Professional Documents

Culture Documents

ANTISEEPAGE AND CONSOLIDATION GROUTING OF THE CHIRKEY HYDROELECTRIC DAM FOUNDATION

Uploaded by

Af RymOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ANTISEEPAGE AND CONSOLIDATION GROUTING OF THE CHIRKEY HYDROELECTRIC DAM FOUNDATION

Uploaded by

Af RymCopyright:

Available Formats

ANTISEE

PAGE

OF FOUNDATION

DAM

OF

AND

CONSOLIDATION

AND

CHIRKEY

ABUTMENTS

HYDROELECTRIC

GROUTING

OF

THE

POWER

ARCH

STATION*

V. G. Skokov

UDC 627.82:624.152.612.3

The arch dam o f the Chirkey Hydroelectric Power Station is one of the highest in the world, its total height

being 230 m. and the m a x i m u m thickness of the arch portionat the plugbase amounting to 30 m. The stresses in

portions of the dam foundations subjected to the maximum loading can reach 100 k g / c m z. The region where the

dam is being constructed is highly seismic. The latest of the large earthquakes, with a magnitude of 8, occurred

in 1970, during its construction.l"

The dam is being constructed in a mountain gorge passing through limestones which are bedded almost horizontally, with a low dip (3 to 8") toward the right band and also upstream. The limestone beds are interbedded

with c l a y e y - m a r l y seams 5 to 30 cm thick. The jointing of the rocks comprising the dam foundation is related

to their tectonics. Owing to the proximity of large tectonic fracture zones (the nearest passes 350 m below the dam

site), the Chirkey gorge limestones are intersected by numerous tectonic joints with openings of up to 10 em and

sometimes 20 cm. accompanied by displacements and fragmentation zones. The strikes and dips of the joints vary

considerably. Along the steeply dipping joints paralleling the river, a b u t m e n t - r e l i e f joints develop, passing into

shears. This r e l i e f jointing is observed in both abutments. On the lefr bank, shear zones are traced to a depth

of 200 m. The unstable blocks that form are caused mostly by the inclined tectonic joints dipping toward the river

and filled with clayey material, or the seams of clay or marl along the bedding planes.

The joint void ratio 0yr.) for the surface portion of the rock, which is subjected to weathering ranges from

1 to 13% (mo;tly 2 to 4%). At depth (80 to 100 m from the surface), the rock has a j.v.r, of 0.2 to 0.b~o, hut

within zones o f large tectonic jointing it reaches 1 to 1.5%. The permeability of the limestones is conditioned b y

their jointing and the presence of rmmerous marly and clayey seams. Joints which determine the permeability of

rocks can be divided into two main groups:

a) Small cleavage joints, which impart a general but weak permeability to the rock, mostly along the seams;

b) large tectonic joints which form the main source of a high but local permeability of the rock, maintained

for hundreds o f meters along the joints. Of particularly high permeability are the fragmented rocks at the nodes

of joint intersections, where the permeability coefficient k reaches 5 to 10 m/day, and sometimes 20 m / d a y .

In the gorge abutments, permeability diminishes with depth according to the same law as applies to the

jointing intensity. The mean values of k are 0.1 to 0.6 m/day, and at a depth o f 60 m and greater its value under

the d a m - p l u g foundation does not. as a rule. exceed 0.015 m / d a y . These rocks, compared with the layer above.

can be regarded forming as a relatively watertight zone, except for two segments which were disclosed during

grouting operations. The segment on the left bank is associated with a local fissure which was traced in the grout

holes at depths exceeding 120 m. The segment on the right bank, located over 100 m from the dam, is associated

with a group of joints located at even greater depths.

=The Chirkey Hydroelectric Power Station is described in an article by M. V. Mitrushkin and E. I. Shnyrov, Gidrotekh. Srroitel., No. 9 (1974). Also see the literature cited at the end of this a r t i c l e - The Editors.

TSee the article by B. M. Erakhtin. "Effectsof earthquakes in the re,on of the Chirkey Hydroelectric Planr~"

Gidrotekh. Stroitel..No. 12 (1971)- The Editors.

