Professional Documents

Culture Documents

Varian, Inc. 2700 Mitchell Drive Walnut Creek

Uploaded by

kstaziOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Varian, Inc. 2700 Mitchell Drive Walnut Creek

Uploaded by

kstaziCopyright:

Available Formats

Varian, Inc.

2700 Mitchell Drive

Walnut Creek, CA 94598 USA

Saturn® 2000 GC/MS

Pre-Installation Instructions

The information provided here will help you identify and prepare a suitable installation site for

your Saturn GC/MS. After you have prepared the site, and your Saturn GC/MS has been

delivered, please contact your local Varian, Inc. office to schedule your installation.

For Saturn 2100 systems, refer to these instructions plus the 3900 GC Pre-Installation

Instructions. For other Saturn systems, refer to these instructions plus the CP-3800 GC

Pre-Installation Instructions.

The Varian Saturn GC/MS has been designed to operate reliably under carefully controlled

environmental conditions. It is your responsibility to provide a suitable location, power source,

and operating environment. Operating or maintaining a system in operational conditions outside

of the power and operating environment limits described below could cause failures of many

types. The repair of such failures is specifically excluded from the Warranty and Service

contract conditions.

All phases of the installation site preparation must conform to local safety,

electrical, and building codes. These codes take precedence over any

CAUTION recommendations in these instructions, and compliance to them is the

responsibility of the customer.

Contents

Space and Weight Requirements............................................................ 2

Power Requirements ............................................................................... 3

Operating Environment............................................................................ 5

Temperature/Humidity ...................................................................... 5

Particulate Matter.............................................................................. 6

Vibration............................................................................................ 6

Exhaust System................................................................................ 6

Gas Requirements................................................................................... 6

GC Carrier Gases ............................................................................. 6

CI Reagent Gases (with CI option only) ........................................... 6

Other Gases ..................................................................................... 7

Gas Lines.......................................................................................... 7

Capillary Columns ................................................................................... 7

Solvents................................................................................................... 7

Network Requirements ............................................................................ 7

Computer/Printer Requirements.............................................................. 7

Specifications.................................................................................... 7

Qualified PCs.................................................................................... 8

Qualified Printers .............................................................................. 8

Inspection ................................................................................................ 8

Unpacking and Installation ...................................................................... 9

Parts and Supplies .................................................................................. 9

Preventive Maintenance .......................................................................... 9

Trademark Acknowledgment................................................................... 9

03-914629-00:7 1 of 9 Saturn 2000 GC/MS Pre-installation Instructions

Space and Weight Requirements

Before arranging for delivery of the Saturn GC/MS to your facility, please make sure that all

passages to the site of installation are at least 91.5 cm (36 in.) wide. Allow additional room for

maneuvering the shipping container around corners and/or through doors.

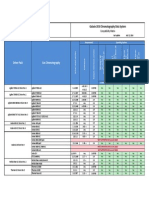

Table 1 identifies the space and weight requirements of the Saturn GC/MS components. The

Saturn GC/MS is intended to sit on a workbench that is wide enough and deep enough to

accommodate these components, and sturdy enough to support their combined weight. Varian

recommends the layout shown in Figure 1, and the space allowances in Table 2.

Table 1 Dimensions and Weights of the Saturn System Components

Height Width Depth Weight

Instrument in. cm in. cm in. cm lb. kg

1

Saturn MS 18 46 12 30 22 56 66 30

3900 GC 18 46 13 32 22 56 51 23

CP-3800 GC 20 51 26 66 22 56 95 43

CP-8400 AutoSampler / CP-8410 16 41 9 23 18 46 20 9

AutoInjector (sits on top of GC)

CP-8200 AutoSampler (sits on top 20 51 6 16 16 41 24 11

of GC)

Tekmar 3000 Purge and Trap 19 48 9 23 18 46 37 17

Archon Purge and Trap AutoSampler 17 43 22 55 21 53 80 36

Tekmar ALS-2016 27 69 15 38 15 38 35 16

Genesis Headspace AutoSampler 22 56 28 71 18 46 110 50

2

Saturn Chromatography Workstation 20 51 17 43 21 53 35 16

(computer with monitor, approximate

values)

1

Allow an additional 76 cm (30 in.) of vertical clearance above the mass spectrometer module to allow for

routine maintenance.

