uploaded by

sowjanyaavkCopyright:

Available Formats

Si l ti f Eth l D h d ti

2013 9 23()

Simulation of Ethanol Dehydration

Using Cyclohexane as an Entrainer

()

Limit of Distillation by Azeotrope

1.0

Distillation range is restricted by

the azeotropic point.

Ethanol / Water System

r

M

o

l

e

F

r

a

c

t

i

o

n

o

f

E

t

h

a

n

o

l

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Binary azeotropic mixtures, such

as ethanol/water and IPA/water,

can be separated into their pure

components by distillation by the

addition of a third component, so

called the entrainer, which forms

a ternary azeotrope with a lower

Azeotropic Distillation 2

Liquid Mole Fraction of Ethanol

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

V

a

p

o

0.0

0.1

0.2

y p

boiling point than any binary

azeotrope

Separation of Azeotropic Mixture

Shift the Azeotropic Point by Changing Pressure.

Supercritical Fluid Extraction Using Supercritical

CO

2

Solvent

2

Pervaporation Method: Proposed by SKEC

Vacuum Distillation

Azeotrope between ethanol and water disappears at

11.5kPa.

Add the Third Component.

Azeotropic Distillation 3

Azeotropic Distillation: Entrainer (Benzene, CHX, NC5)

Extractive Distillation: Solvent (Ethylene Glycol)

Azeotropic vs. Extractive Distillation (1)

Azeotropic distillation

By forming a ternary heterogeneous azeotrope lower than any

other binary azeotropic temperatures, nearly pure ethanol can be

obtained as a bottom product in an azeotropic distillation column. p p

Ethanol is obtained as a bottom product from an azeotropic

distillation column using an entrainer such as benzene or normal

pentane.

Extractive distillation

By adding a solvent which is exclusively familiar with a

wanted component in a feed mixture, a desired component

can be obtained in an extractive distillation column

Azeotropic Distillation 4

can be obtained in an extractive distillation column

overhead.

Ethanol is obtained as a top product from an extractive distillation

with ethylene glycol solvent.

Azeotropic vs. Extractive Distillation (1)

FEED

RECYCLE

UPPER

PHASE

LOWER

PHASE

FEED

SOLVENT

PURE ETHANOL

Azeotropic Distillation 5

PURE ETHANOL

Azeotropic Distillation Extractive Distillation

Principles of Azeotropic Distillation

.8

.9

1.0

Ethanol

P

A

F II

A : 78.07

o

C B : 67.99

o

C

C : 69.31

o

C D : 63.88

o

C

0.0 .1 .2 .3 .4 .5 .6 .7 .8 .9 1.0

0.0

.1

.2

.3

.4

.5

.6

.7

W

R

D

B

C

V

G

III

I

Only mixtures in region II will give the desired

products of pure ethanol as a bottom product.

Azeotropic Distillation 6

Water Benzene

Aqueous ethanol can be separated into their pure components by

distillation by the addition of a third component, so called the entrainer,

which forms a ternary heterogeneous azeotrope with a lower than any

other binaryazeotropes.

How to Select an Entrainer

.9

1.0

Ethanol

A

F

P

A : 78.07

o

C B : 75.08

o

C

.1

.2

.3

.4

.5

.6

.7

.8

F

W

B

C

R

D

V

G

A : 78.07 C B : 75.08 C

C : 73.44

o

C D : 69.94

o

C II

III

I

Azeotropic Distillation 7

In this case, pure ethanol cannot be obtained since

G is in region III.

0.0 .1 .2 .3 .4 .5 .6 .7 .8 .9 1.0

0.0

Water Water Ether

C

Homogeneous Azeotrope (1): Ethanol-Water

105

T

e

m

p

e

r

a

t

u

r

e

(

o

C

)

85

90

95

100

Azeotropic Distillation 8

Mole Fraction of Ethanol

0.0 0.2 0.4 0.6 0.8 1.0

T

75

80

Homogeneous Azeotrope (2): Ethanol-Benzene

80

82

T

e

m

p

e

r

a

t

u

r

e

(

o

C

)

70

72

74

76

78

Azeotropic Distillation 9

Mole Fraction of Ethanol

0.0 0.2 0.4 0.6 0.8 1.0

T

66

68

70

Heterogeneous Azeotrope (3): Benzene-Water

Azeotropic Distillation 10

Theory of Azeotropic Distillation (I)

Ethanol / Benzene

Benzene / Water Ethanol / Water

Azeotropic Distillation 11

Theory of Azeotropic Distillation (II)

Ethanol

Water is

concentrated on

Ethanol H

2

O

Highly

interaction

concentrated on

vapor side.

Dew point

temperature

Azeotropic Distillation 12

H

2

O

Benzene

Benzene

valley

Theory of Extractive Distillation

Ethanol is concentrated

on vapor side.

