Professional Documents

Culture Documents

Fag Bearing

Uploaded by

Edy Ae0 ratings0% found this document useful (0 votes)

96 views2 pagesbearing

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbearing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

96 views2 pagesFag Bearing

Uploaded by

Edy Aebearing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Ideal floating bearing

for high load calender roll

Examples of Application Engineering

WL 13 524 EA

Soft calender Manufacturer: Metso Paper; Operator: UPM-Kymmene, Kaipola, Finland

UPM is one of the worlds leading

producers of printing papers.

The five main business areas are:

Magazine Paper Division

Newsprint Division

Fine and Specialty Papers

Converting Division

Wood Products Division

The Kaipola plant is producing

705 000 tons/year magazine, newsprint and directory papers. To give

the papers a smooth surface and

even thickness, they are using

online calenders.

These calender rolls, bearings and

bearing housings are assembled at

normal ambient temperature. During

start up of the calender, the thermo

rolls are heated up by thermo-oil

with a temperature in the range of

200 C.

Due to this heat influence, the rolls

are expanding axially for several

millimeters and a very good floating

bearing effect for the operating site

is necessary. The bearings in the

bottom position can be high loaded

by the roll weight and the sometimes

very high nip load.

For this reason, only a small

additional axial load acting on the

bearings is acceptable.

Soft Calender at UPM Kaipola, PM4

Operating conditions

Roll weight

Nip load

Nip width

Thermo-oil temperature

Bearing load radial

56,8 tons

280 kN/m

7 300 mm

up to 210 C

1 300 kN

As a counter measure, a FAG spherical roller bearing with

the following designation was installed:

232/500-K-MB-J47AA-T52BW-C4

Suffix J47AA means a PTFE coating of the outside of the

outer ring. In high loaded contact areas, PTFE provides for

good sliding properties and for a very low coefficient of

friction.

The floating bearing in this arrangement is a spherical

roller bearing. The floating effect is realized by a moving

outer ring in the housing.

Soon after start up of the machine, problems occurred

with premature failures. One aspect, which contributed

to failure, was the axial load. Thus, the axial load

on the bearings was measured. The result of the

measurement was a too high axial load that caused an

unequal loading of the two rows of rollers, contributing

to premature failures.

PTFE-Coating at OD

The measurement of the axial load was repeated

and the coefficient of friction was reduced by more

than 85%.

The axial force on the bearings was only approx. 13%

of the axial force before and the problem was solved.

Customer benefits

Load distribution in floating bearing without axial load

Long bearing service life due to minimized thrust loads

High paper quality by P5 running accuracy

Standard spherical roller bearings at both ends of the

roll

Reduced and cost-effective inventory.

Measured Axial Force (kN)

99/05/07 Printed in Germany by Druckhaus WEPPERT GmbH

Nip load

Measured axial force

Time

Coefficient of friction during a period of 3 weeks at heating up and cooling

down and varying nip loads and temperatures permanently << 0,05 !!!

Schaeffler KG

Heavy Industries

Pulp & Paper

Postfach 1260

97419 Schweinfurt (Germany)

Phone +49 9721 91-0

Fax

+49 9721 91-3435

E-Mail pulp_paper@schaeffler.com

Internet www.fag.com

You might also like

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- 1 - Module 2Document15 pages1 - Module 2Kelvin karaniNo ratings yet

- Bearing LayoutDocument30 pagesBearing LayoutmayasfaresNo ratings yet

- 11 - In. Milled Tooth Bits Developed For Niche: High-Speed Turbine Applications in RussianDocument4 pages11 - In. Milled Tooth Bits Developed For Niche: High-Speed Turbine Applications in Russianmsm.ele2009No ratings yet

- 002005ea 5Document42 pages002005ea 5AliArababadiNo ratings yet

- Bearing Mounting DesignDocument42 pagesBearing Mounting Designraghunath.psNo ratings yet

- 3 WL 00200-5 Ex. 23-41Document30 pages3 WL 00200-5 Ex. 23-41NuM NaNo ratings yet

