Professional Documents

Culture Documents

Design of one-way and two-way slabs

Uploaded by

George GeorgianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of one-way and two-way slabs

Uploaded by

George GeorgianCopyright:

Available Formats

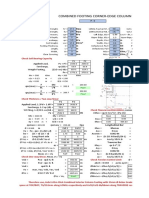

CARMEL B. SABADO CE-162 PROF. GERONIDES P.

ANCOG

BSCE-5 2nd Excel Program SEPT. 6, 2009

*note:the boxes in yellow should be inputed by the designer,while blue ones are computed by the program. =)

****====DESIGN OF ONE-WAY SLAB====****

4.6 m 4.6 m

GIVEN:

Concrete,f

c

' =

27.5 Mpa

Steel,f

y

=

414 Mpa

Unit weight of concrete,w

c

=

23.5

kN/m

3

1) L / 20 ; simply supported

Slab live load = 4.8 kPa 2) L / 24 ; one end continuous

clear span,L = 4.6 m 3) L / 28 ; two end continuous

main bar diameter = 10 mm 4) L / 10 ; cantilever

temp. bar diameter = 8 mm

TYPE OF SLAB SECTION: 3 h = L / 28 ; TWO END CONTINUOUS

L

28

say h = 165 mm

COMPUTE LOADS:

DEAD LOAD(DL)

self weight = w

c

h

= 3.8775 Kpa

assume floor finish = 25 mm

assume floor finish = yw

c

= 0.5875 Kpa

total DL = 4.465 KPa

LIVE LOAD(LL)

service load = 4.8 Kpa

wu = 1.2DL + 1.6LL = 13.038 Kpa

COMPUTE MOMENTS: M = cwL2

coefficients, c L(m) w(kPa) (kN.m/m)

0.11111111 4.6 13.038 30.6537867

0.07142857 4.6 13.038 19.7060057

0.04166667 4.6 13.038 11.49517

COMPUTE FOR :

1.4/ f

y

= 0.0033816

f

c

'/ 4f

y

= 0.0031667

h = = 164.2857 mm

use

min

= 0.00316669

0.02129829

main bar reinforcement = 78.5398163

temp bar reinforcement = 50.2654825

COMPUTE THE REQUIRED As AND SPACING OF BAR REINFORCEMENTS

interior support at mid-span exterior support

M

u

= = 30.65379 19.706006 11.49517 (kN-m/m)

d = h - (20+/2) = = 120 120 120 (mm

2

)

R

u

= M

u

/(.9bd

2

) = 2.365261 1.5205251 0.88697299

= = 0.006036 0.0038007 0.00218471

use = 0.006036 0.0038007 0.00316669

A

s

= bd = 724.2973 456.08248 380.003206

(mm

2

)

s = 1000Ao/As = 108.4359 172.20529 206.681984

TEMPERATURE BAR SPACING REQUIREMENT:

fy < 414MPa

temp.

= 0.002

fy = 414MPa

temp.

= 0.0018

fy > 414MPa

temp.

= 0.0018(414)/fy

MINIMUM RHO FOR TEMPERATURE BARS:

min

= 200/fy

= 0.48309179

temp. = 0.0018

A

s,temp

=

temp

bd

= 216

(mm

2

)

temp bar spacing = 215

(mm

2

)

SLAB DETAILS FOR BENDING OF REINFORCEMENTS

fixed bar spacing at mid-span, s = 150

A

s

(required) = 456.082484

A

s

(actual) = 1000A

o

/s(fixed) 523.598776

design is ok!!!=)

at exterior support

A

p

= A

s

(actual)2/3 = 349.06585

A

s

(required) = 380.003206

design is not safe!!!=(

provide extra bars,n = 1

A

p

= A

p

+ n(A

o

) = 427.605667

design is ok!!!=)

at interior support

A

p

= A

s

(actual)4/3 = 698.131701

A

s

(required) = 724.297269

design is not safe!!!=(

provide extra bars, n = 2

A

p

= A

p

+ n(A

o

) = 855.211333

design is ok!!!=)

=

(

+

=

) 600 (

1600 ' 85 .