Ethanol

Ethanol H2O

Highly

Azeotropic Distillation 13

EG

Highly

interaction

H

2

O EG

Configuration of Azeotropic Distillation

Recyclestream

Feed

Concentrated ethanol

Upper

phase

Lower phase

Concentrator

Azeo Column Stripper

Decanter

Azeotropic Distillation 14

Wastewater

Pureethanol Wastewater

Problem: Ethanol Dehydration

Feedstock information

Feed Composition

1) Ethanol : 10mole%

2) Water : 90mole% 2) Water : 90mole%

Feed Condition

1) Inlet Temperature : 25

o

C

2) Inlet Pressure : 200 kPa

Flow Rate

1) 100 Kg-mole/hr

Entrainer: Cyclohexane

Azeotropic Distillation 15

Entrainer: Cyclohexane

Cooling Medium: Cooling water

1) In/Out Temperature : 32

o

C /40

o

C

2) Decanter Operating Temperature : 45

o

C

Simulation Procedure

Step 1: Selection of Proper Thermo Model & Construction

of Binodal Curve

Step 2: Finding Binary &TernaryAzeotropic Points Step 2: Finding Binary & Ternary Azeotropic Points

Step 3: Construction of Binary & Ternary Residual Curves

Step 4: Concentrator Simulation

Step 5: Azeotropic Column Simulation

Step 6: Azeo +Dryer(Stripper) Column Simulation

Azeotropic Distillation 16

Step 7: Simulation of Overall Azeotropic Distillation Unit

Step 8: Optimization of Ethanol Dehydration Process

Step 1a: Selection of Proper Thermo. Model

NRTL. This model has up to 8 adjustable binary

parameters that can be fitted to data.

(

(

(

+ =

k

k kj

l

lj lj l

ij

j

k

k kj

ij j

k

k ki

j

j ji ji

i

x G

G x

x G

G x

x G

x G

t

t

t

ln

2

T

c

T

b

a

ij ij

ij ij

+ + = t

Azeotropic Distillation 17

( ) | |

ij ij ij ij

T G t | o + = exp

2

T T

j j

Step 1b: Construction of Binodal Curve

Binodal Curve Construction

using NRTL

1) Water

Ethanol

00 1) Water

2) Ethanol

3) Cyclohexane

Temperature =45

o

C

Binary Interaction Parameters

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Plait point

Comp I Comp J A(I,J ) A(J ,I) o(I,J )

1 2 721.10 437.83 0.4685

Azeotropic Distillation 18

Water

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0.0

0.1

CHX

0.9

1.0

1 3 1,225.89 2,807.80 0.1600

2 3 -60.00 660.00 0.3000

Step 2a: Finding Azeotropes (Ethanol+Water)

Step-2a.prz

Azeotropic Distillation 19

Ethanol=0.8839 mole fraction

Step 2a: Finding Azeotropes (Ethanol+Water)

STREAM I D AZEO L V

NAME

PHASE LI QUI D LI QUI D VAPOR

THERMO I D NRTL01 NRTL01 NRTL01

FLUI D MOLAR FRACTI ONS

1 ETHANOL 0.8839 0.8839 0.8839

2 H2O 0. 1161 0. 1161 0. 1161

3 CH 0. 0000 0. 0000 0. 0000

TOTAL RATE, KG- MOL/ HR 1. 0000 1. 0000 1. 0000

TEMPERATURE, C 78.1046 78.1047 78.1047

PRESSURE, KG/ CM2 1. 0330 1. 0330 1. 0330

* / 2 1269 03 2 1269 03 0 0114

Azeotropic Distillation 20

ENTHALPY, M*KCAL/ HR 2. 1269E- 03 2. 1269E- 03 0. 0114

MOLECULAR WEI GHT 42. 8113 42. 8113 42. 8113

MOLE FRAC VAPOR 0. 0000 0. 0000 1. 0000

MOLE FRAC LI QUI D 1. 0000 1. 0000 0. 0000

Step 2b: Finding Azeotropes (Ethanol+CHX)

Step-2b.prz

Azeotropic Distillation 21

Ethanol=0.4515 mole fraction

STREAM I D AZEO L V

NAME

PHASE LI QUI D LI QUI D VAPOR

THERMO I D NRTL01 NRTL01 NRTL01

Step 2b: Finding Azeotropes (Ethanol+CHX)