Translated from Gidrotekhnicheskoe Sttoltel'swo, No. 10, pp. 6-9, October, 1974.

909

V. G. SKOKOV

910

//

3/

C~ment consumption per lin.m.

,kg

3{700

11

2~00 1 1

IOD~ 41

/f

Kg t

//

GR-4

r.. . . . . .

:------

~"

!

I

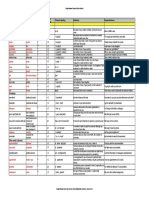

Fig. 1. Diagram of cement consumption in adits GR-1 to GR-4 (kg per lin.m).

The deformafional properties of the lirn~sron~ comprising the foundation of the Chirkey Dam vary greatly.

The deformation moduins ranges from 20 to 400 rons/cm z, depending on jointing and the content of clays and marls.

The design of foundation antiseepage and consolidation work provides for: a) the formation of a groat cuctain

with an area of 135,000 m z and a depth of 200 to 300 m in the abutments and 60 m into the foundation (down to the

wa mrtight zone); b) consolidation grouting of 780, 000 m s of rock formations immediately ad joining the dam base

and the power station building; c) system of deep drain holes; d) rock-boit strengthening of the left abutment of

the dam. The principal aim o f the grout curtain and the drainage system is to reduce and intercept the seepage

flow and to lower the seepageoflow levels beyond the curtain.

The overall dimensions of the curtains and their spatiat layout were detecmined from the results of engineering-geological investigations, and were checked in plane and three-dimensional electro-hydrodynamic analogy

models. The modeling also enabled the gradients across the curtain to be determined, which reached maximum

values of 16 to 18. Such high values are explained, not only by the great height of the dam, but also by certain

imperfections inthe method used for modeling the c u m i n elemem. The curtain thickness adopeted in the models.

equal to 0.8 to 1.0 times the final spacing of the grout holes, is undervalued and, therefore, gives gradients which

are higher than the actual. The curtain tighme~s (flow into the monitoring holes) was limited to not more than 0.01

liter~/rain.

Curtain grouting was commenced ha 1969. Presented below are some results of the grouting work which

ensured the reservoir could be filled within the limits necessary for commissioning the first turbogenerators.

ANTISEEPAGE AND CON,q'3LIDATION GROUTING OF FOUNDATION AND ABUTMENTS

911

The drilling and grouting of holes was carried out from adits lined with concrete 0.5 m thick, after backfill

grouting between the rock and the lining in the adit crown. Backfill grouting was carried out at a pressure of 3 to 5

aim or more. through holes which pierced the rock/lining interface and entered the rock to a depth of 0.2 to 0.5 m.

This grouang not o.~y filled the voids between the rock and the concrete but also the adjoining rock joints. For

example, in backfill grours o f a lenguh of143 m o f a d i t GR-i (Grouting, Right), the upper adit in the right abutment

a mixture o f 45 tons of c e m e n t and 25 tons of sand were injected, although overbreak during driving was rare and

cavities were insignificant.

The f r s t stage in the curtain work was grouting the rock behind the adit lining to a depth of 5 to 6 m outside

the lining, at pressures o f 15 to 40 a i m . The overall volume of this grouting was significantly reduced by reducing

the length o f the adits and their cross section (from 5 or 4.5 m to 4 or 3.5 m), deletion of grouting along the downstream wall, increasing the grout pressures, and providing a layout of curtain-stage interlinking which protected

the adits from the u~stream side by suitably changing the inclination of the curtain holes and increasing their depth.

The rock grouting behind the adit lining required nearly 2000 tons o f cement, which amounted to approximately 20% of the total c e m e n t usage on the curtain. Distribution of c e m e n t consumption along the adits was not

uniform. The main usages were confined to the zones of intersection of the adits with the major tectonic joints

(see Fig. 1), along which the grout traveled for very long distances. For instance, leakages into adjoining adits

were observed a t distances of 45 to 60 m from the injection point. The grouting significantly consolidated the

rock over practically the whole area of the curtain; the natural average values o f unit water consumption were 0.1 to

0.5 l i t e r / ( m i n 9 m z) and in the first-stage holes, drilled for the deep curtain, it was at a rate within the range 0.05

to 0.08 l i t e r / ( r a i n - m Z ) . The principal operation in constructing a curtain is grouting the deep holes: This involved

over 60.000 m of drilling and more than 8000 tons of cement.