75 . max

fy fy

fc |

Slab Details Scheme 1: Bending of reinforcements

10 mm bent 2/3 spaced @

150 mm

1 -extra top bar is needed 2 -extra top bars are needed

165

mm

1 8 10 mm bent 2/3 spaced @

-extra top bar is needed mm temp bars @ 150 mm

215 mm

2

-extra top bars are needed

Slab Details Scheme 2: Cutting of reinforcements

10 mm 10 mm 10 8 mm

190 oc 380 oc 190 oc 215 oc

10 mm 8 mm 10 mm

190 mm spacing 215 mm spacing 190 mm spacing 10

mm 95

mm spacing

PROF. GERONIDES P. ANCOG

CARMEL B. SABADO CE-162 PROF. GERONIDES P. ANCOG

BSCE-5 2nd Excel Program SEPT. 6, 2009

*note:the boxes in yellow should be inputed by the designer,while blue ones are computed by the program. =)

****====DESIGN OF TWO-WAY SLAB====****

7.7 m

6.2 m

Estimate slab thickness based on code minimum thickness requirement.

GIVEN: Trial depth, h:

f

c

' =

20.7 MPa = 154.444 mm

f

y

=

414 MPa say 160 mm

w

c

=

23.6

kN/m

bar size = 12 mm

Live load = 6.65 kPa

L

A

=

6.2 m

L

B

=

7.7 m

Slab load:

DL:

slab: w

c

h =

3.776 kPa

finish, assume 25mm cement finish 0.025w

c

=

0.59 kPa

TOTAL = 4.366 kPa

LL: 6.65 kPa

Ultimate load: w

u

= 1.4DL + 1.7LL =

17.417 kPa

Slab aspect ratio, m:

= 0.80519481

Positve moments:

Case 4:

coeff, c

w L M=c wL

M

a, pos DL

0.039 4.366 6.2 6.545

M

a, pos LL

0.048 6.65 6.2 12.270

M

au, pos

= 1.2DL + 1.6LL

27.486

M

b, pos DL

0.016 4.366 7.7 4.142

M

b, posLL

0.02 6.65 7.7 7.886

M

bu, pos

= 1.2DL + 1.6LL

17.587

( )

180

2 B A

h

+

=

B

A

L

L

m =

Negative moments:

At continuous edge:

coeff, c

w

u

L

M=c wL

M

a, neg

0.071 17.4174 6.2 47.536 kN-m/m

M

b,neg

0.029 17.4174 7.7 29.948 kN-m/m

At discontinuous edge: M = 1/3(M

pos

)

M

a, neg

9.162 kN-m/m

M

b,neg

5.862 kN-m/m

Design of middle strip in the short direction:

h d

Mu = Mmax = = 47.536 Kn-m

Trial d = h - (20 + /2) = = 134 mm

= 2.94152773

= 0.00274742

= 0.0160318

= 0.007826 ok, use this rho!!!=)

= 113.097336 mm2

As = bd = 1048.63208 mm2

= 107.852256 mm oc

At mid-span:

Mu = 27.486 Kn-m

Ru = 1.70085368

p = 0.00432879 ok, use this rho!!!=)

As = 580.058496 mm2

s = 194.975742 mm oc

At discontinuous end:

Mu = 9.162 Kn-m

Ru = 0.56695123

p = 0.00139225 use pmin!!!=(

As = 368.154098 mm2

s = 307.201078 mm oc

Design od middle strip in the long direction:

h d

Mu = 29.948 Kn-m

= 122 mm

Ru = 2.23563347

p = 0.00579519 ok, use this rho!!!=)

Ao = 113.097336 mm2

As = 776.555368 mm2

s = 145.639758 mm oc

dL = h - (20 + 1.5)

2

/

bd

M

R

u

u

|

=

min

min

4

'

,

4 . 1

(

(

=

y

c

y

f

f

f

(

(

+

=

y s

s

y

c

f E

E

f

f

003 .

003 . ' 85 .

75 .

1

max

|

(

(

=

y

u

f

R e

e

2

1 1

1

(

=

' 85 .