2

Allow an additional 20 cm x 20 cm (8 in. x 8 in.) of bench space beside the keyboard for mouse operation.

Table 2 Spatial Set-up Requirements for Saturn GC/MS

Recommendations Purpose Recommended Distance

Allow adequate space to the right of Permit access to the transfer line ~ 61 cm (24 in.)

the GC/MS. and turbomolecular pump. See

Figure 1.

Allow adequate space behind the Provide clear space for air 15 to 30 cm (6 to 12 in.)

system. circulation, gas lines, and electrical

connections.

Allow vertical clearance above the Dissipate heat and allow for routine ≥102 cm (4 in.)

GC/MS. maintenance.

Allow additional bench space beside Enable mouse operation. 20 cm x 20 cm (8 in. x 8 in.)

the Workstation keyboard

03-914629-00:7 2 of 9 Saturn 2000 GC/MS Pre-installation Instructions

Figure 1 Recommended System Layout

The 24.5 kg (54 lb) mechanical pump belongs on the floor beneath the workbench on which the

Saturn system sits. To accommodate the pump, the workbench should be no higher than 91 cm

(36 in.); if you use a higher table, be sure to place a suitable stand or support under the table to

elevate the pump. If your bench adjoins a wall, you will either need to drill a 38 mm (1.5 in.)

diameter hole through the bench to accommodate the vacuum hose, or to place a suitable shelf

above and behind the Saturn GC/MS for the pump.

Power Requirements

You are responsible for providing two dedicated fourplex single-phase power sources with earth

grounds hard-wired to the main power panel ground. Within North America these power

sources must be 20A, 100-130 Vac, 60 Hz ±3 Hz, and outside North America they must be

10A, 200-260 Vac, 50 Hz ±3 Hz. One of these fourplex power sources is for the mass

spectrometer, computer, monitor; and printer the other fourplex power source is for the gas

chromatograph and (optional) 8200 AutoSampler. If you have additional sample preparation

devices or test equipment, we recommend a separate dedicated power source for their

operation.

Care must be taken to ensure that sources of radio frequency interference (RFI) and

electromagnetic interference (EMI) are not placed on the same power line, or share the same

ground plane, since this can degrade the performance of the GC. Equipment such as motors,

solenoids, fluorescent light fixtures, and radio communication transmitters should be isolated

from the instrument and connecting cables as much as possible.

The power cable from the GC is approximately 2m (6 ft) long and fitted with National Electronics

Manufacturers Association (NEMA) 5-20P power plugs. The NEMA 5-20P power plug and

corresponding outlet are shown in Figure 2(a). NEMA 5-20P plugs are rated at 20A and

120 Vac.

03-914629-00:7 3 of 9 Saturn 2000 GC/MS Pre-installation Instructions

The power cable from the mass spectrometer is approximately 2.5m (8 ft) long and fitted with

US Standard National Electronics Manufacturers Association (NEMA) 5-15P power plugs. The

NEMA 5-15P power plug and corresponding outlet are shown in Figure 2(b). NEMA 5-15P

plugs are rated at 15A and 120 Vac.

Systems shipped outside the United States and Canada are fitted with CEE 7/7 plugs; these are

rated at 16A and 230 Vac. The CEE 7/7 plug and outlet are shown in Figure 2(c).

Figure 2 NEMA 5-20P, NEMA 5-15P, and CEE 7/7 Power Plugs and Outlets

The power cables for the computer, monitor, and printer are approximately 2m (6 ft) long. They

are fitted with NEMA 5-15P plugs. The power cable from the 8200 AutoSampler is about 2m

(6 ft) long, and is fitted with a NEMA 5-15P plug rated at 120V.

With a 120V power source, the maximum amperage requirements for each of the Saturn

GC/MS components are as follows:

Component Amperes

Mass Spectrometer 12

CP-3800 Gas Chromatograph 20

3900 Gas Chromatograph 11

CP-8200 AutoSampler 0.5

Computer 3

Monitor 2

Laser Printer 3-4

NOTE: With a 230V power source, the maximum amperage requirement of each of the

above components is one-half of the amperage given above.

