Professional Documents

Culture Documents

Discover Dts I SRR

Uploaded by

Stev BetancurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Discover Dts I SRR

Uploaded by

Stev BetancurCopyright:

Available Formats

CYAN BLACK MAGENTA YELLOW

Bajaj Auto Limited

Akurdi Pune 411 035 India

Tel +91 20 27472851

Fax +91 20 27407385

www.bajajauto.com

Service

Ready

Reckoner

Service

Ready

Reckoner

CYAN BLACK MAGENTA YELLOW

The description and illustrations in this Service Ready Reckoner are not

to be taken as binding on the manufacturer. The essential features of

the type described and illustrated herein remaining unaltered, BAJAJ

AUTO LIMITED reserve the right to carry out at any moment, without

being obliged to bring this Service Ready Reckoner up-to-date,

modifications on the vehicle, parts or accessories, as may be

convenient and necessary.

Copying, quoting or reproducing any part of this Service Ready

Reckoner without the written permission of BAJAJ AUTO LIMITED, is

expressly prohibited.

DOC. NO. 36 02 0355 REV. NO.: 00, SEP. 04

NOTICE

TECHNICAL SPECIFICATIONS

PRE-DELIVERY INSPECTION CHECK LIST

ENGINE EXPLODED VIEW

TIGHTENING TORQUES - ENGINE AND FRAME

SERVICE DATA - ENGINE AND FRAME

ELECTRICAL WIRING DIAGRAMS

WARRANTY, SERVICES AND RESISTANCES

LOCTITES

PARTS IDENTIFICATION

PRECAUTIONARY MEASURES

IMPORTANT ENGINE ASSEMBLY TIPS

PERIODIC MAINTENANCE AND LUBRICATION

FREQUENTLY ASKED QUESTIONS (FAQs)

INDIVIDUAL CIRCUIT DIAGRAMS

STANDARD PROCEDURE FOR CO CHECKING AND SETTING

TUNE UP FOR OPTIMUM MILEAGE

CYAN BLACK MAGENTA YELLOW

1

T E C H N I C A L S P E C I F I C A T I O N S

Type Four stroke, Single cylinder, Natural air cooled.

No. of cylinders One

Bore 57.00 mm.

Stroke 48.80 mm.

Engine displacement 124.52 cc.

Compression ratio 9.5 +0.5:1

Idling Speed 1400 +100 rpm.

Max. net power 8.47 kW (11.51 Ps) at 8000 rpm.

Max. net torque 10.8 Nm at 6500 rpm.

Ignition System Micro controller based digital C.D.I.

0 0

Ignition Timing 10 BTDC at 1400 rpm., 26 BTDC at 3500 rpm

Carburettor Keihin NCV 24, Side Draught, CV Type.

Spark Plug 2 Nos. Champion RG4HC (Resistive)

Spark Plug Gap 0.6 to 0.7 mm.

Lubrication Wet sump, Forced.

Starting Kick Start

Electric start.

ENGINE

DISCOVER

Clutch Wet, Multidisc type.

Transmission 4 speed constant mesh.

st

Gear Ratios: 1 gear 2.92 : 1

nd

2 gear 1.72 : 1

rd

3 gear 1.16 : 1

th

4 gear 0.88 : 1

Final drive ratio 3.21 : 1

Frame Type Double cradle.

Suspension Front (Stroke 135mm.) Telescopic

Rear Trailing arm with coaxial hydraulic shock

absorbers, and triple rate coil springs.

Brakes Front Mechanically expanding

shoe and drum type.

Rear Mechanically expanding shoe and drum type.

Tyres Front 2.75 x 17, 6 PR

Rear 3.00 x 17, 6 PR

Tyre Pressure

2

Front 1.75 Kg/cm (24.5 Psi)

2

Rear Solo 2.00 Kg/cm (28.0 Psi)

2

Rear Pillion 2.25 Kg/cm (32.0 Psi)

CHASSIS & BODY

DISCOVER

2

T E C H N I C A L S P E C I F I C A T I O N S

Rims Front 1.60 x 17

Rear 1.85 x 17

Fuel Tank Capacity 10 litres with 2.3 litres of reserve

Steering Handle Bar

Accelerator Twist grip type on RH side of handle bar

Gears Left foot pedal operated

Clutch Lever operated on LH side of handle bar

Brakes Front Lever operated on RH side of handle bar

Rear Pedal operated by right foot

System 12 V (AC+DC)

Battery 12V 9Ah For ES, 12V 2.5Ah For KS

Head Lamp 35/35 W-HS1 For ES, 60/55 W-HS4 For KS

Pilot Lamp 5W - 2 Nos. For ES 4W - 1 No. For KS

Tail/Stop lamp 5/21 W

Turn signal lamp 10 W

Hi beam indi. lamp 1.7 W

Speedometer lamp 3.4 W

CONTROLS

ELECTRICALS

DISCOVER

Turn Pilot Indi. Lamp 1.7W - 2 Nos.

Neutral indi. lamp 1.7 W

Fuel Gauge 3.4 W

Horn 12V DC

Length 2030 mm.

Width 760 mm.

Height 1065 mm.

Wheel base 1305 mm.

Turning circle radius 2100 mm. (Minimum)

Ground clearance 175 mm. (Minimum)

Vehicle kerb weight 129 kg. For ES 125 kg. For KS

Gross veh. weight 259 Kg. For ES 255 kg. For KS

Maximum speed 100 Km/hr. with single rider (65 Kg)

0

Climbing ability 25% (14 Maximum)

DIMENSIONS

WEIGHTS

PERFORMANCE

DISCOVER

Notes:

Values given above are nominal and for guidance only. 15% variation is allowed to

cater for production and measurement variation.

All dimensions are under unladen condition.

Definitions of terminologies wherever applicable are as per relevant IS/ISO standards.

Specifications are subject to change without notice.

CYAN BLACK MAGENTA YELLOW

3

P. D . I . C H E C K L I S T

TO CHECK CHECK FOR

ENGINE :

FRAME :

Engine oil SAE 20W40

API SG+JASO MA

Grade

Idling Speed (Warm up)

Kick operation

Fasteners (Check torque

Fuel Tank / Pipes

Fuel Tap

Carburettor

A. WHEELS

Tyre Pressure

Rim runout (With tyre)

Oil level. Top up if required.

Oil leakage if any.

Check / adjust if required.

(1400 + 100 rpm)

Smooth Operation.

Engine mtg. at Cyl. Head (2.2 Kgm.)

& correct if required) at Front & Rear (3.2 Kgm.)

Oil drain plug (3.0 Kgm.)

Leakages / Fitment.

Smooth operation.

Leakages, Fitment - Orientation & angle

Breather pipe routing.

2

Front - 1.75 Kg/cm

2

Rear - 2.00 Kg/cm (Solo),

2

2.25 Kg/cm (Double)

Radial - (0.8 mm or less)

Axial - (1.0 mm or less)

FUEL SYSTEM :

TO CHECK CHECK FOR

FRAME :

Spokes Check & tighten if required.

Drive chain Slackness (25-35 mm)

Lubrication (SAE 90)

Check chain lock position.

Front brake lever free play (2-3 mm)

Rear brake pedal free play (25-30 mm)

Lever free play (2-3 mm)

Smooth operation.

Grip free play (2-3 mm)

Smooth operation.

Choke Free play (2-3 mm) & smooth operation.

Smooth operation, Oil leakage.

Proper notch setting # Preload setting:

2nd notch (same on both side)

Smooth operation (Loose or tight).

D) LOCK OPERATION Steering and Ignition, Fuel tank,

Seat lock, Side cover LH.

B) CONTROLS

Brakes

Clutch

Throttle

C) SUSPENSION

Front fork

Rear shock absorber

Steering

DIRECTION OF

CHAIN ROTATION

4

P. D . I . C H E C K L I S T

TO CHECK CHECK FOR

E) FASTENERS Check split pin of Front & Rear axle nut.

Rear shock mounting nut (3.5 Kgm.)

Front fork top clamping bolts.

(2.5 to 3.0 Kgm.)

A. BATTERY Electrolyte level / Specific gravity 1.240.

Charging, Connect -ve terminal and

apply petroleum jelly.

Routing of Breather pipe, Fuse.

B. ALL BULBS WORKING Head light, Pilot, Tail / Stop, Side indicator,

Speedometer, Indicator lamps and

Fuel Gauge.

C. SWITCH OPERATION LH and RH control switch.

Ignition switch.

Ride control brake switch (Front & Rear)

and Clutch switch.

D. STARTER MOTOR Proper working / Engagement.

(Use choke for cold starting)

A. STARTING* Cold start and Warm start.

Idling speed (Warm condition)

1400 + 100 rpm

ELECTRICAL

TEST DRIVE (2-3 kms)

Any other defects

Look for any external damages in Transit : Please check, record & rectify.

1. Moisture / Oil collecting tube of Air Filter should be properly fitted and

routed correctly.

TO CHECK CHECK FOR

B. DRIVIABILITY Throttle response

Gear shifting / Clutch operation

Brakes (Front & Rear)

Speedometer, Odometer and Trip meter.

C. CO % CHECK CO should be 1.75-2.25% in warm condition

D. CLEANING Wash & Clean vehicle properly.

* IMPORTANT :

BEFORE STARTING, PLEASE ENSURE FOLLOWING.

Check the fitment of Reed Switch and Magnet.

Max. gap between Magnet and Reed Switch to be 2.5 mm.

Check for working of the Reed Switch assly. and Magnet by using multimeter.

Press and Confirm that both the Spark Plug caps have been fitted correctly.