FLUI D MOLAR FRACTI ONS

1 ETHANOL 0.4515 0.4515 0.4515

2 H2O 0. 0000 0. 0000 0. 0000

3 CH 0. 5485 0. 5485 0. 5485

TOTAL RATE, KG- MOL/ HR 1. 0000 0. 9999 1. 0000

TEMPERATURE, C 64.7286 64.7286 64.7286

PRESSURE, KG/ CM2 1. 0330 1. 0330 1. 0330

* / 2 1454 03 2 1451 03 0 0105

Azeotropic Distillation

ENTHALPY, M*KCAL/ HR 2. 1454E- 03 2. 1451E- 03 0. 0105

MOLECULAR WEI GHT 66. 9635 66. 9635 66. 9636

MOLE FRAC VAPOR 0. 0000 0. 0000 1. 0000

MOLE FRAC LI QUI D 1. 0000 1. 0000 0. 0000

22

Step 2c: Finding Azeotropes (Water+CHX)

Step-2c.prz

Azeotropic Distillation 23

Cyclohexane=0.7017 mole fraction

STREAM I D AZEO L V

NAME

PHASE LI QUI D LI QUI D VAPOR

THERMO I D ALCO01 ALCO01 ALCO01

Step 2c: Finding Azeotropes (Water+CHX)

FLUI D MOLAR FRACTI ONS

1 ETHANOL 0. 0000 0. 0000 0. 0000

2 H2O 0. 2983 0. 2983 0. 2983

3 CH 0.7017 0.7017 0.7017

TOTAL RATE, KG- MOL/ HR 1. 0000 1. 0000 1. 0000

TEMPERATURE, C 69.2771 69.2771 69.2771

PRESSURE, KG/ CM2 1. 0330 1. 0330 1. 0330

* / 2 2118 03 2 2118 03 0 0104

Azeotropic Distillation

ENTHALPY, M*KCAL/ HR 2. 2118E- 03 2. 2118E- 03 0. 0104

MOLECULAR WEI GHT 64. 4300 64. 4300 64. 4300

MOLE FRAC VAPOR 0. 0000 0. 0000 1. 0000

MOLE FRAC TOTAL LI QUI D 1. 0000 1. 0000 0. 0000

MOLE FRAC LI QUI D1 0. 7025 0. 7025 N/ A

MOLE FRAC LI QUI D2 0. 2975 0. 2975 N/ A

24

Step 2d: Finding Azeotropes (Ethanol+Water+CHX)

Step-2d.prz

Azeotropic Distillation 25

Ethanol=0.3239, Water=0.1495 mole fraction

Step 2d: Finding Azeotropes (Ethanol+Water+CHX)

STREAM I D AZEO L V

NAME

PHASE LI QUI D LI QUI D VAPOR

THERMO I D ALCO01 ALCO01 ALCO01

FLUI D MOLAR FRACTI ONS

1 ETHANOL 0.3239 0.3239 0.3239

2 H2O 0.1495 0.1495 0.1495

3 CH 0. 5266 0. 5266 0. 5266

TOTAL RATE, KG- MOL/ HR 1. 0000 1. 0000 1. 0000

TEMPERATURE, C 62.2956 62.2955 62.2955

PRESSURE, KG/ CM2 1. 0330 1. 0330 1. 0330

* / 1 9549 03 1 9549 03 0 0105

Azeotropic Distillation

ENTHALPY, M*KCAL/ HR 1. 9549E- 03 1. 9549E- 03 0. 0105

MOLECULAR WEI GHT 61. 9354 61. 9354 61. 9354

MOLE FRAC VAPOR 0. 0000 0. 0000 1. 0000

MOLE FRAC TOTAL LI QUI D 1. 0000 1. 0000 0. 0000

MOLE FRAC LI QUI D1 0. 5551 0. 5551 N/ A

MOLE FRAC LI QUI D2 0. 4449 0. 4449 N/ A

26

Results for Step 2

Ethanol

1.0

0.0

A: 78.105

o

C, B: 64.729

o

C

C: 69 277

o

C D: 62 296

o

C

0 3

0.4

0.5

0.6

0.7

0.8

0.9

0.1

0.2

0.3

0.4

0.5

0.6

0.7

A

B

D

C: 69.277

o

C, D: 62.296

o

C

Entrainer Selection

Criteria 1

Azeotropic Distillation 27

Water

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0.0

0.1

0.2

0.3

CHX

0.8

0.9

1.0

C

D

Step 3: Construction of Residual Curves

Ethanol

1.0

0.0

Entrainer Selection Criteria 2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0.1

0.2

0.3

0.4

0.5

0.6

0.7

A

B

D

II

Only mixtures in region II will give the desired

products of pure ethanol as a bottom product.

