Professional Documents

Culture Documents

A380 Fuel System Training Manual

Uploaded by

Santty JamiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A380 Fuel System Training Manual

Uploaded by

Santty JamiCopyright:

Available Formats

A380 TECHNICAL TRAINING MANUAL GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

This document must be used for training purposes only

Under no circumstances should this document be used as a reference

It will not be updated.

All rights reserved No part of this manual may be reproduced in any form, by photostat, microfilm, retrieval system, or any other means, without the prior written permission of AIRBUS S.A.S.

AIRBUS Environmental Recommendation Please consider your environmental responsability before printing this document.

A380 TECHNICAL TRAINING MANUAL

LEVEL I - ATA 28 FUEL

Fuel System Introduction (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Fuel Storage Presentation (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 Engine Feed Presentation (Me) (1) . . . . . . . . . . . . . . . . . . . . . . . . . . .10 Engine Feed Presentation (US) (1) . . . . . . . . . . . . . . . . . . . . . . . . . . .20 APU Fuel System Presentation (Me) (1) . . . . . . . . . . . . . . . . . . . . . .30 APU Fuel System Presentation (US) (1) . . . . . . . . . . . . . . . . . . . . . .34 Fuel Transfers Presentation (Me) (1) . . . . . . . . . . . . . . . . . . . . . . . . .38 Fuel Transfers Presentation (US) (1) . . . . . . . . . . . . . . . . . . . . . . . . .42 Refuel Defuel System Presentation (Me) (1) . . . . . . . . . . . . . . . . . . .46 Refuel Defuel System Presentation (US) (1) . . . . . . . . . . . . . . . . . . .52 Jettison System Presentation (Me) (1) . . . . . . . . . . . . . . . . . . . . . . . .58 Jettison System Presentation (US) (1) . . . . . . . . . . . . . . . . . . . . . . . .62 Fuel Quantity Management System Presentation (Me) (1) . . . . . . . .66 Fuel Quantity Management System Presentation (US) (1) . . . . . . . .70 Fuel System Maintenance (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74 Fuel Tank Safety Presentation (1) . . . . . . . . . . . . . . . . . . . . . . . . . . .76

LAY08521 - L1AT4T0

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

TABLE OF CONTENTS

Jan 13, 2009 Page 1

A380 TECHNICAL TRAINING MANUAL

FUEL SYSTEM INTRODUCTION (1)

General

The fuel system comprises different sub-systems, which are: - storage, - engine feed, - APU fuel, - fuel transfers, - refuel/defuel, - jettison, - and fuel quantity management.

LAY08521 - L1AT4T0 - LM28Z1000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL SYSTEM INTRODUCTION (1)

Jan 13, 2009 Page 2

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28Z1000000001

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL SYSTEM INTRODUCTION (1) Jan 13, 2009 Page 3

A380 TECHNICAL TRAINING MANUAL

FUEL STORAGE PRESENTATION (1)

General

The main function of the storage system is to safely store the fuel, which supplies the engines and APU. The storage system contains fuel in tanks and safely lets the fuel thermally expand. It regulates tank air pressure. It also gives protection against fire and means to collect condensed water from the fuel tanks. On the aircraft, fuel is stored in eleven fuel tanks. In the wings there are: - the feed tanks 1 and 2 (LH) and 3 and 4 (RH), - the LH and RH inner tanks, - the LH and RH mid tanks, - the LH and RH outer tanks. In the Trimmable Horizontal Stabilizer (THS) is the trim tank. In each wing there is a surge tank and a vent tank. These tanks are used for temporary storage of any fuel that overflows from the wing tanks and for wing tank air venting. On the right hand side of the THS there is a vent/surge tank. This tank is used for temporary storage of the fuel that overflows from the trim tank and for trim tank air venting.

LAY08521 - L1AT4T0 - LM28P1000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL STORAGE PRESENTATION (1)

Jan 13, 2009 Page 4

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P1000000001

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL STORAGE PRESENTATION (1) Jan 13, 2009 Page 5

A380 TECHNICAL TRAINING MANUAL

FUEL STORAGE PRESENTATION (1)

Fuel Tanks

The feed tanks are used to supply fuel to the engines. They have one closed area called the collector cell, which is a reservoir for the engine fuel feed pumps. A dedicated jet pump is used to keep the collector cell full. All other fuel tanks are storage and transfer tanks. Access to the tanks is gained through manhole panels. Each tank has one or more water drain valves.

LAY08521 - L1AT4T0 - LM28P1000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL STORAGE PRESENTATION (1)

Jan 13, 2009 Page 6

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P1000000001

FUEL TANKS

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL STORAGE PRESENTATION (1) Jan 13, 2009 Page 7

A380 TECHNICAL TRAINING MANUAL

FUEL STORAGE PRESENTATION (1)

Venting System

The tank venting system keeps the air pressure in the fuel tanks near to the external air pressure. The tank venting system prevents abnormal differential pressure, which could damage the fuel tank/aircraft structure. This function is especially necessary during the refuel or defuel operations and when the aircraft climbs or descends. This system also gives all means to safely discharge from the aircraft, any fuel overflowing from the fuel tanks. The tank venting system is a fully automatic mechanical system. There are no manual controls and no electrical components. WING TANKS Each wing fuel tank is individually connected to the surge tank by internal vent pipes. The surge tank is connected to a vent tank, which is connected to the atmosphere through a NACA intake and flame arrestor. The collector cells in the engine feed tanks are vented into the feed tanks through holes located at the top of the cells. TRIM TANK The trim tank is connected to a vent/surge tank by internal vent pipes. The vent/surge tank is connected to the atmosphere through a NACA intake and flame arrestor. Vent protectors (flame arrestors) prevent the ignition of the fuel vapor in the wing vent tanks and in the trim vent/surge tank in case of external fire. If abnormal condition occurs in the fuel system, which causes large quantities of fuel to enter the vent tank or the vent/surge tank, then the vent protectors let the fuel flow freely overboard. Overpressure protectors located in the vent tanks or the vent/surge tank, makes sure that the pressure in the vent tanks, or the vent/surge tank, and thus the fuel tanks, does not exceed the design limits.

LAY08521 - L1AT4T0 - LM28P1000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL STORAGE PRESENTATION (1)

Jan 13, 2009 Page 8

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P1000000001

VENTING SYSTEM

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL STORAGE PRESENTATION (1) Jan 13, 2009 Page 9

A380 TECHNICAL TRAINING MANUAL

ENGINE FEED PRESENTATION (ME) (1)

General

The engine feed system makes sure that the fuel is supplied to all the engines during all flight conditions and can be isolated from one or more engines, when necessary. The engine feed fuel pump system comprises four independent parts, one per engine. Under normal operation, each part supplies the fuel from its related feed tank to the associated engine. The crossfeed system can interconnect each part of the engine feed pump system. The engine Low-Pressure (LP) shut-off system lets each engine be isolated or shut-off from the engine feed system. These operations are controlled from the cockpit integrated control panels and the related information is shown on the ECAM FUEL page of the System Display (SD).

LAY08521 - L1AT4T0 - LM28P2000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

ENGINE FEED PRESENTATION (ME) (1)

Jan 13, 2009 Page 10

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P2000000001

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel ENGINE FEED PRESENTATION (ME) (1) Jan 13, 2009 Page 11

A380 TECHNICAL TRAINING MANUAL

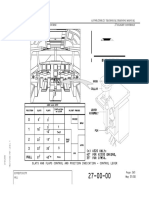

ENGINE FEED PRESENTATION (ME) (1)

Engine Feed Fuel Pump

For each part of the engine fuel feed system, there are two fuel pumps installed in each feed tank collector cell, one main pump and one standby pump. Each pump has a pressure switch to monitor the output fuel pressure. Each fuel pump system is usually manually controlled from the P/BSWs on the overhead-integrated control panel 1235 VM. When the main pump is in low-pressure condition, the related standby pump automatically starts. Engine feed information is shown on the ECAM FUEL page of the SD.