2

1 1

' 85 .

c

u

y

c

f

R

f

f

2

4

b o

D A

t

=

s

o

A

A

s

1000

=

At mid-span:

Mu = 17.587 Kn-m

Ru = 1.31289578

p = 0.00329931 ok, use this rho!!!=)

As = 402.515809 mm2

s = 280.976133 mm oc

At discontinuous end:

Mu = 5.862 Kn-m

Ru = 0.43763193

p = 0.00107057 use pmin!!!=(

As = 335.185074 mm2

s = 337.417577 mm oc

Check for shear:

Total load on panel, Wt = LALBwu = 831.5067 Kn

= 0.71

= 38.3357 Kn/m

Shear concrete:

d = 134 mm

= 91.44948 shear is okay!!=)

SLAB DETAILS FOR BENDING OF REINFORCEMENTS

Short Direction:

fixed bar spacing at mid-span, s = 150 mm oc

As(actual) = 1000Ao/s(fixed) = 753.9822 >As required at mid-span, ok

As(required) = 580.0585

at exterior support

Ap = As(actual)2/3 = 502.6548 >As required at exterior support,ok

As(required) = 368.1541

at interior support

Ap = As(actual)4/3 = 1005.31 <As required,provide extra bars

As(required) = 1048.632

provide extra bars, n = 2

Ap = Ap + n(Ao) = 1231.5 >As required at interior support,ok

Long Direction:

fixed bar spacing at mid-span, s = 220 mm oc

As(actual) = 1000Ao/s(fixed) = 514.0788 >As required at mid-span, ok

As(required) = 402.5158

at exterior support

Ap = As(actual)2/3 = 342.7192 >As required at exterior support,ok

As(required) = 335.1851

at interior support

Ap = As(actual)4/3 = 685.4384 <As required,provide extra bars

As(required) = 776.5554

provide extra bars, n = 2

Ap = Ap + n(Ao) = 911.6331 >As required at interior support,ok

Shear per m of long beam, Case 4: CA

B

T A

A

L

W C

v

2

=

bd

f

V

c

vc uc

6

'

| =

provide 2 extra top bars

12mm @150 oc bent 2/3

12mm @ 220 oc bent 2/3

provide 2 extra top bars

L

A

/4 L

A

/2 L

A

/4 L

A

/4

column strip middle strip column strip column strip

Slab thickness = 160 mm

Slab Details Scheme 2: Cutting of Reinforcements

12 top bars @ 245

12 bot bars @ 250

12 top bars @ 150

L

A

/4 L

A

/2 L

A

/4 L

A

/4

column strip middle strip column strip column strip

Slab thickness = 160 mm

1

2

b

o

t

b

a

r

s

@

1

7

5

1

2

t

o

p

b

a

r

s

@

1

0

5

L

B

/

2

L

B

/

4

1

2

t

o

p

b

a

r

s

@

2

4

5

m

i

d

d

l

e

s

t

r

i

p

L

B

/

2

c

o

l

u

m

n

s

t

r

i

p

L

B

/

4

c

o

l

u

m

n

s

t

r

i

p

L

B

/

4

c

o

l

u

m

n

s

t

r

i

p

L

B

/

4

L

B

/

4

c

o

l

u

m

n

s

t

r

i

p

L

B

/

4

>As required at exterior support,ok

>As required at exterior support,ok

structural design of purlin

You might also like

- Design of Columns: I.Determination If Long Column or Short ColumnDocument26 pagesDesign of Columns: I.Determination If Long Column or Short ColumnJohn Paul Hilary EspejoNo ratings yet

- Designing of Ground Level Water Tank 2003 FormatDocument4 pagesDesigning of Ground Level Water Tank 2003 Formatajith chandranNo ratings yet

- Slab DesignDocument10 pagesSlab DesignKeeperNo ratings yet

- Design of Shear Wall FootingDocument11 pagesDesign of Shear Wall FootingJohn Paul Hilary EspejoNo ratings yet

- Structural Computation: Phase 7-A Block 17 Lot 04 Orchard & Residential Estate, Salitran, Dasmariñas, CaviteDocument9 pagesStructural Computation: Phase 7-A Block 17 Lot 04 Orchard & Residential Estate, Salitran, Dasmariñas, CaviteEdward Jade EmolagaNo ratings yet