Confirm tightness and correct fitment of primary leads to both the H.T. Coils.

AFTER STARTING, PLEASE ENSURE FOLLOWING.

Confirm that both the Spark Plugs are firing by using a Timing light or

Stroboscope with the engine idling.

CYAN BLACK MAGENTA YELLOW

5

P E R I O D I C MA I N T E N A N C E A N D L U B R I C A T I O N C H A R T

l : Indicates operation to

be performed.

: More frequent cleaning

may be required when

driving in dusty

condition.

A - Adjust

CL - Clean

C - Check

L - Lubricate

T - Tighten

R - Replace

Note:

Parts/Lubricants to be

replaced as per Periodic

Maintenance and Lubrication

Chart are mandatory and the

same are chargeable to

customer.

1. Servicing l l l l l

2. Idle speed / CO% C,A l l l l l

3. Engine oil (SAE 20W40 of API SG+JASO MA) R l l Every 5000 kms.

4. Valve clearance A l Every 5000 kms.

5. Oil strainer / Centrifugal filter CL Every 10000 kms.

6. Air cleaner element CL l l l l l

7. Air cleaner element R Every 10000 kms.

8. Carburettor CL,A l l l l l

9. Fuel system leakages C,R l l l l l

10. Fuel pipes R 1 Year Every 1 Year

11. Spark plug / gap CL,A l l l l l

12. Spark plug (2 Nos.) R Every 10000 kms.

13. Battery electrolyte level C,A 15 Days l l l l l

14. Brake light switch C,A l l l l l

15. Clutch play A l l l l l

16. Throttle play A l l l l l

17. Rear brake pedal play A l l l l l

18. Brake lining wear C,R l l l l l

19. Steering play C,A l l l l l

20. All fasterners tightness including engine mtg. T l l l l l

Sr.

No. Operation

Whichever

comes first

750 2,500

RECOMMENDED FREQUENCY

Initial Subsequent

5,000 7,500 Every 2,500km Kms.

Days

OR

30 90 150 225 Every 75 days

6

P E R I O D I C MA I N T E N A N C E A N D L U B R I C A T I O N C H A R T

l : Indicates operation to

be performed.

: More frequent cleaning

may be required when

driving in dusty

condition.

A - Adjust

CL - Clean

C - Check

L - Lubricate

T - Tighten

R - Replace

Note:

Parts/Lubricants to be

replaced as per Periodic

Maintenance and Lubrication

Chart are mandatory and the

same are chargeable to

customer.

21. Engine mounting silent blocks R Every 20000 kms.

22. Tyre tread wear C,R l l l l

23. General lubrication L l l l l l

24. Steering stem bearing L 1 Year Every 10000 kms.

25. Wheel bearing L 1 Year Every 10000 kms.

26. Swing arm mounting bush R l Every 20000 kms.

27. Front fork C l l l

28. Front fork oil R Every 10000 kms.

29. Spoke tightness and rim runout C,A l l l l l

30. Rear shock absorber C,R l l l l l

31. Drive chain L Every 500 km

32. Drive chain slack A Every 2500 km

33. Drive chain wear / Remove and Lubricate C,R l Every 5000 kms

34. Gap between Reed switch and TPS magnet C,A l l l l l

Sr.

No. Operation

Whichever

comes first

750 2,500

RECOMMENDED FREQUENCY

Initial Subsequent

5,000 7,500 Every 2,500km Kms.

Days

OR

30 90 150 225 Every 75 days

CYAN BLACK MAGENTA YELLOW

7

P A R T S I D E N T I F I C A T I O N - P U L S A R 1 5 0 D T S i

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Cylinder Head with Cover

DH 1015 29

Rubberised silent bush fitted in head cover.

Cylinder Head with Cover

DH 1015 29

Bigger combustion chamber cavity.

DH mark is embossed on casting.

Cylinder Complete

DH 1015 27

Bigger bore.

-----

Piston Assembly

DH 1015 30

DHU mark is embossed on piston crown.

Large in diameter.

Part No.

-----

8

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

P A R T S I D E N T I F I C A T I O N - D I S C O V E R

Cylinder Head with Cover

DS 1011 09

Steel bush fitted in head cover.

Cylinder Head with Cover

DS 1011 09

Smaller combustion chamber cavity.

DS mark is embossed on casting.

Cylinder Complete

DS 1012 54

Smaller bore.

-----

Piston Assembly

DS 1010 13

Two valve relieve grooves are provided on piston crown.

Smaller in diameter.

-----

CYAN BLACK MAGENTA YELLOW

9

P A R T S I D E N T I F I C A T I O N - P U L S A R 1 5 0 D T S i

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Piston Pin

DH 1012 70

No chamfer.

Cam Chain

DH 1010 50

More in length 313 mm.

Chain Guide

DH 1010 10

Length is 178 mm.

Length is more.

Wall thickness is more.

Part No.

Part Name

Description

Identification Mark

Guide Chain (Tight)

DH 1010 17

No curvature at bottom location.

10

P A R T S I D E N T I F I C A T I O N - D I S C O V E R

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Piston Pin

DS 1010 86

Chamfer is provided.

Cam Chain

DS 1010 36

One chain link mark with white paint.

Less in length 300 mm.

Chain Guide

Length is 168 mm.

Length is less.

Wall thickness is less.

DS 1010 11

Part No.

Part Name

Description

Identification Mark

Guide Chain (Tight)

DS 1010 12

Curvature at bottom location.

CYAN BLACK MAGENTA YELLOW

11

P A R T S I D E N T I F I C A T I O N - P U L S A R 1 5 0 D T S i

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Crankshaft Assembly

DH 1010 57

DH mark is embossed on con-rod.

Clutch Spring

DH 1014 83

Spring has 5 coil turns.

Spring is marked with Yellow colour paint.

Clutch Hub

DH 1014 34

Height is 22.5 mm.

Height is more.

Part No.

Part Name

Description

Identification Mark

Guide Split

DH 1013 74

Splines on ID

Web shape is different.

12

P A R T S I D E N T I F I C A T I O N - D I S C O V E R

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Crankshaft Assembly

DS 1011 84

Groove for square key cotter on clutch side shaft.

Clutch Spring

DS 1011 16

Spring has 4 coil turns.

Spring is marked with Red colour paint.

Clutch Hub

DH 1013 46

Height is 20.5 mm.

Height is less.

Part No.

Part Name

Description

Identification Mark

Guide Split

DS 1011 06

No splines on ID.

Web shape is different.

CYAN BLACK MAGENTA YELLOW

13

P A R T S I D E N T I F I C A T I O N - P U L S A R 1 5 0 D T S i

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Gear Change Lever

DH 1011 34

Open end welding dimension is 38.2.

Guide Gear Shift

DH 1014 95

More wide.

Have 5 pins.

Rotor Assembly

DS 1110 08

Pick up coil sensor projection length is 18.13 mm.

Pick up coil sensor is less in length.

18.53 mm.

Part No.

Part Name

Description

Identification Mark

Wiring Harness

DH 2010 29

Yellow colour insulation tape fitted on harness.

14

P A R T S I D E N T I F I C A T I O N - D I S C O V E R

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

Gear Change Lever

DS 1011 34

Open end welding dimension is 36.53

Guide Gear Shift

DS 1010 79

Small in size and shape.

Have 4 pins.

Rotor Assembly

DS 1110 08

Pick up coil sensor projection length is 20.00 mm.

Pick up coil sensor is more in length.

20.00 mm.

Part No.

Part Name

Description

Identification Mark

Wiring Harness

DS 2010 01 For KS Version and DS 2010 32 For ES Version.

Red colour insulation tape fitted on harness.

CYAN BLACK MAGENTA YELLOW

15

P A R T S I D E N T I F I C A T I O N - P U L S A R 1 5 0 D T S i

Part No.

Part Name

Description

Identification Mark

Part Name

Description

Identification Mark

CDI

DH 1110 19

DH mark is embossed on body.

Rear Wheel Sprocket

DJ 1510 18

Has 42 teeths.

42 T mark and yellow passivated.

Part No.

16

P A R T S I D E N T I F I C A T I O N - D I S C O V E R

Part No.

Part Name

Description

Identification Mark

Part No.

Part Name

Description

Identification Mark

CDI

DS 1110 03

DS mark is embossed on body.

Rear Wheel Sprocket

DS 1510 59

Has 45 teeths.

45 TALS mark and black in colour.

CYAN BLACK MAGENTA YELLOW

18

T I G H T E N I N G T O R Q U E S - E N G I N E

CHAIN TENSIONER MTG. BOLTS

1.1 kgm.

OUTPUT SPROCKET BOLTS

1.1 kgm. 1.5 kgm.

GUIDE GEAR ALLEN BOLT

CRANKCASE JOINING BOLT

1.1 kgm.

STARTER COUNTER BOLT

1.1 kgm.

CLUTCH COVER BOLTS

1.1 kgm.

CYL. HEAD BKT. MTG. BOLTS

2.0 to 2.2 kgm. 3.0 to 3.2 kgm.

ENGINE MOUNTING BOLTS

2.0 to 2.2 kgm.

ENGINE MOUNTING NUTS

SILENCER MOUNTING NUTS

2.5 kgm.

SILENCER MOUNTING BOLT

3.5 kgm.

CRANKCASE JOINING BOLTS

1.1 kgm.