LAY08521 - L1AT4T0 - LM28P2000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

ENGINE FEED PRESENTATION (ME) (1)

Jan 13, 2009 Page 12

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P2000000001

ENGINE FEED FUEL PUMP

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel ENGINE FEED PRESENTATION (ME) (1) Jan 13, 2009 Page 13

A380 TECHNICAL TRAINING MANUAL

ENGINE FEED PRESENTATION (ME) (1)

Crossfeed System

The crossfeed system enables any engine to be fed from any engine feed tank. It can be also used to correct fuel imbalance between tanks, in case of emergency condition or for maintenance purpose. The crossfeed system has four crossfeed valves, which are normally closed. When a crossfeed valve is open, the related fuel feed is available in a common fuel gallery between all the four valves. If a second crossfeed valve is opened, the two fuel feed systems are connected together. The crossfeed valves can be manually controlled by the four P/BSWs identified on the overhead-integrated control panel 1235VM as CROSSFEED 1 to CROSSFEED 4. Alternatively, the aircraft wiring automatically controls the crossfeed valves: - in the event of an electrical emergency condition, - by the Fuel Quantity Management System (FQMS) for an automatic ground transfer. The crossfeed valve position is shown on the ECAM FUEL page of the SD.

LAY08521 - L1AT4T0 - LM28P2000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

ENGINE FEED PRESENTATION (ME) (1)

Jan 13, 2009 Page 14

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P2000000001

CROSSFEED SYSTEM

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel ENGINE FEED PRESENTATION (ME) (1) Jan 13, 2009 Page 15

A380 TECHNICAL TRAINING MANUAL

ENGINE FEED PRESENTATION (ME) (1)

Low-Pressure Shut-Off System

The engine Low-Pressure shut-off system has one LP valve per engine. Each valve can be opened or closed using the related ENG MASTER switch (1125 VU) on the cockpit pedestal. In case of engine fire, the operation of the engine FIRE P/BSW on the overhead-integrated control panel 1245 VM, will close the related LP valve and stop the fuel supply to the engine. The LP valve position data is shown on the ECAM FUEL page of the SD.

LAY08521 - L1AT4T0 - LM28P2000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

ENGINE FEED PRESENTATION (ME) (1)

Jan 13, 2009 Page 16

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P2000000001

LOW-PRESSURE SHUT-OFF SYSTEM

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel ENGINE FEED PRESENTATION (ME) (1) Jan 13, 2009 Page 17

A380 TECHNICAL TRAINING MANUAL

ENGINE FEED PRESENTATION (ME) (1)

Heat Exchanger Fuel System

The A380 has a pair of Hydraulic Heat Exchangers (HHX), in order to cool down the high-pressure hydraulic fluid. This system acts as a back-up only in the event of a failure of the primary air/hydraulic heat exchanger. A bypass line on the engine fuel feed pipes of the engine 1 and the engine 4, diverts some fuel through the fuel/hydraulic heat exchangers via an isolation valve and then returns the heated fuel to the related engine feed tank. Control of the isolation valve, and thus feed fuel recirculation, is fully automatic from the FQMS. Recirculation is inhibited when the related feed tank contains insufficient fuel.

LAY08521 - L1AT4T0 - LM28P2000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

ENGINE FEED PRESENTATION (ME) (1)

Jan 13, 2009 Page 18

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P2000000001

HEAT EXCHANGER FUEL SYSTEM

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel ENGINE FEED PRESENTATION (ME) (1) Jan 13, 2009 Page 19

A380 TECHNICAL TRAINING MANUAL

ENGINE FEED PRESENTATION (US) (1)

General

The engine feed system makes sure that the fuel is supplied to all the engines during all flight conditions and can be isolated from one or more engines, when necessary. The engine feed fuel pump system comprises four independent parts, one per engine. Under normal operation, each part supplies the fuel from its related feed tank to the associated engine. The crossfeed system can interconnect each part of the engine feed pump system. The engine Low-Pressure (LP) shut-off system lets each engine be isolated or shut-off from the engine feed system. These operations are controlled from the cockpit integrated control panels and the related information is shown on the ECAM FUEL page of the System Display (SD).

LAY08521 - L1AT4T0 - LM28P2000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

ENGINE FEED PRESENTATION (US) (1)

Jan 13, 2009 Page 20

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P2000000002

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel ENGINE FEED PRESENTATION (US) (1) Jan 13, 2009 Page 21

A380 TECHNICAL TRAINING MANUAL

ENGINE FEED PRESENTATION (US) (1)

Engine Feed Fuel Pump

For each part of the engine fuel feed system, there are two fuel pumps installed in each feed tank collector cell, one main pump and one standby pump. Each pump has a pressure switch to monitor the output fuel pressure. Each fuel pump system is usually manually controlled from the P/BSWs on the overhead-integrated control panel 1235 VM. When the main pump is in low-pressure condition, the related standby pump automatically starts. Engine feed information is shown on the ECAM FUEL page of the SD.

LAY08521 - L1AT4T0 - LM28P2000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

ENGINE FEED PRESENTATION (US) (1)

Jan 13, 2009 Page 22

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P2000000002

ENGINE FEED FUEL PUMP

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel ENGINE FEED PRESENTATION (US) (1) Jan 13, 2009 Page 23

A380 TECHNICAL TRAINING MANUAL

ENGINE FEED PRESENTATION (US) (1)

Crossfeed System

The crossfeed system enables any engine to be fed from any engine feed tank. It can be also used to correct fuel imbalance between tanks, in case of emergency condition or for maintenance purpose. The crossfeed system has four crossfeed valves, which are normally closed. When a crossfeed valve is open, the related fuel feed is available in a common fuel gallery between all the four valves. If a second crossfeed valve is opened, the two fuel feed systems are connected together. The crossfeed valves can be manually controlled by the four P/BSWs identified on the overhead-integrated control panel 1235VM as CROSSFEED 1 to CROSSFEED 4. Alternatively, the aircraft wiring automatically controls the crossfeed valves: - in the event of an electrical emergency condition, - by the Fuel Quantity Management System (FQMS) for an automatic ground transfer. The crossfeed valve position is shown on the ECAM FUEL page of the SD.

LAY08521 - L1AT4T0 - LM28P2000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

ENGINE FEED PRESENTATION (US) (1)

Jan 13, 2009 Page 24

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P2000000002

CROSSFEED SYSTEM

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel ENGINE FEED PRESENTATION (US) (1) Jan 13, 2009 Page 25

A380 TECHNICAL TRAINING MANUAL

ENGINE FEED PRESENTATION (US) (1)

Low-Pressure Shut-Off System

The engine Low-Pressure shut-off system has one LP valve per engine. Each valve can be opened or closed using the related ENG MASTER switch (1125 VU) on the cockpit pedestal. In case of engine fire, the operation of the engine FIRE P/BSW on the overhead-integrated control panel 1245 VM, will close the related LP valve and stop the fuel supply to the engine. The LP valve position data is shown on the ECAM FUEL page of the SD.

