Professional Documents

Culture Documents

Diff Moc Weld

Uploaded by

yokelomeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diff Moc Weld

Uploaded by

yokelomeCopyright:

Available Formats

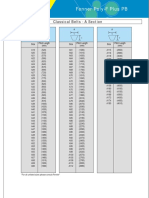

ASME P NO

STEEL

TYPE

25 CR 20 NI

(310)

18 CR 12 NI

2-3 MO

(316,317)

18 CR 8 NI

Cb or Ti

(347,321)

18 CR 8 NI

(304)

2.5 CR

3.5 MO

9 CR

0.5 MO

7 CR 0.5

MO

5 CR

0.5 MO

2.25 CR

1 MO

1.25 CR

0.5 MO

0.5 CR

0.5 MO

CARBON

MOLY

PLAIN

CARBON

1

PLAIN

CARBON

15 a EA*

16,17aEA

15 a EA*

16,17aEA

15 a EA*

16,17aEA

15 a EA*

16,17aEA

15cA

2cA

2aDC 2aDC 2aDC 2dGCD 2cGCD 2bFB 4,2bFB 2,1,3aEA

3

CARBON

MOLY

15 b FB*

16,17bFB

15 b FB*

16,17bFB

15 b FB*

16,17bFB

15 b FB*

16,17bFB

15cA

2cA

4,5eDC 4,5eDC 4,5aDC 4,5dGCD 4,5cGCD 4,5bFB 4,3bFB

3

0.5 CR

0.5 MO

15 b FB*

16,17bFB

15 b FB*

16,17bFB

15 b FB*

16,17bFB

15 b FB*

16,17bFB

a 5aDC 5eDC 5aDC 5dGCD 5cGCD 5bFED

4

1.25 CR

0.5 MO

15cGC*

16,17cGC

15cGC*

16,17cGC

15cGC*

16,17cGC

15cGC*

16,17cGC

a 5aDC 5eDC 5aDC 5dGCD 5cGCD

5

2.25 CR

1 MO

15dGC*

16,17dGC

15dGC*

16,17dGC

15dGC*

16,17dGC

15dGC*

16,17dGC

a 6aDC 6aDC 6aDC 6dGCD a.

5

5 CR

0.5 MO

15eD*

16,17eD

15eD*

16,17eD

15eD*

16,17eD

15eD*

16,17eD

a 8aDC 8aDC 8aDC b.

5

7 CR

0.5 MO

15eD*

16,17eD

15eD*

16,17eD

15eD*

16,17eD

15eD*

16,17eD

a 9aDC 9aDC c.

5

9 CR

0.5 MO

15eD*

16,17eD

15eD*

16,17eD

15eD*

16,17eD

15eD*

16,17eD

a 10eDC d.

9

2.5 CR

3.5 MO

15cA*

16,17cA

15cA*

16,17cA

15cA*

16,17cA

15cA*

16,17cA

7cAb e.

8

18 CR 8 NI

(304)

15,11 aHd 11,13aHd 11,12aHd 11aHd

8

18 CR 8 NI

CB OR TI

(347,321)

15,12 aH 12,13aHd 12aHe

8

18 CR 12 NI

2-3 MO

(316,317)

15,13 aH 13aHcd

8

25 CR

20 NI (310)

14aH *

1. E6010-11 7. E80XX-C2 13. E316-XX

2. E70XX 8. E502-XX 14. E310-XX

3. E7010-A1 9. E7CR-XX 15. E309-XX A

4. E7018-A1 10. E505-XX 16. ENiCrFe-3 B

5. E80XX-B2 11. E308-XX 17. ENiCrFe-2 C

6. E90XX-B3 12. E347-XX D

a NONE # # Filler Metal Notes: E None for 3/4" max . Thickness.

b 150F MIN * Digits"XX" represent 15,16 or 18 low hydrogen coatings. F None for 5/8" max . Thickness.

c 250F MIN * Above filler metal comply with the following G

d 300F MIN 1-2-AWS A5.1 ASTM A233 8-15 AWS A5.4 ASTM A298

e 400F MIN 3-7-AWS A5.5 ASTM A316

* Items 16 and 17 refers to Inconel filler materials. H None for normal service.

such as inconel "182" or equal and Inco Weld A,

or equal,respectively. POST WELD HEAT NOTES.

