Professional Documents

Culture Documents

Schedule

Uploaded by

Tej Vir SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schedule

Uploaded by

Tej Vir SinghCopyright:

Available Formats

SCHEDULE A - AIR HANDLING AND AIR CONDITIONING UNITS

TAG

TYPE

LOCATION

MAKE

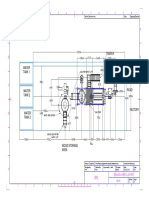

ACCU-1 OUTDOOR CONDENSING UNIT ROOF

MITSUBISHI ELECTRIC

FOR ACU-1

/ APPROVED EQUAL

MODEL

PUMY-P48NHMU

HEATING COOLING

(KW)

(KW)

14.0

ACU-1

INDOOR SPLIT AC UNIT

PCFY-P125VKM-E

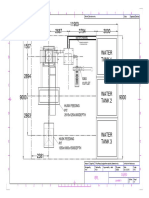

AHU-1

ROOF TOP AHU FOR GAS

CONTROL RM

ROOF TOP AHU FOR HX. RM.3 ROOF

VENMAR/ ENGINEERED AIR/

APPROVED EQUAL

VENMAR/ ENGINEERED AIR/

APPROVED EQUAL

ROOF TOP AHU FOR HX RM.1, ROOF

HX RM.2, EXIST. PUMP RM.

VENMAR/ ENGINEERED AIR/

APPROVED EQUAL

AHU-2

AHU-3

ELECT.

ROOM

ROOF

MITSUBISHI ELECTRIC

/ APPROVED EQUAL

14.0

HIGH

AIR

FLOW

(L/s)

MAX.

LOW AIR E.S.P. NOISE MOTOR AMPS

START

FLOW (L/s) (Pa) @5 FEET (KW)

(MCA) VOLTS PHASE

BY

26

208

1

517

342.0 L/s

44

75.8

1652

826.0 L/s

53.3

1888

944.0 L/s

125.0 62

Pa

125.0 64

Pa

130.0

4248

2124.0 L/s

125.0 63

Pa

0.76

208

1.52

575

1.52

575

1.52

575

FLUID

INTERLOCKED WEIGHT FLUID FLUID FLUID PRESSURE

DROP

WITH

(Kg)

IN

OUT FLOW

CONTROL BY

NOTES

150

TYPE: OUTDOOR CONDENSING UNIT; C/W MANUFACTURER'S APPROVED INSTALLATION

KIT, WIND SCREEN, LOCAL DISCONNECT, MODULAR VARIABLE REFRIGERANT

FLOW SYSTEM, INVERTER DUTY COMPRESSOR

T'STAT TEMPERATURE

50

TYPE: INDOOR UNIT; C/W BUILT-IN CAPACITY CONTROL, CONDENSATE PUMP, PAC

CONTROLLER

REMOTE CONTROLLER

EF-1A, 1B

2000

82 C 71 C 1.9 L/s 45.0 kPa

TYPE: ROOF TOP UNIT; 2 SPEED (VFD DRIVEN), CORROSION RESISTANCE COATING,

C/W 400 HIGH ROOF CURB, FACTORTY BUILT-IN VFD

EF-2

2200

82 C 71 C 1.3 L/s 36.0 kPa

TYPE: ROF TOP UNIT; 2-SPEED (VFD DRIVEN); LOW SPEED WHEN OA=<18C, HIGH

SPEED WHEN OA>18C, CORROSION RESISTANCE COATING, C/W 400 HIGH ROOF

CURB, FACTORTY BUILT-IN VFD

EF-3, EF-4,

1900

82 C 71 C 3.2 L/s 24.0 kPa

TYPE: ROOF TOP UNIT; 2 SPEED (VFD DRIVEN); LOW SPEED WHEN OA=<18C, HIGH

EF-5

SPEED WHEN OA>18C, CORROSION RESISTANCE COATING, C/W 400 HIGH ROOF

CURB, FACTORTY BUILT-IN VFD

ALL UNITS SHALL BE PROVIDED WITH UNIT MOUNTED WEATHER PROOF LOCAL DISCONNECT SWITCH. DIV.16 TO PROVIDE POWER AT THE UNITS. 120V CONTROL WIRING BETWEEN THE UNITS AND REMOTE CONTROL PANELS BY DIV.16. HEATING FLUID CIRCULATED THROUGH COILS SHALL BE 50% ETHYLENE GLYCOL. FOR THE AIR HANDLING UNITS, 3-WAY CONTROL

VALVES SHALL BE FACTORY PIPED, WIRED AND CONTROLLED BY AHU CONTROLLER.