- Rotationalmoulding 180215050228Document25 pagesRotationalmoulding 180215050228RizwanSaifiNo ratings yet

- Mec 602 Bearing DesignDocument148 pagesMec 602 Bearing DesignJonnalgadda Sameer KumarNo ratings yet

- Why SKF? Single Row Cylindrical Roller Bearings: Common ApplicationsDocument2 pagesWhy SKF? Single Row Cylindrical Roller Bearings: Common ApplicationsDebabrata PaulNo ratings yet

- Crowning Benefits - Paper, Film & Foil ConverterDocument3 pagesCrowning Benefits - Paper, Film & Foil ConverteravgpaulNo ratings yet

- En - 1999 01 07 - T - WL 21507 Ea Srbs in Polysius Vertical Roller Mill QuadropolDocument2 pagesEn - 1999 01 07 - T - WL 21507 Ea Srbs in Polysius Vertical Roller Mill QuadropolmiteshmechNo ratings yet

- Power Point Template 3 1Document52 pagesPower Point Template 3 1Red ReidNo ratings yet

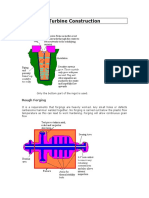

- Turbine ConstructionDocument7 pagesTurbine ConstructionPrasannaNo ratings yet

- 0901d1968047dcbf SKF High Temperature Bearings - 14961 - 2 EN - MM PDFDocument40 pages0901d1968047dcbf SKF High Temperature Bearings - 14961 - 2 EN - MM PDFMunkhdolgor ZorigtbaatarNo ratings yet

- Finishing EnglDocument49 pagesFinishing EnglSalim NgaosNo ratings yet

- Lubricants: Friction and Lubrication of Large Tilting-Pad Thrust BearingsDocument17 pagesLubricants: Friction and Lubrication of Large Tilting-Pad Thrust BearingsIrfan OmercausevicNo ratings yet

- Prepared By: PESB Technical Service Department (2019)Document60 pagesPrepared By: PESB Technical Service Department (2019)ASY178100% (4)

- 13 A ExtrusionDocument20 pages13 A Extrusionshreeghadage7No ratings yet

- Air As Bearing SystemDocument4 pagesAir As Bearing System李宗耀No ratings yet

- Factors Affecting Production in Spinning MillDocument38 pagesFactors Affecting Production in Spinning MillSivam Ravi67% (3)

- Large Format Additive ManufacturingDocument29 pagesLarge Format Additive ManufacturingWei QuanNo ratings yet

- Coupling Design and SelectionDocument11 pagesCoupling Design and SelectionVivek RathodNo ratings yet

- Cam ViceDocument50 pagesCam ViceAakash Dindigul100% (1)

- Clutch Plate Material PropertiesDocument16 pagesClutch Plate Material PropertiesClive Jerison VNo ratings yet

- Calendering ProcessDocument21 pagesCalendering ProcessMercyJatindro67% (3)

- Superior Bearings For Extruder GearboxesDocument5 pagesSuperior Bearings For Extruder GearboxesChetan PrajapatiNo ratings yet

- Split Spherical Roller Bearings in Fans: Examples of Application Engineering WL 22 503 EADocument2 pagesSplit Spherical Roller Bearings in Fans: Examples of Application Engineering WL 22 503 EAMauro Portugal LagardaNo ratings yet

- Unit III - Bulk Deformation ProcessesDocument48 pagesUnit III - Bulk Deformation ProcessesRavitej SuraparajuNo ratings yet

- Nylon Bearing Design PresentationDocument17 pagesNylon Bearing Design PresentationAndrey VishnevskiyNo ratings yet

- Heat Loss Comparision Between Leading Edge Groove and Conventional Pad Bearing.Document7 pagesHeat Loss Comparision Between Leading Edge Groove and Conventional Pad Bearing.Dharmendra JainNo ratings yet

- Metal Spinning, Flow Turning & Flow FormingDocument56 pagesMetal Spinning, Flow Turning & Flow FormingRajeswari RNo ratings yet