LAY08521 - L1AT4T0 - LM28P2000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

ENGINE FEED PRESENTATION (US) (1)

Jan 13, 2009 Page 26

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P2000000002

LOW-PRESSURE SHUT-OFF SYSTEM

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel ENGINE FEED PRESENTATION (US) (1) Jan 13, 2009 Page 27

A380 TECHNICAL TRAINING MANUAL

ENGINE FEED PRESENTATION (US) (1)

Heat Exchanger Fuel System

The A380 has a pair of Hydraulic Heat Exchangers (HHX), in order to cool down the high-pressure hydraulic fluid. This system acts as a back-up only in the event of a failure of the primary air/hydraulic heat exchanger. A bypass line on the engine fuel feed pipes of the engine 1 and the engine 4, diverts some fuel through the fuel/hydraulic heat exchangers via an isolation valve and then returns the heated fuel to the related engine feed tank. Control of the isolation valve, and thus feed fuel recirculation, is fully automatic from the FQMS. Recirculation is inhibited when the related feed tank contains insufficient fuel.

LAY08521 - L1AT4T0 - LM28P2000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

ENGINE FEED PRESENTATION (US) (1)

Jan 13, 2009 Page 28

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P2000000002

HEAT EXCHANGER FUEL SYSTEM

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel ENGINE FEED PRESENTATION (US) (1) Jan 13, 2009 Page 29

A380 TECHNICAL TRAINING MANUAL

APU FUEL SYSTEM PRESENTATION (ME) (1)

General

The APU fuel system supplies fuel to the Auxiliary Power Unit (APU). The system comprises a dedicated fuel line connected to the engine 4 fuel feed system of the right wing, two valves and an APU fuel pump. The APU MASTER SWitch controls the APU fuel supply. The APU FIRE P/BSW can stop the APU fuel supply. The APU fuel system status is shown on the ECAM FUEL page of the System Display (SD).

LAY08521 - L1AT4T0 - LM28P3000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

APU FUEL SYSTEM PRESENTATION (ME) (1)

Jan 13, 2009 Page 30

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P3000000001

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel APU FUEL SYSTEM PRESENTATION (ME) (1) Jan 13, 2009 Page 31

A380 TECHNICAL TRAINING MANUAL

APU FUEL SYSTEM PRESENTATION (ME) (1)

APU Fuel system

Selection of the APU MASTER SWitch on the overhead panel controls the fuel demand of the APU. The APU is supplied with fuel from the number 4 engine feed manifold. If the main or standby engine 4 feed pump is operating, the pressure is normally sufficient to operate the APU. However, if the pressure in the fuel line is not sufficient, the APU fuel pump will start automatically and will supply fuel to the APU. The APU fuel system has two valves that control the fuel supply to the APU, the APU pipe isolation valve and the APU Low Pressure (LP) valve. The APU pipe isolation valve prevents the APU fuel line from being pressurized when the APU is not in use. The APU LP valve located at the rear end of the APU fuel feed line isolates the APU from the fuel supply. If an emergency situation occurs (APU fire or emergency shut down) or if the Fuel Quantity Management System (FQMS) detects an APU feed line damage, the APU fuel pump stops, the APU pipe isolation valve and the APU LP valve are automatically controlled to the close position. The ECAM FUEL page of the SD indicates the status of the APU fuel system.

LAY08521 - L1AT4T0 - LM28P3000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

APU FUEL SYSTEM PRESENTATION (ME) (1)

Jan 13, 2009 Page 32

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P3000000001

APU FUEL SYSTEM

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel APU FUEL SYSTEM PRESENTATION (ME) (1) Jan 13, 2009 Page 33

A380 TECHNICAL TRAINING MANUAL

APU FUEL SYSTEM PRESENTATION (US) (1)

General

The APU fuel system supplies fuel to the Auxiliary Power Unit (APU). The system comprises a dedicated fuel line connected to the engine 4 fuel feed system of the right wing, two valves and an APU fuel pump. The APU MASTER SWitch controls the APU fuel supply. The APU FIRE P/BSW can stop the APU fuel supply. The APU fuel system status is shown on the ECAM FUEL page of the System Display (SD).

LAY08521 - L1AT4T0 - LM28P3000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

APU FUEL SYSTEM PRESENTATION (US) (1)

Jan 13, 2009 Page 34

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P3000000002

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel APU FUEL SYSTEM PRESENTATION (US) (1) Jan 13, 2009 Page 35

A380 TECHNICAL TRAINING MANUAL

APU FUEL SYSTEM PRESENTATION (US) (1)

APU Fuel system

Selection of the APU MASTER SWitch on the overhead panel controls the fuel demand of the APU. The APU is supplied with fuel from the number 4 engine feed manifold. If the main or standby engine 4 feed pump is operating, the pressure is normally sufficient to operate the APU. However, if the pressure in the fuel line is not sufficient, the APU fuel pump will start automatically and will supply fuel to the APU. The APU fuel system has two valves that control the fuel supply to the APU, the APU pipe isolation valve and the APU Low Pressure (LP) valve. The APU pipe isolation valve prevents the APU fuel line from being pressurized when the APU is not in use. The APU LP valve located at the rear end of the APU fuel feed line isolates the APU from the fuel supply. If an emergency situation occurs (APU fire or emergency shut down) or if the Fuel Quantity Management System (FQMS) detects an APU feed line damage, the APU fuel pump stops, the APU pipe isolation valve and the APU LP valve are automatically controlled to the close position. The ECAM FUEL page of the SD indicates the status of the APU fuel system.

LAY08521 - L1AT4T0 - LM28P3000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

APU FUEL SYSTEM PRESENTATION (US) (1)

Jan 13, 2009 Page 36

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P3000000002

APU FUEL SYSTEM

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel APU FUEL SYSTEM PRESENTATION (US) (1) Jan 13, 2009 Page 37

A380 TECHNICAL TRAINING MANUAL

FUEL TRANSFERS PRESENTATION (ME) (1)

General

The wing transfer system controls the movement of fuel between wing fuel tanks. The trim transfer system controls the longitudinal Center of Gravity (CG) of the aircraft. For this function the system moves fuel from the wing tanks to the trim tank (aft transfer) or from the trim tank to the wing tanks (forward transfer). Aft transfers are only possible when the aircraft is on the ground. There are 3 types of transfers: - main transfers: to supply fuel to the feed tanks, - load alleviation transfers: to alleviate structural loads in flight or on ground, - Center of Gravity (CG) transfers: to control CG and to fulfill longitudinal aircraft balance. They are automatically controlled by the Fuel Quantity Management System (FQMS) but can be manually overridden. Transfer data is displayed on the ECAM FUEL page of the System Display (SD).

LAY08521 - L1AT4T0 - LM28P4000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL TRANSFERS PRESENTATION (ME) (1)

Jan 13, 2009 Page 38

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P4000000001

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL TRANSFERS PRESENTATION (ME) (1) Jan 13, 2009 Page 39

A380 TECHNICAL TRAINING MANUAL

FUEL TRANSFERS PRESENTATION (ME) (1)

Fuel Transfer Routes

Wing transfers are done by using the forward gallery (or the aft gallery in case of failure) transfer pumps, transfer valves and inlet valves. Trim transfers use the trim pipe and valves to connect to the aft gallery (or the forward gallery in case of failure). All transfers are controlled by the FQMS, provided that all transfer pumps are selected ON, using their related P/BSWs on the overhead-integrated control panel 1235 VM. Manual override is possible from the FUEL panel.

