Professional Documents

Culture Documents

Codigos de Erro

Uploaded by

Marco OlivettoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Codigos de Erro

Uploaded by

Marco OlivettoCopyright:

Available Formats

320B & 320B L Excavators 5GW00001-UP (MACHINE) POWERED BY 3066 En...

Pgina 1 de 6

Fechar o SIS

Tela anterior

produtos: EXCAVATOR

Modelo: 320B L EXCAVATOR 5GW00250

Configurao: 320B & 320B L Excavators 5GW00001-UP (MACHINE) POWERED BY 3066 Engine

Teste e Ajustes

308B, 311B, 312B, 315B, 317B, 318B, 320B, 322B, 325B, 330B, M325B and W330B

Excavators Engine and Pump Control

Nmero de Mdia -RENR1998-06

Data de Publicao -01/10/2004

Data de Atualizao -06/10/2004

i01260546

Troubleshooting Diagnostic Codes

SMCS - 7569

Table 1

Real Time Error Codes

Code

Description Of Problems

1301

Engine oil pressure is too low.

1302

Engine coolant temperature is too high.

1303

Hydraulic oil temperature is too high.

1304

The air filter is clogged.

1305

Battery Voltage is not normal.

2201

Governor actuator feedback sensor circuit is open or shorted to battery.

2202

Governor actuator feedback sensor circuit is shorted to ground.

2301

Governor actuator feedback signal is not stable.

2302

Governor actuator feedback signal deviates.

2303

Governor actuator does not move.

2304

Calibration data error.

3201

Monitor RAM is not normal.

4101

Electric power supply to the controller is too much (43 volts).

4102

Over-current in proportional reducing valve.

4103

Proportional reducing valve is circuit is open.

4105

Over-current in digital output (trenching solenoid).

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 12/11/2015

320B & 320B L Excavators 5GW00001-UP (MACHINE) POWERED BY 3066 En... Pgina 2 de 6

4106

Over-current in digital output (fine control solenoid).

4107

Over-current in digital output (travel speed change solenoid).

4108

Over-current in digital output (travel alarm).

410A

Over-current in digital output (swing break solenoid).

4201

Engine speed is not normal.

4202

Engine coolant temperature sensor is shorted to ground.

4203

Hydraulic oil temperature sensor is shorted to ground.

4204

PWM sensor of pump delivery pressure is shorted to ground.

4207

PWM sensor of pump delivery pressure has an open circuit.

420A

Fuel sensor is shorted to ground.

420B

Fuel sensor is open or shorted to battery voltage.

420C

Electric power supply is too low (below 23 volts).

420D

Electric power supply is too high (above 32 volts).

420E

Engine speed dial is not one of the specified 10.

4301

Data mismatch 1 between alternator and speed sensor (alternator is abnormal).

4302

Data mismatch 2 between alternator and speed sensor (speed sensor is abnormal).

4303

Engine stalls.

A201

Monitor communication is not normal.

A202

Monitor takes too much time to respond to a controller signal.

A203

Communication is abnormal in controller.

The alert indicators for the controller and/or the monitor are illuminated, when the engine/pump

control detects a diagnostic code in the normal mode. The Real Time Error function of the "Data

Mode" is used in order to show the detected diagnostic codes. The following troubleshooting

procedures were written in order to help troubleshoot the system. However, the same procedures

may be used to help determine the areas that may have caused an error to be logged.

Note: When a diagnostic code for a sensor is present, the corresponding alert indicator on the

monitor panel is activated. For example, if the coolant temperature sensor is shorted to +battery,

then the following conditions will result:

1. The corresponding error code is stored in memory.

2. The gauge for the engine coolant temperature shows the region with the problem.

3. The action lamp will FLASH. Item 2 and item 3 are identical to the warning indications that

are activated if the engine actually overheats.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 12/11/2015

320B & 320B L Excavators 5GW00001-UP (MACHINE) POWERED BY 3066 En... Pgina 3 de 6

Troubleshooting Procedures

1. Controller self-diagnostic LED display

No power supply to controller

Communication problem between controller and monitor (A201, A202, A203).

Monitor is abnormal (3201).

2. Fuel gauge indication is abnormal (420A and 420B).

3. Engine coolant overheat indicator comes ON (1302).

Engine coolant temperature gauge indication is abnormal (4202).

4. Hydraulic oil temperature alarm indicator comes ON (1303).

Hydraulic oil temperature gauge indication is abnormal (4203).