Never plug the mass spectrometer and the gas chromatograph into the same power source;

otherwise, you may overload the fourplex power source. Never use the free outlet on each of

the power sources for equipment drawing more than 2A.

03-914629-00:7 4 of 9 Saturn 2000 GC/MS Pre-installation Instructions

The quality of the power supplied to your Saturn GC/MS is very important. The power must be

100-130 Vac, 60 Hz ±3 Hz (200-260 Vac, 50 Hz ±3 Hz outside North America), and it must be

stable, i.e., it must be free of fluctuations due to slow changes in the average voltage or to

changes resulting from surges, sags, or transients.

• Slow average changes are gradual, long-term changes in the average root mean

square (RMS) voltage level, with typical durations greater than 2 seconds.

• Sags and surges are sudden changes in average RMS voltage level, with typical

durations between 50 µsec and 2 seconds.

• Transients (or impulses) are brief voltage excursions of up to several thousand volts

with durations of less than 50 µsec.

Constant high line voltage or surges in voltage may produce overheating and component

failures. Constant low line voltage or sags in voltage may cause the system to function

erratically, or even to cease functioning. Transients, even of a few microseconds duration, may

cause electronic devices to fail catastrophically or degrade sufficiently to significantly shorten

device lifetime. It is important to establish the quality of the line power in your laboratory prior to

installation of the Saturn GC/MS.

Occasionally, you may encounter line power sources of unacceptable quality; such power

sources may adversely affect the operation of the Saturn GC/MS. You may want to contact a

specialist in power conditioning services.

Operating Environment

You are responsible for providing an acceptable operating environment. Attention paid to the

operating environment will ensure the continued peak performance of your Saturn GC/MS.

Temperature/Humidity

The optimum operating temperature is between 18° and 21 °C (65° and 70 °F).

NOTE: As laboratory temperature increases, system reliability decreases. All electronic

components generate heat while operating. This heat must be dissipated to the

surrounding air if the components are to operate reliably.

The turbomolecular pump temperature cutoff control protects the bearing and prolongs its

lifetime. If the laboratory temperature is significantly above 27 °C (80 °F), the pump cutoff

temperature could be reached; this would cause the pump to shut down.

The diffusion pump’s temperature cutoff control protects the fluid from overheating. If the

laboratory temperature is above 35 °C (95 °F), the pump will shut down.

There must be a good flow of air around the system. Your air conditioning system must be

capable of maintaining a constant temperature (within operational limits) in the immediate

vicinity of the system. The average steady-state heat load of the Saturn GC/MS is 6000 BTUs,

with a possible short-term heat dissipation of 15000 BTUs during startup.

Hot air vented from the GC column oven may contribute to room heating and to the resulting air

conditioning load. Ducting the GC column oven air out of the lab should reduce this heating

effect.

The relative humidity (RH) of the operating environment must be between 40 and 80%, with no

condensation. Operating a Saturn GC/MS at very low humidity will result in the accumulation

and discharge of static electricity shortening the life of electronic components. Operating the

system at high humidity will produce condensation and result in short circuits.

Varian recommends that your laboratory be equipped with a temperature/humidity monitor. This

will ensure that your laboratory is always in conformance with temperature and humidity

specifications.

03-914629-00:7 5 of 9 Saturn 2000 GC/MS Pre-installation Instructions

Particulate Matter

Take necessary precautions to minimize particulates in the laboratory environment. A layer of

dust on the electronic components could act as an insulating blanket, and reduce heat transfer

to the surrounding air.

Vibration

Ensure that lab benches are free from vibrations, e.g., those caused by equipment in adjoining

locations. Because the mechanical pump vibrates during operation, you should install it on the

floor beneath the Saturn GC/MS, rather than alongside the system on the workbench.

Exhaust System

It is your responsibility to provide an adequate exhaust system. Most compounds introduced

into the mass spectrometer will eventually be exhausted from the mechanical pump, along with

the small amounts of oil vapor that these pumps characteristically emit. Therefore, the pump

outlets should be connected to a fume exhaust system. Consult local regulations for the proper

method of exhausting the fumes from your system.

Gas Requirements

GC Carrier Gases

Helium

Minimum 99.998% ultra-high purity, with less than 1.0 ppm each of water, oxygen, and total

hydrocarbons. One 257 ft3 tank with Matheson regulator #3104-580, or equivalent tank and

regulator.