Azeotropic Distillation 28

Water

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0.0

0.1

0.2

CHX

0.8

0.9

1.0

C

I

III

0.9

1.0

Ethanol

A

Step 3: Construction of Residual Curves

0.3

0.4

0.5

0.6

0.7

0.8

B

D

II

III

Azeotropic Distillation

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0.0

0.1

0.2

Water Cyclohexane

C

29

I

Step 3a: Feed having composition in region I

Top Product

Composition Mole %

Region 01.prz

Feedstock

Composition Mole %

Water 10.00

Ethanol 20.00

CHX 70.00

Total Flow 100 00

p

Water 16.06

Ethanol 33.47

CHX 50.46

Total Flow 59.75

Bottom Product

Azeotropic Distillation 30

Total Flow 100.00

Composition Mole %

Water 1.00

Ethanol -

CHX 99.00

Total Flow 40.25

STREAM I D 1 2 3

NAME

PHASE LI QUI D LI QUI D LI QUI D

THERMO I D NRTL01 NRTL01 NRTL01

Step 3a: Stream Summary

Composition Mole fraction

Water 0.1495

Ethanol 0.3239

CHX 0.5266

FLUI D MOLAR FRACTI ONS

1 WATER 0. 1000 0. 1606 1. 0000E- 02

2 ETHANOL 0. 2000 0. 3347 0. 0000

3 CH 0. 7000 0. 5046 0.9900

TOTAL RATE, KG- MOL/ HR 100. 0001 59. 7473 40. 2528

TEMPERATURE, C 25. 0000 44. 0000 82. 4224

PRESSURE, BAR 2. 5000 1. 0340 1. 5890

* / 0 3362 0 3340 0 5312

Azeotropic Distillation

ENTHALPY, M*KJ / HR 0. 3362 0. 3340 0. 5312

MOLECULAR WEI GHT 69. 9282 60. 7848 83. 4998

MOLE FRAC VAPOR 0. 0000 0. 0000 0. 0000

MOLE FRAC TOTAL LI QUI D 1. 0000 1. 0000 1. 0000

MOLE FRAC LI QUI D1 0. 7323 0. 5207 0. 9913

MOLE FRAC LI QUI D2 0. 2677 0. 4793 8. 7310E- 03

31

Step 3b: Feed having composition in region III

Top Product

Composition Mole %

Region 03.prz

Feedstock

Composition Mole %

Water 50.00

Ethanol 20.00

CHX 30.00

Composition Mole %

Water 16.00

Ethanol 33.55

CHX 50.45

Total Flow 59.04

Bottom Product

Azeotropic Distillation 32

Total Flow 100.00

Composition Mole %

Water 99.00

Ethanol 0.33

CHX 0.67

Total Flow 40.96

Step 3b: Stream Summary

STREAM I D 1 2 3

NAME

PHASE LI QUI D LI QUI D LI QUI D

THERMO I D NRTL01 NRTL01 NRTL01

Composition Mole fraction

Water 0.1495

Ethanol 0.3239

CHX 0.5266

FLUI D MOLAR FRACTI ONS

1 WATER 0. 5000 0. 1600 0.9900

2 ETHANOL 0. 2000 0. 3355 4. 7329E- 03

3 CH 0. 3000 0. 5045 5. 2671E- 03

TOTAL RATE, KG- MOL/ HR 100. 0001 59. 0365 40. 9636

TEMPERATURE, C 25. 0000 44. 0000 81. 9645

PRESSURE, BAR 2. 5000 1. 0340 1. 5890

* / 0 2614 0 3301 0 2556

Azeotropic Distillation 33

ENTHALPY, M*KJ / HR 0. 2614 0. 3301 0. 2556

MOLECULAR WEI GHT 43. 4698 60. 7981 18. 4965

MOLE FRAC VAPOR 0. 0000 0. 0000 0. 0000

MOLE FRAC TOTAL LI QUI D 1. 0000 1. 0000 1. 0000

MOLE FRAC LI QUI D1 0. 3095 0. 5204 5. 2241E- 03

MOLE FRAC LI QUI D2 0. 6905 0. 4796 0. 9948

Step 3c: Feed having composition in region II

Top Product

Composition Mole %

Region 02.prz

Feedstock

Composition Mole %

Water 5.00

Ethanol 70.00

CHX 25.00

Total Flow 100 00

p

Water 24.74

Ethanol 27.23

CHX 48.03

Total Flow 40.41

Bottom Product

Azeotropic Distillation 34

Total Flow 100.00

Composition Mole %

Water 0.00

Ethanol 99.00

CHX 1.00

Total Flow 59.59

Step 3c: Stream Summary

STREAM I D 1 2 3

NAME

PHASE LI QUI D LI QUI D LI QUI D

THERMO I D NRTL01 NRTL01 NRTL01

Composition Mole fraction

Water 0.1495

Ethanol 0.3239

CHX 0.5266

FLUI D MOLAR FRACTI ONS

1 WATER 0. 1000 0. 1606 0. 0100

2 ETHANOL 0. 6000 0. 3373 0.9900