Although the weighted mean values of unit water flow into the final-stage holes in several areas (e.g., on the

left bank, in the middle and lower stages of the curtain) were below the required norm, the results of tests on monitor

holes in the first stage of the left-bank curtain showed, on the one hand, the efficacy o f the grouting and, on the

other hand, the necessity to provide a second curtain or additional holes in various areas. Out o f 109 monitoring

tests, the average value of the unit inflow in 103 cases was 0.004 l i t e r / ( m i n , m 2) and. in six cases, from 0.03 to

0.075 t i t e r / ( m i n - m Z ) . After grouting the stage II holes, only two tests out of 56 showed an inflow above the norm

[0.02 and 0.07 l i t e r / ( m i n , mZ)]. Here a third row of holes was drilled. The average inflow along the second row

was about 0.0~3 l i t e r / r a i n - m " . A third, and in places a fourth, row of holes was grouted in zones where the curtain

was intersected by major tectonic joints. Along the right-hand curtain the mean value of the unit inflow in the

monitored holes (within the limits of the commissioning levels in the completed areas) was less than 0.005 l i t e r /

(min. mZ).

A number o f engineering innovations were introduced to increase the efficiency of the grouting work, namely:

a) the inelinometry o f holes on a mass scale; b) automated monitoring and recording of the main grouting parameters, primarily the pressure, which ensured a general improvement in the standard of grouting; c) grouting of the

holes in ascending zones, thus increasing the tabor output on grouting and drilling work; d) putting into production

the method of grouting curtains through rising holes, which made it possible to reduce the maximum depth of the

holes and the number of adits; e) introduction of a stage-by-stage monitoring of the acceptance of and payment

for the work; f) modernization of the drilling rig type NKR-100M, resulting in the achievement of drilling depths

which greatly exceeded the rated figure; g) development and introduction of a single-column packer, pressure

regulator, a centralized s e m i - a u t o m a t i c grout-mix assembly, etc.

The grouting result~ were analyzed continually as part of the work and the necessary corrections made to

the design. The extent of the work on the left bank was increased: The first row of the curtain was extended 30

to ~8 m into the bank, without increasing the overall volume of the work, through deletion of holes or their reduction in the water-retaining areas.

As a supplementary monitoring of the grouting results, full-scale and laboratory investigations were carried

oat in the zones of the. tectonic joints. The exposed and ~elected specimens of the hardened grout showed a good

adhesion to the clay filling the joints. Prolonged pumping of water into the joints confirmed the stability of the

grout-sealed johat filler against seepage under gradients exceeding 20. Seepage deformations, accompanied by

copious piping of clay material, commenced with gradients exceeding 60.

912

V . G . SKOKOV

Consolidation grouting of the dam foundation, to increase and equalize the deformation modulus of the jointed

rock in the zone o f high compressive stresses, is being carried out over the whole darn-to-rock contact area. In a d dition, the consolidation grouting serves as the junction between the curtain and the dam body; therefore, it must

meet requirements o f watertighmess. The consolidation gm~ting was carried out through radiating holes drilled

from adits in the zone of their junction with the dam, under the surcharge provided by the dam concrete (as a role,

not less than 30 m), after the joints between the blocks had been grouted. The monolithic concrete surcharge permite grouting under high pressure (up to 40 alma).

Where the concrete surcharge was small or missing, cracking was once observed in recently placed concrete

(although the injection point was only 15 m from the concrete, grout escaped into the excavation along the clay

seams in the rock). In another instance, when grouting was being done without a concrete surcharge, but at pressures not exceeding 10 to 20 atm, supplementary opening of joints in the rock occurred and grout appeared at the

excavation surface. The m a i n body of the work was carried out under a considerable (over 30 m) surcharge of concrete and without any significar/t complications.