NOTE: The presence of >1 ppm oxygen or water in the carrier gas supply may

significantly affect the performance of the Saturn GC/MS; it may also damage such

components as the capillary column, filaments, and multiplier. Varian recommends that

you verify that your gas suppliers use controlled tanks; this will ensure that purity

standards are maintained. If you purchase pure gases in contaminated tanks, you may

end up with a contaminated system requiring costly and time consuming repair.

Use of a carrier gas filter is required for optimum performance and to protect your system from

potential contamination. Your GC Accessory Kit includes a GC/MS Gas Clean Oxygen/Moisture

filter (part number CP-17973) and filter base. This easy-to-remove gas filter cartridge combines

three highly adsorptive materials in one filter to remove water, oxygen, and organic compounds

to purify the GC/MS gas. Carrier gas filters should be installed in a location where the indicator

is visible. The filter should be replaced when the indicator shows that the filter is saturated. For

replacement procedures, refer to the instructions enclosed with your filter.

CI Reagent Gases (with CI option only)

Methane, Isobutane

99.99% purity. One lecture bottle with a two-stage pressure regulator, which has a stainless

steel diaphragm and maximum inlet pressure of 15 psi (1 bar).

Ammonia

99.99%, anhydrous grade. One lecture bottle with a two-stage pressure regulator, which has a

stainless steel diaphragm and maximum inlet pressure of 15 psi (1 bar).

03-914629-00:7 6 of 9 Saturn 2000 GC/MS Pre-installation Instructions

Other Gases

See the CP-3800 GC Pre-Installation Instructions for information on gases required for

AutoSamplers and Cryogenic options.

Gas Lines

Methane, isobutane, and ammonia gas supply lines connect directly to the CI gas inlet without

any terminating fittings. For other gas line requirements see the CP-3800 GC Pre-Installation

Instructions.

Capillary Columns

The Saturn GC/MS accommodates the following GC fused-silica capillary columns:

• Narrow bore: 0.25 mm ID; length ≥15m (50 ft)

• Wide bore: 0.32 mm ID; length ≥30m (100 ft)

Solvents

You will also need the following solvents and reagents as you operate and maintain your Saturn

GC/MS.

• Methanol, HPLC grade

• Acetone, HPLC grade

Please handle and store all solvents in accordance with standard safety procedures.

Network Requirements

If you are planning to connect your GC/MS to a company network, you will need to provide a

10Base2 connection (10BaseT for Saturn 2100) to the back panel of the CP-3800 GC or 3900

GC. In addition, the company network must allow TCP/IP communications to be routed across it

from the GC to the Saturn GC/MS Workstation. For basic Ethernet cabling information, please

refer to the CP-3800 GC Operator's Manual or the 3900 GC Getting Started Manual, included

on the Saturn CD. Any hardware, adapters, cables, and configuration and setup work required

to convert from the company network wiring type to 10Base2 (or 10BaseT) wiring will need to

be provided by you or your network administrator. This hardware must comply with the IEEE

802.3 standard.

Computer/Printer Requirements

Specifications

If you decide to purchase a computer from another vendor, please contact your local Varian

Sales / Service Office for pre-purchase advice. The computers that Varian recommends change

with the market availability, but they generally meet the following specifications:

Requirements for Windows NT or Windows 2000:

• Pentium processor, at least 500 MHz

• At least 128 MB RAM

• Administrator privilege for installation

03-914629-00:7 7 of 9 Saturn 2000 GC/MS Pre-installation Instructions

Qualified PCs

At the time of this printing, the computers and printers listed below have been tested and found

to be satisfactory for use with the Saturn GC/MS Workstation software.