- 3.column DesignDocument48 pages3.column DesignReuben James BangaoilNo ratings yet

- One Way Slab Design: Ref: Nilson-13Th Edition-418 Page ExampleDocument4 pagesOne Way Slab Design: Ref: Nilson-13Th Edition-418 Page Examplerasedul islamNo ratings yet

- Seismic Analysis of Proposed Two-Storey BuildingDocument13 pagesSeismic Analysis of Proposed Two-Storey Buildingkenneth nobleNo ratings yet

- Grade Beam Design DoneDocument8 pagesGrade Beam Design DoneLenard SantiagoNo ratings yet

- Design of Two Way Slab: DESIGN FOR 2S-1 and 3S-1Document100 pagesDesign of Two Way Slab: DESIGN FOR 2S-1 and 3S-1Cesar MigoNo ratings yet

- Factors affecting wind pressure on roofsDocument1 pageFactors affecting wind pressure on roofsCzarinaCanarAguilarNo ratings yet

- Truss-and-Purlins-Design Alternative DesignDocument8 pagesTruss-and-Purlins-Design Alternative DesignAiron Kaye SameloNo ratings yet

- Structural Design StepsDocument4 pagesStructural Design StepsAnonymous ciKyr0tNo ratings yet

- Analysis of Reinforced Concrete BeamsDocument1 pageAnalysis of Reinforced Concrete BeamsAly Arquillano JrNo ratings yet

- Concrete slab and beam design calculationsDocument16 pagesConcrete slab and beam design calculationsGing LimjocoNo ratings yet

- Prepared By:: Engr. Mark Roger R Huberit Ii Civil / Structural Engineer PRC NO. 072279Document9 pagesPrepared By:: Engr. Mark Roger R Huberit Ii Civil / Structural Engineer PRC NO. 072279Mark Roger Huberit IINo ratings yet

- Hassanal Bagundang BSCE-5Document5 pagesHassanal Bagundang BSCE-5D MNo ratings yet

- Calculation NoteDocument10 pagesCalculation NoteJay EvansNo ratings yet

- RCD-DeSIGN Engr. Mark ChristianDocument9 pagesRCD-DeSIGN Engr. Mark ChristianTaki TachibanaNo ratings yet

- Design of Floor (Slab 4) : La LBDocument10 pagesDesign of Floor (Slab 4) : La LBAyreesh Mey SpntNo ratings yet

- Proposed Two Storey Aparment Building Struct AnalysisDocument26 pagesProposed Two Storey Aparment Building Struct AnalysisIver Ace BihisNo ratings yet

- Tourism Office Building Computations: Truss 2Document32 pagesTourism Office Building Computations: Truss 2Jesselle CelestialNo ratings yet

- Hostel Stair Design DataDocument5 pagesHostel Stair Design DataDENCONo ratings yet

- STAAD - Pro & STAAD Advanced Concrete Designer RCDC: (Beams, Slabs, Columns and Footings)Document49 pagesSTAAD - Pro & STAAD Advanced Concrete Designer RCDC: (Beams, Slabs, Columns and Footings)Arnold VercelesNo ratings yet

- Column DesignsDocument29 pagesColumn DesignssitehabNo ratings yet

- BEAM DESIGN & Column DesignDocument3 pagesBEAM DESIGN & Column DesignVea Anne Austria GirayNo ratings yet

- Wind LoadDocument10 pagesWind LoadGrace Talaroc SuperalesNo ratings yet

- 3.1a - Reliability & RedundancyDocument6 pages3.1a - Reliability & RedundancyklynchelleNo ratings yet

- Design of Footing For Edge Column1Document6 pagesDesign of Footing For Edge Column1sivakumarNo ratings yet

- RESIDENTIAL TOWNHOUSE STRUCTURAL DESIGNDocument8 pagesRESIDENTIAL TOWNHOUSE STRUCTURAL DESIGNNick OperarioNo ratings yet

