Professional Documents

Culture Documents

Working of Universal Testing Machine (UTM

Uploaded by

Rajesh DwivediCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Working of Universal Testing Machine (UTM

Uploaded by

Rajesh DwivediCopyright:

Available Formats

Strength of Materials (9024)

Experiment No. 2

Experiment No. 2

1.0 TITLE :

To understand the working of Universal Testing Machine (UTM) for various tests.

2.0

PRIOR CONCEPTS:

Force, Load, Tensile force, Compressive force, tangential force.

3.0

NEW CONCEPTS:

Proposition 1: Gradual Load Load starting from zero and applied with constant increment up to required value. Concept Structure :

Proposition 2 : Types of Loads Axial Load : Load acting along longitudinal axis of the member. Tensile load causes elongation and Compressive load causes contraction of the member. Transverse Load : Load acting perpendicular to longitudinal axis of the member and causes bending of the member. Shear Load : Load acting tangentially along a surface of the member and causes cutting like effect.

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

o 9

Experiment No. 2

Strength of Materials (9024)

Concept Structure :

Proposition No. 3 : Universal Testing Machine The machine comprises of two basic units, one is the Control unit and other is loading unit. Control unit : The load is applied and recorded by this unit. The load is applied with control valve and released by release valve. The load is applied with the help of hydraulic pressure. Loading unit : In this unit actual loading of the specimen takes place - consists of three crossheads namely upper head, middle head and lower head. Using appropriate crossheads tensile, compressive, shear, bending load with the help of different attachment can be applied.

10 o

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

Strength of Materials (9024)

Experiment No. 2

Concept Structure :

4.0

LEARNING OBJECTIVES:

Intellectual skills: To study different parts of UTM & their function. To know working principle of UTM. To select proper crossheads for particular type of load application. Motor skills: Ability to handle different fixtures and attachments. Ability to observe cross head movements. Ability to measure loads on load dial gauges.

5.0

APPARATUS AND MATERIALS

Apparatus: Universal Testing Machine(UTM), tension grips, shear attachment, bending attachment, compression plates, hardness attachment. Materials: Specimen of timber with standard dimensions. Learning material : Brochure supplied with the machine.

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

o 11

Experiment No. 2

Strength of Materials (9024)

6.0

DESIGN OF EXPERIMENT:

Label the numbered parts and state their functions.

12 o

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

Strength of Materials (9024)

Experiment No. 2

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

o 13

Experiment No. 2

Strength of Materials (9024)

7.0

STEPWISE PROCEDURE:

1. 2. 3. Ensure that all the switches and main switches are put on. Ensure that release valve and the control valve mounted on control unit are closed. Move the middle crosshead of loading unit up and down with the help of mechanical motors, there by the space from upper crosshead and middle crosshead decreases or increases. This helps us to adjust the gap between crossheads as per length of the specimen. Now put the machine on and open the control valve slowly. Observe the upward movement of upper and lower crosshead. The middle crosshead will remain stationary. One can control the movement speed of crosshead using control valve.

4.

14 o

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

Strength of Materials (9024)

Experiment No. 2

5.

6. 7.

8.

9. 10. 11.

As soon as the control valve is opened observe the changes on load dial/display along with displacement dial/display. The value for load will increase for some time and then remain stationary but the values for displacement will go on increasing. This load value is nothing but the dead weight of lower crosshead. Now make the load reading zero with the help of tare switch. Shut down the machine. Close the control valve and open the release valve. Note the backflow of hydraulic oil and observe slow lowering of the crosshead. The value for load will decrease for some time and then become negative and the values for displacement will go on decreasing. This is termed as adjustment of dead weight of crosshead. Teacher shall explain the disadvantages if this adjustment is not done properly. Put the timber specimen between middle and lower crosshead. Ensure that there is a small gap within crossheads and the specimen. After selecting suitable range on load dial gauge close the release valve and slowly open the control valve. Note the readings of load at three different instants. Apply the load till failure of the specimen takes place, this is the maximum load or failure load generally denoted by P. Put off the machine. Close the control valve and open the release valve.