5. Engine oil pressure alarm indicator comes ON (1301).

Engine oil pressure alarm indicator is abnormal.

6. Clogged air filter indicator comes ON (1304).

Clogged air filter indicator is abnormal.

7. Engine coolant level indicator is abnormal.

8. Hydraulic oil level indicator is abnormal.

9. Engine oil level indicator is abnormal.

10. Hydraulic oil filter indicator is abnormal.

11. Charge alert indicator comes ON while engine is running (4301).

Check of speed sensor (4201 and 4302).

12. Battery voltage is abnormal (not within 23 to 32 volts), (1405, 4101, 420C and 420D).

13. Engine speed dial does not work (engine speed does not change), (420E and 2303).

14. Low idle switch does not work.

15. AEC is abnormal.

16. Check of feedback signal from governor actuator (2201, 2202, 2301, and 2302).

17. Controllability is bad in boom priority mode (4105).

18. The stick moves slowly (4106).

19. The torque of the swing is weak in the swing priority mode (4105).

20. The travel alarm is abnormal (4108).

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 12/11/2015

320B & 320B L Excavators 5GW00001-UP (MACHINE) POWERED BY 3066 En... Pgina 4 de 6

21. Automatic travel speed change (Low/High) is abnormal (4107, 4204 and 4207).

22. Swing is inoperable (410A).

23. 1. Check over-current at proportional reducing valve (4103).

24. 2. Check open circuit at proportional reducing valve (4103).

25. 3. Check short circuit of proportional reducing valve to battery voltage.

26. Calibration data error (2304).

27. Engine stalls (4303).

Example Of Troubleshooting

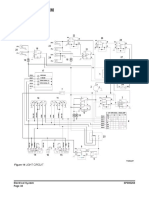

Illustration 1

g00663017

Example Of A Checking Procedure For The Electronic Control System

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 12/11/2015

320B & 320B L Excavators 5GW00001-UP (MACHINE) POWERED BY 3066 En... Pgina 5 de 6

(1) Preparations.

(2) Problem description.

(3) Error code character display (Ch. D.)

(4) Check item.

(5) Probable causes and solutions.

Note: The character display on the monitor panel will indicate an error code on the character

display (3). The charts that follow should be used in order to troubleshoot the problems that are

indicated by the error code on the character display (3) .

A check of a connector will provide information about the connectors that should be checked

before troubleshooting. Check the specified connectors for improper connections. A loose contact

between two connectors can be caused by water in the connectors.

Check the connectors before troubleshooting.

Preparations (1) provide information on the preliminary arrangements that must be made before

troubleshooting.

The problem description (2) will indicate the problems that are shown by the character display on

the monitor panel.

The error code that is shown will indicate specific codes for real time errors and error log. The

service program that is selected will determine the pattern of the character display.

The section for "check items" (4) will list items that must be checked by using a multimeter.

The "check items" (4) information, "0 Ohms" means that "continuity is present" and

"infinite" means that "there is no continuity".

Connector check : (other than "[/em/]"): 0 Ohms

Note: (Other than "[/em/]" means all of the terminals or all the pins of the connector, except the

one that is specified in "[ ]".

The following information is an example of the terms in "Check Items (4)".

Example: (1)-(2) of CONN56M

(1) is the pin number

(2) is the short circuit indication

"CONN56" is the connector number.

M is the male (M) or female (F) half of the connector.

The probable causes (5) show the probable cause(s) of a problem.

The solution (5) shows the corrective action that should be taken in order to solve a particular

problem. The statement "Replace" includes "Repair if possible".

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 12/11/2015

320B & 320B L Excavators 5GW00001-UP (MACHINE) POWERED BY 3066 En... Pgina 6 de 6

The key start switch should be placed in the OFF position, before a continuity check is performed.

This prevents the power supply from damaging the tester or shorting the power supply.

The key start switch should be in the ON position, before the voltage is measured. The engine

should be operating unless you are instructed not to have the engine in operation. A stable input

and output of the controller cannot be obtained unless the engine is running.

NOTICE

To avoid damage to the electrical components when the power supply

is ON, ensure that the wires and the connectors that have been

disconnected, do not contact the machine.

Direitos Autorais 1993 - 2015 Caterpillar Inc.

Thu Nov 12 22:25:37 UTC-0200 2015

Todos os Direitos Reservados.