SCHEDULE B - FANS

AIR

FLOW

(HIGH)

850 L/s

AIR

FLOW

(LOW)

MAX.

NOISE MOTOR

DRIVE

TYPE

TAG

TYPE

E.S.P SONES LOAD VOLTS PHASE INTERLOCKED WITH WEIGHT (Kg)

NOTES

__

EF-1A ROOF UPBLAST EXHAUST FAN

DIRECT

125 Pa 14.1

430 W 575

3

AHU-1

50

TYPE: ROOF UPBLAST, EXPLOSION PROOF MOTOR, ALL SUITABLE FOR CLASS-1 , DIV-1 APPLICATION; HI-PRO POLYESTER CORROSION RESISTANCE

COATING, UL/cUL 705, SWITCH, NEMA 7 AND 9, TOGGLE, JUNCTION BOX MOUNTED AND WIRED, 250H ROOF CURB, BDD

__

EF-1B ROOF UPBLAST EXHAUST FAN

GAS ROOM

GREENHECK/APPROVED EQUAL CUE-161-B

850 L/s

DIRECT 125 Pa 14.1

430 W 575

3

AHU-1

50

TYPE: ROOF UPBLAST, EXPLOSION PROOF MOTOR, ALL SUITABLE FOR CLASS-1 , DIV-1 APPLICATION; HI-PRO POLYESTER CORROSION RESISTANCE

COATING, UL/cUL 705, SWITCH, NEMA 7 AND 9, TOGGLE, JUNCTION BOX MOUNTED AND WIRED, 250H ROOF CURB, BDD

EF-2 ROOF UPBLAST EXHAUST FAN

HX RM.3

GREENHECK/APPROVED EQUAL CUBE-240-7 1936 L/s 968 L/s DIRECT 125 Pa 9.8

560 W 575

3

AHU-2 CONTROLLER 75

TYPE: ROOF UPBLAST, 2 SPEED, ALL ALUMINIUM CONSTRUCTION; COATING: HI-PRO POLYESTER COATING; C/W 250H ROOF CURB, BDD

EF-3 ROOF UPBLAST EXHAUST FAN

HX RM.1

GREENHECK/APPROVED EQUAL CUBE-240-7 1936 L/s 968 L/s DIRECT 125 Pa 9.8

560 W 575

3

AHU-3 CONTROLLER 75

TYPE: ROOF UPBLAST, 2 SPEED, ALL ALUMINIUM CONSTRUCTION, COATING: HI-PRO POLYESTER COATING; C/W 250H ROOF CURB, BDD

EF-4 ROOF UPBLAST EXHAUST FAN

HX RM.2

GREENHECK/APPROVED EQUAL CUE-200-7

1464 L/s 732 L/s DIRECT 125 Pa 9.7

560 W 575

3

AHU-3 CONTROLLER 65

TYPE: ROOF UPBLAST, 2 SPEED, ALL ALUMINIUM CONSTRUCTION; COATING: HI-PRO POLYESTER COATING; C/W 250H ROOF CURB, BDD

EF-5 ROOF UPBLAST EXHAUST FAN

PUMP RM

GREENHECK/APPROVED EQUAL CUE-180HP-5 992 L/s 496 L/s DIRECT 125 Pa 10.8

373 W 575

3

AHU-3 CONTROLLER 80

TYPE: ROOF UPBLAST, 2 SPEED, ALL ALUMINIUM CONSTRUCTION; COATING: HI-PRO POLYESTER COATING; C/W 250H ROOF CURB, BDD

__

EF-6 ROOF UPBLAST EXHAUST FAN

ELEC. RM

GREENHECK/APPROVED EQUAL CUE-200-7

1510 L/s

DIRECT 125 Pa 10.1

560 W 575

3

MD-4

65

TYPE: ROOF UPBLAST, ALL ALUMINIUM CONSTRUCTION; COATING: HI-PRO POLYESTER COATING; VFD CONTROL BY DIV. 16; C/W 250H ROOF CURB, BDD