- Design Data: Design of Floor Slab ContinousDocument12 pagesDesign Data: Design of Floor Slab ContinousMohit VermaNo ratings yet

- Upper Basement: Waffle Slab DesignDocument3 pagesUpper Basement: Waffle Slab DesignVinay KumarNo ratings yet

- Structural Design Criteria: Load Type Type of OccupancyDocument8 pagesStructural Design Criteria: Load Type Type of OccupancyJoseph TuzonNo ratings yet

- Site: Date: Job No. Designer: Sheet No.: Calculation/ SketchDocument6 pagesSite: Date: Job No. Designer: Sheet No.: Calculation/ SketchAlma M. LaraNo ratings yet

- SIMPLIFIED RC DESIGN FORMULA FOR BEAMS AND SLABSDocument3 pagesSIMPLIFIED RC DESIGN FORMULA FOR BEAMS AND SLABSnap_carinoNo ratings yet

- Determination of Footing Dimensions: Na All FDocument4 pagesDetermination of Footing Dimensions: Na All FMohammed ElemamNo ratings yet

- SC Balinagay Builders Proposed Residential Building Cost BreakdownDocument2 pagesSC Balinagay Builders Proposed Residential Building Cost BreakdownMark Christian EsguerraNo ratings yet

- Design of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsDocument3 pagesDesign of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsThirdie LerajeNo ratings yet

- Final Output More SepadaDocument1,298 pagesFinal Output More SepadaJHON CLYDE SEPADANo ratings yet

- Col PedDocument1 pageCol PedMark Christian EsguerraNo ratings yet

- Concentric Column: Design of Square/Rectangular Isolated FootingDocument21 pagesConcentric Column: Design of Square/Rectangular Isolated FootingangeladolfoNo ratings yet

- Engineers: My Notes StructuralDocument14 pagesEngineers: My Notes StructuralGladies Mhay Binay SandovalNo ratings yet

- Cantilever BeamDocument3 pagesCantilever BeamFeliciano Esteban DominguezNo ratings yet

- COMBINED FOOTING DESIGNDocument34 pagesCOMBINED FOOTING DESIGNErwin ObenzaNo ratings yet

- 02 12 16 Member DesignDocument2 pages02 12 16 Member DesignclarkgaguiNo ratings yet

- NEW - Structural Design & Analysis (Pt. 1)Document23 pagesNEW - Structural Design & Analysis (Pt. 1)Rein Aira OrdanezNo ratings yet

- Windload AnalysisDocument6 pagesWindload AnalysisJerico Enriquez CacaoNo ratings yet

- Column Design 300x300Document7 pagesColumn Design 300x3001234 1234No ratings yet

- Structural ComputationsDocument238 pagesStructural ComputationsbambagenNo ratings yet

- Concrete column and beam loads5.0976Document33 pagesConcrete column and beam loads5.0976Angie BitesNo ratings yet

- Seismic AnalysisDocument13 pagesSeismic AnalysisJea Manguing-YubalNo ratings yet

- Structural Analysis & DesignDocument8 pagesStructural Analysis & Designkurt paulo manaloNo ratings yet

- Design of combined footingDocument6 pagesDesign of combined footingEric John PedrosoNo ratings yet

- Earthquake Lateral ForcesDocument10 pagesEarthquake Lateral ForcesOnurUmanNo ratings yet

- Slab design calculations and steel requirementsDocument2 pagesSlab design calculations and steel requirementsvidudalaraviNo ratings yet

- Design of Isolated Mat FootingDocument5 pagesDesign of Isolated Mat FootingYAROFENo ratings yet

- Design of Square Footing F2Document18 pagesDesign of Square Footing F2Mohammed Sumer100% (1)

- Design of Rectangular Columns with Biaxial BendingDocument21 pagesDesign of Rectangular Columns with Biaxial BendingBhaskar BabiNo ratings yet

- Design of Rectangular Water Tank with Dimensions 6m x 4m x 3.5mDocument268 pagesDesign of Rectangular Water Tank with Dimensions 6m x 4m x 3.5mchetanmale89% (28)