17

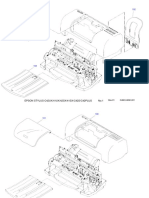

E N G I N E E X P L O D E D V I E W

CYLINDER HEAD ASSEMBLY

CYLINDER BLOCK / PISTON

CRANKSHAFT

CRANKCASE & COVERS

TRANSMISSION

STATOR & ROTOR ASSEMBLY

SILENCER

CLUTCH MECHANISM

OIL PUMP & FILTER

CLUTCH COVER

CHAIN TENSIONER & CHAIN GUIDE

KICK MECHANISM

STARTER MECHANISM (ELECTRIC)

CYAN BLACK MAGENTA YELLOW

19

T I G H T E N I N G T O R Q U E S - E N G I N E

OIL PUMP MOUNTING BOLTS

1.1 kgm.

CENTRIFUGAL OIL FILTER NUT

5.5 kgm. 5.5 kgm.

CLUTCH NUT (L.H. THREADS)

ROTOR MOUNTING BOLT

4.5 kgm.

KICK GUIDE BKT. HOLDER BOLTS

1.1 kgm.

GENERATOR COVER BOLTS

1.1 kgm.

CYLINDER HEAD COVER NUTS

3.5 kgm. 1.1 kgm.

CYLINDER HEAD COVER BOLTS CAM SPROCKET ALLEN BOLT

1.4 kgm.

STARTER MOTOR BOLTS

1.1 kgm.

DRAIN CAP

3.0 kgm.

SPARK PLUGS (2 NOS.)

1.4 kgm.

20

T I G H T E N I N G T O R Q U E S - F R A ME

REAR SPROCKET MTG. NUT

1.8 to 2.5 kgm.

SLEEVE NUT

8.0 kgm.

FRONT AXLE NUT

4.0 to 5.0 kgm.

REAR AXLE NUT

8.0 to 10.0 kgm. 3.0 to 4.0 kgm.

TORQUE ROD NUT

2.0 kgm.

HANDLE BAR HOLDER BOLTS STEERING TOP BOLT

4.5 to 5.0 kgm. 0.5 kgm.

STG. STEM NUT (SLOTTED) LOWER CLAMP BOLTS

3.0 to 3.2 kgm.

UPPER CLAMP BOLT

3.0 to 3.2 kgm.

SWING ARM PIVOT NUT

4.5 to 5.5 kgm.

R.S.A. MTG. NUTS/BOLTS

UPPER - 3.5 to 4.0 kgm.

LOWER - 2.5 kgm.

CYAN BLACK MAGENTA YELLOW

21

S E R V I C E D A TA - E N G I N E

COMP. PRESSURE

Standard

2

12-14 kg/cm

Service Limit

2

9.1-14 kg/cm

CAM HEIGHT

Standard 30.80 30.4

Service Limit 30.5 30.00

Ex. Inlet

VALVE STEM DIAMETER

4.46

4.40

4.46

4.40

Inlet Exhaust

Standard

Service Limit

VALVE STEM BEND

TIR 0.01 Standard

TIR 0.03 Service Limit

VALVE HEAD THICKNESS

0.5 0.8

Inlet Exhaust

Standard

0.3 0.6 Service Limit

CAM SHAFT CHAIN 20 LINKS

127 - 127.2 Standard

128 Service Limit

20-link length

1st 2nd 21st

MEASURE THIS LENGTH

CYLINDER INSIDE DIA.

57.010-57.017 Standard

57.017-57.024 Service Limit

10mm

20mm

40mm

PISTON DIAMETER

56.978-56.900 Standard

56.988-56.998 Service Limit

7mm

ALL DIMENSIONS ARE IN MM.

PISTON/CYL. CLEARANCE

0.019 - 0.039

0.05

Standard

Service Limit

ROCKER ARM INSIDE DIA.

10.00 - 10.01 Standard

10.04 Service Limit

CAM SPROCKET DIAMETER

61.4 Standard

61.3 Service Limit

VALVE SPRING FREE LENGTH

41.6

Outer

37.9

Inner

Standard

Service Limit 40.6 36.9

CYLINDER HEAD WARP

Standard 0.00

Service Limit 0.05

VALVE CLEARANCE

0.05

Inlet

0.10

Exhaust

Standard

0.05 0.10 Service Limit

ROCKER ARM SHAFT DIA.

9.97 - 9.98 Standard

9.92 Service Limit

22

S E R V I C E D A TA - E N G I N E

PISTON RING/GROOVE CLEARANCE

Standard 0.02-0.06

Top

0.01-0.05

Second

Service Limit 0.16 0.15

PRESSURE PLATE WARP

0.15 Standard

0.25 Service Limit

CONROD BIG END AXIAL CLEARANCE

Standard 0.1-0.35

Service Limit 0.45

ENGINE OIL SPECIFICATIONS

Grade : SAE 20W40 of API SG +

JASO MA grade or superior.

Quantity : 1000 ml (Drain and Refill)

Oil Change : Every 2,500 km.

Frequency Check and Top-up if required.

Oil Strainer Cleaning : Every 10,000 km.

CARBURETTOR

SPECIFICATIONS

Item DISCOVER

Make & type NCV 24

Keihin Side

Draught, CV

Idling speed 1400 + 100

VC screw 2.5 + 1.0

Turn

Jet needle Fixed,

clip position No clip

provision.

Main jet #128

Pilot jet #35

CO% 1.75-2.25

SHIFT DRUM GROOVE WIDTH

5.05-5.15 Standard

5.25 Service Limit

SHIFT FORK PAD THICKNESS

4.97

4.90

Standard

Service Limit

SHIFT FORK GUIDE PIN DIA.

Standard 4.97

Service Limit 4.90

FRICTION PLATE THICKNESS

2.9-3.1 Standard

2.75 Service Limit

CLUTCH SPRING FREE LTH

30.4 Standard

29.4 Service Limit

CRANK SHAFT RUN OUT

TIR 0.02 max. Standard

TIR 0.05 Service Limit

PISTON RING END GAP

0.15-0.30

Top

0.30-0.45

Second

Standard

0.55 0.70 Service Limit

ALL DIMENSIONS ARE IN MM.

CYAN BLACK MAGENTA YELLOW

23

S E R V I C E D A TA - F R A ME

BR. PANEL CAM HOLE DIA.

Standard 12.0-12.03

Service Limit 12.15

FR. BRAKE PAD THICKNESS

7.4

3.8

Standard

Service Limit

BR. SHOE LINING THICKNESS

3.85-4.15

2.0

Standard

Service Limit

BRAKE DRUM INDISE DIA.

130.00 - 130.16

130.75

Standard

Service Limit

AXLE RUN OUT

TIR 0.1

TIR 0.2

Standard

Service Limit

100 mm

AXIAL WHEEL RUN OUT

TIR 0.8

TIR 2.0

Standard

Service Limit

RADIAL WHEEL RUN OUT

TIR 0.8

TIR 2.0

Standard

Service Limit

DRIVE CHAIN SLACK

25 - 35

35 - 45

Standard

Service Limit

DRIVE CHAIN LENGTH

254 - 254.6

259

Standard

Service Limit

20-link length

1st 2nd 21st

MEASURE THIS LENGTH

REAR SPROCKET WARP

TIR 0.4

TIR 0.5

Standard

Service Limit

BRAKE CAM DIAMETER

11.95-11.98

11.88

Standard

Service Limit

ALL DIMENSIONS ARE IN MM.

FRONT FORK OIL

Grade :

SAE 10W20

Capacity :

145 + 2.5 ml

(per leg)

Oil change

frequency :

After every

10,000 Kms.

FR. TYRE TREAD DEPTH

5.0

1.0

Standard

Service Limit

REAR TYRE TREAD DEPTH

6.6

1.5

Standard

Service Limit

FR. FORK SPRING FREE LTH.

420

416

Standard

Service Limit

Free Length

24

E L E C T R I C A L WI R I N G D I A G R A M - ( E L E C T R I C S T A R T )

G/W B/Y

R/Y

Y/R

L/W L/W Y

B/YW

B/Y

Br/B

RELAY

(FOR INTERLOCKING)

B/Y

(P.NO. DS 20 1016)

(P.NO. DJ 20 1024)

R/W

HORN

Y

Y/L R/BY

PASS

SWITCH

CONTROL SWITCH RH

R/Y R Y Y/L

PO

OFF ON

LIGHT

SWITCH

STARTER

SWITCH

RBr/B Y Y/L

R/Y

BBr

W

B/Y

Y/RW/R

L/W RL/W

COIL

PULSING

MAGNETO

C.D.I. ASSY.

BB/W

B/Y

B

B

STARTER MOTOR

R

FUSE

(15 Amps.)

R

W/B

B

R/Y

STARTER RELAY

WITH DAMPER BATTERY

12V-9Ah

Lg

Lg

R/B

B/Y

W/Y

FUEL LEVEL

GUAGE

POSITION LAMP

12V-5W- 2 Nos.

Br

B/Y

W/Y

Lg

Gr

G

R

R/B

G

FUEL

METER **

TURN SIGNAL

INDICATOR LAMP *

(FRONT LH )

HIGH BEAM

INDICATOR LAMP *

R/B

R/W

ILLUMINATION

LAMP **

R

B/Y

B/Y

B/Y

R/B

O

CONTROL SWITCH LH

W Y

HI LO L R

O

F

F

O

N

Y/R L/WL/WW/R

RB/Y

B/Y

GrGB

B G GrO R/B

G G

B/Y

/ B Y

B/Y

B/Y B/Y

Gr

B/Y B/Y

B/Y B/Y

L

B/Y

R R/W

B/Y

L

Gr Gr

BrL

L Br O Br

G G

B/Y

BrL

L Br

R/Y

Br

W

B/W B/W

W

Br

Lg

W/Y

B/Y

Br

Gr Gr

NEUTRAL

SWITCH

HORN

SWITCH

TURN

SIGNAL

SWITCH

DIMMER

SWITCH

SIGNAL

LAMP

REAR LH

SIGNAL

LAMP

REAR RH

REAR BRAKE

SWITCH

TURN SIGNAL

RELAY

REGULATOR

FRONT BRAKE

SWITCH

SIGNAL LAMP

FRONT LH

HEAD LAMP

ASSY/LAMP

12V-35/35W HS1

IGNITION

SWITCH

NEUTRAL

LAMP *

SIGNAL LAMP

FRONT RH

LAMP 12V-10W

EARTH-FRAME

CABLE ASSY. RED

CABLE ASSY. EARTH

CLUTCH

SWITCH

B/Y

G/W

Br

B/Y

G/W

LgY/G

SPARK

PLUG

H.T.COIL

B/R

SWITCH ASSY.