8.0

OBSERVATIONS :

Table for load and displacement

9.0

QUESTIONS:

Write answers to Q ......, Q ......, Q ......, Q ...... (Teacher shall allot the question) 1. Enlist the tests to be performed on the universal testing machine. 2. State the operational principle of UTM. 3. Why release valve is opened, after the machine is put off? Give reason. 4. How to adjust the dead weight of crosshead? 5. What will happen if the machine is put on keeping the release valve open? 6. Why is it necessary to adjust the dead weight of crossheads? Give reason. 7. State the type of oil used for UTM available in your lab. 8. Can you perform Rockwell Hardness Test on UTM. 9. How wire ropes and LT stay wires are fixed in the jaws of UTM. 10. What will happen if dummy pointer of a UTM is missing?

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

o 15

Experiment No. 2

Strength of Materials (9024)

(Space for answer)

Signature of Teacher

16 o

MAHARASHTRA STATE BOARD OF TECHNICAL EDUCATION

You might also like

- Universal Testing MachineDocument28 pagesUniversal Testing MachineMarc Anthony de VillaNo ratings yet

- Tensile Report Group7Document21 pagesTensile Report Group7muhd hariz100% (1)

- Universal Testing MachineDocument3 pagesUniversal Testing MachineFarooq Shah100% (1)

- Spring TestDocument5 pagesSpring Testmohanadymt50% (2)

- Closed Coil Helical SpringsDocument12 pagesClosed Coil Helical SpringsAtish Kumar100% (7)

- Reflection Report On Rockwell Hardness Tes 2Document3 pagesReflection Report On Rockwell Hardness Tes 2Prashant PawarNo ratings yet

- Standard Testing Procedure - Tensile TestingDocument3 pagesStandard Testing Procedure - Tensile Testingdevendrasingh2021100% (1)

- Tensile TestDocument9 pagesTensile TestMohamed Reeza100% (1)

- Introduction To Materials TestingDocument6 pagesIntroduction To Materials Testinggosaye desalegnNo ratings yet

- Gauges and Gauge DesignDocument12 pagesGauges and Gauge DesignAmir JodeyriNo ratings yet

- Double Shear TestDocument4 pagesDouble Shear TestHarit Bala50% (2)

- EGR 236 Lab 10 Helical Spring TestDocument3 pagesEGR 236 Lab 10 Helical Spring TestBahah Tyty100% (2)

- Modulus of Elasticity for Mild SteelDocument6 pagesModulus of Elasticity for Mild Steelafzal taiNo ratings yet

- Tensile Test of Mild SteelDocument6 pagesTensile Test of Mild SteelAnshuman Dash100% (2)

- Calibration of A Bourdon ManometerDocument5 pagesCalibration of A Bourdon ManometerMyat Thu HtetNo ratings yet

- Is 3025 (P-14) For ConductivityDocument4 pagesIs 3025 (P-14) For Conductivityamishraioc0% (1)

- Rockwell Hardness TestDocument4 pagesRockwell Hardness TestAsifIqbal100% (2)

- Torque MeasurementDocument43 pagesTorque Measurementvadithya1515No ratings yet

- Charpy Impact Test - Lab ReportDocument18 pagesCharpy Impact Test - Lab ReportChitra Nadia100% (1)

- Bend and Re-Bend Test of Steel Reinforcing Bar: Laboratory 5Document7 pagesBend and Re-Bend Test of Steel Reinforcing Bar: Laboratory 5sainathNo ratings yet

- Izod Impact Test Aim:-: Apparatus Used:-Impact Testing MachineDocument4 pagesIzod Impact Test Aim:-: Apparatus Used:-Impact Testing MachineNagLakshmanan100% (1)

- Tensile TestDocument4 pagesTensile TestHarsha Vardhana50% (8)

- SM Lab (Tension Test)Document15 pagesSM Lab (Tension Test)sushilkumar100% (1)

- Pneumatic Power HammerDocument19 pagesPneumatic Power HammerRishabh GuptaNo ratings yet

- Tensile Test PDFDocument3 pagesTensile Test PDFRamona Mv M VNo ratings yet

- Design of Transmission Systems Subject Code: 342Document49 pagesDesign of Transmission Systems Subject Code: 342Muthuvel MNo ratings yet

- ASTM C109 Compressive Strength of Hydraulic Cement MortarsDocument2 pagesASTM C109 Compressive Strength of Hydraulic Cement MortarsAmanda Ariesta ApriliaNo ratings yet

- Experiment 5 - Tensile TestDocument17 pagesExperiment 5 - Tensile TestSubuk T. Rathod0% (2)