- Surface GrindingDocument18 pagesSurface GrindingSachin MohandasNo ratings yet

- Alcolor DampeningDocument30 pagesAlcolor DampeningSaranovicu Krsto100% (3)

- New Rolling Method of Reversing Cold Rolling MillDocument10 pagesNew Rolling Method of Reversing Cold Rolling MillVikas SharmaNo ratings yet

- Jul 08 Planetary Gear Box.Document10 pagesJul 08 Planetary Gear Box.RKVSK1No ratings yet

- Air BDocument21 pagesAir BAishwarya AishuNo ratings yet

- 02 - K-101 Rotor DamageDocument13 pages02 - K-101 Rotor Damagemsaadi717No ratings yet

- Air Refrigeration Cycle PDFDocument14 pagesAir Refrigeration Cycle PDFAbhinavZanvarNo ratings yet

- FAG ApplicationDocument2 pagesFAG ApplicationbogdanostinNo ratings yet

- Module 4-Part-1Document44 pagesModule 4-Part-1Renjin J BrightNo ratings yet

- 3 - Idt Af - BKMDocument106 pages3 - Idt Af - BKMVishnuNo ratings yet

- Air BDocument20 pagesAir BVaibhav Chaudhari BldNo ratings yet

- Rolling - Bearings - in - Paper - Machines Otros2Document16 pagesRolling - Bearings - in - Paper - Machines Otros2FreddyNo ratings yet

- Advantages of Rotating Machines: - Less Balancing Problems - Low Lubricating Oil Consumption - Higher ReliabilityDocument32 pagesAdvantages of Rotating Machines: - Less Balancing Problems - Low Lubricating Oil Consumption - Higher ReliabilityBilalPervezNo ratings yet

- Research Paper On Hybrid BearingDocument6 pagesResearch Paper On Hybrid Bearingc9rz4vrm100% (1)

- Flex CouplingDocument19 pagesFlex CouplingPradeep_VashistNo ratings yet

- Fixed Dummy Blocks: PurposeDocument2 pagesFixed Dummy Blocks: PurposeAlson LeeNo ratings yet

- 100284156Document10 pages100284156Shumail ZafarNo ratings yet

- Leafspring ReportDocument60 pagesLeafspring ReportDaniel Yesudasan100% (4)

- Power Sector Western Region: Technology DayDocument114 pagesPower Sector Western Region: Technology Dayabhayiimc100% (1)

- Design Guide For Forging SDocument19 pagesDesign Guide For Forging Schidambaram kasiNo ratings yet

- HM150 Roller BrochureDocument8 pagesHM150 Roller BrochurePriyanshu GuptaNo ratings yet

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Refractory ReferenceDocument11 pagesRefractory ReferenceEdy AeNo ratings yet

- WKLN Operating ManualDocument12 pagesWKLN Operating ManualEdy AeNo ratings yet

- HGC - Horizontal, Multistage, High-Pressure Ring-Section PumpDocument2 pagesHGC - Horizontal, Multistage, High-Pressure Ring-Section PumpEdy AeNo ratings yet

- Impeller Eye Compatibility ModeDocument6 pagesImpeller Eye Compatibility ModeEdy AeNo ratings yet

- NTN Ball and Roller Bearing CatalogDocument399 pagesNTN Ball and Roller Bearing Catalogdaniarsalan100% (2)

- Cocked BearingDocument3 pagesCocked BearingEdy AeNo ratings yet

- Benchmarking Boiler Tube FailuresDocument11 pagesBenchmarking Boiler Tube FailuresEdy AeNo ratings yet

- PetrochmBoiler Remaning LifeDocument2 pagesPetrochmBoiler Remaning LifeEdy AeNo ratings yet

- pdf81 As68rcDocument4 pagespdf81 As68rcValBMSNo ratings yet

- TECH - Wyntk - Truss Facts For Eng and ArcDocument24 pagesTECH - Wyntk - Truss Facts For Eng and Arcshaikh85No ratings yet

- Basic Water ChemistryDocument4 pagesBasic Water ChemistryZAHID HUSSAINNo ratings yet