Rede Particular Para Licenciados SIS.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 12/11/2015

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hyundai 210LC7 Hydraulic System DiagramDocument35 pagesHyundai 210LC7 Hydraulic System DiagramMarco Olivetto100% (6)

- Amana Stove Range AER5715QAS Service Manual P1Document36 pagesAmana Stove Range AER5715QAS Service Manual P1Andrew GeddesNo ratings yet

- Base 6x6 Panther SpecificationDocument55 pagesBase 6x6 Panther Specificationfnajsdfnl100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 966h PDFDocument13 pages966h PDFaeylxd100% (3)

- 312C - Esquema EletricoDocument2 pages312C - Esquema EletricoMarco OlivettoNo ratings yet

- 12H - Specs0Document5 pages12H - Specs0Marco OlivettoNo ratings yet

- Elevator Control Wiring and Simple Configuration: Button ModeDocument7 pagesElevator Control Wiring and Simple Configuration: Button ModeAgnelo FernandesNo ratings yet

- 1079 3Document5 pages1079 3Marco OlivettoNo ratings yet

- Air Con GuideDocument65 pagesAir Con GuidePeter Vom VersuchNo ratings yet

- Heui Fuel System c9 Engine PDFDocument25 pagesHeui Fuel System c9 Engine PDFmark100% (6)

- Combinational Logic CircuitsDocument6 pagesCombinational Logic CircuitsJohn Brix Balisteros100% (1)

- Motor DB58TIS PDFDocument198 pagesMotor DB58TIS PDFRonaldi motter75% (16)

- 621D ZF Electrical SchematicDocument2 pages621D ZF Electrical SchematicMarco Olivetto75% (4)

- Hyundai Erro CarregadeiraDocument43 pagesHyundai Erro CarregadeiraMarco OlivettoNo ratings yet

- Condor v1.0 Default Keyboard Assignments: Command Default Key RemarksDocument2 pagesCondor v1.0 Default Keyboard Assignments: Command Default Key RemarksMarco OlivettoNo ratings yet

- Komatsu PC300 Errors CodeDocument6 pagesKomatsu PC300 Errors CodeMg Roy87% (15)

- Manual Partes Perforadora MD6420Document576 pagesManual Partes Perforadora MD6420maocaleirl100% (7)

- CS 533E Cat Manual de Peças e ServiçosDocument824 pagesCS 533E Cat Manual de Peças e ServiçosMarco Olivetto0% (1)

- CS 533E Cat Manual de Peças e ServiçosDocument824 pagesCS 533E Cat Manual de Peças e ServiçosMarco Olivetto0% (1)

- Seletora 924F CaterpillarDocument6 pagesSeletora 924F CaterpillarMarco OlivettoNo ratings yet

- Pressure JSDocument3 pagesPressure JSMarco OlivettoNo ratings yet

- Operation and Maintenance Manual: 1106D Industrial EngineDocument106 pagesOperation and Maintenance Manual: 1106D Industrial EngineJan AhmedNo ratings yet

- 1104D and 1106D Series: EPG Mechanical and Electronic Installation ManualDocument153 pages1104D and 1106D Series: EPG Mechanical and Electronic Installation ManualJan AhmedNo ratings yet

- Main Control Valve: Electrical System 318D2 ExcavatorDocument2 pagesMain Control Valve: Electrical System 318D2 ExcavatorMarco Olivetto100% (1)

- HL740 9SDocument4 pagesHL740 9SMarco Olivetto0% (1)

- Service Instructions 6Document3 pagesService Instructions 6nicho.estilo96No ratings yet

- 318D2 - Ar CondicionadoDocument2 pages318D2 - Ar CondicionadoMarco OlivettoNo ratings yet

- Supra FuseDocument4 pagesSupra FuseMarco OlivettoNo ratings yet

- Supra F3J/TD Fin: MD 14 May 04Document2 pagesSupra F3J/TD Fin: MD 14 May 04Marco OlivettoNo ratings yet

- Htail - V2 Buble DancerDocument3 pagesHtail - V2 Buble DancerMarco OlivettoNo ratings yet

- Grader engine spring color changesDocument8 pagesGrader engine spring color changesMarco OlivettoNo ratings yet

- 0.06Document2 pages0.06Marco OlivettoNo ratings yet

- 0.8 Oz Kevlar or 2 Oz Glass Hinge, Sheared Bias, Glued Into SlitsDocument2 pages0.8 Oz Kevlar or 2 Oz Glass Hinge, Sheared Bias, Glued Into SlitsMarco OlivettoNo ratings yet