LAY08521 - L1AT4T0 - LM28P4000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL TRANSFERS PRESENTATION (ME) (1)

Jan 13, 2009 Page 40

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P4000000001

FUEL TRANSFER ROUTES

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL TRANSFERS PRESENTATION (ME) (1) Jan 13, 2009 Page 41

A380 TECHNICAL TRAINING MANUAL

FUEL TRANSFERS PRESENTATION (US) (1)

General

The wing transfer system controls the movement of fuel between wing fuel tanks. The trim transfer system controls the longitudinal Center of Gravity (CG) of the aircraft. For this function the system moves fuel from the wing tanks to the trim tank (aft transfer) or from the trim tank to the wing tanks (forward transfer). Aft transfers are only possible when the aircraft is on the ground. There are 3 types of transfers: - main transfers: to supply fuel to the feed tanks, - load alleviation transfers: to alleviate structural loads in flight or on ground, - Center of Gravity (CG) transfers: to control CG and to fulfill longitudinal aircraft balance. They are automatically controlled by the Fuel Quantity Management System (FQMS) but can be manually overridden. Transfer data is displayed on the ECAM FUEL page of the System Display (SD).

LAY08521 - L1AT4T0 - LM28P4000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL TRANSFERS PRESENTATION (US) (1)

Jan 13, 2009 Page 42

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P4000000002

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL TRANSFERS PRESENTATION (US) (1) Jan 13, 2009 Page 43

A380 TECHNICAL TRAINING MANUAL

FUEL TRANSFERS PRESENTATION (US) (1)

Fuel Transfer Routes

Wing transfers are done by using the forward gallery (or the aft gallery in case of failure) transfer pumps, transfer valves and inlet valves. Trim transfers use the trim pipe and valves to connect to the aft gallery (or the forward gallery in case of failure). All transfers are controlled by the FQMS, provided that all transfer pumps are selected ON, using their related P/BSWs on the overhead-integrated control panel 1235 VM. Manual override is possible from the FUEL panel.

LAY08521 - L1AT4T0 - LM28P4000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL TRANSFERS PRESENTATION (US) (1)

Jan 13, 2009 Page 44

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P4000000002

FUEL TRANSFER ROUTES

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL TRANSFERS PRESENTATION (US) (1) Jan 13, 2009 Page 45

A380 TECHNICAL TRAINING MANUAL

REFUEL DEFUEL SYSTEM PRESENTATION (ME) (1)

General

The refuel/defuel system controls the flow of fuel into or out of the aircraft. Two refuel/defuel couplings are installed in the leading edge of each wing providing an interface between the refuel/defuel system and the external fuel source. The refuel/defuel procedures can be initiated and controlled from the overhead panel in the cockpit or from the Integrated Refuel Panel (IRP) in the RH lower belly fairing. The different refuel/defuel system operations are: - automatic refuel from the cockpit, - automatic refuel from the IRP, - manual refuel, - manual pressure defuel, - manual suction defuel, - automatic ground transfer (Center of Gravity control), - manual ground transfer. In all modes of operation overbalance and overflow protection is done by the Fuel Quantity Management System (FQMS).

LAY08521 - L1AT4T0 - LM28P5000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

REFUEL DEFUEL SYSTEM PRESENTATION (ME) (1)

Jan 13, 2009 Page 46

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P5000000001

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel REFUEL DEFUEL SYSTEM PRESENTATION (ME) (1) Jan 13, 2009 Page 47

A380 TECHNICAL TRAINING MANUAL

REFUEL DEFUEL SYSTEM PRESENTATION (ME) (1)

CG Targeting

To do an automatic refuel, the FQMS uses two different control methods: - CG targeting method, where the FQMS controls fuel loading and distribution to achieve a specific target aircraft Centre of Gravity (CG), - single vector method, where the FQMS controls fuel loading and distribution in accordance with a fixed/predefined sequence. To refuel to a specific CG target, the actual Zero Fuel Weight (ZFW) and the Zero Fuel Center of Gravity (ZFCG) values must be entered into the fuel management function through any of these means by: - manual entry onboard the aircraft using the Multi-Function Display (MFD) and Flight Management System (FMS), - manual entry on board the aircraft using the Onboard Maintenance Terminal (OMT) or the Onboard Information Terminal (OIT), - automatic uplink of data from an airline ground terminal using the Aircraft Communication Addressing and Reporting System (ACARS). If specific ZFW and ZFCG values are not given, then the aircraft will be refueled to default values using the single vector method. During an automatic refuel, the FQMS controls, which tanks receive fuel, when they receive fuel and the quantity of fuel they receive. The fuel management function calculates the fuel mass necessary in each tank to reach the ground CG target. During a manual refuel, the operator controls the fuel loading and distribution within the safety limits set by the FQMS. After refueling, if new or updated ZFW and ZFCG values are entered, an automatic ground transfer can be done from the cockpit with the AUTO GND XFR P/BSW.

LAY08521 - L1AT4T0 - LM28P5000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

REFUEL DEFUEL SYSTEM PRESENTATION (ME) (1)

Jan 13, 2009 Page 48

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P5000000001

CG TARGETING

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel REFUEL DEFUEL SYSTEM PRESENTATION (ME) (1) Jan 13, 2009 Page 49

A380 TECHNICAL TRAINING MANUAL

REFUEL DEFUEL SYSTEM PRESENTATION (ME) (1)

Fuel Routes

To fill the tanks, the refuel/defuel coupling is connected, via auxiliary refuel valves to 2 galleries of interconnected pipe-work, the forward gallery and the aft gallery. The layout of the pipe-work gives two separate routes into each wing fuel tank. In each tank, individual branch pipes end by an inlet valve. The fuel feed system is connected to forward gallery via a transfer/defuel valve. The trim pipe is connected to each aft and forward gallery, via a trim pipe isolation valve. The trim line ends with 2 trim tank inlet valves which give the only refuel route to the trim tank. Downstream of each tank inlet valve, the tank piping is connected to a single or group of refuel diffusers. All valves are controlled by the FQMS. To fill the fuel tanks to their maximum capacity, the aircraft must be at the usual ground attitude datum of level +/- 2 degrees. With four fuel hoses connected (to the refuel/defuel couplings), the minimum time to refuel the aircraft (from the tanks empty to the maximum capacity) at a refuel supply pressure of 2.75 bar (40 psi) is approximately 60 minutes.

LAY08521 - L1AT4T0 - LM28P5000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

REFUEL DEFUEL SYSTEM PRESENTATION (ME) (1)

Jan 13, 2009 Page 50

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P5000000001

FUEL ROUTES

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel REFUEL DEFUEL SYSTEM PRESENTATION (ME) (1) Jan 13, 2009 Page 51

A380 TECHNICAL TRAINING MANUAL

REFUEL DEFUEL SYSTEM PRESENTATION (US) (1)

General

The refuel/defuel system controls the flow of fuel into or out of the aircraft. Two refuel/defuel couplings are installed in the leading edge of each wing providing an interface between the refuel/defuel system and the external fuel source. The refuel/defuel procedures can be initiated and controlled from the overhead panel in the cockpit or from the Integrated Refuel Panel (IRP) in the RH lower belly fairing. The different refuel/defuel system operations are: - automatic refuel from the cockpit, - automatic refuel from the IRP, - manual refuel, - manual pressure defuel, - manual suction defuel, - automatic ground transfer (Center of Gravity control), - manual ground transfer. In all modes of operation overbalance and overflow protection is done by the Fuel Quantity Management System (FQMS).