- MBR- DUBAI HILLS ESTATE DEVELOPMENT LANDSCAPING COST PROPOSALDocument1 pageMBR- DUBAI HILLS ESTATE DEVELOPMENT LANDSCAPING COST PROPOSALlayaljamal2No ratings yet

- General Details RoofingDocument1 pageGeneral Details RoofingGeorge GeorgianNo ratings yet

- PC 7r1Document6 pagesPC 7r1George GeorgianNo ratings yet

- T2Document1 pageT2George GeorgianNo ratings yet

- SDocument1 pageSGeorge GeorgianNo ratings yet

- 3Document4 pages3George GeorgianNo ratings yet

- 2Document1 page2George GeorgianNo ratings yet

- DetailDocument1 pageDetailGeorge GeorgianNo ratings yet

- Torsional Amplification Factor - Ax-For Response Spectrum Analysis (RSA)Document3 pagesTorsional Amplification Factor - Ax-For Response Spectrum Analysis (RSA)George GeorgianNo ratings yet

- Seismic Design Manual (SEAOC) Vol 1 - Code Application ExamplesDocument171 pagesSeismic Design Manual (SEAOC) Vol 1 - Code Application Examplesmgrubisic60% (5)

- Nitoproof 600Document4 pagesNitoproof 600sandeepuaeNo ratings yet

- T1Document1 pageT1George GeorgianNo ratings yet

- Water TanksDocument1 pageWater TanksGeorge GeorgianNo ratings yet

- B 2Document1 pageB 2George GeorgianNo ratings yet

- B4Document1 pageB4George GeorgianNo ratings yet

- 0.85m (-0.55mm FROM ROAD: Missed Road Base Layer 25Cm As Per The Soil ReportDocument1 page0.85m (-0.55mm FROM ROAD: Missed Road Base Layer 25Cm As Per The Soil ReportGeorge GeorgianNo ratings yet

- B3Document1 pageB3George GeorgianNo ratings yet

- BDocument1 pageBGeorge GeorgianNo ratings yet

- Sub-Grade Is Less Than Required in Soil Report 26,250 kn/m3..!!Document1 pageSub-Grade Is Less Than Required in Soil Report 26,250 kn/m3..!!George GeorgianNo ratings yet

- Safe Out PutDocument9 pagesSafe Out PutGeorge GeorgianNo ratings yet

- Tower CraneDocument1 pageTower CraneGeorge GeorgianNo ratings yet

- Foundation Level - 1M From Road LVL Is Less Than Required in Soil Report - 1.5M As Minimum!!Document15 pagesFoundation Level - 1M From Road LVL Is Less Than Required in Soil Report - 1.5M As Minimum!!George GeorgianNo ratings yet

- Tower Crane Found.Document1 pageTower Crane Found.George GeorgianNo ratings yet

- TensionDocument1 pageTensionGeorge GeorgianNo ratings yet

- Thick PlateDocument1 pageThick PlateGeorge GeorgianNo ratings yet

- Moduls of Rapture..Document1 pageModuls of Rapture..George GeorgianNo ratings yet

- Thermal LoadsDocument1 pageThermal LoadsGeorge GeorgianNo ratings yet

- Miss Matching Model 1.48M, Drawings 1.15M, (More Pressure On Raft in Actual)Document1 pageMiss Matching Model 1.48M, Drawings 1.15M, (More Pressure On Raft in Actual)George GeorgianNo ratings yet

- Raft LevelDocument1 pageRaft LevelGeorge GeorgianNo ratings yet

- PunchingDocument1 pagePunchingGeorge GeorgianNo ratings yet

- (Nima Naghibi) Rethinking Global Sisterhood Weste PDFDocument220 pages(Nima Naghibi) Rethinking Global Sisterhood Weste PDFEdson Neves Jr.100% (1)

- Clinical behavior analysis and RFT: Conceptualizing psychopathology and its treatmentDocument28 pagesClinical behavior analysis and RFT: Conceptualizing psychopathology and its treatmentAnne de AndradeNo ratings yet

- Hong Kong A-Level Chemistry Book 3ADocument69 pagesHong Kong A-Level Chemistry Book 3AMARENG BERNABENo ratings yet