* Where two or more filler materials are listed the Above condition may vary form differten code.

first is preffered unless otherwise indicated. For 70 kpsi carbon steel do not exceed 1250 F.

SELECTION ARE LISTED FOR BASE METAL TO 3/4" THK.

For low carbon base metal e.g. 304L,316L etc are use low carbon or

stabilized filler metals.e.g.E304L,E316L,E347 or E348.

Type 321 filler metalavailable for inert gas welding only.

Low nickel to low chrome dissimilar joints are infrequently used.

E80XX-C1 electrods should be used when joining 2.5 NI to 2.5 NI

material, otherwise follow 3.5 NI procedure.

E317-xx should be used to joining 317 SS itself,otherwise follow

316SS procedure.

Filler Materials

AWS-ASTM Designation

1100-1250 F

1100-1200 F

Do not use weldments operating above 650 F or

subject to cyclic load.

POST WELD HEAT TREATMENT

PREHEAT AND INTERPASS TEMP.

REQUIREMENT

TEMP IS BELOW THAN 32'F.

MOISTURE REMOVAL.

* HEAT BASE METAL SURFACE TO G32 F FOR

* PREHEAT AND HOLD MIN 50'F WHEN AMBIANT

HEAVEOR SECTIONS OR ASSEMBLIES MAY REQUIRED

HIGHER PRE HEAT TEMP.

AVOID THERMAL GRADIANTS ACROSS PLAIN THK.

FOR CONDITION "a"

PREHEAT RATESS SHOULD BE CONTROLLED TO

1325-1375 F

Anneal (1650 F)

PREHEATING NOTES:

16-17 AWS ASTM B295 A5.11

None for 4 1/2" max .O.D. and 1/2" max wall pipe girth

joint.Use of lower carbon electrod B2L or B3L is

recomonded.

You might also like

- 3 05 A Welding Specification of Carbon Steel Alloy SteelDocument40 pages3 05 A Welding Specification of Carbon Steel Alloy SteelvancongthanhNo ratings yet

- Welding Chart The Complete Reference Guide To WeldingDocument2 pagesWelding Chart The Complete Reference Guide To WeldingJitu JenaNo ratings yet

- Stainless Steel Welding by Weld RealityDocument50 pagesStainless Steel Welding by Weld RealitylightwinterdayNo ratings yet

- Filler Rods and Wires For Stainless Steel: Gas Tungsten Arc WeldingDocument1 pageFiller Rods and Wires For Stainless Steel: Gas Tungsten Arc WeldingKarthikeyan ShanmugavelNo ratings yet

- Sac, Çubuk & Kütükler Shapes, Plates &bars Sac, Çubuk & Kütükler Astm/Asme DIN StasDocument4 pagesSac, Çubuk & Kütükler Shapes, Plates &bars Sac, Çubuk & Kütükler Astm/Asme DIN StaseragornNo ratings yet

- Materials Vs ConsumablesDocument1 pageMaterials Vs ConsumablesElizabeth SpenceNo ratings yet

- Welding GuideDocument48 pagesWelding Guideedu_canete100% (2)

- AES-W-016 welding filler metalsDocument2 pagesAES-W-016 welding filler metalsmalika_00No ratings yet

- Cross Reference of Astm Material Specifications Covering Cast and Equivalent Forged ValvesDocument1 pageCross Reference of Astm Material Specifications Covering Cast and Equivalent Forged ValvesmuhammedemraanNo ratings yet

- Welding Electrode ChartDocument2 pagesWelding Electrode ChartZaheed Manoo50% (2)

- Valve Material EquivalentsDocument3 pagesValve Material EquivalentsAndre Villegas Romero100% (1)

- Metrode Cryogenic ER316 B-38Document5 pagesMetrode Cryogenic ER316 B-38Claudia MmsNo ratings yet

- International Standard ReferenceDocument14 pagesInternational Standard ReferenceKARTHIGEYAN.RNo ratings yet