LAY08521 - L1AT4T0 - LM28P5000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

REFUEL DEFUEL SYSTEM PRESENTATION (US) (1)

Jan 13, 2009 Page 52

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P5000000002

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel REFUEL DEFUEL SYSTEM PRESENTATION (US) (1) Jan 13, 2009 Page 53

A380 TECHNICAL TRAINING MANUAL

REFUEL DEFUEL SYSTEM PRESENTATION (US) (1)

CG Targeting

To do an automatic refuel, the FQMS uses two different control methods: - CG targeting method, where the FQMS controls fuel loading and distribution to achieve a specific target aircraft Centre of Gravity (CG), - single vector method, where the FQMS controls fuel loading and distribution in accordance with a fixed/predefined sequence. To refuel to a specific CG target, the actual Zero Fuel Weight (ZFW) and the Zero Fuel Center of Gravity (ZFCG) values must be entered into the fuel management function through any of these means by: - manual entry onboard the aircraft using the Multi-Function Display (MFD) and Flight Management System (FMS), - manual entry on board the aircraft using the Onboard Maintenance Terminal (OMT) or the Onboard Information Terminal (OIT), - automatic uplink of data from an airline ground terminal using the Aircraft Communication Addressing and Reporting System (ACARS). If specific ZFW and ZFCG values are not given, then the aircraft will be refueled to default values using the single vector method. During an automatic refuel, the FQMS controls, which tanks receive fuel, when they receive fuel and the quantity of fuel they receive. The fuel management function calculates the fuel mass necessary in each tank to reach the ground CG target. During a manual refuel, the operator controls the fuel loading and distribution within the safety limits set by the FQMS. After refueling, if new or updated ZFW and ZFCG values are entered, an automatic ground transfer can be done from the cockpit with the AUTO GND XFR P/BSW.

LAY08521 - L1AT4T0 - LM28P5000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

REFUEL DEFUEL SYSTEM PRESENTATION (US) (1)

Jan 13, 2009 Page 54

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P5000000002

CG TARGETING

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel REFUEL DEFUEL SYSTEM PRESENTATION (US) (1) Jan 13, 2009 Page 55

A380 TECHNICAL TRAINING MANUAL

REFUEL DEFUEL SYSTEM PRESENTATION (US) (1)

Fuel Routes

To fill the tanks, the refuel/defuel coupling is connected, via auxiliary refuel valves to 2 galleries of interconnected pipe-work, the forward gallery and the aft gallery. The layout of the pipe-work gives two separate routes into each wing fuel tank. In each tank, individual branch pipes end by an inlet valve. The fuel feed system is connected to forward gallery via a transfer/defuel valve. The trim pipe is connected to each aft and forward gallery, via a trim pipe isolation valve. The trim line ends with 2 trim tank inlet valves which give the only refuel route to the trim tank. Downstream of each tank inlet valve, the tank piping is connected to a single or group of refuel diffusers. All valves are controlled by the FQMS. To fill the fuel tanks to their maximum capacity, the aircraft must be at the usual ground attitude datum of level +/- 2 degrees. With four fuel hoses connected (to the refuel/defuel couplings), the minimum time to refuel the aircraft (from the tanks empty to the maximum capacity) at a refuel supply pressure of 2.75 bar (40 psi) is approximately 60 minutes.

LAY08521 - L1AT4T0 - LM28P5000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

REFUEL DEFUEL SYSTEM PRESENTATION (US) (1)

Jan 13, 2009 Page 56

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P5000000002

FUEL ROUTES

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel REFUEL DEFUEL SYSTEM PRESENTATION (US) (1) Jan 13, 2009 Page 57

A380 TECHNICAL TRAINING MANUAL

JETTISON SYSTEM PRESENTATION (ME) (1)

General

In case of an emergency situation, the jettison system is used to dump fuel overboard to decrease the aircraft gross weight before landing. The jettison system operation can only be initiated manually, but it can be stopped manually or automatically. It is always under the control of the Fuel Quantity Management System (FQMS). Only the fuel in the transfer tanks is jettisoned. There is no fuel jettison from the feed tanks. The jettison system data is displayed on the ECAM FUEL page of the system display (SD).

LAY08521 - L1AT4T0 - LM28P6000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

JETTISON SYSTEM PRESENTATION (ME) (1)

Jan 13, 2009 Page 58

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P6000000001

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel JETTISON SYSTEM PRESENTATION (ME) (1) Jan 13, 2009 Page 59

A380 TECHNICAL TRAINING MANUAL

JETTISON SYSTEM PRESENTATION (ME) (1)

Jettison System

Once fuel jettison has been manually initiated by means of two guarded P/BSWs, ARM and ACTIVE, located on the cockpit overhead panel 1211 VM, operation of the jettison system is automatic. The jettison valves are controlled by the FQMS via the aircraft wiring. The jettison-rate is approximately 3300 kg (7275 lb) per minute. Fuel is simultaneously jettisoned from the outer, mid and inner tanks of each wing. If there is fuel in the trim tank, a forward fuel transfer occurs. Up to twelve transfer pumps can be automatically started to supply the fuel flow from the fuel tanks to the forward and aft galleries. The fuel flows through the galleries, the left and right jettison valves, the jettison pipes and overboard of each wing. The system can be manually stopped by the crew through the guarded P/BSWs, ARM and ACTIVE, or automatically if the FQMS stops the operation at a pre-set jettison final gross weight. The jettison system data is displayed on the ECAM FUEL page of the (SD).

LAY08521 - L1AT4T0 - LM28P6000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

JETTISON SYSTEM PRESENTATION (ME) (1)

Jan 13, 2009 Page 60

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P6000000001

JETTISON SYSTEM

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel JETTISON SYSTEM PRESENTATION (ME) (1) Jan 13, 2009 Page 61

A380 TECHNICAL TRAINING MANUAL

JETTISON SYSTEM PRESENTATION (US) (1)

General

In case of an emergency situation, the jettison system is used to dump fuel overboard to decrease the aircraft gross weight before landing. The jettison system operation can only be initiated manually, but it can be stopped manually or automatically. It is always under the control of the Fuel Quantity Management System (FQMS). Only the fuel in the transfer tanks is jettisoned. There is no fuel jettison from the feed tanks. The jettison system data is displayed on the ECAM FUEL page of the system display (SD).

LAY08521 - L1AT4T0 - LM28P6000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

JETTISON SYSTEM PRESENTATION (US) (1)

Jan 13, 2009 Page 62

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P6000000002

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel JETTISON SYSTEM PRESENTATION (US) (1) Jan 13, 2009 Page 63

A380 TECHNICAL TRAINING MANUAL

JETTISON SYSTEM PRESENTATION (US) (1)

Jettison System

Once fuel jettison has been manually initiated by means of two guarded P/BSWs, ARM and ACTIVE, located on the cockpit overhead panel 1211 VM, operation of the jettison system is automatic. The jettison valves are controlled by the FQMS via the aircraft wiring. The jettison-rate is approximately 3300 kg (7275 lbs) per minute. Fuel is simultaneously jettisoned from the outer, mid and inner tanks of each wing. If there is fuel in the trim tank, a forward fuel transfer occurs. Up to twelve transfer pumps can be automatically started to supply the fuel flow from the fuel tanks to the forward and aft galleries. The fuel flows through the galleries, the left and right jettison valves, the jettison pipes and overboard of each wing. The system can be manually stopped by the crew through the guarded P/BSWs, ARM and ACTIVE, or automatically if the FQMS stops the operation at a pre-set jettison final gross weight. The jettison system data is displayed on the ECAM FUEL page of the (SD).

LAY08521 - L1AT4T0 - LM28P6000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

JETTISON SYSTEM PRESENTATION (US) (1)

Jan 13, 2009 Page 64

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P6000000002

JETTISON SYSTEM

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel JETTISON SYSTEM PRESENTATION (US) (1) Jan 13, 2009 Page 65

A380 TECHNICAL TRAINING MANUAL

FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (ME) (1)

General

The Fuel Quantity Management System (FQMS) automatically controls and monitors most of the sub-systems of the fuel system. This is achieved using avionics computing units to acquire system data, do various computations and generate control and indication signals/data. The main functions are: - fuel quantity measurement, - fuel temperature measurement, - Centre of Gravity calculation, - fuel transfer control/management, - system indications, - system monitoring and test, - fault reporting. These functions are hosted in the system's avionics resources.