The grouting remits are subjected to a double monitoring: a) the usual pumping tests, including the determination of unit water-consumption rates: and b) seismic testing, including the determination of the longitudinal velocities before and after grouting. During the investigation period, the relationship between the magnitude of the

static deformation modulus and the velocity Vp was determined. On this basis a monitoring value of Vp=4.5 km/sec

was adopted.

Before grouting, the longitudinal velocities vary within a wide range (2 to 6.5 km/sec). High velocities (3.5

to 6.5 k m / s e e ) are typical for the lower part of the dam site (excepting the plug foundation, where, due to the cleanup of an excavation o f considerable area, a lamination of the rock occurred). For the upper part of the site, low

velocity values (2 to 4.5 kin/see) are typical. On the right-bank excavation cut the velocity increases gradually

from the surface into the rock m a s s . At a distance of 30 m from the excavation surface, the velocities reach m i d interval values of 4 to 5 k m / s e e and then stabilize. On the left bank a weakened zone was disclosed, with depressed longitudinal velocities (2.5 to 4 kin/see). The zone is confined to tectonic joints, is 15 to 20 m wide, set back

20 to 30 m from the excavation surface, and was traced in the meddle and upper parts of the dam site.

Upon completion o f grouting the longitudinal velocities increase and stabilize. Thus, under the left-bank wing

of the plug, in the area adjoining adit GL-4 the velocities following grouting increased from 5 to 6 km/see to 5.5

to 6.5 kin/see under the wing, and from 3.5 to 6.4 kin/see to 5 to 6.4 kin/see in the zone of adit GL-4. Velocities

exceeding 6 k m / s e e are characteristic for joint-free rock, grouting o f which is ineffective and unnecessary. After

grouting the dam plug base, velocities increased from 2.5 to 5 k m / s e e to 4.6 to 6.5 km/sec.

Dam settlements observed before grouting, when its height ranged up to 75 m, were 5 to 6 mm. After the

dam joints had been grouted and intensive grouting had commenced in the foundation, a gradual reversal, that is,

a rise of 3 to 5 mm was observed although the dam had reached a height of 130 m. This is also indicative of the

effectiveness of the grouting of the foundations and joints of the dam.

CONCLUSIONS

1. The remits of engineering-geological explorations during grouting were confirmed. The necessary refinements regarding the geologic structure, in~nduced after the excavations had been opened up, the underground

excavations driven, and effected during groutin b were taken into account in the course o f the work.

2. The principal c e m e n t intakes during grouting are related to the system of tectonic joints, along which

the main seepage routes could be expected to form. The actual thickness of the curtain exceeds the theoretical

prerequisites o f modeling standards and conditions.

3. The method applied ensured effective grouting. The high pressure (40 to 45 arm) was fully justified. The

adopted hole spacing and curtain arrangement in rows, ensure the specified watertlghmess of 0.01 l i t e r / ( m i n - mZ).

The data yielded by geophysical investigations and settlement measurements testify to the success achieved with

the consolidation grouting.

ANTISEEPAGE AND CONSOLIDATION GROUTING OF FOUNDATION AND ABUTMENTS

913

4. Laboratory and full-scale investigations during the grouting work confirmed the post-grouting stability of

~he joint fillers against seepage.

5. The grouting results point to the possibility of reducing the volume of the work, principally, the grouting

of rock behind the adit linings.

You might also like

- Construction of BridgesDocument104 pagesConstruction of BridgesV Venkata Narayana89% (9)

- Expansive Clays in Deep Railway CutDocument8 pagesExpansive Clays in Deep Railway Cutscribd_geotecNo ratings yet

- CFRD 15 Lsmartín MXDocument10 pagesCFRD 15 Lsmartín MXjnfNo ratings yet

- Design and Construction of the Rion-Antirion BridgeDocument17 pagesDesign and Construction of the Rion-Antirion BridgeApoorva SinghNo ratings yet

- Seismic Protection of The Guadalfeo Bridge by Viscous DampersDocument10 pagesSeismic Protection of The Guadalfeo Bridge by Viscous Dampersavmurugan87No ratings yet