3 CH 0. 3000 0. 5021 9. 3357E- 11

TOTAL RATE, KG- MOL/ HR 100. 0001 59. 7492 40. 2509

TEMPERATURE, C 25. 0000 59. 1697 90. 1506

PRESSURE, BAR 2. 5000 1. 0340 1. 5890

* / 0 2936 0 4575 0 4415

Azeotropic Distillation 35

ENTHALPY, M*KJ / HR 0. 2936 0. 4575 0. 4415

MOLECULAR WEI GHT 54. 6913 60. 6889 45. 7885

MOLE FRAC VAPOR 0. 0000 0. 0000 0. 0000

MOLE FRAC LI QUI D 1. 0000 1. 0000 1. 0000

Step 4: Concentrator Simulation

Basis: Feed =100 Kg-mole/hr

Feed

Concentrated ethanol

Concentrator

g

x

F

=0.10

Ethanol Mole Balance

F x

F

=D x

D

(Nearly Pure Water at

Column Bottom)

( ) ( )

36 11

1 . 0 100

=

=

F F

x F x F

D

Azeotropic Distillation 36

Waste water

( )

36 . 11

88 . 0

= = = =

azeo D

x x

D

Initial Estimates for Concentrator

Azeotropic Distillation 37

Product Specifications & Variables

Azeotropic Distillation 38

STREAM I D 1 2 3

NAME

PHASE LI QUI D LI QUI D LI QUI D

THERMO I D NRTL01 NRTL01 NRTL01

Stream Summary Around Concentrator

FLUI D MOLAR PERCENTS

1 ETHANOL 10. 0000 80. 7992 0. 1000

2 WATER 90. 0000 19. 2008 99.9000

TOTAL RATE, KG- MOL/ HR 100. 0001 12. 2678 87. 7323

TEMPERATURE, C 25. 0000 45. 0000 112. 2049

PRESSURE, KG/ CM2 2. 5000 1. 0330 1. 5890

ENTHALPY, M*KCAL/ HR 0. 0470 0. 0139 0. 1777

20 8205 40 6832 18 0431

Azeotropic Distillation

MOLECULAR WEI GHT 20. 8205 40. 6832 18. 0431

MOLE FRAC VAPOR 0. 0000 0. 0000 0. 0000

MOLE FRAC LI QUI D 1. 0000 1. 0000 1. 0000

39

Step 5a: Azeotropic Column Simulation

V

Azeo Column

F

F

2

R

W

Composition of Stream F

Component Mole %

Ethanol 80.7992

Water 19 2008

Azeotropic Distillation 40

P

Water 19.2008

Flow Rate 72.2608 K-mol/hr

Step 5b: Decanter Simulation

V

R

W

Assume OVHD Vapor Composition, V around ternary azeotrope

Mole %

Azeotropic Distillation 41

Mole %

CHX 53.00

Ethanol 31.00

Water 16.00

Step 5b: Decanter Simulation (Continued)

TI TLE PROJ =AZEOTROPE, PROB=FLASH, USER=J . H. CHO

PRI NT I NPUT=ALL, RATE=M, FRACTI ON=M, PERCENT=M

DI MENSI ON METRI C

COMPONENT DATA

LI BI D 1, CH/ 2, ETHANOL/ 3, WATER

THERMODYNAMI C DATA THERMODYNAMI C DATA

METHOD SYSTEM( VLLE) =NRTL, SET=NRTL01

STREAM DATA

PROP STRM=V, TEMP=45, PRES=1. 033, RATE( M) =100, & COMPOSITION(M)=1,53/2,31/3,16

UNI T OPERATI ONS

FLASH UI D=COND, NAME=Condenser , KPRI NT

FEED V

PRODUCT L=R, W=W

I SO TEMPERATURE=45, PRESSURE=1. 033

END

V (Mole %) R (Mole %) W (Mole %)

Azeotropic Distillation 42

( ) ( ) ( )

CHX 53.00 92.5560 4.2709

Ethanol 31.00 7.2189 60.2960

Water 16.00 0.2251 35.4331

Flow Rate 100 % 55.20 % 44.80 %

Step 5c: Component Mass Balance Around Azeo Column

Water balance around Azeotropic Column

( ) ( ) 808 . 0 1 808 . 0 1 2678 . 12 _

2

+ = F feed Azeo

2

192 0 35542 2 F + =

F

2

R

V

2

192 . 0 35542 . 2 F + =

( ) ( ) 354331 . 0 4880 . 0 =V W

Azeo Column

F

W

P

V = 15874 . 0

2

192 . 0 35542 . 2 15874 . 0 F V + = - (1)

Azeotropic Distillation 43

Step 5c: Component Mass Balance Around Azeo Column

Ethanol balance around Azeotropic Column

F

2

R

V

( ) ( ) ( )

2

808 . 0 60296 . 0 4480 . 0 F V =

2

808 . 0 27013 . 0 F V =

Azeo Column

F

W

P

Aqueous phase Stripper

V F = 33432 . 0

2 - (2)

Combining Eq. (1) & (2):

15131 . 25 = V 40859 . 8

2

= F K-mol/hr, K-mol/hr

Azeotropic Distillation 44

Aqueous phase Stripper

F

2

.