- Lab ReportDocument21 pagesLab ReportMuhammad YasirNo ratings yet

- Engineering Mechanics Lab ManualDocument36 pagesEngineering Mechanics Lab ManualSri RNo ratings yet

- Vickers Hardness Test ReportDocument9 pagesVickers Hardness Test ReportMoiz Amir100% (1)

- Torsion Test Lab ReportDocument17 pagesTorsion Test Lab Reportlong0% (2)

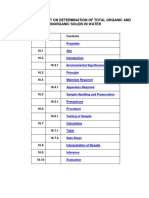

- 16.0 Experiment On Determination of Total Organic and Inorganic Solids in WaterDocument13 pages16.0 Experiment On Determination of Total Organic and Inorganic Solids in WaterVishnu NandakumarNo ratings yet

- ME 457 Experimental Solid Mechanics (Lab) Torsion Test: Solid and Hollow ShaftsDocument5 pagesME 457 Experimental Solid Mechanics (Lab) Torsion Test: Solid and Hollow Shaftsanon-735529100% (2)

- Gauge Design Guide for Inspection LimitsDocument26 pagesGauge Design Guide for Inspection LimitsMurali100% (3)

- Tension Test On Hot Rolled Plain Steel Bar (ASTM-A615/615-M)Document19 pagesTension Test On Hot Rolled Plain Steel Bar (ASTM-A615/615-M)Adil Javed Chaudhary67% (3)

- Impact Test ReportDocument7 pagesImpact Test Reportgammoora92% (25)

- Compression TestDocument15 pagesCompression TestEhsanulhaq786100% (1)

- Material Selection For Brake DiscDocument10 pagesMaterial Selection For Brake Discmost_lost89% (38)

- Charpy Impact TestDocument4 pagesCharpy Impact TestChinmay Deo80% (5)

- 01-Explain With Neat Sketch The Construction Working and Application of Following Instruments - Vernier Caliper & MicrometerDocument2 pages01-Explain With Neat Sketch The Construction Working and Application of Following Instruments - Vernier Caliper & Micrometerphase_shekhar2188% (8)

- NABL 218 - Desktop SurveillanceDocument8 pagesNABL 218 - Desktop Surveillancezilangamba_s45350% (1)

- Applied Mechanics Centrifugal Force ExperimentDocument21 pagesApplied Mechanics Centrifugal Force ExperimentLovisha HorrilNo ratings yet

- Unit-3 Tolerance AnalysisDocument78 pagesUnit-3 Tolerance AnalysisMECH PEDIANo ratings yet

- Mechanical System Design by R. B. Patil (PREVIEW)Document7 pagesMechanical System Design by R. B. Patil (PREVIEW)sdafg23% (13)

- Expt 2 (A) - Impact Test On Metal SpecimenDocument5 pagesExpt 2 (A) - Impact Test On Metal Specimenjyoti swaroop repaka100% (2)

- Centre vs Capstan Lathe: Key Differences Explained in 11 PointsDocument1 pageCentre vs Capstan Lathe: Key Differences Explained in 11 Pointsvenkateshyadav2116No ratings yet

- Direct Shear Test On MSDocument15 pagesDirect Shear Test On MSafzal tai100% (1)

- Impact Test of Metal SpecimenDocument18 pagesImpact Test of Metal SpecimenmosaddakNo ratings yet

- Is 14858 2000 Compression Testing Machine Used For Testing of Concrete and Mortar RequirementsDocument9 pagesIs 14858 2000 Compression Testing Machine Used For Testing of Concrete and Mortar RequirementsVanu VamalaiNo ratings yet

- CMT Chapter7 UTMDocument9 pagesCMT Chapter7 UTMAidan Paul Arlanza EscotoNo ratings yet

- Testing Materials Strength with a Universal Testing MachineDocument10 pagesTesting Materials Strength with a Universal Testing MachineMitchell MarvilNo ratings yet

- Fatigue SomDocument13 pagesFatigue SomOmed HajiNo ratings yet

- Mos Lab Manul by Abhidhesh YadavDocument45 pagesMos Lab Manul by Abhidhesh YadavabhiNo ratings yet

- Experiment No. 2: Title Group MembersDocument5 pagesExperiment No. 2: Title Group MembersMansoob BukhariNo ratings yet

