Professional Documents

Culture Documents

ASTM A249/A249M-04a and UI: Not For Production Use (For Reference Only)

Uploaded by

nieav280Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM A249/A249M-04a and UI: Not For Production Use (For Reference Only)

Uploaded by

nieav280Copyright:

Available Formats

Not For Production Use (For Reference Only)

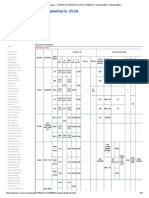

ASTM A249/A249M-04a and UI

Specification for Welded Austenitic Steel Boiler, Superheater, Heat Exchanger, and Condenser Tubes

Note - Identical to ASME SA249

Elements

(C) Carbon, max

(Mn) Manganese, max

(P) Phosphorus, max

(S) Sulfur, max

(Si) Silicon

(Ni) Nickel

(Cr) Chromium

(Mo) Molybdenum

(Ti) Titanium

ASTM Chemical Requirements

304

304L

309S

S30400

S30403

S30908

0.080

0.030

0.08

2.000

2.000

2.000

0.045

0.045

0.045

0.030

0.030

0.030

1.000

1.000

1.000

8.0-11.0

8.0-12.0

12.0-15.0

18.0-20.0

18.0-20.0

22.0-24.0

N/A

N/A

N/A

N/A

N/A

N/A

Mechanical Testing Test

ASTM

United

Flare

Not Required

Required

Flatten

Required

Required

Flange

Required

Required

Reverse Bend

Required

Required

Tension Test

Required

Required

Eddy Current

Required*

Required

Hydrostatic

Required*

Not Required

Pressure

Not Required

Required *

316

S31600

0.080

2.000

0.045

0.030

1.000

10.0-14.0

16.0-18.0

2.0-3.0

N/A

316L

S31603

0.030

2.000

0.045

0.030

1.000

10.0-14.0

16.0-18.0

2.0-3.0

N/A

321

S33200

0.080

2.000

0.045

0.030

1.000

9.0-12.0

17.0-19.0

N/A

5xC-0.70

Product Marking

-Man. Name or brand, spec. number, and grade on tube. For tubes

less than 1 1/4" in diameter or under 3' in length, a tag may be

secured to the box or bundle.

Mechanical Properties

Type

*Air pressure test 30 psi tubes over 20' for HBA / 180 grit / ID Polish tubes

* ASTM required either an Eddy Current or a Hydrostatic test be performed.

Size

Surface Condition

-The tubes, after heat treatment, shall be chemically descaled

or pickled free of scale. Pickling or chemical descaling is not

needed if bright annealing is used.

** Subsequent to welding and prior to final heat treatment, tubes shall

be cold worked either in both weld and base metal or in weld metal only.

Test

Outside Diameter

ASTM

United

Heat Treatment

-The material will be heat treated to a minimum of 1900 degrees F

and quenched.

Squareness

ASTM

United

304

304L

309S

316

316L

321

Tensile

Yield

min, ksi (Mpa) min, ksi (Mpa)

75 (515)

70 (484)

75 (515)

75 (515)

70 (485)

75 (515)

30 (205)

25 (170)

30 (205)

30 (205)

25 (170)

30 (205)

Elong. At 2"

min, %

Hardness

Rockwell B, max.

35

35

35

35

35

35

90

90

90

90

90

90

Dimensional Requirements

Length**

Straightness

ASTM

United

ASTM

United

Weld Height

ASTM

United

1/2"

+/- .004

+/- .004

N/A

.015

-0 +1/8

-0 +1/8

.030/36"

.030/36"

.006

3/4"

+/-.004

+/-.004

N/A

.015

-0 +1/8

-0 +1/8

.030/36"

.030/36"

.006

1"

+/-.006

-.006/+.002

N/A

.015

-0 +1/8

-0 +1/8

.030/36"

.030/36"

.006

1-1/2"

+/- .006

-.006/+.002

N/A

.025

-0 +1/8

-0 +1/8

.030/36"

.030/36"

.006

2"

+/- .010

-.006/+.002

N/A

.035

-0 +3/16

-0 +3/16

.030/36"

.030/36"

.006

2-1/2"

+/- .012

-.008/+.002

N/A

.040

-0 +3/16

-0 +3/16

.030/36"

.030/36"

.010

3"

+/- .015

-.008/+.003

N/A

.045

-0 +3/16

-0 +3/16

.030/36"

.030/36"

.010

3-1/2"

+/- .015

-.008/+.003

N/A

.045

-0 +3/16

-0 +3/16

.030/36"

.030/36"

.010

4"

+.015 / -.025

-.008/+.003

N/A

.045

-0 +3/16

-0 +3/16

.030/36"

.030/36"

.010

6"

+.015 / -.025 +.015 / -.025

N/A

.045

-0 +3/16

-0 +3/16

.030/36"

.030/36"

.010

** These tolerances apply to 24 ft. lengths or less. For lengths over 24 ft. add a tolerance of 1/8 in. for each 10 ft., or fraction thereof, up to a max of 1/2 in.