__

EF-7 ROOF UPBLAST EXHAUST FAN

ELEC.WORKSHOP GREENHECK/APPROVED EQUAL CUE-080-VG 165 L/s

DIRECT 100 Pa 8.2

45 W

120

1

MD-5

60

TYPE: ROOF UPBLAST, ALL ALUMINIUM CONSTRUCTION; COATING: HI-PRO POLYESTER COATING, VENTILATION TIMER SWITCH, C/W 250H ROOF CURB, BDD

__

EF-8 ROOF UPBLAST EXHAUST FAN

WASHROOM

GREENHECK/APPROVED EQUAL CUE-095-9

47 L/s

DIRECT 87 Pa 10.1

90 W

120

1

30

TYPE: ROOF UPBLAST, ALL ALUMINIUM CONSTRUCTION; COATING: HI-PRO POLYESTER COATING; C/W 250H ROOF CURB, BDD

__

SF-1 INLINE CENTRIFUGAL SUPPLY FAN BOILER ROOM

GREENHECK/APPROVED EQUAL SQ-160-A

1275 L/s

DIRECT 375 Pa 17.5

1500 W 575

3

MD-3

110

TYPE: INLINE SUPPLY FAN; SPRING ISOLATORS; VFD DRIVEN; HI-PRO POLYESTER COATING

ALL FANS SHALL BE PROVIDED WITH UNIT MOUNTED WEATHER PROOF LOCAL DISCONNECT SWITCH. EF-7 AND EF-08 CONTROL BY TIMER SWITCH.

SERVING ROOM /

LOCATION

MAKE

MODEL

GAS ROOM

GREENHECK/APPROVED EQUAL CUE-161-B

TAG

UH-1

UH-2

UH-3

UH-4

UH-5

UH-6

UH-7

UH-8

UH-9

UH-10

UH-11

UH-12

UH-13

TYPE

UNIT HEATER

UNIT HEATER

UNIT HEATER

UNIT HEATER

UNIT HEATER

UNIT HEATER

UNIT HEATER

UNIT HEATER

UNIT HEATER

UNIT HEATER

UNIT HEATER

UNIT HEATER

UNIT HEATER

LOCATION

BOILER RM

BOILER RM

BOILER RM

BOILER RM

BOILER RM

ELECT. WORKSHOP

PUMP RM

PUMP RM

HX. RM. 3

HX.RM. 2

WASHROOM

HEX RM. 1

HEX RM. 1

MAKE

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

TRANE/APPROVED EQUAL

MODEL

UHSBA181TA000A

UHSBA181TA000A

UHSBA181TA000A

UHSBA181TA000A

UHSBA181TA000A

UHSBA251TA101A

UHSBA181TA000A

UHSBA181TA000A

UHSBA181TA000A

UHSBA181TA000A

UHSBA181TA000A

UHSBA181TA000A

UHSBA181TA000A

SCHEDULE C - HYDRONIC WATER HEATERS

HOT

AIR

HOT

HOT

TEMP TEMP

HEATING WATER FLOW MOTOR

FLOW (L/s) (L/s) WATTS VOLTS PHASE IN (C) OUT (C)

(KW)

NOTES

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

7.3

0.148 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

3.7

0.085 L/s 160

12.5

120

1

93

82

C/W WALL MOUNTED THERMOSTAT AND COMBINATION ISOLATION/ CIRCUIT BALANCING VALVE; COATING: PHENOLIC COATING (BAKED)