• Dell Optiplex GXa 266 Pentium II

• Dell Optiplex GX-1 350 Pentium II

• Dell Optiplex GX-1 400 Pentium II

• Dell Optiplex GX-1 500 Pentium III

• Dell Optiplex GX-1 550 Pentium III

• Dell Optiplex GX110 667 Pentium III

• Dell Optiplex GX110 800 Pentium III

• Dell Optiplex GX150 1GHz Pentium III

• Dell Optiplex GX260 2.0GHz Pentium 4

• Dell Latitude C610 800 Pentium III

Qualified Printers

• Hewlett Packard DeskJet 660C (with HP 550C driver)

• Hewlett Packard DeskJet 692C or 695C color printer

• Hewlett Packard DeskJet 710C, 810C, or 932C color printer

• Hewlett Packard DeskJet 5550 color printer

• Hewlett Packard LaserJet 4+, 5, 5M, or 5P printer

• Hewlett Packard LaserJet 4000 printer (with PCL 5e driver)

• Hewlett Packard LaserJet 4050 printer

• Hewlett Packard LaserJet 4100 printer

• Hewlett Packard Color LaserJet 4550 printer

• Hewlett Packard LaserJet 6P printer

• Hewlett Packard LaserJet 2100 printer (with PCL 5e driver)

• Lexmark 3000 Color Jetprinter

Inspection

When your Saturn GC/MS arrives, carefully inspect the exterior of the shipping cartons for

evidence of any damage that might have occurred during shipment. Inspect the cartons for the

following:

• Water stains

• Cuts, punctures, or deep indentations

• Crushed corners or excessively abraded edges

If one or more of the above conditions are evident on any of the shipping cartons, report the

conditions to the carrier at time of receipt.

Systems are shipped either FOB Varian or FOB Destination. The manner of shipment

determines who has responsibility for filing a claim against the carrier if the system is damaged

in transit. Most systems are shipped FOB Varian, and in this instance any damages incurred in

shipment are the responsibility of the purchaser and the carrier. Contact Varian Service for

assistance with claims filing and billing for repairs if necessary. If the system is shipped FOB

Destination, contact Varian Order Processing who will file a claim against the carrier. Note,

however, that Varian will not accept liability for damage if you receive obviously damaged

materials but do not make note of the damage on the receiving documents.

03-914629-00:7 8 of 9 Saturn 2000 GC/MS Pre-installation Instructions

When your Saturn GC/MS arrives, move it indoors to a protected place and call Varian Service

to schedule your installation.

Unpacking and Installation

A Varian Customer Service Representative will unpack and install the Saturn GC/MS once it

has arrived and you have prepared the installation site. At the time of installation, the customer

service representative will demonstrate the fundamentals of operation and maintenance. To

take full advantage of this on-site visit, please arrange to have your system operator available

during the installation.

At the time of installation, the customer service representative will demonstrate that your system

meets the performance specifications written into your sales contract. Please do not make

plans to analyze samples with the system until after the installation has been completed and

you have accepted the conditions of delivery.

Parts and Supplies

The Saturn 2000 GC/MS Hardware Manual provides a list of parts and supplies for routine

operation.

Preventive Maintenance

You will be responsible for performing routine and preventive maintenance of the gas

chromatograph, mass spectrometer, and data system.

Please note that it is essential that you perform regular preventive maintenance. By performing

this maintenance, you will increase the life of the system, increase system uptime, and enjoy

optimum system performance. Please refer to the Saturn 2000 GC/MS Hardware Manual for

details. Your Varian customer service representative will also describe/demonstrate these

procedures at the time of installation.

Trademark Acknowledgment

Microsoft and Windows are registered trademarks of Microsoft Corporation. Other brand and

product names are trademarks or registered trademarks of their respective holders.

03-914629-00:7 9 of 9 Saturn 2000 GC/MS Pre-installation Instructions

You might also like

- Auditing Trs by IcapDocument53 pagesAuditing Trs by IcapArif AliNo ratings yet

- Option Box Service Manual Assembling Procedure: Shimadzu Corporation Analytical & Measuring Instrument DivisionDocument48 pagesOption Box Service Manual Assembling Procedure: Shimadzu Corporation Analytical & Measuring Instrument DivisionDanCosminNo ratings yet

- Setup 5973N MSD 6890 GC systemDocument1 pageSetup 5973N MSD 6890 GC systemErik PetersonNo ratings yet

- ICPMS-2030: Pre-Installation RequirementsDocument17 pagesICPMS-2030: Pre-Installation Requirementspilar100% (1)

- Varian GC-MS - Saturn 2000 MS Operators ManualDocument597 pagesVarian GC-MS - Saturn 2000 MS Operators ManualdegindelNo ratings yet