- 4WE10 New Series Directional Valves NG10Document9 pages4WE10 New Series Directional Valves NG10Paulo ArrudaNo ratings yet

- Vernacular Architecture: Bhunga Houses, GujaratDocument12 pagesVernacular Architecture: Bhunga Houses, GujaratArjun GuptaNo ratings yet

- RISO MZ Servicemanual EnglDocument438 pagesRISO MZ Servicemanual Englkuvalda2000_8645336367% (3)

- Morpho Full Fix 2Document9 pagesMorpho Full Fix 2Dayu AnaNo ratings yet

- 1 API 653 Exam Mar 2015 MemoryDocument12 pages1 API 653 Exam Mar 2015 MemorymajidNo ratings yet

- Chicago TemplateDocument4 pagesChicago TemplateJt MetcalfNo ratings yet

- Product Differentiation and Market Segmentation As Alternative Marketing StrategiesDocument7 pagesProduct Differentiation and Market Segmentation As Alternative Marketing StrategiesCaertiMNo ratings yet

- All Types of Switch CommandsDocument11 pagesAll Types of Switch CommandsKunal SahooNo ratings yet

- Marikina Development Corporation vs. FiojoDocument8 pagesMarikina Development Corporation vs. FiojoJoshua CuentoNo ratings yet

- 1F4 Catalog0808Document12 pages1F4 Catalog0808Edwin Ng0% (1)

- Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International General Certificate of Secondary EducationAdaaan AfzalNo ratings yet

- Pub - Perspectives On Global Cultures Issues in Cultural PDFDocument190 pagesPub - Perspectives On Global Cultures Issues in Cultural PDFCherlyn Jane Ventura TuliaoNo ratings yet

- 2022 - J - Chir - Nastase Managementul Neoplaziilor Pancreatice PapilareDocument8 pages2022 - J - Chir - Nastase Managementul Neoplaziilor Pancreatice PapilarecorinaNo ratings yet

- Chapter 1 Critical Thin...Document7 pagesChapter 1 Critical Thin...sameh06No ratings yet

- Math 2 Unit 9 - Probability: Lesson 1: "Sample Spaces, Subsets, and Basic Probability"Document87 pagesMath 2 Unit 9 - Probability: Lesson 1: "Sample Spaces, Subsets, and Basic Probability"Anonymous BUG9KZ3100% (1)

- Eports: India's Defiance of Religious Freedom: A Briefing On Anti-Conversion' LawsDocument16 pagesEports: India's Defiance of Religious Freedom: A Briefing On Anti-Conversion' LawsGabriela StevensNo ratings yet

- A Laboratory Experiment in Crystals and Crystal Model Building ObjectivesDocument7 pagesA Laboratory Experiment in Crystals and Crystal Model Building ObjectivesrajaaNo ratings yet

- Optitex Com Products 2d and 3d Cad SoftwareDocument12 pagesOptitex Com Products 2d and 3d Cad SoftwareFaathir Reza AvicenaNo ratings yet

- The Ideal Structure of ZZ (Alwis)Document8 pagesThe Ideal Structure of ZZ (Alwis)yacp16761No ratings yet

- NetworkingDocument1 pageNetworkingSherly YuvitaNo ratings yet

- 2018 Diesel TOYOTA Jun11Document90 pages2018 Diesel TOYOTA Jun11eko sulistyo75% (4)

- ccpc15 Supportive and Preventive WorkbookDocument30 pagesccpc15 Supportive and Preventive WorkbookJeremy HamptonNo ratings yet

- Classification of MatterDocument2 pagesClassification of Matterapi-280247238No ratings yet

- JKR Specs L-S1 Addendum No 1 LED Luminaires - May 2011Document3 pagesJKR Specs L-S1 Addendum No 1 LED Luminaires - May 2011Leong KmNo ratings yet

- Laboratory Manual: Semester: - ViiiDocument15 pagesLaboratory Manual: Semester: - Viiirsingh1987No ratings yet

- MARCOMDocument35 pagesMARCOMDrei SalNo ratings yet

- DelhiDocument40 pagesDelhiRahul DharNo ratings yet