- Evinos Mornos TunnelDocument21 pagesEvinos Mornos TunnelsharathknNo ratings yet

- Geotechnical Studies and Design of La - Yesca - DamDocument11 pagesGeotechnical Studies and Design of La - Yesca - Damjdav1206No ratings yet

- Tunnelling challenges overcome at Tala hydroelectric projectDocument9 pagesTunnelling challenges overcome at Tala hydroelectric projectAnanda SenNo ratings yet

- BARRAGE SPECSDocument8 pagesBARRAGE SPECSVirat AhujaNo ratings yet

- Bouldin Dam Case HistoryDocument8 pagesBouldin Dam Case HistoryNat TikusNo ratings yet

- Geotechnical Studies and Design of La - Yesca - DamDocument11 pagesGeotechnical Studies and Design of La - Yesca - DamKarmen Cano IbarraNo ratings yet

- TS104Document7 pagesTS104Harold TaylorNo ratings yet

- 2002 Kempfert MexikoDocument6 pages2002 Kempfert MexikolingamkumarNo ratings yet

- Water Power Penstocks Hydrodynamic Pressures Due To Earthquakes Oct 2005Document5 pagesWater Power Penstocks Hydrodynamic Pressures Due To Earthquakes Oct 2005Bagheri HessamNo ratings yet

- UHE Barra GrandeDocument12 pagesUHE Barra Grandemarlon_schNo ratings yet

- An Open-Pit Coalmine Surcharged by Artesian Water PressureDocument22 pagesAn Open-Pit Coalmine Surcharged by Artesian Water PressurebrowncasNo ratings yet

- Ground Movement Associated With Trench Excavation and Their Effect On Adjacent ServicesDocument3 pagesGround Movement Associated With Trench Excavation and Their Effect On Adjacent ServicesEnri05No ratings yet

- Performance of The Tunnel Lining Subjected To Decompression Effects On Very Soft Clay DepositsDocument2 pagesPerformance of The Tunnel Lining Subjected To Decompression Effects On Very Soft Clay DepositsFederico MontesverdesNo ratings yet

- From Calamity To Full ComplianceDocument8 pagesFrom Calamity To Full ComplianceYannick LiemNo ratings yet

- Design of Grand Ethiopian Renaissance, RCC Main DamDocument10 pagesDesign of Grand Ethiopian Renaissance, RCC Main DamabrahamNo ratings yet

- Caso 1 - Tunel Sismico BoluDocument4 pagesCaso 1 - Tunel Sismico BoluCarlos Catalán CórdovaNo ratings yet

- Seismic Design of Underground Structures: The Bolu Tunnel UpgradeDocument5 pagesSeismic Design of Underground Structures: The Bolu Tunnel UpgradeJavier_GLNo ratings yet

- Numerical Analysis of Leakage through Geomembrane Lining Systems for DamsDocument7 pagesNumerical Analysis of Leakage through Geomembrane Lining Systems for DamsHồ ThắngNo ratings yet

- De G Grice 2010 Christchurch Ocean Outfall Microtunnel Settlement Backanalysis IAEGDocument8 pagesDe G Grice 2010 Christchurch Ocean Outfall Microtunnel Settlement Backanalysis IAEGlamyikchongNo ratings yet

- Schleiss External Water Pressure (E)Document10 pagesSchleiss External Water Pressure (E)Naresh ANo ratings yet

- The Sitina Motorway Tunnel in Bratislava: InfraprojektDocument8 pagesThe Sitina Motorway Tunnel in Bratislava: InfraprojektHarold TaylorNo ratings yet

- Designing Cut-Off Walls Under Concrete DamDocument17 pagesDesigning Cut-Off Walls Under Concrete DamNazakat HussainNo ratings yet

- Excavation of The Ridracoli Hydraulic Tunnels Using A Double-Shield T B MDocument25 pagesExcavation of The Ridracoli Hydraulic Tunnels Using A Double-Shield T B MReza OsgouiNo ratings yet

- Efficiency of Relief Means From Seepage Pressure of Tunnel LiningDocument6 pagesEfficiency of Relief Means From Seepage Pressure of Tunnel LiningHarold TaylorNo ratings yet