ALL HEATERS SHALL BE PROVIDED WITH UNIT MOUNTED LOCAL DISCONNECT SWITCH

SCHEDULE D - ELECTRIC HEATERS

ELECTRICAL

LOAD

TAG

LOCATION

MAKE

MODEL

VOLTS PHASE

NOTES

EBH-1

EXIT STAIRS

RUFFNECK / APPROVED EQUAL

CX1-600160-036

3600 W

575

3

C/W EXPLOSION PROOF CABINET HEATER C/W BUILT-IN EXPLOSION PROOF THERMOSTAT ALL SUITABLE FOR CLASS-1, DIV-1

EBH-2

CORRIDOR

OUELLET / APPROVED EQUAL

ODI2006

2000 W

575

3

C/W BUILT-IN TERMOSTAT WITH CONTROL KNOB AND DISCONNECT SWITCH

EBH-3

CORRIDOR

OUELLET / APPROVED EQUAL

ODI1006

1000 W

575

3

C/W BUILT-IN TERMOSTAT WITH CONTROL KNOB AND DISCONNECT SWITCH

EBH-4

EXISTING STAIRS NO.1

OUELLET / APPROVED EQUAL

ODI2006

2000 W

575

3

C/W BUILT-IN TERMOSTAT WITH CONTROL KNOB AND DISCONNECT SWITCH

EBH-5

EXISTING STAIRS NO.1

OUELLET / APPROVED EQUAL

ODI2006

2000 W

575

3

C/W BUILT-IN TERMOSTAT WITH CONTROL KNOB AND DISCONNECT SWITCH

EUH-1

GAS ROOM B/F

RUFFNECK / APPROVED EQUAL

FX5-600360-050-T-D-P-C

5000 W

575

3

TYPE: SUITABLE FOR CLASS-1, DIV-1 C/W BUILT-IN EXP.PROOF T'STAT, DISCONNECT SWITCH, PILOT LIGHT, HERESITE COATING

EUH-2

GAS ROOM M/F

RUFFNECK / APPROVED EQUAL

FX5-600360-050-T-D-P-C

5000 W

575

3

TYPE: SUITABLE FOR CLASS-1, DIV-1 C/W BUILT-IN EXP.PROOF T'STAT, DISCONNECT SWITCH, PILOT LIGHT, HERESITE COATING

EUH-3

GAS ROOM M/F

RUFFNECK / APPROVED EQUAL

FX5-600360-050-T-D-P-C

5000 W

575

3

TYPE: SUITABLE FOR CLASS-1, DIV-1 C/W BUILT-IN EXP.PROOF T'STAT, DISCONNECT SWITCH, PILOT LIGHT, HERESITE COATING

EUH-4

GAS ROOM M/F

RUFFNECK / APPROVED EQUAL

FX5-600360-050-T-D-P-C

5000 W

575

3

TYPE: SUITABLE FOR CLASS-1, DIV-1 C/W BUILT-IN EXP.PROOF T'STAT, DISCONNECT SWITCH, PILOT LIGHT, HERESITE COATING

EUH-5

ELECTRICAL ROOM

OUELLET/ APPROVED EQUAL

OWD-I-S-L-TM-03036

3000 W

575

3

TYPE: WASHDOWN STAINLESS STEEL ELECTRICAL, C/W UNIT MOUNTED T'STAT, DISCONNECT SWITCH, PILOT LIGHT, FAN SWITCH

EUH-6

ELECTRICAL ROOM

OUELLET/ APPROVED EQUAL

OWD-I-S-L-TM-03036

3000 W

575

3

TYPE: WASHDOWN STAINLESS STEEL ELECTRICAL, C/W UNIT MOUNTED T'STAT, DISCONNECT SWITCH, PILOT LIGHT, FAN SWITCH

EWH-1

ELECTRIC WALL HEATER

OUELLET/ APPROVED EQUAL

OAC04000

4000 W

208

1

TYPE: ELECTRIC WALL HEATER, C/W DISCONNECT SWITCH, SUMMER FAN SWITCH, BUILT-IN T'STAT, CORROSION RESISTANCE COATING

ALL HEATERS SHALL BE PROVIDED WITH UNIT MOUNTED LOCAL DISCONNECT SWITCH. UNIT HEATERS SHALL BE SUPPLIED LOOSEBY THE HEATER MANUFACTURER AND SHALL BE INSTALLED AND WIRED BY THE CONTRACTOR.