- Fatigue TestDocument2 pagesFatigue Testunam123No ratings yet

- Fatigue 1Document3 pagesFatigue 1Mahesh KhadeNo ratings yet

- Tension Test On Steel Rod - Procedure and ResultsDocument6 pagesTension Test On Steel Rod - Procedure and ResultsTapabrata RoyNo ratings yet

- Rotating Fatigue PDFDocument2 pagesRotating Fatigue PDFMia FarhanaNo ratings yet

- MOS Lab Manual - NewDocument41 pagesMOS Lab Manual - NewPavan Kalyan SuryavamshiNo ratings yet

- Fundamentals and Practices in Colouration of Textiles PDFDocument433 pagesFundamentals and Practices in Colouration of Textiles PDFRajesh Dwivedi100% (1)

- Fundamentals and Practices in Colouration of Textiles PDFDocument433 pagesFundamentals and Practices in Colouration of Textiles PDFRajesh Dwivedi100% (1)

- New Technology PresDocument28 pagesNew Technology PresRajesh DwivediNo ratings yet

- Disposable Medical Textiles by Nazneen SurtiDocument27 pagesDisposable Medical Textiles by Nazneen SurtiRajesh DwivediNo ratings yet

- Single Cloth Construction: Chapter One General Knowledge On Woven FabricDocument8 pagesSingle Cloth Construction: Chapter One General Knowledge On Woven FabricRajesh DwivediNo ratings yet

- Be210 Slides Wa3Document4 pagesBe210 Slides Wa3Rajesh DwivediNo ratings yet

- ControlDocument1 pageControlRajesh DwivediNo ratings yet

- FabriCleanTM Pulse-Jet Fabric Filters OverviewDocument10 pagesFabriCleanTM Pulse-Jet Fabric Filters OverviewMurray BookchinNo ratings yet

- TRR Stud PresDocument19 pagesTRR Stud PresRajesh DwivediNo ratings yet

- Project Report Vinay PresentationDocument47 pagesProject Report Vinay PresentationRajesh DwivediNo ratings yet

- Project PresentationDocument24 pagesProject PresentationRajesh DwivediNo ratings yet

- Stat RecapDocument23 pagesStat RecapRajesh DwivediNo ratings yet

- Six SigmaDocument20 pagesSix SigmaRajesh DwivediNo ratings yet

- MKB Cash Pash MohairDocument40 pagesMKB Cash Pash MohairRajesh DwivediNo ratings yet

- 3-2-1 Twill Weave DerivativesDocument12 pages3-2-1 Twill Weave DerivativesRajesh DwivediNo ratings yet

- Basic 2Document74 pagesBasic 2Rajesh DwivediNo ratings yet

- Normal DistributionDocument21 pagesNormal DistributionRajesh DwivediNo ratings yet

- Continous DistributionDocument23 pagesContinous DistributionRajesh DwivediNo ratings yet

- Chi Square TestDocument26 pagesChi Square TestRajesh DwivediNo ratings yet

- SynopsisDocument31 pagesSynopsisRajesh DwivediNo ratings yet

- Technical Textile in MarineDocument23 pagesTechnical Textile in MarineRajesh Dwivedi100% (1)

- Use of Software in Textile: Jawaharlal Drda Institute of Engineering and Technology, YavatmalDocument8 pagesUse of Software in Textile: Jawaharlal Drda Institute of Engineering and Technology, YavatmalRajesh Dwivedi100% (1)

- Praju&AvantiDocument20 pagesPraju&AvantiRajesh DwivediNo ratings yet

- Enterprise Resource Planning in Apparel IndustryDocument16 pagesEnterprise Resource Planning in Apparel IndustryRajesh DwivediNo ratings yet

- RatanDocument13 pagesRatanRajesh DwivediNo ratings yet

- Amit FinalDocument23 pagesAmit FinalRajesh DwivediNo ratings yet

- Paramesh SeminarDocument30 pagesParamesh SeminarRajesh DwivediNo ratings yet

- SPCDocument62 pagesSPCRajesh DwivediNo ratings yet

- ProbabilityDocument62 pagesProbabilityRajesh Dwivedi100% (1)

- SimulationDocument61 pagesSimulationRajesh DwivediNo ratings yet

- Circular Ring Structure AnalysisDocument5 pagesCircular Ring Structure AnalysisBALRAJNo ratings yet