R

TAIL LAMP

ASSY

TAIL/STOP

LAMP

12V-5/21 W

TURN SIGNAL

INDICATOR LAMP *

(FRONT RH)

NC

NO

P

** LAMP

12V, 3.4W

(QTY. 2)

METER

ASSY.

* LAMP

12V, 1.7W

(QTY. 4)

SPARK

PLUG

H.T.COIL

CYAN BLACK MAGENTA YELLOW

25

E L E C T R I C A L WI R I N G D I A G R A M - ( K I C K S T A R T )

R/B

CAPACITOR

W

W

/R

L/W

L/W

REGULATOR

FUSE (15A)

W

/B

B/Y

G R

BATTERY

12V 2.5AH

B/Y

R

Y

B/Y

B/Y

Y/R

Gr R

COIL

PULSING

MAGNETO

Lg

Lg

R/B

B/Y

W

/Y

FUEL LEVEL GUAGE

Br

B/Y

W/Y

Lg

Gr

G

R

R/B

G

R/B

R/W

Br/W

B/Y

R

/ B Y

B/Y

R B /

W Y

O

F

F

O

N

Y RB/Y

B/Y

Br B

O GrGB

G G

B Y /

/ B Y

/ B Y

/ B Y / B Y

Gr

/ B Y / B Y

/ B Y / B Y

L

/ B Y

R R

/ B Y

L

Gr Gr

BrL

L Br O Br

G G

B Y /

BrL

L Br

R Y /

Br

W

B W / / B W

W

Br

Lg

W/Y

B/Y

Br

Gr Gr

NEUTRAL

SWITCH

HORN

SIGNAL

LAMP

REAR LH

SIGNAL

LAMP

REAR RH

REAR BRAKE

SWITCH

TURN SIGNAL

RELAY

FRONT BRAKE

SWITCH

SIGNAL LAMP

FRONT LH

HEAD LAMP

ASSY/LAMP

12V-60/55W

POSITION

LAMP12V-4W

IGNITION

SWITCH

SIGNAL LAMP

FRONT RH

LAMP 12V-10W

EARTH-FRAME

Y/L

YR

LIGHT SWITCH

ON

OFF

PO

CONTROL SWITCH RH

R/BO GrGB

R L LO HI O

B/Y Y R/B

R/B

Y/L

R/Y

Y

Y/L

TAIL LAMP

ASSY

TAIL/STOP

LAMP

12V-5/10 W

SPARK

PLUG

B

H.T.COIL

B/Y

B

C.D.I. ASSY.

SWITCH ASSY.

W

/R

R B/W

B/R

W/G W/G

SPARK

PLUG H.T.COIL

** LAMP

12V, 3W

(QTY. 3)

* LAMP

12V, 1.4W

(QTY. 5)

FUEL METER

ILLUMINATION

LAMP **

ILLUMINATION

LAMP **

ILLUMINATION

LAMP **

TURN SIGNAL

INDICATOR LAMP *

(FRONT LH )

HIGH BEAM

INDICATOR LAMP *

NEUTRAL LAMP *

TURN SIGNAL

INDICATOR LAMP *

(FRONT RH)

PASS

SWITCH

CONTROL SWITCH LH

HORN

SWITCH

TURN

SIGNAL

SWITCH

DIMMER

SWITCH

26

I N D I V I D U A L C I R C U I T D I A G R A M ( E S )

AC LIGHTING

CIRCUIT

ON

PASS SWITCH

CONTROL SWITCH RH

PO

OFF

POSITION

LAMP

12V-5W

HI LO

DIMMER SWITCH

R.R. UNIT

HEAD

LAMP

ASSY/

LAMP

12V-35/

35W HS1

TAIL/STOP

LAMP

12V-5/21W

INDICATOR

LAMP

HIGH BEAM

12V 1.4W

ILLUMINATION

LAMP

TACHOMETER

12V 3W

ILLUMINATION

LAMP

FUEL METER

12V 3W

ILLUMINATION

LAMP

SPEEDOMETER

12V 3W

MAGNETO

POSITION

LAMP

12V-5W

CONTROL SWITCH LH

B/Y

B/R

B/Y

B/Y

B/Y

B/Y

R/W

R/W

R/W

R

/W

R

R

R

R

Y

Y

/L

Y

Y

/L

Y

B

/Y

Y

/R

Y

/R

Y

R

R

R

B/Y

B/Y

B

/Y

B

/Y

R/Y

R

/Y

B

/R

B/R

B/R

B

/R

B

/R

B/Y

B

/Y

R/W

R

B/Y

CYAN BLACK MAGENTA YELLOW

27

I N D I V I D U A L C I R C U I T D I A G R A M ( E S )

STARTER MOTOR AND

BATTERY CHARGING CIRCUIT

CLUTCH

SWITCH

EARTH-FRAME

NEUTRAL

LAMP

CONTROL SWITCH RH

STARTER

SWITCH

INTERLOCK RELAY

STARTER

MOTOR

NEUTRAL

SWITCH

MAGNETO

STARTER RELAY

FUSE

(15 Amps.)

BATTERY

12V 9Ah

NO

P

NC

O

F

F

O

N

IGNITION

SWITCH

R.R. UNIT

Lg

Br

L

g

Lg

L

g

Lg

Br

B

r

W

W

W

B

/Y

B/Y

G/W

G

/W

G

/W

B

r/W

R

/Y

Br/W

R/Y

R

/Y

R/Y

R

R

R B

B

Y

/G

Y/G

Y

/G

B

/Y

B

/Y

B

/Y

WL

/W

L

/W

L

/W

L

/W

B

/Y

B/Y

28

I N D I V I D U A L C I R C U I T D I A G R A M ( E S )

IGNITION

CIRCUIT

O

F

F

O

N

SPARK

PLUG H.T.COIL

C.D.I. ASSY.

REED SWITCH

ASSY.

COIL

PULSING

MAGNETO

IGNITION

SWITCH

SPARK

PLUG H.T.COIL

B/Y

B

/Y

B/Y

B

/Y

B

B

B

B

B

B

B

B/R

B

/R R

B

/W

B/W

W

/R

W/R

R

R

G

Y

CYAN BLACK MAGENTA YELLOW

29

I N D I V I D U A L C I R C U I T D I A G R A M ( E S )

SIDE INDICATOR AND

HORN CIRCUIT

HORN

MAGNETO

STARTER

MOTOR

FUSE

(15 Amps.)

STARTER

RELAY

O

CONTROL SWITCH LH

HI

L R

O

F

F

O

N

HORN

SWITCH

TURN SIGNAL

SWITCH

SIGNAL

LAMP

REAR LH

12V 10W

SIGNAL

LAMP

REAR RH

12V 10W

TURN SIGNAL RELAY

SIGNAL

LAMP

FRONT LH

12V 10W

IGNITION

SWITCH

SIGNAL

LAMP

FRONT RH

12V 10W

LH TURN

SIGNAL

INDICATOR

LAMP

12V 1.4W

RH TURN

SIGNAL

INDICATOR

LAMP

12V 1.4W

+

BATTERY

12V-9Ah

Gr Gr

G

r

G

r

Gr

Gr

B/Y

B/Y

B/Y

B

/Y

B/Y

B

/Y

B/Y

G

G

G

G

G

Br

W

W B

/Y

B/Y

B

r

O

O

O

B

B

B

r

B

/Y

B

R

W

/B

W

30

I N D I V I D U A L C I R C U I T D I A G R A M ( E S )

FUEL GAUGE AND

BRAKE LIGHT CIRCUIT

MAGNETO

STARTER

MOTOR

FUSE

(15 Amps.)

STARTER RELAY

BATTERY

12V-9Ah

O

F

F

O

N

REAR

BRAKE SWITCH

FRONT

BRAKE SWITCH

IGNITION

SWITCH

TAIL LAMP

ASSY

TAIL/STOP

LAMP

12V-5/21 W

FUEL

METER

FUEL LEVEL

GUAGE

Br

B

r

Br

B

/Y

B/Y

R B

W

/B

W

W

W/Y

W/Y

B

rLL

L

B/Y

B

r

CYAN BLACK MAGENTA YELLOW

31

Warm up the CO Gas Analyzer for

10 t o 15 mi nut es bef or e

proceeding further. Warming up is

essential every time machine is

put on to purge out any gases left

in side.

Carry out Span Check as per

manufacturer's recommendation

to confirm the OK condition of the

Equipment (If Span Check does

not confirm the reading, then carry

Readiness of CO Gas Analyzer:

S T A N D A R D P R O C E D U R E F O R C O C H E C K I N G A N D S E T T I N G

out Gas Cal i br at i on as per manuf act ur er s

recommendation). Set the Equipment display to Zero

before taking the reading.