LAY08521 - L1AT4T0 - LM28P7000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (ME) (1)

Jan 13, 2009 Page 66

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P7000000001

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (ME) (1) Jan 13, 2009 Page 67

A380 TECHNICAL TRAINING MANUAL

FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (ME) (1)

FQMS Architecture

The FQMS comprises a number of electronic LRUs/LRMs, fuel system application software and sensors. Part of the FQMS application software is installed on two Fuel Quantity Data Concentrators (FQDCs), the primary part of the software is installed on four CPIOMs-F. The FQDCs interface between the system's in-tank sensors and probes, pumps and valves, and the CPIOMs-F. The following sensors and probes in the system are: - capacitance probes, for fuel level measurement, - Probe Compensators Temperature Units (PCTUs), for fuel permittivity measurement, - dual element temperature sensors, for fuel temperature measurement, - arrangement of a compensator (with single integral temperature sensor) and a densitometer (with single integral temperature sensor) on a common back plate named Fuel Properties Measurement Units (FPMUs), for determination of the characteristics of an uplifted fuel. The FQMS also includes an Integrated Refuel Panel (IRP), which is used to control and observe ground operations such as refuel, defuel and ground transfers. The FQMS Application Software in the CPIOMs-F is divided into seven partitions. Each partition is responsible for the realization of certain FQMS functions. The partitions are split in MONitor and COMmand partitions. The COM partitions and their corresponding functions are: - Measurement: fuel quantity determination, fuel temperature determination, overflow condition determination and fault monitoring/reporting, - Management: management of fuel uplift, fuel transfer between aircraft tanks, defuel or jettison, generation of pump/valve control stimuli and fault monitoring/reporting,

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

- CG Measurement: computation of aircraft gross weight, aircraft longitudinal center of gravity and aft center of gravity target and fault monitoring/reporting. The MON partitions and their corresponding functions are: - Integrity: checking of system computations to ensure safety and high integrity, - Monitor: checking of system conditions to detect erroneous computations, - CG Measurement: second computation of aircraft gross weight, aircraft longitudinal center of gravity and aft center of gravity target, - System BITE: system health determination, side changeover control, collection of system fault reports, fault isolation and reporting and management of interactive dialogue with CMS. The four CPIOMs-F are grouped into pairs to form two computing lanes or sides. Through the two FQDCs, each side receives, via ARINC 429 communication buses, data from probes and sensors as well as feedback data from the fuel system's active pumps and valves. They also receive data from the Integrated Refuel Panel.

LAY08521 - L1AT4T0 - LM28P7000000001

FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (ME) (1)

Jan 13, 2009 Page 68

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P7000000001

FQMS ARCHITECTURE

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (ME) (1) Jan 13, 2009 Page 69

A380 TECHNICAL TRAINING MANUAL

FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (US) (1)

General

The Fuel Quantity Management System (FQMS) automatically controls and monitors most of the sub-systems of the fuel system. This is achieved using avionics computing units to acquire system data, do various computations and generate control and indication signals/data. The main functions are: - fuel quantity measurement - fuel temperature measurement - Centre of Gravity calculation - fuel transfer control/management - system indications - system monitoring and test - fault reporting These functions are hosted in the system's avionics resources.

LAY08521 - L1AT4T0 - LM28P7000000002

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (US) (1)

Jan 13, 2009 Page 70

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P7000000002

GENERAL

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (US) (1) Jan 13, 2009 Page 71

A380 TECHNICAL TRAINING MANUAL

FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (US) (1)

FQMS Architecture

The FQMS comprises a number of electronic LRUs/LRMs, fuel system application software and sensors. Part of the FQMS application software is installed on two Fuel Quantity Data Concentrators (FQDCs), the primary part of the software is installed on four CPIOMs-F. The FQDCs interface between the system's in-tank sensors and probes, pumps and valves, and the CPIOMs-F. The following sensors and probes in the system are: - capacitance probes, for fuel level measurement, - Probe Compensators Temperature Units (PCTUs), for fuel permittivity measurement, - dual element temperature sensors, for fuel temperature measurement, - arrangement of a compensator (with single integral temperature sensor) and a densitometer (with single integral temperature sensor) on a common back plate named Fuel Properties Measurement Units (FPMUs), for determination of the characteristics of an uplifted fuel. The FQMS also includes an Integrated Refuel Panel (IRP), which is used to control and observe ground operations such as refuel, defuel and ground transfers. The FQMS Application Software in the CPIOMs-F is divided into seven partitions. Each partition is responsible for the realization of certain FQMS functions. The partitions are split in MONitor and COMmand partitions. The COM partitions and their corresponding functions are: - Measurement: fuel quantity determination, fuel temperature determination, overflow condition determination and fault monitoring/reporting, - Management: management of fuel uplift, fuel transfer between aircraft tanks, defuel or jettison, generation of pump/valve control stimuli and fault monitoring/reporting,

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

- CG Measurement: computation of aircraft gross weight, aircraft longitudinal center of gravity and aft center of gravity target and fault monitoring/reporting. The MON partitions and their corresponding functions are: - Integrity: checking of system computations to ensure safety and high integrity, - Monitor: checking of system conditions to detect erroneous computations, - CG Measurement: second computation of aircraft gross weight, aircraft longitudinal center of gravity and aft center of gravity target, - System BITE: system health determination, side changeover control, collection of system fault reports, fault isolation and reporting and management of interactive dialogue with CMS. The four CPIOMs-F are grouped into pairs to form two computing lanes or sides. Through the two FQDCs, each side receives, via ARINC 429 communication buses, data from the two group of probes and sensors as well as feedback data from the fuel system's active pumps and valves. They also receive data from the Integrated Refuel Panel.

LAY08521 - L1AT4T0 - LM28P7000000002

FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (US) (1)

Jan 13, 2009 Page 72

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P7000000002

FQMS ARCHITECTURE

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL QUANTITY MANAGEMENT SYSTEM PRESENTATION (US) (1) Jan 13, 2009 Page 73

A380 TECHNICAL TRAINING MANUAL

FUEL SYSTEM MAINTENANCE (1)

Fuel Safety Items

When you work on aircraft, make sure that you obey all the AMM safety procedures. This will prevent injury to persons and /or damage to the aircraft. Here is an overview of main safety precautions relative to the fuel system. Make sure that the safety area is clear and clean. Respect the safety precautions within the safety distances. During a refueling, the area must be kept clear to let the tanker move away in an emergency. Aircraft must not be refueled less than 30 meters (100ft) from radar or HF radio equipment under test or in operation in the aircraft or ground installation. Put the '' NO SMOKING '' warning notices around the work area. Ground and bond the aircraft. In the work area: - do not use any material / tool which may cause sparks, - use only necessary and approved electrical / electronic equipment, - make sure the air flow is sufficient to work safely in tanks, otherwise use a respirator, - do not pull or move metal objects along the ground, - immediately flush away or remove any fuel leakage. Make sure that you have the proper fire fighting equipment available. The fuel/kerosene is poisonous. Avoid any contact between fuel and your eyes, mouth, nose, ears or your skin. Use the approved protective clothing to prevent personal contamination and formation of static electricity.