- G1969 90006 TOF Maintenance v4Document150 pagesG1969 90006 TOF Maintenance v4Jeramiah SpencerNo ratings yet

- Ssi LC 06 2018Document25 pagesSsi LC 06 2018Validaciones Vicar100% (1)

- Thermo Easy NLC Service Manual PDFDocument364 pagesThermo Easy NLC Service Manual PDFrajeeshNo ratings yet

- Perkin Elmer ICP-OES Instructions - 0Document11 pagesPerkin Elmer ICP-OES Instructions - 0Luis Alberto Ramirez PerezNo ratings yet

- SOLAAR Software Manual 9499 400 30011Document102 pagesSOLAAR Software Manual 9499 400 30011Ricardo VegaNo ratings yet

- LC ApplicationsDocument129 pagesLC Applicationshaben9036No ratings yet

- G1946 1956 Parts TableDocument37 pagesG1946 1956 Parts TabledegindelNo ratings yet

- Varian GC-MS - Saturn 2000 GC-MS Hardware Manual 914978Document200 pagesVarian GC-MS - Saturn 2000 GC-MS Hardware Manual 914978lab5e19100% (1)

- G10&G10S Product Family Service ManualDocument135 pagesG10&G10S Product Family Service ManualPranish Pradhan100% (1)

- Ms Workstation Tutorial ManualDocument225 pagesMs Workstation Tutorial ManualShanika Yasantha MatharageNo ratings yet

- Customer Information: Varian 450 GC - Preventive Maintenance Checklist StandardDocument12 pagesCustomer Information: Varian 450 GC - Preventive Maintenance Checklist StandardChung NguyenNo ratings yet

- Hydride Vapor Generator: For Shimadzu Atomic Absorption SpectrophotometerDocument23 pagesHydride Vapor Generator: For Shimadzu Atomic Absorption SpectrophotometerKhalid Zghear100% (2)

- Trace MS Hardware Manual Rev BDocument153 pagesTrace MS Hardware Manual Rev BGC powerNo ratings yet

- Agilent MSDDocument60 pagesAgilent MSDMohammed Nabil Ahmed0% (1)

- 4000 MS Users GuideDocument41 pages4000 MS Users Guidechemistry_se2636No ratings yet

- Data Acquisition With 3800 GC ControlDocument166 pagesData Acquisition With 3800 GC ControlmardonioandradeNo ratings yet

- Kogene Food SafetyDocument24 pagesKogene Food SafetyChandra Mohan RajendranNo ratings yet

- 91494711Document97 pages91494711vzimak2355No ratings yet

- 4500 ICP-MS Sev - Man PDFDocument536 pages4500 ICP-MS Sev - Man PDFMohammadNo ratings yet

- MS Manual PDFDocument211 pagesMS Manual PDFFabricio AmorimNo ratings yet

- Galaxie 2010 Chromatography CompatibilityDocument3 pagesGalaxie 2010 Chromatography CompatibilitymardonioandradeNo ratings yet

- GC 2010ErrMsgDocument18 pagesGC 2010ErrMsgJe RivasNo ratings yet

- GCMS-QP2010Ultra - SE User'sGuide (Ver2.6) PDFDocument378 pagesGCMS-QP2010Ultra - SE User'sGuide (Ver2.6) PDFnguyenvietanhbtNo ratings yet

- Manual 220msDocument94 pagesManual 220msAlex Core Thoxic100% (1)

- Agilent QQQ Method Development and OptimizationDocument46 pagesAgilent QQQ Method Development and OptimizationCLPHtheoryNo ratings yet

- GC2014 MAnual Usuario PDFDocument318 pagesGC2014 MAnual Usuario PDFJHON ALEXANDER BEDOYA BUILESNo ratings yet

- Varian Vacuum Pump Manual Covers Models 949-9315 to 949-9336Document71 pagesVarian Vacuum Pump Manual Covers Models 949-9315 to 949-9336HumbertoNo ratings yet

- G8020-90005 5800 5900 Service Manual Draft 0 - 1Document246 pagesG8020-90005 5800 5900 Service Manual Draft 0 - 1andri purnomoNo ratings yet

- Application Report DMA 80 Evo Coal USREV061019Document4 pagesApplication Report DMA 80 Evo Coal USREV061019Roni GustiwaNo ratings yet