Readiness of the Vehicle:

Before checki ng the CO

emission, prepare the vehicle

for checking the CO >>>

Warm up the engine to

i t s nor mal oper at i ng

temperature by riding 5

to 6 Kms. The Clutch cover should be warm

enough by feel.

Ensure the Choke is in OFF position.

Screw in Volume Control Screw completely. Engine

should die down in this condition.

Note: If engine does not go off, then attend to the

additional air supply problem in the carburetor circuit &

intake system. After solving the problem once again

confirm that engine should die down on closing the

Volume Control Screw.

Confirm the Volume Control Screw to it recommended

position of 2.5 turns.

Set Idling speed to specified Idling to 1400 + 100 rpm

of respective engines. Raise the engine to moderate

speed at no load condition for about 15 seconds.

Then bring back to specified idling RPM.

Taking the Reading:

Insert 'Special Probe' in

the Silencer tail end

pipe properly. Use right

mouth pi ece of the

probe to suit with tail

end pipe of respective

vehi cl e. The speci al

probe is a combination

of adaptor and probe. It

comes with adjustable

stand.

32

S T A N D A R D P R O C E D U R E F O R C O C H E C K I N G A N D S E T T I N G

Precaution: Always ensure rubberised taper portion is

intact with the tail end of the silencer and adaptor is

mounted on the stand at suitable height such that

ingression of fresh air does not take place. The probe

and silencer should be held in same axis.

Note the CO / HC Readings when the reading display

stabilizes.

As per Emission Norms the recommended CO% for

2 Wheelers is 4.5% at Idling RPM. But CO% for Bajaj

Vehicles, for best results in terms of fuel efficiency are

different for different models. For Discover the ideal

CO% is between 1.75 to 2.25% at Idling rpm with

Volume Control Screw between 0.5 to 4.5 turns out.

If the reading is shown excess or less than BAL

Specifications for respective model, then try to achieve

by adjusting Volume Control Screw.

- Turning out Volume Control Screw will lead to more

CO% & turning in will lead to less CO%.

Note: Remember the Volume Control Screw should not

be taken out more than the recommended position.

Every time Volume Control Screw setting is changed

specified Idling RPM must be restored and then reading

should be considered.

After rectifying the problem confirm the CO% in the

same way as mentioned above.

Imp: For Better Mileage and Performance, achieve CO%

as recommended.

In Discover for better mileage and performance achieve

values given below.

Recommended CO% value w.r.t. Volume Control Screw

and Idling RPM for Better Fuel Efficiency

Model

Recommended

CO%

Volume Control Screw

Position

Recommended

Idling RPM

Discover 1.75% 2.25% 0.5 to 4.5 1400 + 100

If the CO% is not falling with in recommended % in spite

of adjusting the Volume Control Screw then find out the

cause and rectify the same.

CYAN BLACK MAGENTA YELLOW

33

T U N E - U P F O R O P T I MU M MI L E A G E

Reed Switch : Maintenance Reed Switch : Checking

Reed Switch : Setting

Magnet should not touch

with reed switch.

Gap between Magnet &

Reed Switch should not be

more than 2.5 mm.

Movement of throttle lever

with magnet assembly and

Reed Switch fitted should

be free.

Check throttle lever movement by rotating it with

hand. It should not be sticky in operation and

should return back it self on releasing.

Accelerator cable play: 2-3

mm by adj ust i ng t he

Adjuster (A).

Protude stopper (B) of the

throttle lever bracket must

on idling screw (C) tip.

Keep t hr ot t l e at zer o

position. (Fig. 1).

On connecting multimeter to

Reed Switch coupler it

should show continuity.

When throttle is open and

Reed Swi t ch magnet

crosses to straight edge of

fix bracket of Reed Switch

(Fig. 2) multimeter should

show discontinuity.

0.00

On De-acceleration, when of

Reed Switch magnet re-

coinsides with straight edge

of fix bracket of Reed

Switch (Fig. 3) Multimeter

should show continuity.

1

1

Gap

2.5mm max.

B

A

C

Fig. 1

Fig. 2

Fig. 3

34

T U N E - U P F O R O P T I MU M MI L E A G E

Engine Maintenance

SPARK PLUG:

RG 4 HC.

Spark Plug Gap :

0.6 to 0.7 mm.

Replace at every :

10,000 Kms.

0.6 to

0.7MM

AIR FILTER:

Clean at every 2,500 Kms.

Replace at every

10,000 Kms.

COMPRESSION PRESSURE

Standard :

2

12 to 14 Kg/cm

Service Limit:

2

9.1 to 14 Kg/cm

Other Mandatory Checks

a. Ensure no fuel leakage through fuel cock, fuel

lines.

b. Ensure free rotation of both the wheels.

c. Ensure correct tyre pressure -

Front wheel : 28 PSI, Rear wheel : 32 PSI

d. Set control cable free play:

Clutch lever 2-3 mm.

Front brake lever 2-3 mm.

Rear brake pedal 25-30 mm.

e. Chain slackness : 25 to 35 mm.

TAPPET CLEARANCE

Inlet valve: 0.05 mm

Exhaust valve: 0.1 mm

CARBURATTOR

Idling : 1400 + 100 rpm.

Vol ume Cont rol screw

setting : 2.5 + 2.0 turns.

CO % : 1.75 to 2.25 %.

CYAN BLACK MAGENTA YELLOW

35

WA R R A N T Y A N D S E R V I C E S

Sr. No. Service Type Kms./days *

1 1st Free with 00,500 - 00,750 Kms. or 30 days.

Oil change

2 2nd Free 02,000 - 02,500 Kms. or 90 days.

3 3rd Free with 04,500 - 05,000 Kms. or 150 days.

Oil change

4 4th Free 07,000 - 07,500 Kms. or 225 days.

5 1st Paid with 09,500 - 10,000 Kms. or 300 days.

Oil change

6 2nd Paid 12,000 - 12,500 Kms. or 375 days.

7 3rd Paid with 14,500 - 15,000 Kms. or 450 days.

Oil change

8 4th Paid 17,000 - 17,500 Kms. or 525 days.

9 5th Paid with 19,500 - 20,000 Kms. or 600 days.

Oil change

10 6th Paid 22,000 - 22,500 Kms. or 675 days.

11 7th Paid with 24,500 - 25,000 Kms. or 675 days.

Oil change

12 8th Paid 27,000 - 27,500 Kms. or 675 days.

13 9th Paid with 29,500 - 30,000 Kms. or 675 days.

Oil change

Warranty

2 Years Or 30,000 Kms.

Warranty

2 Years Or 30,000 Kms.

whichever occurs earlier.

R E S I S T A N C E S

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 10 200 + 30 White/Red Black/Yellow

PICKUP COIL :

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 15 + 3 Red Black/Yellow

CHARGING COIL

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 1.0 + 0.3 Blue/White Black/Yellow

BATTERY CHARGING COIL(KS)

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 1.2 + 0.3 Blue/White Blue/White

BATTERY CHARGING COIL(ES)

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 1.0 + 0.3 Yellow/Red Black/Yellow

LIGHTING COIL (KS)

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 0.7 + 0.3 Yellow/Red Black/Yellow

LIGHTING COIL (ES)

36

L O C T I T E S

CYAN BLACK MAGENTA YELLOW

35

WA R R A N T Y A N D S E R V I C E S

Sr. No. Service Type Kms./days *

1 1st Free with 00,500 - 00,750 Kms. or 30 days.

Oil change

2 2nd Free 02,000 - 02,500 Kms. or 90 days.

3 3rd Free with 04,500 - 05,000 Kms. or 150 days.

Oil change

4 4th Free 07,000 - 07,500 Kms. or 225 days.

5 1st Paid with 09,500 - 10,000 Kms. or 300 days.

Oil change

6 2nd Paid 12,000 - 12,500 Kms. or 375 days.

7 3rd Paid with 14,500 - 15,000 Kms. or 450 days.

Oil change

8 4th Paid 17,000 - 17,500 Kms. or 525 days.

9 5th Paid with 19,500 - 20,000 Kms. or 600 days.

Oil change

10 6th Paid 22,000 - 22,500 Kms. or 675 days.

11 7th Paid with 24,500 - 25,000 Kms. or 675 days.

Oil change

12 8th Paid 27,000 - 27,500 Kms. or 675 days.

13 9th Paid with 29,500 - 30,000 Kms. or 675 days.

Oil change

Warranty

2 Years Or 30,000 Kms.

Warranty

2 Years Or 30,000 Kms.

whichever occurs earlier.

R E S I S T A N C E S

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 10 200 + 30 White/Red Black/Yellow

PICKUP COIL :

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 15 + 3 Red Black/Yellow

CHARGING COIL

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 1.0 + 0.3 Blue/White Black/Yellow

BATTERY CHARGING COIL(KS)

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 1.2 + 0.3 Blue/White Blue/White

BATTERY CHARGING COIL(ES)

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 1.0 + 0.3 Yellow/Red Black/Yellow

LIGHTING COIL (KS)

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 0.7 + 0.3 Yellow/Red Black/Yellow

LIGHTING COIL (ES)

36

L O C T I T E S

Bolt for Plate stopper bearing.

Screw for Pick up mounting on cover.

Screw for Stator mounting on cover.

Allen bolt for Sprocket fitment on cam shaft.

Flanged bolt for Oil pump fitment on crankcase

RH.

Allen bolt for Chain tensioner to crankcase RH.

Flanged bolt for Assembly of crankcase LH & RH.

Allen bolt for Sprocket fitment on output shaft.

Screw for Kick lever.

Flanged bolt for Starter motor fitment on cover RH.

Screw for Starter motor cover.

Flanged bolt for Stopper for plate starter clutch

gear return.