- Pipes General - Materials Equivalent Used ASTM Grades Bolts NutsDocument4 pagesPipes General - Materials Equivalent Used ASTM Grades Bolts Nutsskilach100% (1)

- 7 classes of dissimilar steel filler metalsDocument1 page7 classes of dissimilar steel filler metals911targa100% (1)

- Material WeldingDocument1 pageMaterial WeldingDebashish ChatterjeeNo ratings yet

- Pamela Anderson's SMAW and GTAW filler metal selection guideDocument10 pagesPamela Anderson's SMAW and GTAW filler metal selection guideJames RodriguezNo ratings yet

- Valve DetailDocument5 pagesValve DetailRakesh RanjanNo ratings yet

- Gestra Check ValveDocument4 pagesGestra Check Valvetilakthakar1No ratings yet

- ASTM Standards 1Document4 pagesASTM Standards 1balajiNo ratings yet

- ASTM Grades ExplainedDocument4 pagesASTM Grades ExplainedAnonymous 6ZWS6IG2J9No ratings yet

- W.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden RussiaDocument1 pageW.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden RussiaDouglas CortezziNo ratings yet

- Steel Info 02Document28 pagesSteel Info 02yw_oulalaNo ratings yet

- Piping ComponentDocument19 pagesPiping Componentreach_arindomNo ratings yet

- Cevi UniDocument6 pagesCevi UniGoran PatekNo ratings yet

- Alloy Steels Nickel Cobalt AlloysDocument1 pageAlloy Steels Nickel Cobalt AlloysMichaelben MichaelbenNo ratings yet

- Carbon steel impact test materialsDocument4 pagesCarbon steel impact test materialsnike_y2kNo ratings yet

- ASTM Grades Explained for Pipes, Fittings, Flanges & MoreDocument4 pagesASTM Grades Explained for Pipes, Fittings, Flanges & Moremohan babuNo ratings yet

- FCAW - Flux Coredpowder Cored WiredDocument40 pagesFCAW - Flux Coredpowder Cored WiredGabor VatoNo ratings yet

- MaterialsDocument1 pageMaterialsakv030011No ratings yet

- Recom. de Soldadura XARDocument4 pagesRecom. de Soldadura XARelias667No ratings yet

- PIPING MATERIALS COMPARISON TABLEDocument12 pagesPIPING MATERIALS COMPARISON TABLEJay Vinoth100% (2)

- Trim Number Chart API ValveDocument2 pagesTrim Number Chart API ValveJuliusMaximus12No ratings yet

- Metrode Dissimilar Consumable SelectorDocument7 pagesMetrode Dissimilar Consumable SelectorClaudia MmsNo ratings yet

- Boiler Tube 01 PDFDocument2 pagesBoiler Tube 01 PDFseaqu3stNo ratings yet

- Cat 4160-SC A00 ParkerDocument8 pagesCat 4160-SC A00 ParkerFabian Antonio RoldanNo ratings yet

- Zetkama Globe Valves 215Document16 pagesZetkama Globe Valves 215qazi12No ratings yet

- Equivalent Valve Forged CastDocument1 pageEquivalent Valve Forged CastdicintraNo ratings yet

- FSH TigDocument105 pagesFSH TigChee WeiNo ratings yet

- Astm GradesDocument3 pagesAstm GradeszackjipangNo ratings yet

- Consumable ProcedureDocument4 pagesConsumable ProcedureshifaniNo ratings yet

- Electrode SelectionDocument1 pageElectrode SelectionAbhishek Nag100% (1)

- SS - Filler Wire SelectionDocument26 pagesSS - Filler Wire SelectionBaraa AzebNo ratings yet

- Steel - Equivalent GradesDocument17 pagesSteel - Equivalent Gradessmsett100% (5)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- Pulley Information and Centre Distance Allowances: Table 3. Dimensions of Standard V-Grooved PulleysDocument1 pagePulley Information and Centre Distance Allowances: Table 3. Dimensions of Standard V-Grooved PulleysyokelomeNo ratings yet