- Numerical Simulation of A Deep Excavation Near A Shield TunnelDocument9 pagesNumerical Simulation of A Deep Excavation Near A Shield TunnelEfi GusfianaNo ratings yet

- 13-Ground Water Contrl in Shaft Boring Operation 1992Document5 pages13-Ground Water Contrl in Shaft Boring Operation 1992Hari Prasad PidikitiNo ratings yet

- Barton-High Pressure Pre-Grouting. TTI Sept 2004 p28-30 PART IDocument3 pagesBarton-High Pressure Pre-Grouting. TTI Sept 2004 p28-30 PART Icastille1956No ratings yet

- CFRD 17 - Roy Ruiz VásquezDocument18 pagesCFRD 17 - Roy Ruiz VásquezjnfNo ratings yet

- Em-3 17Document9 pagesEm-3 17Parvatha Vardhan GandrakotaNo ratings yet

- Uljarević - CONVERGENCE MEASUREMENTS AND DATA ANALYSIS IN THE ACCESS TUNNEL OF DERIVATION TUNNELDocument10 pagesUljarević - CONVERGENCE MEASUREMENTS AND DATA ANALYSIS IN THE ACCESS TUNNEL OF DERIVATION TUNNELMilan UljarevicNo ratings yet

- Excavation of 17 KM Long Head Race Tunnel For 1000mw KarchamDocument12 pagesExcavation of 17 KM Long Head Race Tunnel For 1000mw KarchamkhjkfjhsdklajNo ratings yet

- Protecting Buildings from Tunnelling Settlement with GroutingDocument12 pagesProtecting Buildings from Tunnelling Settlement with GroutingfreezefreezeNo ratings yet

- GroutDocument11 pagesGroutParasuram BonangiNo ratings yet

- Concrete DamsDocument144 pagesConcrete DamsspattiwarNo ratings yet

- Ground Deformations Above A Large Shallow Tunnel EDocument10 pagesGround Deformations Above A Large Shallow Tunnel ECarlos ValdésNo ratings yet

- Paper - TopProject - CoulterMartinDocument9 pagesPaper - TopProject - CoulterMartinherdiana_hanifahildaNo ratings yet

- Stability of Underground Openings Near SinkholeDocument7 pagesStability of Underground Openings Near SinkholeAmilton filhoNo ratings yet

- 243 Design Construction - Cut-Off Walls Under The Arapuni DamDocument19 pages243 Design Construction - Cut-Off Walls Under The Arapuni DamSelah AbdulahiNo ratings yet

- Rion Anti Rion BridgeDocument7 pagesRion Anti Rion BridgeNagar NitinNo ratings yet

- Tunneling On Soft Soils PDFDocument12 pagesTunneling On Soft Soils PDFGourab MandalNo ratings yet

- Ensuring Safety During Construction of Double-Track Subway Tunnels in Quaternary DepositsDocument11 pagesEnsuring Safety During Construction of Double-Track Subway Tunnels in Quaternary DepositsMapeixNo ratings yet

- Tunnelling and Underground Space Technology: SciencedirectDocument9 pagesTunnelling and Underground Space Technology: SciencedirectEduardo CepedaNo ratings yet

- QC 04Document9 pagesQC 04Rohit K JainNo ratings yet

- Karuma Cavern DesignDocument6 pagesKaruma Cavern DesignBinodNo ratings yet

- Alteration of Hyd Conductivity by Tunnel Excavation Pusch 1989Document5 pagesAlteration of Hyd Conductivity by Tunnel Excavation Pusch 1989Yue Liang Sian ZiNo ratings yet

- Application of Expansion Joints in DiaphDocument8 pagesApplication of Expansion Joints in DiaphLuthfi NNo ratings yet

- Engineering Academy: InstructionsDocument12 pagesEngineering Academy: Instructionssaxenaarpita41No ratings yet

- Pipe Jacked TunnelsDocument10 pagesPipe Jacked Tunnelsretk0801No ratings yet

- Airport Central Drained BasementDocument5 pagesAirport Central Drained BasementLeonardo CruzNo ratings yet