Clutch nut.

Apply before assembly: 638 (Colour - Green)

Guide gear allen bolt.

Kick guide bolts.

Drum stopper arm bolt.

Starter counter one way clutch allen bolts.

Oil separator plate screws.

Bolt holding spring for stopper arm.

Stopper bolt - changer lever spring.

Apply before assembly : 243 (Colour - Blue)

243

CYAN BLACK MAGENTA YELLOW

35

WA R R A N T Y A N D S E R V I C E S

Sr. No. Service Type Kms./days *

1 1st Free with 00,500 - 00,750 Kms. or 30 days.

Oil change

2 2nd Free 02,000 - 02,500 Kms. or 90 days.

3 3rd Free with 04,500 - 05,000 Kms. or 150 days.

Oil change

4 4th Free 07,000 - 07,500 Kms. or 225 days.

5 1st Paid with 09,500 - 10,000 Kms. or 300 days.

Oil change

6 2nd Paid 12,000 - 12,500 Kms. or 375 days.

7 3rd Paid with 14,500 - 15,000 Kms. or 450 days.

Oil change

8 4th Paid 17,000 - 17,500 Kms. or 525 days.

9 5th Paid with 19,500 - 20,000 Kms. or 600 days.

Oil change

10 6th Paid 22,000 - 22,500 Kms. or 675 days.

11 7th Paid with 24,500 - 25,000 Kms. or 675 days.

Oil change

12 8th Paid 27,000 - 27,500 Kms. or 675 days.

13 9th Paid with 29,500 - 30,000 Kms. or 675 days.

Oil change

Warranty

2 Years Or 30,000 Kms.

Warranty

2 Years Or 30,000 Kms.

whichever occurs earlier.

R E S I S T A N C E S

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 10 200 + 30 White/Red Black/Yellow

PICKUP COIL :

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 15 + 3 Red Black/Yellow

CHARGING COIL

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 1.0 + 0.3 Blue/White Black/Yellow

BATTERY CHARGING COIL(KS)

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 1.2 + 0.3 Blue/White Blue/White

BATTERY CHARGING COIL(ES)

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 1.0 + 0.3 Yellow/Red Black/Yellow

LIGHTING COIL (KS)

Range

(Ohms)

Connections Reading

(Ohms) Meter +ve Meter -ve

X 1 0.7 + 0.3 Yellow/Red Black/Yellow

LIGHTING COIL (ES)

36

L O C T I T E S

Bolt for Plate stopper bearing.

Screw for Pick up mounting on cover.

Screw for Stator mounting on cover.

Allen bolt for Sprocket fitment on cam shaft.

Flanged bolt for Oil pump fitment on crankcase

RH.

Allen bolt for Chain tensioner to crankcase RH.

Flanged bolt for Assembly of crankcase LH & RH.

Allen bolt for Sprocket fitment on output shaft.

Screw for Kick lever.

Flanged bolt for Starter motor fitment on cover RH.

Screw for Starter motor cover.

Flanged bolt for Stopper for plate starter clutch

gear return.

Clutch nut.

Apply before assembly: 638 (Colour - Green)

Guide gear allen bolt.

Kick guide bolts.

Drum stopper arm bolt.

Starter counter one way clutch allen bolts.

Oil separator plate screws.

Bolt holding spring for stopper arm.

Stopper bolt - changer lever spring.

Apply before assembly : 243 (Colour - Blue)

243

I MPORTANT ENGI NE ASSEMBLY TI PS

Engine Mounting Bolt Tighten Sequence

Whenever engine is mounted on the frame or during periodic services always

tighten engine mounting bolts in the sequence shown in the figure. This will

ensure proper mounting of the engine and will reduce the vibrations and also

increase the life of mounting rubber bushes.

5

7

6

10

9

8

3

4

2

1

CYAN BLACK MAGENTA YELLOW

38

Confirm the free rotation; shifting of gears after assembling.

Always align the gear box into neutral gear position and then assemble

both the crank cases.

Bolt sizes are different. Ensure 1 longest bolt is fitting in clutch side

crankcase and 1 long bolt is fitting towards breather side cranckase.

Confirm the free rotation of crank shaft and centering of crankshaft.

While fitting kick spring, make sure that spring sharp edge does not

scratch against crankcase surface and damage the surface finish.

Special nut has left hand threads and round cut mark around the nut.

Do not lock the rotor holder special tool against the pickup coil sensor

on rotor and gear change shaft.

Always lubricate the needle roller bearing when over hauled. Incorrect

bolt size fitment on body starter may result in locking of rotor or gear

counter assembly.

Place a piece of clean cloth above hollow portion of crank case to

arrest piston pin circlip if it falls during fitment.

Before fitting the sleeve spark plug apply thin layer of molybdenum

disulphide grease on the entry chamfers for the O rings.

Ensure that the O mark on washer always faces upwards.

Ensure the sprocket marks are aligned horizontally with cylinder head

top machined face and the piston is at TDC.

Improper tightening sequence may cause warpage in cylinder head

cover and it can be damage permanently.

Precautions to be taken while assembling of engine

P R E C A U T I O N A R Y ME A S U R E S

While removing engine foundation bolts, first remove the topmost and

then go down progressively.

After removing all the engine connections lift up and remove the

engine from RHS of the vehicle.

Improper loosening sequence may cause warpage in cylinder head

cover and it can be damage permanently.

Drain the engine oil into a clean tray by loosening and removing

strainer cap located on LH side of crankcase.

As fas as possible do not let oil to wet the top of the piston, or the

combustion chamber in the cylinder.

If cylinder block is tight in dowels, lightly tap with hands in upward

direction. If still tight use a plastic or woodem rod and pry it upwards.

When taping the drift for removal of gudgeon pin, confirm that the

connecting rod is held firmly against the direction of tapping to avoid

damage to big end bearing of crank shaft.

Starter cover base is fitted on the crankcase with liquid gasket

application hence tap gently for easy detachment.

Clutch nut have left hand threads.

Precautions to be taken while dismantling of engine

37

I MP O R T A N T E N G I N E A S S E MB LY T I P S

Input Shaft has special nut.

Input Shaft has Left hand threads.

No need of applying Loctite 243.

Washer for Input shaft nut is same as of primary gear.

The special nut has ring mark for identification.

Secure the cam chain sprocket by the tool given

below firmly and then tighten the sprocket allen bolt

(A).

Ensure that the O mark on washer always faces

outwards when tightening the allen bolt (A).

Valve timing

Ensure the sprocket marks (A) are aligned

horizontally with cylinder head top machined face.

Ensure the piston is at TDC.

Ensure T mark on rotor matching the ccase mark.

The clutch collar having hole is to be slided into the

clutch housing for effective lubrication.

Bigger gear to be assembled facing the dust cap side

while assembling the starter counter gear.

Chain top edge to be kept between the two marks

during chain slackness adjustment.

Remove the allen head grub screw before removing

the sleeve spark plug.

Before fitting the sleeve spark plug apply thin layer or

molybdenum di-sulphide grease on the entry

chamfers for the O rings.

Always blow compressed air through the oil

passages in reverse direction of oil flow and ensure

the passages are clear.

Apply a thin layer of liquid gasket on body of the

starter cover.

When splitting crankcase always remove.

First : 1 longest bolt fitted from clutch side.

Second : 1 long bolt fitted from magneto side and

then remove all bolts from magneto side.

A A

A

CYAN BLACK MAGENTA YELLOW

39

F R E Q U E N T LY A S K E D Q U E S T I O N S - F A Q S

What are the features of Discover DTS-i motorcycle?

B Discover DTS-i has many Unique; Advanced & Contemporary

features as mentioned below.

Unique Features:

High Power of____________ 11.51 Ps.

Greater Torque of_________ 10.80 N-m.

Max. Speed of____________100 Kmph.

Least emission of CO, so great environment friendly vehicle.

Unique and cute Headlamp fairing with twin pilot lamps and

option of Round Headlamp as well that matches to the profile of

the vehicle.

Advanced Features:

Digital Twin Spark Ignition System (DTS-i) with Twin Map for

accurate ignition timing.

Throttle Responsive Ignition Control System (TRICS).

Optimized engine combustion characteristics to provide ultimate

performance.

Contemporary Features:

Strongest & Sturdier frame & stiffer rectangular cross-sectioned

swing arm to with stand twists and all kind of road tortures.

Longest wheel base in its class for better road holding

characteristics.

Highest rear wheel travel to ensure most comfortable ride in all

terrain.

Longest fr. suspension travel in its class to provide pleasant ride.

Brightest Headlamp with 60 / 55 Watt Halogen bulb for safer night

ride.

What is DTS - i ?

B DTS-i stands for Digital Twin Spark Ignition - an Advanced Technology

which will be the heart of a new breed of high performance engines

from Bajaj.

What is the Advanced Technology in DTS-i ?

B DTS-i engines incorporate Two Spark Plugs (hence called Twin Spark)

in the cylinder head, a Microprocessor controlled (like computers)

Digitally operated CDI which accurately controls the Ignition Timing

and TRICS or Throttle Responsive Ignition Control System, which is a

non-contact switch on the Carburetor body and this changes the

Ignition Map based on Throttle position.

B Combined actions of these technological breakthroughs enhances the

Overall Performance likes Power, Pick-up, and Mileage etc.

Why Twin Spark Plugs ?

B Conventionally in a 4-stroke engine the spark plug is at one end of the

combustion chamber. It means the Air fuel mixture combustion is

better around the sparkplug, rather than the opposite side of the

combustion chamber. Because of the longer time needed for the

combustion to take place on the far side (opposite side of the spark

plug) overall combustion is slow, leading to poor combustion efficiency.