- Pulley Dimensions and Belt Specifications TableDocument1 pagePulley Dimensions and Belt Specifications TableyokelomeNo ratings yet

- GK ChartDocument1 pageGK ChartyokelomeNo ratings yet

- 2 Rupees India Complete Signature Set (B-1 To B-36)Document1 page2 Rupees India Complete Signature Set (B-1 To B-36)yokelomeNo ratings yet

- Home About Us Contact Us Product Info Links Customer Login View BasketDocument2 pagesHome About Us Contact Us Product Info Links Customer Login View BasketyokelomeNo ratings yet

- 2 Rupees India Complete Signature Set (B-1 To B-36)Document1 page2 Rupees India Complete Signature Set (B-1 To B-36)yokelomeNo ratings yet

- APISeal CodingDocument1 pageAPISeal CodingyokelomeNo ratings yet

- V Belt LengthDocument2 pagesV Belt LengthtabuliniNo ratings yet

- Scan App Review - CamScanner PDF ScannerDocument2 pagesScan App Review - CamScanner PDF ScanneryokelomeNo ratings yet

- Stationary Sealing Rings for Rotating EquipmentDocument6 pagesStationary Sealing Rings for Rotating EquipmentyokelomeNo ratings yet

- Restructuring of Spares Planning Group As Per Category Codes Wef 03/10/17Document1 pageRestructuring of Spares Planning Group As Per Category Codes Wef 03/10/17yokelomeNo ratings yet

- Scan Doc by CamScannerDocument1 pageScan Doc by CamScanneryokelomeNo ratings yet

- Electrical Safety 0001Document4 pagesElectrical Safety 0001yokelomeNo ratings yet

- FSMDocument4 pagesFSMyokelomeNo ratings yet

- Square Keyway TolerancesDocument4 pagesSquare Keyway TolerancesyokelomeNo ratings yet

- Home About Us Contact Us Product Info Links Customer Login View BasketDocument2 pagesHome About Us Contact Us Product Info Links Customer Login View BasketyokelomeNo ratings yet

- Metric Key Keyway DimensionsDocument1 pageMetric Key Keyway DimensionsyokelomeNo ratings yet

- ASGP MECHANICAL PARTS LISTDocument1 pageASGP MECHANICAL PARTS LISTyokelomeNo ratings yet

- Synchronous BeltsDocument6 pagesSynchronous BeltsyokelomeNo ratings yet

- Classical BeltDocument3 pagesClassical BeltyokelomeNo ratings yet

- Code SeriesDocument1 pageCode SeriesyokelomeNo ratings yet

- Metric FastenersDocument5 pagesMetric Fastenerskh_thakor1983No ratings yet

- Material Specification ChartDocument1 pageMaterial Specification ChartIdu Baz AzharNo ratings yet

- All The Information at - One - PlaceDocument134 pagesAll The Information at - One - PlaceDeepthy VasavanNo ratings yet

- Pipe Schedule AllDocument1 pagePipe Schedule AllyokelomeNo ratings yet

- 1st InstructionDocument1 page1st InstructionyokelomeNo ratings yet

- INDIAN Steel TableDocument6 pagesINDIAN Steel TableKingshuk SarkarNo ratings yet

- Material Specification ChartDocument1 pageMaterial Specification ChartIdu Baz AzharNo ratings yet

- New Microsoft Office Excel 2007 WorkbookDocument1 pageNew Microsoft Office Excel 2007 WorkbookRahul BagraitNo ratings yet

- Wet Scrubbers 022002 PDFDocument8 pagesWet Scrubbers 022002 PDFbaharuonlyhumanNo ratings yet

- Dust Collector ValvesDocument8 pagesDust Collector ValvesAnonymous lswzqloNo ratings yet

- Induced Roll Magnetic Separator: Data Sheet - IRMDocument5 pagesInduced Roll Magnetic Separator: Data Sheet - IRMMIzan NursiadiNo ratings yet

- 159 0000 R66 Wa PDFDocument1,700 pages159 0000 R66 Wa PDFConrado Pinho JuniorNo ratings yet