- 236885e5fe4c044 EkDocument226 pages236885e5fe4c044 Ekcrls_marcosNo ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The North River Tunnels. Paper No. 1155From EverandTransactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The North River Tunnels. Paper No. 1155No ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The Cross-Town Tunnels. Paper No. 1158From EverandTransactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The Cross-Town Tunnels. Paper No. 1158No ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159From EverandTransactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159No ratings yet

- 2023 AlKhafajietalDocument17 pages2023 AlKhafajietalAf RymNo ratings yet

- Unsatchlef 2024 ProlongationDocument2 pagesUnsatchlef 2024 ProlongationAf RymNo ratings yet

- President and Fellows of Harvard CollegeDocument2 pagesPresident and Fellows of Harvard CollegeAf RymNo ratings yet

- Evaluation of Open Pit Mine Slope Stability AnalysisDocument12 pagesEvaluation of Open Pit Mine Slope Stability AnalysisAf RymNo ratings yet

- Ppr12 262alr PDFDocument17 pagesPpr12 262alr PDFAf RymNo ratings yet

- Simplified new approaches for seismic performance evaluation of earthfill damsDocument24 pagesSimplified new approaches for seismic performance evaluation of earthfill damsAf RymNo ratings yet

- Ppr12 262alr PDFDocument17 pagesPpr12 262alr PDFAf RymNo ratings yet

- Remedial Measures - LuDocument9 pagesRemedial Measures - LuAf RymNo ratings yet

- 1 s2.0 014890629193108I MainDocument1 page1 s2.0 014890629193108I MainAf RymNo ratings yet

- Engineering geological properties assessment of northwest Damghan rocksDocument2 pagesEngineering geological properties assessment of northwest Damghan rocksAf RymNo ratings yet

- Prediction of in Situ Permeability For Limestone Rock Using Rock Quality Designation IndexDocument4 pagesPrediction of in Situ Permeability For Limestone Rock Using Rock Quality Designation IndexAf RymNo ratings yet

- GROUND STABILISATION - The Why's and How's of High Pressure Grouting (Editor's Choice) Part 1Document4 pagesGROUND STABILISATION - The Why's and How's of High Pressure Grouting (Editor's Choice) Part 1Af RymNo ratings yet

- GROUND STABILISATION - The Why's and How's of High Pressure Grouting (Editor's Choice) Part 1Document4 pagesGROUND STABILISATION - The Why's and How's of High Pressure Grouting (Editor's Choice) Part 1Af RymNo ratings yet

- Lugeon Test Interpretation, RevisitedDocument10 pagesLugeon Test Interpretation, Revisitedmanu100% (2)

- Application of The Theory of Limit Analysis For The Study of The Behavior of The Ground Anchor in Homogeneous SoilDocument14 pagesApplication of The Theory of Limit Analysis For The Study of The Behavior of The Ground Anchor in Homogeneous SoilAf RymNo ratings yet

- Modelling Approach For Gravity Dam Break Analysis: Mourad Boussekine, Lakhdar DJEMILIDocument6 pagesModelling Approach For Gravity Dam Break Analysis: Mourad Boussekine, Lakhdar DJEMILIAf RymNo ratings yet

- 2) Word - List - Straightforward - Pre-Intermediate - Translations - French PDFDocument51 pages2) Word - List - Straightforward - Pre-Intermediate - Translations - French PDFAf RymNo ratings yet

- 1-S2.0-S0013795201000850-Main Lu PDFDocument11 pages1-S2.0-S0013795201000850-Main Lu PDFAf RymNo ratings yet

- Food Conformity BA 550-13Document9 pagesFood Conformity BA 550-13puipuiesperaNo ratings yet

- Atpl Formula MergedDocument74 pagesAtpl Formula Mergeddsw78jm2mxNo ratings yet

- Example 02 - Moment Capacity of A Concrete Beam - Reinforced Concrete Design ReviewDocument5 pagesExample 02 - Moment Capacity of A Concrete Beam - Reinforced Concrete Design ReviewJohn Michael GeneralNo ratings yet