Step 5c: Component Mass Balance Around Azeo Column

V

CHX flow from the decanter

( ) ( ) ( ) 48806 . 0 042709 . 0 4480 . 0 15131 . 25 = = K-mol/hr

F

F

2

R

W

V

Azeotropic Distillation

Azeo Column

P

45

V

Step 5: Azeotropic Distillation Column Simulation

F

F

2

R

W

Bz

Azeotropic Distillation

Controller

P

46

Step 7: Simulation of an Overall Azeotropic Unit

Azeotropic Distillation 47

Overall Process.prz

Future Works

Minimization of overall reboiler heat duties by varying the top

concentration of ethanol at concentrator top for three-

columns configuration

Comparison of three-columns and two-columns

configuration in ethanol dehydration using several entrainers

Application of an environmentally-friendly entrainer, NC5 to

obtain an absolute ethanol in azeotropic distillation

Experimental works for ternary LLE rather than each binary

VLEs &LLE

Azeotropic Distillation 48

VLE s & LLE

Comparison of an extractive distillation process using

solvent with an azeotropic distillation process using entrainer

The End. The End.

Azeotropic Distillation 49

You might also like

- 2016 Book IrrigationAndDrainageEngineeriDocument747 pages2016 Book IrrigationAndDrainageEngineeriJesús Garre Ruiz100% (2)

- Measure RPA ROI with KPIsDocument4 pagesMeasure RPA ROI with KPIsAdnan FarooqNo ratings yet

- Fractal ForestsDocument50 pagesFractal ForestsWell Fournier0% (1)

- Chapter - 2 DistillationDocument75 pagesChapter - 2 DistillationJACOB DAVENo ratings yet

- Distillation TypesDocument34 pagesDistillation TypesJoshua Johnson100% (1)

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4From EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Rating: 5 out of 5 stars5/5 (1)

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Clearings 2018Document22 pagesClearings 2018ldxb2001100% (1)

- Minimum Reflux RatioDocument9 pagesMinimum Reflux RatioEmmanuelNo ratings yet

- Universiti Teknologi Mara Fakulti Kejuruteraan Kimia Chemical Engineering Laboratory Ii CHE523Document14 pagesUniversiti Teknologi Mara Fakulti Kejuruteraan Kimia Chemical Engineering Laboratory Ii CHE523Heather Jarvis100% (2)

- Chapter 3 Stage and Continuous Gas Liquid Separation Processes PDFDocument46 pagesChapter 3 Stage and Continuous Gas Liquid Separation Processes PDFazim100% (1)

- Rip Bushing PDFDocument38 pagesRip Bushing PDFTravis Wood100% (1)

- Separation Processes - I (CHE F244) Total Marks - 15 Due Date & Time: 01/07/2020, 5:00 PM AssignmentDocument4 pagesSeparation Processes - I (CHE F244) Total Marks - 15 Due Date & Time: 01/07/2020, 5:00 PM AssignmentElliot AldersonNo ratings yet

- Packed Distillation Column ExperimentDocument20 pagesPacked Distillation Column ExperimentChan Chun ChenNo ratings yet

- MSOCHA3 Tutorial 1 Multicomponent AbsorptionDocument5 pagesMSOCHA3 Tutorial 1 Multicomponent AbsorptionTshwarelo MahlakoaneNo ratings yet

- Absorption of Carbon Dioxide Into WaterDocument11 pagesAbsorption of Carbon Dioxide Into WaterEstelle Jean CauilanNo ratings yet

- Cre 1 IntroductionDocument4 pagesCre 1 IntroductionEvangeline LauNo ratings yet

- Liquid LiquidDocument8 pagesLiquid LiquidAnonymous b9fcR5No ratings yet

- CSTRDocument20 pagesCSTRSharing Caring100% (1)

- Lab 1Document12 pagesLab 1JoeJeanNo ratings yet

- Lab ReportDocument10 pagesLab ReportKathleen De Vera BarrilNo ratings yet

- Separation Processss Lecture NotesDocument17 pagesSeparation Processss Lecture NoteskeatyNo ratings yet

- 4.3. Consider The Flowsheet For The Manufacture of Vinyl Chloride in Figure 4.8Document2 pages4.3. Consider The Flowsheet For The Manufacture of Vinyl Chloride in Figure 4.8Anonymous QwUTQlAO100% (1)