In fact Discover DTS-i delivers power & performance of 125 cc

engine and economy of 100 cc engine. More over the Comfort,

Convenient & Safety are ultimate to any motorcycle on Indian road

with the capacity of 100 to 135 cc engine.

40

F R E Q U E N T LY A S K E D Q U E S T I O N S - F A Q S

B Placing another Spark plug opposite to the original one enables the

sparks to occur simultaneously, thus reducing the time for combustion

to take place, thereby increasing combustion efficiency and its speed

with tremendous benefits.

What is the DIGITAL in Digital Twin Spark ignition ?

B Conventional Analogue type CDIs work in a very constricted manner.

They are unable/constrained to control the ignition advance or retard

for specific points in the entire engine rpm range. They could either

advance or retard but not do both for specific points in the engine rpm

range.

B The Ignition System of DTS-i is Digitally operated. An 8 bit

Microprocessor is programmed to decide and control the Ignition

Advance or Retard at any point in the entire engine rpm range. It is

like a computer being programmed to run in a specific way. There is

tremendous consistency and accuracy in the Ignition Timing, which

enhances the overall Performance.

B This Digital CDI has also been programmed to cut the sparks to the

spark plugs at high rpms thereby preventing anybody from damagi ng

the engine. All these advantages are only possible with Digital Chips.

What is TRICS and what is so special about it ?

B A non-contact type switch is mounted on the cable pulley shaft of the

Digital CDI to change the Ignition Advance/Retard map. The amount

of angular movement of the cable pulley shaft depends on the speed

and load demands of the Rider.

B With the adaptation of TRICS, the engine also becomes highly Knock

resistant.

B Throttle Responsive Ignition Control System activates and swaps

between two different Ignition Maps for getting an optimum Ignition

Advance/Retard Timing, for different speed an load conditions. The

switching over of the Ignition maps is Seamless and the switch itself is

completely maintenance free for the life of the Vehicle.

What are the benefits of DTS-i in a nutshell ?

B Digitally managed Optimum Ignition Timing over the entire engine rpm

range for more accuracy and efficiency. And faster & complete

combustion process leading to complete utilization of air-fuel

mixture and thereby results in

Enhanced Power.

Enhanced Pick-up.

Enhanced Mileage.

Enhanced Drivability in all engine operating conditions.

Less Emission of CO. that meets 2005 Emission norms.

Can existing non DTS-i 2 Wheelers be converted into DTS-i

technology ?

B No, the DTS-i technology demands major technological changes in

the engine and vehicle, hence it is almost impossible to convert an

existing 2-wheeler to accept DTS-i technology.The conversion is not

economically viable, as it means almost a complete replacement of

the vehicle/engine.

Does DTS-i costs more in Maintenance ?

B No. The DTS-i technology is tried and tested under extreme

conditions by Bajaj Auto Limited. The systems/parts of DTS-i are

virtually maintenance free.

CYAN BLACK MAGENTA YELLOW

41

F R E Q U E N T LY A S K E D Q U E S T I O N S - F A Q S

How DTS-i is different from VT-I in TVS Centra and AMI in Hero

Honda Ambition ?

B VT-I of TVS Centra and AMI of Hero Honda Ambition only have

swithchable Ignition timing maps and Digital CDIs. The switch of TVS

Centra is not Maintenance free and the switch of Hero Honda

Ambition is a contact type, which means problems or wear and tear.

Why the Tyre size is of 17" where as normally all other

motorcycles traditionally have 18" tyres?

B Discover DTS-i motorcycle has some special geometry as far as

Ride Comfort & Pleasure is concerned. The Specialties are

The longest Wheel Base >>> 1305 mm.

Lowest Center of Gravity.

Longest Front Suspension Travel >>> 135 mm.

Wider distance between both Front fork tubes.

Rear Shock Absorber having Triple Rating Spring & longer stroke.

>>> 85 mm.

Longest Rear Wheel Travel. >>> 110 mm.

All these things are enabling Discover DTS-i to deliver Excellent

Road holding, Better Balancing and Extra ordinary High speed

Stability. With this, there is absolutely no need of 18" tyre.

B Rather here, the 17" tyre, due to reduced weight and lesser road

contact area, it will contribute in enhancing the mileage as compared

to 18" tyre.

DTS-i technology from Bajaj Auto Limited is the future of bikes.

Why Dual Oil Filtration system is not given in Discover DTS-i

where as this feature is given in Wind 125?

B Discover DTS-i engine too has dual oil filtration system. The first

stage filtration is done by extra large strainer with fine mesh. And the

second stage filtration is taken care by in built Centrifugal Oil filter

mounted on crankshaft.

B With extra large strainer and Centrifugal Oil filter, the level of filtration

would be similar to the engine having Primary Strainer and Paper Oil

filter.

Being 125 cc and having higher power, why Discover DTS-i has

not been incorprated with 5-speed gear transmission ?

B Considering utilization of power produced by this engine, to achieve

better low-end torque, pick up and to obtain maximum mileage gear

ratios have been uniformly spread across all gears appropriately. With

this 4-speed transmission is enough to perform the task.

When Discover DTS-i has so advanced engine, then how come

SAI system & BS Valve is not provided in this?

B That is one of the speciality of DTS-i engine. The optimized

combustion process because of two Spark plugs, Digitallyma n a g e d

accurate Ignition and TRICS all together address the advantages of

low emission, better cold startability, enhanced drivability delivered by

SAI System and B S Valve.

B That means, again lesser the components, more the benefits.

Why primary kick mechanism isnt provided in Discover DTS-i

engine?

B To reduce engine components which minimizes the engine weight as

42

F R E Q U E N T LY A S K E D Q U E S T I O N S - F A Q S

well, the kick mechanism is provided is similar to Caliber & Boxer

range of motorcycles.

B Minimized weight contributes in enhancing the mileage and lesser the

components contribute to cost benefits, which we can pass on to our

valued customers.

Why De-compression mechanism like in Pulsar engines is not

provided in Discover DTS-i engine?

B Normally De-compression mechanism is required in higher capacity

engines where one would feel resistance in operating the kick while

starting the engine. Discover DTS-i engine does not require this.

Why Aircraft Type Fuel Tank Cap similar to Pulsar Fuel Tank Cap

is not provided ?

B Petrol tank caps are designed considering shape of Petrol Tanks. The

cap provided on Discover Petrol tank goes well with its shape.

Why the engine noise level is towards higher side in Discover

DTS-i?

B As we have seen that the Discover DTS-i engine is designed and

developed to achieve optimized combustion process. This is achieved

by having higher compression ratio and so many other design

parameters related to Intake and combustion process.

B This complete combustion process will generate some combustion

noise. This noise will be a characteristic of high performance engines

like DTS-i engines.

To minimize this noise, & control vibrations as well, rubber dampers

have been incorporated in the clutch cover & magneto cover.

B Still such noise will always be heard on high performance engines. So

to achieve more from the limited capacity engines we need to accept

the facts.

Of course this fact is not harmful and will not effect on the

performance of the engine.

Why 4-Plate clutch on this engine, where as Wind 125 and

Pulsar engines have 5-Plate clutch ?

B The clutch of Discover DTS-i engine is bigger so the plates (friction

plates) are wider in size. Due to this, the more contact area in line

with 5-Plate clutch is obtained. With this, 4-Plate clutch is big enough

to handle power transmission characteristics.

Why Crankshaft Balancer is not provided in Discover DTS-i

engine?

B The Crankshaft design and geometry is optimized and the Static &

Dynamic balancing factors are well taken care by this crankshaft with

respect to relative rotating components. Thus the crankshaft of

Discover DTS-i engine does not need balancer.

How come 'Discover DTS-i' is expected to give better mileage in

spite of higher capacity 125cc engine?

B So many parameters aspects are incorporated in Discover DTS-i' to

enable it deliver better mileage.

B On technological front, as we have seen so far the package of DTS-i

like Twin Spark Plugs, Digital CDI, Twin Ignition Maps & TRICS in this

Lean Burn engine, all together have improved combustion process

that is leading to -

Complete combustion of air - fuel mixture.

CYAN BLACK MAGENTA YELLOW

F R E Q U E N T LY A S K E D Q U E S T I O N S - F A Q S

0

5

10

15

Power 11.51 8 7.5

Torque 2 0.98 0.9

Discover CT 100 Passion+

7.5

0.9

Splendor

7.7

0.82

Crux

8

0.92

Freedom

0

5

10

15

Power 11.51 10.8 10.7 9.66

Torque 2 1.06 1.07 0.97

Discover Fazer Fredom 125 Victor 125

Will 125 cc bikes become standard on the road as against current

100cc bikes?

B 100 cc bikes are plying on Indian roads now for over a decade. It's a

normal tendency of a person that when he plans to change the

vehicle, he always look for better better power, better capacity, better

pick up. And when because of advancement in engine technology, if

better capacity, say 125 cc engines offers similar economy of 100 cc,

then it influences the trend. We strongly feel 125cc bikes wil become

standard on the Indian road and 100cc bikes will go the way mopeds

have gone.

Does Discover has all the technologies of Pulsar? OR Is DTS-i in

Discover DTS-i' different than in Pulsar?

B The DTS-i technology as such from Bajaj is the same on Pulsar as

well as Discover. The package of DTS-i that comprises Twin Spark

Plugs, Digital CDI, Twin Ignition Maps and TRICS are very much

there and function similar as in case of Pulsar. But the values of

performance are as per the respective engine requirements.

B You can very well see that how the DTS-i technology has enabled

Discover DTS-i' to be close to its Big Brother Pulsar 150 cc.