- Refurbishing A Clansman Battery: Colin Guy G4DDIDocument2 pagesRefurbishing A Clansman Battery: Colin Guy G4DDIScott WyattNo ratings yet

- SITE BOOK Good Practice Guide PDFDocument66 pagesSITE BOOK Good Practice Guide PDFFernando VázquezNo ratings yet

- SVA Aximax 2HL 3698SF Made in USADocument3 pagesSVA Aximax 2HL 3698SF Made in USADhanus KodiNo ratings yet

- Slender Column Moment MagnifierDocument8 pagesSlender Column Moment Magnifiermotiur basumNo ratings yet

- Fan Drive System: Systems OperationDocument5 pagesFan Drive System: Systems Operationallan lariosaNo ratings yet

- 04 09 16 - en Iso 14119.en UsDocument24 pages04 09 16 - en Iso 14119.en UsStefano SquadraniNo ratings yet

- Sunny Boy InstallationDocument204 pagesSunny Boy InstallationSivaprasad KcNo ratings yet

- TRIPATRA'S TANGGUH LNG PROJECT Indonesian EPC company Tripatra recruiting for Tangguh LNG Project rolesDocument28 pagesTRIPATRA'S TANGGUH LNG PROJECT Indonesian EPC company Tripatra recruiting for Tangguh LNG Project rolesKholil JavaNo ratings yet

- DLNSS BL2PDF 9 24 13 PDFDocument65 pagesDLNSS BL2PDF 9 24 13 PDFaswardiNo ratings yet

- Manufacturer Profile for Universal Earthing SystemsDocument3 pagesManufacturer Profile for Universal Earthing Systemskkjha31No ratings yet

- Exp SrilankaDocument10 pagesExp SrilankaAnthony Kabuga100% (1)

- Production Process Management of Packaging in KDS Accessories LimmitedDocument12 pagesProduction Process Management of Packaging in KDS Accessories LimmitedshisantoNo ratings yet

- Inorganic Organic CoatingsDocument9 pagesInorganic Organic Coatingstocamdinhvu100% (1)

- 1 D 713224192Document1 page1 D 713224192Jaganathan KrishnanNo ratings yet

- Electrical Engineer Job Jebel AliDocument1 pageElectrical Engineer Job Jebel AliPrakash SelvarajNo ratings yet

- Jibon Kumar GhoshDocument2 pagesJibon Kumar GhoshArshad SadatNo ratings yet

- 2013 Young Researchers Conference Proceedings PDFDocument142 pages2013 Young Researchers Conference Proceedings PDFErnie Ernie100% (1)

- SOLAR2013 0091 Final-PaperDocument7 pagesSOLAR2013 0091 Final-PaperCrazy VideosNo ratings yet

- Argosy Trucks Maintenance ManualDocument149 pagesArgosy Trucks Maintenance ManualRolf-Ingo Strackerjan100% (1)

- Select the Right Industrial Gearbox in 15 StepsDocument4 pagesSelect the Right Industrial Gearbox in 15 StepssanjushaNo ratings yet

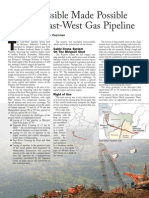

- Reliance East West Pipeline Punj LoydDocument3 pagesReliance East West Pipeline Punj LoydPuneet Zaidu100% (1)

- Mumbai DP 2014-34Document513 pagesMumbai DP 2014-34vikasbapat100% (2)

- Tulasi Rao - MECHANICAL ENGINEER 9 Yeras Experience CswipDocument3 pagesTulasi Rao - MECHANICAL ENGINEER 9 Yeras Experience Cswiptulasirao.nammiNo ratings yet

- Major Project: Pinch Analysis & Process IntegrationDocument8 pagesMajor Project: Pinch Analysis & Process IntegrationShreyJainNo ratings yet

- Cross Purge ProcedureDocument2 pagesCross Purge Procedureankitrao31No ratings yet

- Pbadupws - Nrc.gov Docs ML0731 ML073190432Document57 pagesPbadupws - Nrc.gov Docs ML0731 ML073190432Ashish MahtoNo ratings yet