- Microbial Test KitDocument3 pagesMicrobial Test KitLutfi HidayatNo ratings yet

- Role and Scope of OpmDocument11 pagesRole and Scope of OpmMohammed ShahrukhNo ratings yet

- Formal Report EXP 5 Thin Layer Chromatography of Siling Labuyo ExtractDocument3 pagesFormal Report EXP 5 Thin Layer Chromatography of Siling Labuyo ExtractJan Eric Balete0% (1)

- Qualitest Canada BrochureDocument7 pagesQualitest Canada BrochureBala SingamNo ratings yet

- $R5AM2WWDocument2 pages$R5AM2WWSurood SuruNo ratings yet

- SOP For Refrigeration PlantDocument37 pagesSOP For Refrigeration PlantGaurav Swarup67% (3)

- Solution Manual For Designing and Managing The Supply Chain 3rd Edition by David Simchi LeviDocument56 pagesSolution Manual For Designing and Managing The Supply Chain 3rd Edition by David Simchi LeviOmnia MustafaNo ratings yet

- Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesDocument4 pagesWelded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesmithileshNo ratings yet

- Self-Operated Temperature Regulators Temperature Regulator Type 1Document6 pagesSelf-Operated Temperature Regulators Temperature Regulator Type 1Pocola AdrianNo ratings yet

- David Brown in International MiningDocument9 pagesDavid Brown in International MiningKroya HunNo ratings yet

- Near Bit GammaDocument2 pagesNear Bit GammaQiang ZhangNo ratings yet

- Advanced Cleaning Product Formulations Volume5Document255 pagesAdvanced Cleaning Product Formulations Volume5joe89% (35)

- Reinforcing Bar Couplers-UK-IRE-Edition June 2014 - Version 3Document28 pagesReinforcing Bar Couplers-UK-IRE-Edition June 2014 - Version 3Federico.IoriNo ratings yet

- Formply BrochureDocument4 pagesFormply BrochureAnonymous jLLjBdrNo ratings yet

- Dep Trai Loi Tai AiDocument192 pagesDep Trai Loi Tai AiHoàng Hồng DươngNo ratings yet

- Lateral Support of Wood Beams in Residential Structures PDFDocument4 pagesLateral Support of Wood Beams in Residential Structures PDFBrian-Marti BoatrightNo ratings yet

- Reebol Emulsion ConcentrateDocument2 pagesReebol Emulsion ConcentrateJA WPKNo ratings yet

- Approval Ballast eDocument7 pagesApproval Ballast eAbd ZouhierNo ratings yet

- Cold Storage Design and Refrigeration EquipmentDocument146 pagesCold Storage Design and Refrigeration EquipmentGeorge Van Bommel0% (1)

- As 4176.3-2010 Multilayer Pipes For Pressure Applications Multilayer Piping Systems For Hot and Cold Water PLDocument8 pagesAs 4176.3-2010 Multilayer Pipes For Pressure Applications Multilayer Piping Systems For Hot and Cold Water PLSAI Global - APACNo ratings yet

- ACI - 2019 Arabic - p490-521Document32 pagesACI - 2019 Arabic - p490-521Mustafa Al-QawasmehNo ratings yet

- Assignment FMSDocument2 pagesAssignment FMSAnuragShrivastavNo ratings yet

- ACI 207.1R - 1996 - Mass ConcreteDocument42 pagesACI 207.1R - 1996 - Mass ConcreteJOSENo ratings yet

- Bosch Go 3601JH21E0Document171 pagesBosch Go 3601JH21E0william uribeNo ratings yet

- Poisson's RatioDocument20 pagesPoisson's RatioFaiz HaikalNo ratings yet

- 2.va1 Gedi 00HTF M M5 PHL 0001 - 1Document23 pages2.va1 Gedi 00HTF M M5 PHL 0001 - 1hoangduythanhqbNo ratings yet

- What Every Engineer Should Know About Welding 2Document5 pagesWhat Every Engineer Should Know About Welding 2Sanjay BhootakaNo ratings yet