- 0.06Document2 pages0.06Marco OlivettoNo ratings yet

- Light CircuitDocument1 pageLight CircuitMarco OlivettoNo ratings yet

- Molas e Slug Seletora 120HDocument5 pagesMolas e Slug Seletora 120HMarco OlivettoNo ratings yet

- 7-Series: Electric Walkie Adjustable Straddle StackerDocument2 pages7-Series: Electric Walkie Adjustable Straddle StackerMiguelangel Contreras SanchezNo ratings yet

- Classroom/Shop Manual Chapter 3: Electrical and Electronic Components/ Troubleshooting and ServiceDocument58 pagesClassroom/Shop Manual Chapter 3: Electrical and Electronic Components/ Troubleshooting and ServiceAmir AsyraafNo ratings yet

- Catalogo Protecciones Termicas ALLEN BRADLEY - 193-Pp016 - En-PDocument8 pagesCatalogo Protecciones Termicas ALLEN BRADLEY - 193-Pp016 - En-PbolasalazarNo ratings yet

- Allweiler Screw Pumps AEB GBDocument24 pagesAllweiler Screw Pumps AEB GBDmitrii Pustoshkin100% (1)

- K StarDocument31 pagesK Starrajish2014No ratings yet

- Install and maintain water-cooled screw chillersDocument36 pagesInstall and maintain water-cooled screw chillersMaltin SelmanllariNo ratings yet

- Alerton VLX ExpDocument2 pagesAlerton VLX ExpJandersonDiegoNo ratings yet

- SGM LEKTRA Pmag - T - ENDocument48 pagesSGM LEKTRA Pmag - T - ENEynar FrancoNo ratings yet

- Check List Technam p2008jfDocument2 pagesCheck List Technam p2008jfGourav DasNo ratings yet

- English User Manuel of Mini Rotary OvensDocument40 pagesEnglish User Manuel of Mini Rotary Ovensiliad.zaryabNo ratings yet

- Basic Electrical Controls For Fluid PowerDocument21 pagesBasic Electrical Controls For Fluid PowerSelemon Assefa100% (1)

- 9661 Series DatasheetDocument3 pages9661 Series DatasheetNichitaNo ratings yet

- SUN2000-330KTL-H1, 330KTL-H2 User Manual-Preliminary - ENDocument92 pagesSUN2000-330KTL-H1, 330KTL-H2 User Manual-Preliminary - ENManuelCipagautaZNo ratings yet

- AE1314Document9 pagesAE1314Maria DazaNo ratings yet

- 1SDC200023D0207 - CT Emax2 - 2017 - Video PDFDocument304 pages1SDC200023D0207 - CT Emax2 - 2017 - Video PDFAvijitSinharoyNo ratings yet

- Zelio Logic ATS ApplicationDocument2 pagesZelio Logic ATS Applicationyousuf79No ratings yet

- D165 Series D165 Series: Service Hose Crimpers Service Hose CrimpersDocument32 pagesD165 Series D165 Series: Service Hose Crimpers Service Hose CrimpersJhon VasquezNo ratings yet

- Proline Prosonic Flow 90P, 93P: Technical InformationDocument32 pagesProline Prosonic Flow 90P, 93P: Technical InformationMiladinm1No ratings yet

- Icaro Ul - 120v - Sliding Operator - ManualDocument12 pagesIcaro Ul - 120v - Sliding Operator - ManualServicios TecnicosNo ratings yet

- Liebert Series 7400m - 50hz - Users ManualDocument86 pagesLiebert Series 7400m - 50hz - Users Manualpawanmandeep201250% (2)

- Installation, Operation & Maintenance Instructions: 1100°C - 1200°C Chamber Furnaces Types CSF, BOF & RHFDocument12 pagesInstallation, Operation & Maintenance Instructions: 1100°C - 1200°C Chamber Furnaces Types CSF, BOF & RHFthexsamNo ratings yet

- City Multi - Manual KD79K690H01Document27 pagesCity Multi - Manual KD79K690H01Hung Tran67% (3)

- Los ADocument115 pagesLos AMatt BaasNo ratings yet

- xr60ch en GB 3843020Document4 pagesxr60ch en GB 3843020Ra CubikNo ratings yet