+.004

+.004

+.004

+.006

+.006

+.010

+.010

+.010

+.010

+.010

Wall***

ASTM

United

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

+/- 10%

*** Applicable only when nominal wall is specified. When minimum wall is specified, the tolerance is -0 +18%.

OP-05-01-B ISSUE: 02/26/97 REV: 05/23/05

ref: 2005 ASTM Standard Vol. 01.01

You might also like

- Tabla de Referencias de Aceros Inoxidables (ASTM A213)Document1 pageTabla de Referencias de Aceros Inoxidables (ASTM A213)Baltasar BuchiniNo ratings yet

- Stud Bolt Specification 3Document7 pagesStud Bolt Specification 3santoshblonkarNo ratings yet

- BS 970 SteelsDocument8 pagesBS 970 SteelsTamal Guha100% (2)

- Technical DataDocument17 pagesTechnical Datat_syamprasadNo ratings yet

- Equivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIDocument10 pagesEquivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIPuneet BahriNo ratings yet

- Leaded Tin Bronze C54400Document3 pagesLeaded Tin Bronze C54400nfcastingsNo ratings yet

- A 447Document27 pagesA 447superman3kNo ratings yet

- Basic Steel Selection Based On BS 970 en SeriesDocument8 pagesBasic Steel Selection Based On BS 970 en SeriesAmarendra Pendse100% (1)

- BS 970 steel specifications and European standards comparisonDocument5 pagesBS 970 steel specifications and European standards comparisonaezeadNo ratings yet

- Aisi 200 SeriesDocument19 pagesAisi 200 Seriessgupta_192494No ratings yet

- A 789 - A 789M - 02 Qtc4os0wmkeDocument4 pagesA 789 - A 789M - 02 Qtc4os0wmkeAhmad HajeerNo ratings yet

- ASTM A335 P92 SpecificationDocument4 pagesASTM A335 P92 SpecificationTarun ChandraNo ratings yet

- SteelDocument38 pagesSteelArdeela IlezNo ratings yet

- Astm A269Document5 pagesAstm A269Jose M-hNo ratings yet

- A516 Plate Data SheetDocument3 pagesA516 Plate Data SheetAman BansalNo ratings yet

- A 313 - A 313M - 98 Qtmxmy9bmzezts1sruq - PDFDocument7 pagesA 313 - A 313M - 98 Qtmxmy9bmzezts1sruq - PDFTiến Lượng NguyễnNo ratings yet

- A269Document5 pagesA269Jeffrey StokesNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material ApplicationMuhammadShabbirNo ratings yet

- Astm A270-03 S2 / Asme Bpe and Ui: Not For Production Use (For Reference Only)Document1 pageAstm A270-03 S2 / Asme Bpe and Ui: Not For Production Use (For Reference Only)Federico RevelloNo ratings yet

- Stainless AISI 3XXDocument3 pagesStainless AISI 3XXThitaphol HuyananNo ratings yet

- Astm A335 P9 Alloy Steel PipeDocument3 pagesAstm A335 P9 Alloy Steel PipeHamid MansouriNo ratings yet

- Suhm Spring Works Materials GuideDocument35 pagesSuhm Spring Works Materials GuidelindseyavNo ratings yet

- Properties and Composition of Common Stainless SteelsDocument3 pagesProperties and Composition of Common Stainless SteelsVijayakumar AtthuluriNo ratings yet

- Stainless Steel 304 Material Property Data SheetDocument2 pagesStainless Steel 304 Material Property Data SheetRahul SrivastavaNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- ELGIN02 Pipa TembagaDocument6 pagesELGIN02 Pipa TembagaiwudNo ratings yet

- Piping Equipment SpecificationsDocument4 pagesPiping Equipment Specificationsmabrouk2013No ratings yet

- Structural SteelsDocument1 pageStructural SteelsrjueiNo ratings yet

- Alloy 6005A: We Are AluminumDocument2 pagesAlloy 6005A: We Are AluminumLeo PardNo ratings yet

- Selection of Engg Materials of Equipment and Piping SystemDocument17 pagesSelection of Engg Materials of Equipment and Piping SystemNiraj PandyaNo ratings yet

- Tata Steel Cutting Edges GuideDocument2 pagesTata Steel Cutting Edges GuideKen SmithNo ratings yet

- Web Page Blocked: Home Matter IndexDocument5 pagesWeb Page Blocked: Home Matter Index4arunpandeyNo ratings yet

- A36 Asme/Astm: Carbon Structure Steel To ASTM A36/A36M Standard UseDocument1 pageA36 Asme/Astm: Carbon Structure Steel To ASTM A36/A36M Standard Useadam150161No ratings yet

- S.No Materials Specification DescriptionDocument4 pagesS.No Materials Specification DescriptioniyamNo ratings yet

- Astma 20 PDFDocument6 pagesAstma 20 PDFNoel BGNo ratings yet

- Sunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcesDocument6 pagesSunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcesPrad1979No ratings yet

- ASME SA213M / SA213 T9 Seamless Alloy Steel TubesDocument7 pagesASME SA213M / SA213 T9 Seamless Alloy Steel TubesJayminNo ratings yet