- RXN CH 5Document68 pagesRXN CH 5Yonas AddamNo ratings yet

- Plate Column Distillation EfficiencyDocument7 pagesPlate Column Distillation EfficiencyVijay PrasadNo ratings yet

- Distillation 3Document36 pagesDistillation 3Renu SekaranNo ratings yet

- 42-Single Effect Evaporator-21-May-2021Material I 21-May-2021 Single Effect EvaporatorDocument8 pages42-Single Effect Evaporator-21-May-2021Material I 21-May-2021 Single Effect EvaporatorAbhishek KarpeNo ratings yet

- RI Vs Composition Methanol-Water MixtureDocument12 pagesRI Vs Composition Methanol-Water MixtureAnonymous VeJYFSMWLINo ratings yet

- IYOHA COLLINS 16CF020531 Batch Reactor ReportDocument19 pagesIYOHA COLLINS 16CF020531 Batch Reactor ReportDavid OvieNo ratings yet

- Cebu Institute of Technology - University: CHE501-V1 Group 2Document11 pagesCebu Institute of Technology - University: CHE501-V1 Group 2Joshua ClimacoNo ratings yet

- Exp-9 - Liquid Liquid Extraction in A Packed ColumnDocument5 pagesExp-9 - Liquid Liquid Extraction in A Packed ColumnSiddharth MohapatraNo ratings yet

- CHE 435 Liquid-Liquid Extraction Lab ManualDocument24 pagesCHE 435 Liquid-Liquid Extraction Lab ManualStolen RememberNo ratings yet

- Experiment: Batch Reactor Unit Operations Lab I (CHEGR3787L) Fall 2004Document5 pagesExperiment: Batch Reactor Unit Operations Lab I (CHEGR3787L) Fall 2004Janice YanNo ratings yet

- CONTINUOUS DistillationDocument5 pagesCONTINUOUS DistillationNaseer SattarNo ratings yet

- Theoretical Plates Calculation by McCabe-Thiele MethodDocument4 pagesTheoretical Plates Calculation by McCabe-Thiele Methodmohammad shoaibNo ratings yet

- Gas Absorption and Gas StrippingDocument14 pagesGas Absorption and Gas StrippingEK63No ratings yet

- Chapter 4 - Efficiency of ColumnsDocument38 pagesChapter 4 - Efficiency of ColumnsAnonymous vRU4VlNo ratings yet

- Gas Diffusion UnitDocument20 pagesGas Diffusion Unitsolehah misniNo ratings yet

- Gas Absorption LabDocument8 pagesGas Absorption Labsolehah misni100% (1)

- Distillation LabDocument18 pagesDistillation LabWong XimeiNo ratings yet

- Cooling Tower ReportDocument11 pagesCooling Tower Reportbae zazNo ratings yet

- Week 4 - Vapor-Liquid Separation (Multicomponent Distillation)Document19 pagesWeek 4 - Vapor-Liquid Separation (Multicomponent Distillation)psychopassNo ratings yet

- CPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportDocument24 pagesCPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportSiti Hajar Mohamed100% (1)

- Humidification and Air Conditioning: Lecture No. 8Document6 pagesHumidification and Air Conditioning: Lecture No. 8Anonymous UFa1z9XUANo ratings yet

- Project Report 2 - Final - Design 1 AliffDocument142 pagesProject Report 2 - Final - Design 1 AliffAdi PutraNo ratings yet

- Design of packed absorber column for multi-component gas scrubbingDocument104 pagesDesign of packed absorber column for multi-component gas scrubbingNana kwadwoNo ratings yet

- Energy Transport Notes 2Document102 pagesEnergy Transport Notes 2Faisal MumtazNo ratings yet

- Absorption and StrippingDocument60 pagesAbsorption and StrippingMyvizhi Somasundaram100% (2)

- Saperation 1: Ass. Prof. Adnan Ripin Faculty of Chemical and Energy Engineering Universiti Teknologi MalaysiaDocument79 pagesSaperation 1: Ass. Prof. Adnan Ripin Faculty of Chemical and Energy Engineering Universiti Teknologi MalaysiaNurul AinNo ratings yet

- C4 Lab ReportDocument11 pagesC4 Lab ReportchaitanyaNo ratings yet

- LleDocument30 pagesLlefirstlove_492_736373No ratings yet

- CSTRDocument11 pagesCSTRfarahanisiliasNo ratings yet

- Energy Balance For Distillation ColumnDocument2 pagesEnergy Balance For Distillation ColumnKarar AlalihNo ratings yet

- Tray Dryer PDFDocument17 pagesTray Dryer PDFAdibah AyuniNo ratings yet

- CPI LAB ManualDocument76 pagesCPI LAB ManualFarhad Iqbal100% (2)