- ELSDDocument78 pagesELSDTanya HiltzNo ratings yet

- 5977 MSD and MassHunter Acquisition EFamiliarization ChecklistDocument10 pages5977 MSD and MassHunter Acquisition EFamiliarization ChecklistcamiloviviNo ratings yet

- Perkin Elmer DotLinkBoxDocument48 pagesPerkin Elmer DotLinkBoxmelvin100% (1)

- Clarus500 580UserGuideDocument442 pagesClarus500 580UserGuideSelvaraj VenkatesanNo ratings yet

- Waters Synapt g2 Mass Spectrometry System OomgraDocument236 pagesWaters Synapt g2 Mass Spectrometry System OomgraFafa AlunksNo ratings yet

- Jenway 6310 Service ManualDocument84 pagesJenway 6310 Service ManualJorge OliveiraNo ratings yet

- Waters AquityDocument92 pagesWaters AquityPeter KrasnovNo ratings yet

- G1156 90010 PDFDocument78 pagesG1156 90010 PDFAnonymous LUlSZn42U100% (1)

- ELAN Improvements Service Training RevBDocument19 pagesELAN Improvements Service Training RevBJOSE ABADNo ratings yet

- Quick Guide to Using the Agilent 1100 HPLCDocument2 pagesQuick Guide to Using the Agilent 1100 HPLCmaulanaNo ratings yet

- Galaxie User Guide 91497500Document368 pagesGalaxie User Guide 91497500Muhammad Akbar FahleviNo ratings yet

- Agilent 700 Series - PreinstalDocument62 pagesAgilent 700 Series - Preinstaljuan manuel valdez von furthNo ratings yet

- Pico PH and Conductivity MeterDocument2 pagesPico PH and Conductivity Meterjangri100% (1)

- Shimadzu HPLC Standard OperationDocument49 pagesShimadzu HPLC Standard Operationran_ooNo ratings yet

- 09931371C Clarus 590 GC Hardware GuideDocument320 pages09931371C Clarus 590 GC Hardware GuideLuz Idalia Ibarra RodriguezNo ratings yet

- Varian TOGADocument3 pagesVarian TOGAKiran ChokshiNo ratings yet

- Understanding Instrument Detection Limits (IDL) as a More Accurate Measurement of Mass Spectrometer SensitivityDocument22 pagesUnderstanding Instrument Detection Limits (IDL) as a More Accurate Measurement of Mass Spectrometer Sensitivityinfinity1200No ratings yet

- SOLAAR Series Software ManualDocument106 pagesSOLAAR Series Software ManualMARCOS ALBEIRO DIAZ DUARTENo ratings yet

- Testers Service ManualDocument113 pagesTesters Service ManualFernando AvellanedaNo ratings yet

- G1969-90006 TOF Maintenance v4Document150 pagesG1969-90006 TOF Maintenance v4Jean ChamounNo ratings yet

- And Techniques: Ethos Series Ethos SeriesDocument55 pagesAnd Techniques: Ethos Series Ethos SeriesevalenciaNo ratings yet

- SotaxDocument2 pagesSotaxI SunnahNo ratings yet

- 4000 GC/MS: Pre-Installation InstructionsDocument9 pages4000 GC/MS: Pre-Installation InstructionsZia HaqNo ratings yet

- Level Gauge km26Document28 pagesLevel Gauge km26Carlos A. Mantilla J.No ratings yet

- Maxtron 450 KC237305Document91 pagesMaxtron 450 KC237305tylerroach47717No ratings yet

- Varian Analytical Instruments 2700 Mitchell Drive WalnutDocument10 pagesVarian Analytical Instruments 2700 Mitchell Drive WalnutkstaziNo ratings yet

- CP-3800 GC Operator's ManualDocument181 pagesCP-3800 GC Operator's ManualkstaziNo ratings yet

- CP-3800 GC Getting Started ManualDocument84 pagesCP-3800 GC Getting Started ManualkstaziNo ratings yet

- Gas ChromatographDocument20 pagesGas ChromatographkstaziNo ratings yet

- Vahle Power-ComDocument8 pagesVahle Power-Comkkhalil jibranNo ratings yet

- Eaton 9355 UPS-20-30 kVA-IO ManualDocument104 pagesEaton 9355 UPS-20-30 kVA-IO ManualavitNo ratings yet