- Astm A554-Asme Sa554 Welded Stainless Steel Mechanical TubingDocument3 pagesAstm A554-Asme Sa554 Welded Stainless Steel Mechanical TubingBudy SinagaNo ratings yet

- Astm A335 p11 Specification Sunny SteelDocument4 pagesAstm A335 p11 Specification Sunny SteelPTSBatam TechNo ratings yet

- API 2W Grade 50 Steel Plate Spec SheetDocument1 pageAPI 2W Grade 50 Steel Plate Spec SheetRony LesbtNo ratings yet

- Valve Material Application PDFDocument16 pagesValve Material Application PDFSudherson Jagannathan100% (1)

- Bar STDDocument8 pagesBar STDtushk20100% (1)

- Valve Material ApplicationDocument16 pagesValve Material Applicationme100% (1)

- Material Cross Reference TableDocument3 pagesMaterial Cross Reference TableLuis Pol SistiNo ratings yet

- A 789 - A 789M - 04 Qtc4os9bnzg5tqDocument4 pagesA 789 - A 789M - 04 Qtc4os9bnzg5tqAhmad HajeerNo ratings yet

- ASTM A 182 Forged Alloy SteelDocument6 pagesASTM A 182 Forged Alloy SteelRayan AlfredNo ratings yet

- Thermanit Chromo 9V SMAW enDocument1 pageThermanit Chromo 9V SMAW ensoft4gsmNo ratings yet

- Heat-Treated Structural Steel Product Data SheetDocument2 pagesHeat-Treated Structural Steel Product Data SheetMarco BacianNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- NHOS GUIDE en v4 2Document13 pagesNHOS GUIDE en v4 2nieav280No ratings yet

- HM BrochureDocument6 pagesHM Brochurenieav280No ratings yet

- ACXDocument8 pagesACXnieav280No ratings yet

- Proposal of Radial Drill Machine SER-IDocument2 pagesProposal of Radial Drill Machine SER-Inieav280No ratings yet

- Deltaflux Bypass FlowmeterDocument2 pagesDeltaflux Bypass Flowmeternieav280No ratings yet

- 84734Document8 pages84734nieav280No ratings yet

- 730 Brochure 32942Document4 pages730 Brochure 32942nieav280No ratings yet

- MMT Best of Dubai - 7 Nights PDFDocument2 pagesMMT Best of Dubai - 7 Nights PDFnieav280No ratings yet

- The Engineer's Guide To Drive, Control, and Sensing TechnologyDocument4 pagesThe Engineer's Guide To Drive, Control, and Sensing Technologynieav280No ratings yet

- Different Types of Mechanical SealDocument20 pagesDifferent Types of Mechanical SealGlobe Star Engineers Pvt Ltd63% (8)

- By-Pass Rotameter D D2 TypeDocument2 pagesBy-Pass Rotameter D D2 Typenieav280No ratings yet

- Proposal of Radial Drill Machine SER-IIDocument2 pagesProposal of Radial Drill Machine SER-IInieav280No ratings yet

- Mbs Registration FormDocument1 pageMbs Registration FormavijayakumarsamyNo ratings yet

- Disability Evaluation GuidelinesDocument50 pagesDisability Evaluation Guidelinesbijujc100% (4)

- Disability Evaluation GuidelinesDocument50 pagesDisability Evaluation Guidelinesbijujc100% (4)

- DTR 650 User ManualDocument70 pagesDTR 650 User Manualnieav280100% (1)

- Star Connect Retail Reqeust FormDocument7 pagesStar Connect Retail Reqeust Formhumbjumb2010No ratings yet

- 194DA Payment in Respect of Life Insurance PolicyDocument1 page194DA Payment in Respect of Life Insurance Policynieav280No ratings yet

- GWSSB SOR Section A MaterialDocument56 pagesGWSSB SOR Section A Materialnieav280100% (1)

- Centrifugal Water FiltrationDocument3 pagesCentrifugal Water Filtrationnieav280No ratings yet

- Read Me!Document2 pagesRead Me!Faisal AhmedNo ratings yet

- Manual: Offices - Australia Offices - OverseasDocument4 pagesManual: Offices - Australia Offices - Overseasnieav280No ratings yet

- X-Ray Exposure Chart: 80kV 100kV 120kV 140kV 160kV 180kVDocument1 pageX-Ray Exposure Chart: 80kV 100kV 120kV 140kV 160kV 180kVnieav280No ratings yet

- Snowcem ProductDocument6 pagesSnowcem Productnieav280No ratings yet

- Is 1537Document22 pagesIs 1537Otavio123No ratings yet

- TD-W8968 V2 DatasheetDocument4 pagesTD-W8968 V2 Datasheetnieav280No ratings yet

- IS-3589 Steel Pipes For Water & SewageDocument21 pagesIS-3589 Steel Pipes For Water & Sewagenieav280No ratings yet

- Selpro DatasheetDocument2 pagesSelpro Datasheetnieav280No ratings yet

- Template 1Document1 pageTemplate 1sadingbaliNo ratings yet