- Gas Processors Suppliers Association GPSA Eng (Bookos - Org) - 701-821!1!60!1!20Document20 pagesGas Processors Suppliers Association GPSA Eng (Bookos - Org) - 701-821!1!60!1!20Karen Vl100% (1)

- Heat 4e Chap04 LectureDocument39 pagesHeat 4e Chap04 Lectureehdfhdhdfhdh100% (1)

- John H. S. Lee, K. Ramamurthi - Fundamentals of Thermodynamics-CRC Press (2022)Document165 pagesJohn H. S. Lee, K. Ramamurthi - Fundamentals of Thermodynamics-CRC Press (2022)Diego ForeroNo ratings yet

- Bolted Connection ModuleDocument5 pagesBolted Connection ModuleMakolNo ratings yet

- Air-Conditioning ExperimentDocument12 pagesAir-Conditioning ExperimentSerhat Güven0% (1)

- CE8301 SOM Unit 1Document86 pagesCE8301 SOM Unit 1durai muruganNo ratings yet

- Die CastingDocument267 pagesDie CastingSteel BeingNo ratings yet

- A i r e- M a x A s ia P t e L t d VAV Flow Calibration and Recommended AirflowDocument1 pageA i r e- M a x A s ia P t e L t d VAV Flow Calibration and Recommended AirflowKingsley LimNo ratings yet

- Applications of Different Types of Steam Traps - TLV - A Steam Specialist Company (United Arab Emirates) PDFDocument5 pagesApplications of Different Types of Steam Traps - TLV - A Steam Specialist Company (United Arab Emirates) PDFDũng LêNo ratings yet

- How to Separate Chemical MixturesDocument47 pagesHow to Separate Chemical MixtureschintanNo ratings yet

- Homework Assignment (Conservation of Energy - Bernoulli's Equation)Document13 pagesHomework Assignment (Conservation of Energy - Bernoulli's Equation)Murthada Mutahhar Al-FajriNo ratings yet

- Secant ModulusDocument1 pageSecant ModulushudpalNo ratings yet

- Valve Seat Leakage TestDocument3 pagesValve Seat Leakage Testtaeyun hwngNo ratings yet

- MKL 3 ReportDocument9 pagesMKL 3 ReportMatthew NelsonNo ratings yet

- 04 PDFDocument42 pages04 PDFAla ThajilNo ratings yet

- Mech 3 Sem Strength of Materials c16 Apr 2018Document4 pagesMech 3 Sem Strength of Materials c16 Apr 2018Sundarasetty HarishbabuNo ratings yet

- Corelation For Laboratory Test ParametersDocument36 pagesCorelation For Laboratory Test ParametersCEG BangladeshNo ratings yet

- Namma Kalvi 11th Physics Model Question Papers em 2020 217208 PDFDocument66 pagesNamma Kalvi 11th Physics Model Question Papers em 2020 217208 PDFvvn natrajNo ratings yet

- Optimum LG RatioDocument8 pagesOptimum LG RatioSajal GuptaNo ratings yet

- Gen Chem 2 Quiz 8 13 and Long Quiz 2Document46 pagesGen Chem 2 Quiz 8 13 and Long Quiz 2Kristine Joy Catedrilla100% (4)

- Machine Design: Stress Concentration FactorsDocument30 pagesMachine Design: Stress Concentration FactorsM.HNo ratings yet

- Chemical EquilibriumDocument57 pagesChemical EquilibriumJustin AmaguinNo ratings yet

- Perrys Chemical Engineers Handbook 1999Document14 pagesPerrys Chemical Engineers Handbook 1999Thirunavuk KarasuNo ratings yet

- Internal FlowDocument39 pagesInternal FlowBahaa RaghebNo ratings yet

- 1D Problem Solve Using FEMDocument33 pages1D Problem Solve Using FEMAshok KumarNo ratings yet

- SADDLE SUPPORT DESIGNDocument6 pagesSADDLE SUPPORT DESIGNSISIR KR BARMAN0% (1)

- HDD Design and MethodologyDocument14 pagesHDD Design and MethodologyVipin Gupta100% (4)

- Flow Past NACA AirfoilDocument7 pagesFlow Past NACA AirfoilKarthick Murugesan100% (2)

- Course Title: Thermal System DesignDocument27 pagesCourse Title: Thermal System DesignhailemebrahtuNo ratings yet