- Learning Guide #4: Harar Polytechnic CollegeDocument13 pagesLearning Guide #4: Harar Polytechnic CollegeSami NurNo ratings yet

- New BS-400&420 - Service Manual - V1.0 - ENDocument369 pagesNew BS-400&420 - Service Manual - V1.0 - ENEmilioPerezBallesterosNo ratings yet

- Leica Zeno 20 Android: User ManualDocument42 pagesLeica Zeno 20 Android: User ManualSilviu PredaNo ratings yet

- TriodeDocument40 pagesTriodeTimothy Benson100% (1)

- 63230-216-230B1 Sepam Series 80 Reference ManualDocument288 pages63230-216-230B1 Sepam Series 80 Reference ManualIAMATMANo ratings yet

- Maglumi600,800 V2.8 20160308Document368 pagesMaglumi600,800 V2.8 20160308spiris100% (4)

- Manual Usuario Pantalla Android 10'' para AutoDocument17 pagesManual Usuario Pantalla Android 10'' para AutopablodanieltrumperNo ratings yet

- Samsung RF22K9381SR RefrigeratorDocument220 pagesSamsung RF22K9381SR Refrigeratorhoward.deiner1674No ratings yet

- MFJ-931 Instruction Manual Artificial RF GroundDocument5 pagesMFJ-931 Instruction Manual Artificial RF GroundswandererNo ratings yet

- Sony 897Document22 pagesSony 897Gerardo EspinozaNo ratings yet

- UniWell EX-500Document145 pagesUniWell EX-500Abdulwaheed100% (1)

- Ir 35Document68 pagesIr 35Alexandre MartinsNo ratings yet

- 5px Ups Manual North AmericaDocument25 pages5px Ups Manual North Americaapi-170472102No ratings yet

- Jftot 230 Mark Iv: OPERATION Manual: Revision DDocument163 pagesJftot 230 Mark Iv: OPERATION Manual: Revision DJuLieth PeinadoNo ratings yet

- Openair Rotary Actuators With Spring Return Gca 1: Technical BasicsDocument36 pagesOpenair Rotary Actuators With Spring Return Gca 1: Technical Basicse-genieclimatique.comNo ratings yet

- On Line PD Monitoting of Power System ComponentsDocument148 pagesOn Line PD Monitoting of Power System ComponentsjjcanoolivaresNo ratings yet

- 1 Abnormal Events: Ypes OF Abnormal OccurrencesDocument21 pages1 Abnormal Events: Ypes OF Abnormal Occurrenceszeeshan_bajwa1048100% (7)

- CG8350 User ManualDocument380 pagesCG8350 User ManualKVNo ratings yet

- Parrot Mk6100 Userguide Zone1Document100 pagesParrot Mk6100 Userguide Zone1Maria MartinNo ratings yet

- EMC Electromagnetic CompatibilityDocument36 pagesEMC Electromagnetic CompatibilitysaidiNo ratings yet

- Datamax E-4203Document92 pagesDatamax E-4203Злия Мупо ПиронковNo ratings yet

- User Manual: Installation Fiberoptic Repeater OZD Profi 12M ..Document72 pagesUser Manual: Installation Fiberoptic Repeater OZD Profi 12M ..Augusto Peruffo RodriguesNo ratings yet

- Manual UPS Omnivs500Document24 pagesManual UPS Omnivs500jjthebest24No ratings yet

- Manual Analizador de CloroDocument76 pagesManual Analizador de CloroEscobar ValderramaNo ratings yet

- Operations Manual: SynthesisDocument56 pagesOperations Manual: SynthesisFlorian CiprianNo ratings yet

- Leviton 6AS10-Xxx Atlas-X1 Cat 6A SlimLine Patch CordsDocument2 pagesLeviton 6AS10-Xxx Atlas-X1 Cat 6A SlimLine Patch CordsMaria VictoriaNo ratings yet

- A740-7 5KDocument235 pagesA740-7 5Kam198801No ratings yet

- DXI 800 Operation ManuelDocument80 pagesDXI 800 Operation Manuelsanaz67% (6)