- Private Void BtnDeleteActionPerformedDocument12 pagesPrivate Void BtnDeleteActionPerformedDDDNo ratings yet

- Carbon SteelDocument1 pageCarbon SteeldexterNo ratings yet

- Fish HatcheryDocument14 pagesFish HatcheryYared Mesfin FikaduNo ratings yet

- ABS Approved Foundries May 12 2014Document64 pagesABS Approved Foundries May 12 2014Joe ClarkeNo ratings yet

- T38N/T48N: Suffix Code Instruction ManualDocument1 pageT38N/T48N: Suffix Code Instruction ManualaliNo ratings yet

- Plyometric Training Programs For Young Soccer Players: A Systematic ReviewDocument7 pagesPlyometric Training Programs For Young Soccer Players: A Systematic ReviewsteNo ratings yet

- Revision Module 1,2,3Document129 pagesRevision Module 1,2,3jitamitra88No ratings yet

- Electronics Today 1977 10Document84 pagesElectronics Today 1977 10cornel_24100% (3)

- Sculptures by The SeaDocument1 pageSculptures by The Seaapi-457802597No ratings yet

- Optimization Module For Abaqus/CAE Based On Genetic AlgorithmDocument1 pageOptimization Module For Abaqus/CAE Based On Genetic AlgorithmSIMULIACorpNo ratings yet

- TLUD Handbook, Paul Anderson, V.2010Document19 pagesTLUD Handbook, Paul Anderson, V.2010satyakaamsNo ratings yet

- Introducing The Phenomenon To Be Discussed: Stating Your OpinionDocument8 pagesIntroducing The Phenomenon To Be Discussed: Stating Your OpinionRam RaghuwanshiNo ratings yet

- DodupukegakobemavasevuDocument3 pagesDodupukegakobemavasevuMartian SamaanNo ratings yet

- Computer Vision: Chapter 5. SegmentationDocument16 pagesComputer Vision: Chapter 5. SegmentationThịi ÁnhhNo ratings yet

- Clinical TeachingDocument29 pagesClinical TeachingJeonoh Florida100% (2)

- IBM Release Notes - IBM SPSS Statistics 21.0 - United States PDFDocument3 pagesIBM Release Notes - IBM SPSS Statistics 21.0 - United States PDFraj sharmaNo ratings yet

- Final Paper - PARTIALDocument64 pagesFinal Paper - PARTIALDeanna GicaleNo ratings yet

- 3.0 Wrap Up and SummaryDocument4 pages3.0 Wrap Up and SummaryGian SanchezNo ratings yet

- Techniques-Of-Attitude-Scale-Construction FullDocument344 pagesTechniques-Of-Attitude-Scale-Construction FullLuthfi fharuq Al Fairuz67% (3)

- 2022 Anambra State ITN Mass Campaign Report in Nnewi North LGA by Idongesit EtukudoDocument15 pages2022 Anambra State ITN Mass Campaign Report in Nnewi North LGA by Idongesit EtukudoIdongesit EtukudoNo ratings yet

- HGDocument64 pagesHGCharis PapadopoulosNo ratings yet

- Verb-Particle Constructions in Romance. A Lexical-Syntactic AccountDocument29 pagesVerb-Particle Constructions in Romance. A Lexical-Syntactic AccountWagaJabalNo ratings yet

- The Advantages and Disadvantages If Block ChainDocument7 pagesThe Advantages and Disadvantages If Block ChainKarthik ShettyNo ratings yet

- Acer Veriton S480G Service ManualDocument90 pagesAcer Veriton S480G Service ManualAndreea Georgiana ChirilaNo ratings yet

- LTE Interview QuestionsDocument10 pagesLTE Interview QuestionsMahesh Pratap100% (1)

- CitationCJ4-CB Checklists B v1.2Document4 pagesCitationCJ4-CB Checklists B v1.2Joao Vitor RojasNo ratings yet

- Overview On Image Captioning TechniquesDocument6 pagesOverview On Image Captioning TechniquesWARSE JournalsNo ratings yet