LAY08521 - L1AT4T0 - LM28P8MAINT0001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL SYSTEM MAINTENANCE (1)

Jan 13, 2009 Page 74

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - LM28P8MAINT0001

FUEL SAFETY ITEMS

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL SYSTEM MAINTENANCE (1) Jan 13, 2009 Page 75

A380 TECHNICAL TRAINING MANUAL

FUEL TANK SAFETY PRESENTATION (1)

General

Following three fuel tank explosions over the past 14 years which resulted in 346 fatalities, the U.S Department of Transportation's Federal Aviation Administration (FAA), have introduced new regulations to improve fuel tank safety. These regulations relate to the prevention of ignition sources within fuel tanks of current type certificated aircraft. They require carrying out a one-time fuel system safety and design review.

Critical Design Configuration Control Limitations (CDCCL)

The FAA issued Special Federal Aviation Regulation (SFAR) 88 which gives a detailed description of the CDCCL concept. The DGAC requested the SFAR 88 (TGL 47) to be added to PART 145, PART M and PART 147 to reinforce the application of these regulations. This includes: - a conception part intended to aircraft design features, - a maintenance part. A CDCCL is a limitation requirement to preserve a critical ignition source prevention feature of the fuel system design that is necessary to prevent the occurrence of an unsafe condition. The function of the CDCCL is to give instructions to retain the critical ignition source prevention feature during configuration change that may be caused by alterations, repairs or maintenance actions. The aircraft manufacturers have to emit a document to their customers giving the list of all the maintenance tasks impacted by the CDCCL. For AIRBUS this document is called the Fuel Airworthiness Limitations and it is added to the Airworthiness Limitation Section part 5. CDCCL items are listed in Airworthiness Limitations Form.

LAY08521 - L1AT4T0 - XM28P1000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL TANK SAFETY PRESENTATION (1)

Dec 20, 2007 Page 76

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - XM28P1000000001

GENERAL - CRITICAL DESIGN CONFIGURATION CONTROL LIMITATIONS (CDCCL)

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL TANK SAFETY PRESENTATION (1) Dec 20, 2007 Page 77

A380 TECHNICAL TRAINING MANUAL

FUEL TANK SAFETY PRESENTATION (1)

Fuel System Design Configuration

The Airbus aircraft fuel systems have, by design, a number of features that are intended to protect the system from inadvertent ignition.

LAY08521 - L1AT4T0 - XM28P1000000001

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel

FUEL TANK SAFETY PRESENTATION (1)

Dec 20, 2007 Page 78

A380 TECHNICAL TRAINING MANUAL

LAY08521 - L1AT4T0 - XM28P1000000001

FUEL SYSTEM DESIGN CONFIGURATION

GENERAL FAMILIARIZATION COURSE - T4 (RR Trent 900) LEVEL I - ATA 28 Fuel FUEL TANK SAFETY PRESENTATION (1) Dec 20, 2007 Page 79

AIRBUS S.A.S. 31707 BLAGNAC cedex, FRANCE STM REFERENCE LAY08521 JANUARY 2009 PRINTED IN FRANCE AIRBUS S.A.S. 2009 ALL RIGHTS RESERVED AN EADS COMPANY

You might also like

- 1996 SeaDoo Service ManualDocument316 pages1996 SeaDoo Service ManualDIYRepairManuals100% (4)

- 330C Plano Electrico PDFDocument2 pages330C Plano Electrico PDFRICHARDNo ratings yet

- Delphi Pump Test Plans 4 WebDocument54 pagesDelphi Pump Test Plans 4 WebAspro Brazil Se Iglesias100% (4)

- Cat 322 CDocument2 pagesCat 322 CxuanNo ratings yet

- Undercowl Pocket Guide RRDocument32 pagesUndercowl Pocket Guide RRbnmmauricio100% (3)

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsFrom EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsRating: 5 out of 5 stars5/5 (1)

- Toyota NR Series EnginesDocument34 pagesToyota NR Series Enginesmaty_11_gti100% (1)

- XTO TextbookDocument220 pagesXTO TextbookG SNo ratings yet

- Electronic Injector Catalog Mar 2020 LRDocument24 pagesElectronic Injector Catalog Mar 2020 LRAlejandro Valenzuela100% (1)

- LEVEL I - ATA 27 Flight ControlsDocument66 pagesLEVEL I - ATA 27 Flight ControlswagdiNo ratings yet

- A330-200 NavigationDocument26 pagesA330-200 NavigationTarik Benzineb100% (1)

- 08 A330 Ata 35Document32 pages08 A330 Ata 35Owen100% (1)

- A321 Ata21-00 PDFDocument1 pageA321 Ata21-00 PDFkpilNo ratings yet

- mm10001 4-16-15 Rev K 2Document43 pagesmm10001 4-16-15 Rev K 2Jay R SVNo ratings yet

- ENGINE SENSORS 32 HalDocument32 pagesENGINE SENSORS 32 HalDian Idawati100% (1)

- 29 Hydraulic PowerDocument234 pages29 Hydraulic PowerUcok BabaNo ratings yet

- EMC 1-STN-Level 2 3-ATA 46 PDFDocument10 pagesEMC 1-STN-Level 2 3-ATA 46 PDFbasid911No ratings yet

- Fuel - APU - Engine TrainingDocument288 pagesFuel - APU - Engine TrainingBianco Yep100% (2)

- 24-00 - Electrical Power - GeneralDocument55 pages24-00 - Electrical Power - GeneralMohammad NorouzzadehNo ratings yet

- A380-LEVEL I - ATA 31 Indicating - Recording SystemsDocument70 pagesA380-LEVEL I - ATA 31 Indicating - Recording SystemsGuy100% (1)

- ATA 44 Cabin Systems PDFDocument26 pagesATA 44 Cabin Systems PDFGoitom Teclai100% (3)

- A380-Level II&III - Ata 29 Hydraulic PowerDocument56 pagesA380-Level II&III - Ata 29 Hydraulic Powerfiretooth10No ratings yet

- 25 Equipment FurnishingsDocument146 pages25 Equipment FurnishingsTarik BenzinebNo ratings yet

- 26 Fire Protection-A330FDocument26 pages26 Fire Protection-A330Fpratt777No ratings yet

- ATA 70 POWER PLANT (RR Trent 700)Document340 pagesATA 70 POWER PLANT (RR Trent 700)Sohaib Aslam ChaudharyNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- 16 A330 Ata 28Document152 pages16 A330 Ata 28Owen100% (1)

- 49 Honeywell 36-300 - Diff - L3 - Aug09 - X PDFDocument24 pages49 Honeywell 36-300 - Diff - L3 - Aug09 - X PDFHo Viet ThangNo ratings yet

- A380-Level I - Ata 36 PneumaticDocument26 pagesA380-Level I - Ata 36 PneumaticAbolfazl Mazloomi100% (3)

- 24 Electrical PowerDocument172 pages24 Electrical PowerNurlan CebrayilzadeNo ratings yet

- 23 CommunicationsDocument250 pages23 CommunicationsAhmed ShahNo ratings yet

- Communications CH 23: Training Manual B767-3S2F Ata 23-50Document75 pagesCommunications CH 23: Training Manual B767-3S2F Ata 23-50David OwenNo ratings yet

- A350 Technical Training Manual T1+T2 Mechanical and Avionics A350 RR TRENT XWB Power Plant (Level1)Document214 pagesA350 Technical Training Manual T1+T2 Mechanical and Avionics A350 RR TRENT XWB Power Plant (Level1)Egor Rogulkin100% (1)

- Ajw gtcp331-500b Minipack SN p-1154Document249 pagesAjw gtcp331-500b Minipack SN p-1154Okky Pangestoe WibowoNo ratings yet