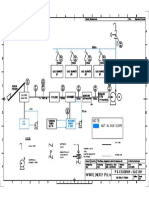

SCHEDULE E - MOTORIZED DAMPERS

TAG

FUNCTION & LOCATION

SIZE (WxH)

MANUFACTURER

MODEL

ACTUATOR MAKE / SERIES

MD-1

SUPPLY ISOLATION FOR AHU-1 / ROOF

400x800-400x800

EBAIR

IPSD

SCHISCHEK EXPLOSION PROOF/ BELIMO 120V-SPRING RETURN CLOSE, ZS-260 EXPLOSION

PROOF ENCLOSURE

MD-2

SUPPLY VENT FOR AHU-1 / ROOF

400x800-400x800

EBAIR

IPSD

SCHISCHEK EXPLOSION PROOF/ BELIMO 120V-SPRING RETURN OPEN, ZS-260 EXPLOSION

PROOF ENCLOSURE

MD-3

SF-1 INTAKE / BOILER ROOM

500x400-500x400

TAMCO

9000 SW

SCHISCHEK/ BELIMO 120V-SPRING RETURN

MD-4

ELECTRICAL ROOM INTAKE

350x700-350x700

TAMCO

9000 SW

SCHISCHEK/ BELIMO 120V-SPRING RETURN

MD-5

ELECTRICAL WORKSHOP INTAKE

1000x400-1000x400 TAMCO

9000 SW

SCHISCHEK/ BELIMO 120V-SPRING RETURN

MD-6

BOILER ROOM AIR VENT

1000x500-1000x500 TAMCO

9000 SW

SCHISCHEK/ BELIMO 120V-SPRING RETURN

NOTE: REFER DRAWING M-106 FOR MORE SCHEDULES. MAKE MODEL OF EQUIPMENT IS ONLY FOR REFERENCE. REFER TO SPECIFICATION.

SCALE

RVA#046220 - 20150910 - IFT

DESIGNED:

J. DASGUPTA

THE REGIONAL MUNICIPALITY

OF DURHAM

BAR IS 25mm ON

ORIGINAL DRAWING

DRAFTED:

P.H. PATEL

0 mm

CHECKED:

INTERLOCKED WITH

TYPE

NOTES

AHU-1

INDUSTRIAL POSITIVE SEAL SS304 INSULATED, SQUARE, TENDEM DAMPER COMMON MOTOR WITH MD-2, NORMALLY CLOSED, OPENS ON

AHU-1 STARTS

AHU-1

INDUSTRIAL POSITIVE SEAL SS304 INSULATED, SQUARE, TENDEM DAMPER COMMON MOTOR WITH MD-1, NORMALLY OPEN, CLOSES ON

AHU-1 STARTS

SF-1

PARALLEL OPEN/CLOSE

LOW LEAKAGE INSULATED FAIL SAFE OPEN

EF-3

PARALLEL OPEN/CLOSE

LOW LEAKAGE INSULATED FAIL SAFE OPEN

EF-7

PARALLEL OPEN/CLOSE

LOW LEAKAGE INSULATED FAIL SAFE OPEN

SF-1

PARALLEL OPEN/CLOSE

LOW LEAKAGE INSULATED FAIL SAFE OPEN

NO.

DATE

NAME

REVISIONS

V.L. NAZARETH

DIGESTER FACILITIES UPGRADE - PHASE 1

25 mm

MECHANICAL

WORKS DEPARTMENT

B.J. MAJANO

APPROVED:

CORBETT CREEK WATER POLLUTION CONTROL PLANT

IF NOT 25mm ON

THIS SHEET, ADJUST

SCALES ACCORDINGLY

RVA PROJECT No.