- GAS ABSORPTION - ReportDocument6 pagesGAS ABSORPTION - Reportgzairene8762No ratings yet

- Diagram/ Image:: Experiment Number: 02Document10 pagesDiagram/ Image:: Experiment Number: 02Roshan Dhikale100% (1)

- Gas AbsorptionDocument42 pagesGas AbsorptionRishab Srivatsa100% (1)

- Climbing Film GanganDocument20 pagesClimbing Film GanganAdeniran Joshua50% (2)

- Nitro BenzeneDocument2 pagesNitro BenzeneSeleneblueNo ratings yet

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsFrom EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsNo ratings yet

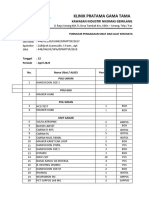

- Pengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuDocument8 pagesPengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuIsma Prasetya WardaniNo ratings yet

- Viking Tech ARG03FTC2551 - C217943Document8 pagesViking Tech ARG03FTC2551 - C217943ALIRIO SOLANONo ratings yet

- أسئلة شاملة 1Document25 pagesأسئلة شاملة 1ibraheemalabsi99No ratings yet

- MTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsDocument4 pagesMTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsbansalrNo ratings yet

- ECO Report 03Document96 pagesECO Report 03ahmedshah512No ratings yet

- REV 0 Material Selection Diagram MSD Blueprint IncDocument5 pagesREV 0 Material Selection Diagram MSD Blueprint IncJohn Patrick Sanay NunezNo ratings yet

- MD - Huzzatul Islam Contact Address: 01, International Airport Road, "Joar Sahara Bajar", APT # 13-F, Uttar Badda, Dhaka-1213, Bangladesh. Cell: +8801722223574Document4 pagesMD - Huzzatul Islam Contact Address: 01, International Airport Road, "Joar Sahara Bajar", APT # 13-F, Uttar Badda, Dhaka-1213, Bangladesh. Cell: +8801722223574Huzzatul Islam NisarNo ratings yet

- From Self Disorders To The Schizophrenic Self: Riccardo Piero Dalle LucheDocument31 pagesFrom Self Disorders To The Schizophrenic Self: Riccardo Piero Dalle LucheMichel de NostredameNo ratings yet

- American Statistical AssociationDocument7 pagesAmerican Statistical Associationmantu6kumar-17No ratings yet

- Final AnswersDocument4 pagesFinal AnswersAnshul SinghNo ratings yet

- Free Study PDF Download from pebexam BlogDocument22 pagesFree Study PDF Download from pebexam Blogk_jaiswalNo ratings yet

- Tugas (UTS) ASPK - Andro Tri Julianda (95017019)Document4 pagesTugas (UTS) ASPK - Andro Tri Julianda (95017019)محمد عزيرNo ratings yet

- CSAT 2019 Spe3D Duguid - Andrew PDFDocument111 pagesCSAT 2019 Spe3D Duguid - Andrew PDFdocturboNo ratings yet

- Frankfurt School taxes and ideology critiqueDocument5 pagesFrankfurt School taxes and ideology critiqueErnesto BulnesNo ratings yet

- C 6 Slings SafetyDocument29 pagesC 6 Slings SafetyAshraf BeramNo ratings yet

- Airtel Case Study Channel StrategyDocument2 pagesAirtel Case Study Channel StrategyTushar GuptaNo ratings yet

- Core-Core Repulsion Integrals: E (A Z ZJJDocument1 pageCore-Core Repulsion Integrals: E (A Z ZJJRaditya D HmNo ratings yet

- Analytical ExpositionDocument7 pagesAnalytical ExpositionEman FakotNo ratings yet

- Beck Thinking and Depression Idiosyncratic Content and Cognitive DistortionsDocument10 pagesBeck Thinking and Depression Idiosyncratic Content and Cognitive DistortionsFrancisco GaravagliaNo ratings yet

- Muhammad Zahrandhika Bastian-3Document2 pagesMuhammad Zahrandhika Bastian-3dhika zahrandhikaNo ratings yet

- Mobil Dynagear Series Performance ProfileDocument2 pagesMobil Dynagear Series Performance ProfileXavier DiazNo ratings yet

- Critical Thinking Handout PDFDocument1 pageCritical Thinking Handout PDFAnoosh IqraNo ratings yet

- Hyponymy and Hypernymy: Jump To Navigationjump To SearchDocument8 pagesHyponymy and Hypernymy: Jump To Navigationjump To SearchSteven HamNo ratings yet

- DSP Lab - ScilabDocument17 pagesDSP Lab - ScilabSai Nikshipth MaddhugaruNo ratings yet

- Training Program for Newly Recruited AEEsDocument7 pagesTraining Program for Newly Recruited AEEsakstrmec23No ratings yet