- 22 Auto FlightDocument30 pages22 Auto Flightsan2inNo ratings yet

- 33 Lights System Presentation (1) : A330 Technical Training ManualDocument34 pages33 Lights System Presentation (1) : A330 Technical Training ManualAshik AslamNo ratings yet

- A320 Training 28 Fuel SystemDocument304 pagesA320 Training 28 Fuel SystemMustafa Assadi86% (7)

- Single Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) GeneralDocument8 pagesSingle Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) Generalripan thakurNo ratings yet

- Level II - Airbus DocumentationDocument24 pagesLevel II - Airbus DocumentationwagdiNo ratings yet

- Ata 49 ApuDocument77 pagesAta 49 ApuSohaib Aslam Chaudhary100% (1)

- Electrical Power OverviewDocument95 pagesElectrical Power OverviewA Wong100% (1)

- Ge 7s12 PDFDocument25 pagesGe 7s12 PDFnangkarak8201100% (2)

- Airbus A300-600/A310 Landing Gear SystemsDocument190 pagesAirbus A300-600/A310 Landing Gear SystemsRaph 1123No ratings yet

- A319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 28 Fuel SystemDocument354 pagesA319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 28 Fuel SystemAhmedHamdyElsaidy100% (7)

- 89n303 The Touareg V10-TDI EngineDocument50 pages89n303 The Touareg V10-TDI Engineeduardorojas007100% (3)

- Operation On Low Sulphur FuelsDocument24 pagesOperation On Low Sulphur FuelsAlejandro Jose Malave RamosNo ratings yet

- 28 FUEL (Metric Units)Document324 pages28 FUEL (Metric Units)fourj747100% (3)

- Fuel SystemDocument6 pagesFuel SystemMrAlbert2009100% (1)

- Ford Presion GasolinaDocument15 pagesFord Presion GasolinaAlainbravopaez100% (1)

- A380 Level I Ata 28 FuelDocument84 pagesA380 Level I Ata 28 FuelGuyNo ratings yet

- Level III - Ata 35 OxygenDocument58 pagesLevel III - Ata 35 Oxygenwagdi0% (1)

- SBcontent PDFDocument65 pagesSBcontent PDFThanh Vinh NguyenNo ratings yet

- Level III - Ata 28 Fuel SystemDocument90 pagesLevel III - Ata 28 Fuel SystemwagdiNo ratings yet

- LEVEL I - ATA 28 FuelDocument66 pagesLEVEL I - ATA 28 Fuelwagdi100% (1)

- Ata 25Document78 pagesAta 25Sohaib Aslam ChaudharyNo ratings yet

- Service Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional InformationDocument11 pagesService Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional Informationa_sharafiehNo ratings yet

- A380-LEVEL I - ATA 31 Indicating - Recording SystemsDocument70 pagesA380-LEVEL I - ATA 31 Indicating - Recording SystemsAbolfazl Mazloomi100% (1)

- Level I - Ata 36 PneumaticDocument26 pagesLevel I - Ata 36 PneumaticwagdiNo ratings yet

- Level I - Ata 46 Nss & OisDocument20 pagesLevel I - Ata 46 Nss & OiswagdiNo ratings yet

- A340 Ata 25Document34 pagesA340 Ata 25Abdelaziz AbdoNo ratings yet

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) NavigationDocument12 pagesSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) Navigationjuan0% (1)

- 01 Avionics Level 1Document342 pages01 Avionics Level 1teminaniNo ratings yet

- LEVEL I - ATA 31 Indicating - Recording SystemsDocument70 pagesLEVEL I - ATA 31 Indicating - Recording SystemswagdiNo ratings yet

- A380 25 B2X1Document24 pagesA380 25 B2X1Elijah Paul Merto100% (1)

- LEVEL I - ATA 30 Ice & Rain ProtectionDocument44 pagesLEVEL I - ATA 30 Ice & Rain ProtectionwagdiNo ratings yet

- Level II - Ata 28 Fuel SystemsDocument40 pagesLevel II - Ata 28 Fuel SystemswagdiNo ratings yet

- Ata 36 PneumaticDocument30 pagesAta 36 PneumaticSohaib Aslam ChaudharyNo ratings yet

- 28 FUEL (Metric Units)Document250 pages28 FUEL (Metric Units)Navid Khalili SafaNo ratings yet

- 45 Onboard Maintenance SystemsDocument56 pages45 Onboard Maintenance SystemsWilliam Jaldin CorralesNo ratings yet

- A319/A320/A321 Technical Training Manual 27 Flight Controls Mechanics / Electrics & Avionics CourseDocument3 pagesA319/A320/A321 Technical Training Manual 27 Flight Controls Mechanics / Electrics & Avionics CourseDavid OwenNo ratings yet

- A380 Lights Maintenance ManualDocument90 pagesA380 Lights Maintenance ManualGuyNo ratings yet

- A330 Tire and Brake InspectionDocument21 pagesA330 Tire and Brake InspectionRithesh Ram NambiarNo ratings yet

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) CommunicationsDocument42 pagesSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) CommunicationsjuanNo ratings yet

- Single Aisle Aircraft Communications ManualDocument102 pagesSingle Aisle Aircraft Communications ManualCassiano CapellassiNo ratings yet

- C5 23 - A330 340 PDFDocument8 pagesC5 23 - A330 340 PDFTanveer AhmedNo ratings yet

- TTM A320 CFM 56 Ata 03 Power Plant Level 1 Aa RCDocument226 pagesTTM A320 CFM 56 Ata 03 Power Plant Level 1 Aa RCmohamed yacine amirecheNo ratings yet

- 6.4L Fuel Supply SystemDocument5 pages6.4L Fuel Supply SystemWilson Bueno100% (1)

- GTS125i Service ManualDocument257 pagesGTS125i Service ManualHoraceNo ratings yet

- Catalogue V 7Document212 pagesCatalogue V 7Keris TidarNo ratings yet

- GacDocument20 pagesGacRhyzza Cortez100% (1)

- Pierburg-Fuel Pump Product Info PDFDocument52 pagesPierburg-Fuel Pump Product Info PDFGauravPradhanNo ratings yet

- Fuel Pump Replacement Kit: CautionDocument2 pagesFuel Pump Replacement Kit: CautionAntonio MonteiroNo ratings yet

- Kumpulan Soal Pak TeguhDocument17 pagesKumpulan Soal Pak TeguhSalim Akbar100% (1)

- Caterpillar Cat 235 EXCAVATOR (Prefix 32K) Service Repair Manual (32K00001-00788)Document24 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 32K) Service Repair Manual (32K00001-00788)rpoy9396615No ratings yet

- Thermal Systems and Heat Transfer: Name Roll No TopicDocument4 pagesThermal Systems and Heat Transfer: Name Roll No Topicsudhagar sNo ratings yet

- Service Publications: Number SubjectDocument5 pagesService Publications: Number Subjectpiyush agrawalNo ratings yet

- Allis Chalmers h3 Hd3 Crawler Tractors Parts CatalogDocument20 pagesAllis Chalmers h3 Hd3 Crawler Tractors Parts Catalogallen100% (42)

- Technical Documentation: Diesel EngineDocument6 pagesTechnical Documentation: Diesel EngineArun KumarNo ratings yet

- Fuel Pump Lead & Fuel Cam AdjustmentDocument10 pagesFuel Pump Lead & Fuel Cam AdjustmentJithin VijayanNo ratings yet

- Operation On Low-Sulphur Fuels: MAN B&W Two-Stroke EnginesDocument24 pagesOperation On Low-Sulphur Fuels: MAN B&W Two-Stroke EnginesRinaldi SiahaanNo ratings yet