046220

WHITBY

ONTARIO

DIGESTER CONTROL BUILDING

SCHEDULES

SHEET NUMBER

66 of 135

DRAWING NUMBER

M001

CONTRACT NUMBER

D2016-036

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 11-Feb-19 A30133-WA 11-Feb-19 A30133-WA: DWG. # Title DL Custom Division of 304260 Ontario LimitedDocument1 page11-Feb-19 A30133-WA 11-Feb-19 A30133-WA: DWG. # Title DL Custom Division of 304260 Ontario LimitedTej Vir SinghNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A30133 Wa PDFDocument1 pageA30133 Wa PDFTej Vir SinghNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Gasifier Melting Furnace SchematicDocument1 pageGasifier Melting Furnace SchematicTej Vir SinghNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Sargroh Corp - Final INVOICEDocument1 pageSargroh Corp - Final INVOICETej Vir SinghNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Fahu 1Document2 pagesFahu 1Tej Vir SinghNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- DG400+WBD LayoutDocument1 pageDG400+WBD LayoutTej Vir SinghNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Quotation: Qty Model Number Description List Each Net Each Net TotalDocument1 pageQuotation: Qty Model Number Description List Each Net Each Net TotalTej Vir SinghNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Fahu 2Document1 pageFahu 2Tej Vir SinghNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Water channel and husk feeding pits layout diagramDocument1 pageWater channel and husk feeding pits layout diagramTej Vir SinghNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Yoga Day cultural activities and summer camp prize distributionDocument1 pageYoga Day cultural activities and summer camp prize distributionTej Vir SinghNo ratings yet

- PG125 LayoutDocument1 pagePG125 LayoutTej Vir SinghNo ratings yet

- DG 350-OT-750kWDocument1 pageDG 350-OT-750kWTej Vir SinghNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- DG400 Layout-IsO A3 Title BlockDocument1 pageDG400 Layout-IsO A3 Title BlockTej Vir SinghNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Heat Exchanger ScheduleDocument1 pageHeat Exchanger ScheduleTej Vir SinghNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Briquette Gasifier-IsO A3 Title BlockDocument1 pageBriquette Gasifier-IsO A3 Title BlockTej Vir SinghNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- North - Workshop BLDG (Chilled Water Type)Document1 pageNorth - Workshop BLDG (Chilled Water Type)Tej Vir SinghNo ratings yet

- MC125 GaDocument1 pageMC125 GaTej Vir SinghNo ratings yet

- CRAC - East - Admin BLDG (DX and Chilled Water Type)Document1 pageCRAC - East - Admin BLDG (DX and Chilled Water Type)Tej Vir SinghNo ratings yet

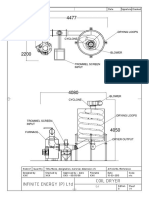

- Cyclone Duct ArrangementDocument1 pageCyclone Duct ArrangementTej Vir SinghNo ratings yet

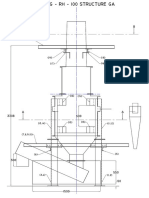

- DDG RH GA Dev DwgsDocument1 pageDDG RH GA Dev DwgsTej Vir SinghNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DDG RH Structure GA2Document1 pageDDG RH Structure GA2Tej Vir SinghNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Dg200 With DryerDocument1 pageDg200 With DryerTej Vir SinghNo ratings yet

- DDG RH Structure GA1Document1 pageDDG RH Structure GA1Tej Vir SinghNo ratings yet

- DDG 300 RefractoryDocument1 pageDDG 300 RefractoryTej Vir SinghNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Coil Dyrer Ga NormalDocument1 pageCoil Dyrer Ga NormalTej Vir SinghNo ratings yet

- DDG RH GA ElevationDocument1 pageDDG RH GA ElevationTej Vir SinghNo ratings yet

- DG200 With FilterDocument1 pageDG200 With FilterTej Vir SinghNo ratings yet

- Coil Dyrer Ga NormalDocument1 pageCoil Dyrer Ga NormalTej Vir SinghNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Coil Dyrer Ga NormalDocument1 pageCoil Dyrer Ga NormalTej Vir SinghNo ratings yet

- TCA785Document16 pagesTCA785Anthony BauNo ratings yet

- USB To Rs 32 ConvertorDocument11 pagesUSB To Rs 32 ConvertoryannickNo ratings yet

- MCQ On Fluid PowerDocument12 pagesMCQ On Fluid Powerraj kunduNo ratings yet

- Electronic Equipment Repair (EE 302) : Lectured By: Pn. Nor Kharul Aina Binti Mat DinDocument5 pagesElectronic Equipment Repair (EE 302) : Lectured By: Pn. Nor Kharul Aina Binti Mat DinSadrina MahamudNo ratings yet