B Discover DTS-i' almost equal to Regular Pulsar 150 cc and close to

Pulsar 150 cc with DTS-i engine. The table below indicates the

comparison.

B More over it even looks like mini Pulsar as well.

Is 125cc Discover DTS-i' is poor man's Pulsar?

B Yes. Why not? It not only resembles Pulsar in masculine physique but

also it is quite sturdier and rigid in built. The Frame, the square box

swing arm all makes it as strong as Pulsar. So it is a mini Pulsar with

economy.

Power Torque

Maximum

Speed

Vehicle

13.02 Ps

11.68 N-mm

(1.19 Kg-m)

120 Kmph Pulsar DTS-i 150 cc

Pulsar 150 cc Regular

Discover DTS-i

12 Ps

10.8 N-m

(1.1 Kg-m)

100 Kmph

11.51 Ps

10.8 N-m

(1.1 Kg-m)

> 100 Kmph

Combustion at accurate timing with respect to engine rpm at

different speeds and loads on the engine.

Altering of Ignition timing depending upon different throttle

positions.

As these activities consistently take place, the fuel efficiency is bound

happen in Discover DTS-i' engine.

Moreover, other certain virtual elements are there to support this

engine for delivering better mileage. The other virtual elements are -

Lesser weight of the engine as compared to other 125 CC engines.

Lesser road resistance due to lesser road contact area on account

of 17" tyres.

Virtual Instructor to the Rider in the form of Ride Control Switch' to

ride the vehicle in Fuel Efficiency Zone'.

Truly speaking, if Discover DTS-i' is ridden within 'Fuel Efficiency

Zone' as per instruction of Ride Control Switch, it can put all other 125

CC engined vehicles on shame and even able to compete shoulder to

shoulder with other 100 CC engined vehicles.

What is Exhaust TEC'?

B Exhaust TEC is a device incorporated in exhaust system of Discover

DTS-i engine. TEC stands for Torque Expansion Chamber. It

improves Scavenging process.

B The exhaust system has this revolutionary feature, which drastically

improves engine torque at low revs without compromising anything at

mid or high engine revs. It has been extensively optimized to get the

maximum possible performance out of the engine. The Silencer also

has a characteristic tonal quality to it. It gives out a pleasant sounding

F R E Q U E N T LY A S K E D Q U E S T I O N S - F A Q S

low frequency boom, which many people associate with the typical

'Bullet' kind of silencer sound. While meeting the mandatory current

Noise norms, it gives the vehicle an identity, which is different from

any other bike, so as to make it very unique.

Normally higher power bikes are heavier in weights. How about

Discover?

B Higher the Power Heavier the Engine has become now a vintage

story (or has become a old proverb) Bajaj R & D with its capability has

engineered and developed Discover DTS-i engine with Higher Power

to Weight Ratio as compared to other 125 CC engines.

B On one side it was successful to make the engine deliver more power

and on the other side it has tried to reduce the engine weight by

simplifying the design as compared to other 125 CC engines.

B The Power to Weight Ratio that means the Power produced per ton

weight of the vehicle in comparison with other vehicle is given below.

Is Power & Pick-up of Discover DTS-i marginally or substantially

better than current 100 cc popular bikes or there's a substantial

improvement?

B No. The Power & Pick up of Discover DTS-i is far.. far better than

the popular 100 CC bikes and even much better than any other 125 CC

bike on the road.

B The Power & Torque comparison is follows.

Discover Victor 125 Fazer

Freedom

Prima 125

Power to Weight

Ratio i.e. Power per

Ton weight of the

vehicle

92 81.86 86.4 96.39

43

You might also like

- Manual Discover 150 SDocument80 pagesManual Discover 150 SStef Incio20% (5)

- Bajaj Catalogo de Partes Pulsar NS160 BSIVDocument77 pagesBajaj Catalogo de Partes Pulsar NS160 BSIVPato ErazoNo ratings yet

- Discover 125 - TRG Note-IbDocument49 pagesDiscover 125 - TRG Note-Ibviaerea100% (1)

- Pulsar - DTSi - UG - III - Workshop Manual 1 PDFDocument16 pagesPulsar - DTSi - UG - III - Workshop Manual 1 PDFNadeem AnsariNo ratings yet

- Avenger 200 SPC BAJAJDocument45 pagesAvenger 200 SPC BAJAJJuan Manuel OrtegaNo ratings yet

- Bajaj Pulsar Service Manual PDFDocument2 pagesBajaj Pulsar Service Manual PDFRandy Jurasic0% (2)

- Pulsar 135 Service Manual (Training Notes)Document86 pagesPulsar 135 Service Manual (Training Notes)M-DIY Exposing Lies67% (3)

- Bajaj - Pulsar135 PDFDocument74 pagesBajaj - Pulsar135 PDFMalik Muhammad100% (2)

- Pulsar 220 Dtsi Service ManualDocument4 pagesPulsar 220 Dtsi Service ManualCesar castro0% (1)

- XCD 125-SPC 30-03-2011 ExportDocument51 pagesXCD 125-SPC 30-03-2011 ExportWilly Mansilla ANo ratings yet

- Ct100 SPC ModifiedDocument44 pagesCt100 SPC Modifiedstwen4669986% (7)

- RTR 160 Service ManualDocument80 pagesRTR 160 Service Manualnox250585% (20)

- Pulsar 220 Workshop Manual ENGLISHDocument45 pagesPulsar 220 Workshop Manual ENGLISHTim ChesbroNo ratings yet

- Discover 125Document85 pagesDiscover 125Michael FelicianoNo ratings yet

- Pulsar 125Document91 pagesPulsar 125Vicky NimbarkNo ratings yet

- Scaner ManualDocument22 pagesScaner ManualAnonymous iaqwR2gZ28100% (4)

- Pulsar 180 Ug4Document67 pagesPulsar 180 Ug4Daniel GutierrezNo ratings yet

- Hero Honda Splendor PlusDocument7 pagesHero Honda Splendor Plusvickypraba57% (7)

- Pulsar 135 LS SPC PDFDocument78 pagesPulsar 135 LS SPC PDFErik HardyNo ratings yet

- Bajaj Pulsar 135 LS ManualDocument35 pagesBajaj Pulsar 135 LS Manualgary4gar86% (14)

- Manual de Pulsar Rs 200 - Set15Document78 pagesManual de Pulsar Rs 200 - Set15Anonymous iaqwR2gZ2867% (3)

- Owner's Manual Pulsar NS160Document52 pagesOwner's Manual Pulsar NS160arNo ratings yet

- SPC CT 110 Es Ks Bs Vi Ug Rev 05 Aug 212Document74 pagesSPC CT 110 Es Ks Bs Vi Ug Rev 05 Aug 212Bharat MalviyaNo ratings yet

- Pulsar 200 NS - MANUAL DE PARTESDocument77 pagesPulsar 200 NS - MANUAL DE PARTESLorenaHernandezNo ratings yet

- 48Document24 pages48prakash amat100% (1)

- Stylus C41SX C41UX C42SX C42UX C42S C42+ Parts List and Diagram PDFDocument9 pagesStylus C41SX C41UX C42SX C42UX C42S C42+ Parts List and Diagram PDFDeniskoffNo ratings yet

- Bajaj Pulsar 150 Dts IDocument75 pagesBajaj Pulsar 150 Dts IErick100% (1)

- Pulsar N-160 BS6 - SPCDocument78 pagesPulsar N-160 BS6 - SPCrefaccionariabajaj.camp267% (3)

- TVS Apache RTR 180 Service Manual Internal Training Manual Rev1Document28 pagesTVS Apache RTR 180 Service Manual Internal Training Manual Rev1Jhonatan ContrerasNo ratings yet

- Hayate 110 PDFDocument68 pagesHayate 110 PDFvivek0630100% (7)

- Spare Parts Catalogue: Bajaj Auto LimitedDocument71 pagesSpare Parts Catalogue: Bajaj Auto Limitedsanjika luckruwan100% (1)

- Boxer S SPC - FinalDocument57 pagesBoxer S SPC - Finalstwen4669971% (7)

- Boxer 150 - 150X InglesDocument60 pagesBoxer 150 - 150X InglesPato Erazo67% (6)

- TVS - Sport 100 - 2012Document43 pagesTVS - Sport 100 - 2012magentaNo ratings yet

- 26 Manual de Servicios Pulsar 150 y 180 UGDocument404 pages26 Manual de Servicios Pulsar 150 y 180 UGFelipe Rodriguez0% (1)

- DISCOVER 125 (Re-Introduced) - 150 BSIII - SPCDocument82 pagesDISCOVER 125 (Re-Introduced) - 150 BSIII - SPCricardo geliz100% (1)

- Discover 150 STDocument82 pagesDiscover 150 STRobertoNo ratings yet

- Pulsar 180 2007 - 61 - 28 - 2Document77 pagesPulsar 180 2007 - 61 - 28 - 2Swapnil SolaskarNo ratings yet

- ApacheDocument15 pagesApacheevelioNo ratings yet

- Manual de Partes Discover 125 ST 0Document71 pagesManual de Partes Discover 125 ST 0Sumit Sharma33% (3)

- Pulsar 220 - FIDocument46 pagesPulsar 220 - FIsupercool_sidd86% (7)

- MANUAL DE SERVICIO WIND 125 InglesDocument21 pagesMANUAL DE SERVICIO WIND 125 Inglesaxxellaxxe100% (6)

- Sym Joyride-Periodical Maintenance ScheduleDocument2 pagesSym Joyride-Periodical Maintenance SchedulesymuserNo ratings yet