- HYW-20 T5: Generating RatesDocument12 pagesHYW-20 T5: Generating RatesRagowo Tri WicaksonoNo ratings yet

- Acme A349 Service ManualDocument34 pagesAcme A349 Service ManualCristian DavidNo ratings yet

- Samsung Aqv09 Aqv12 Service Manual PDFDocument88 pagesSamsung Aqv09 Aqv12 Service Manual PDFAntonio Carlos Del CastilloNo ratings yet

- Toyota Hilux (2015 - 2018) Fuse Box DiagramsDocument10 pagesToyota Hilux (2015 - 2018) Fuse Box DiagramsLucio DiasNo ratings yet

- Transmission Error in Gears Journal Article Summarizes Causes and EffectsDocument3 pagesTransmission Error in Gears Journal Article Summarizes Causes and Effectsarda akkayaNo ratings yet

- 30gtn 1pd UpdateDocument100 pages30gtn 1pd UpdateSyed Ali KhanNo ratings yet

- Service Manual: Pub. No. EE14E-11130Document39 pagesService Manual: Pub. No. EE14E-11130Marcelo Diesel81% (16)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- PLC IO Modules Part1 PDFDocument22 pagesPLC IO Modules Part1 PDFReda NariNo ratings yet

- SEBU7926 - Operation & Maintenance Manual (C7 Urban Transit Bus Engines)Document228 pagesSEBU7926 - Operation & Maintenance Manual (C7 Urban Transit Bus Engines)Rodolfo WongNo ratings yet

- Manual Nevera LGDocument28 pagesManual Nevera LGJoher MarquezNo ratings yet

- ATC-900 Magnum Transfer Switch O & M Manual: DescriptionDocument40 pagesATC-900 Magnum Transfer Switch O & M Manual: DescriptionRajSekhar VarmaNo ratings yet

- Procurement IssuesDocument1,021 pagesProcurement Issuesriyadh al kamalNo ratings yet

- Tissue SectioningDocument21 pagesTissue SectioningGirum TesfayeNo ratings yet

- Lista de Precios Nexxt InfrastructureDocument15 pagesLista de Precios Nexxt InfrastructureMarco Antonio RubinaNo ratings yet

- Helioscope Simulation 13233814 SummaryDocument3 pagesHelioscope Simulation 13233814 SummaryandisaputrawuNo ratings yet

- Modelling of SOI-LDMOS TransistorDocument13 pagesModelling of SOI-LDMOS TransistorchaitudscNo ratings yet

- SMK0965F: Switching Regulator ApplicationsDocument8 pagesSMK0965F: Switching Regulator ApplicationsFale MensNo ratings yet

- Final Project PPTDocument20 pagesFinal Project PPTsadiqul azamNo ratings yet

- Srm-Ist: Industrial Training Bike ZoneDocument20 pagesSrm-Ist: Industrial Training Bike ZoneArsh ChoudharyNo ratings yet

- RAB Mini Plant Minyak Goreng Fortivikasi Vit. ADocument10 pagesRAB Mini Plant Minyak Goreng Fortivikasi Vit. Adoyo sudaryatNo ratings yet

- Domnick Hunter MX 102-110DryerServiceDocument28 pagesDomnick Hunter MX 102-110DryerServiceUntung DarmawanNo ratings yet

- 304 - 2016 06 06Document6 pages304 - 2016 06 06Israel Miranda ZamarcaNo ratings yet

- BRC 300 and PBA 200 User ManualDocument112 pagesBRC 300 and PBA 200 User ManualAtreyo SahaNo ratings yet

- Linde 1219 Technical SpecificationsDocument2 pagesLinde 1219 Technical SpecificationsEmadNo ratings yet

- Festool TS55REQ Supplemental ManualDocument26 pagesFestool TS55REQ Supplemental ManualMarcel ErmersNo ratings yet

- Index: GD251221-en 1 1 7Document7 pagesIndex: GD251221-en 1 1 7'PeRsona NoUn GraTa'No ratings yet

- The Voice of God: Experience A Life Changing Relationship with the LordFrom EverandThe Voice of God: Experience A Life Changing Relationship with the LordNo ratings yet