Professional Documents

Culture Documents

Pharmaceutical Chemistry Journal

Uploaded by

Suman BalyaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pharmaceutical Chemistry Journal

Uploaded by

Suman BalyaniCopyright:

Available Formats

METHODS OF SYNTHESIS AND TECHNOLOGY OF DRUG MANUFACTURE

SYNTHESIS OF METRONIDAZOLE FROM ETHYLENEDIAMINE* M. Ya. Kraft,% P. M. Kochergin, A. M. Tsyganova,f and V. S. Shlikhunova UDC 615.283.612.1.012.1

ed

I- ($-Hydroxyethyl)-2-methyl-5-nitroimidazole (IV, metronidazole) has been widely acceptin medical practice for treating various diseases [8].

We have previously described the preparation of IV from tartaric acid and o-phenylenediamine, whereby the most important intermediate product of the synthesis of IV, 2-methylimidazole (II), was obtained by decarboxylation of 2-methylimidazol-4,5-dicarboxylic acid, the nitration of II was carried out using inorganic nitrates, and the hydroxyethylation of 2-methyl-4(5)-nitroimidazole (III) was effected by means of ethylene chlorohydrin [i, 7, ii]. The simplest single-stage method of preparation of II is synthesis from glyoxal, acetaldehyde, and ammonia [9, 15, 16]. However, because of the high cost of glyoxal and its scarcity, this method cannot be used for the time being for a large-scale production of IV. To extend the raw material base, we carried out a simple synthesis of IV from the cheap and readily available ethylenediamine according to the scheme shown below [2-6]. (--CH~NH2)2 ~ [(--CH2NH3OAc)~]--+ [(--CH2NHAc)=]~ -NH k /~--Me // --N

/CH2CH2OH

O=N--N

N IV

I $

O2N--NH-N III

-NH

N II

To obtain 2-methylimidazoline (I), ethylenediamine and AcOH can be used in a ratio of i mole per 2 moles, at both high (70-97%) and low (10-40%) concentrations. On mixing the aqueous solutions of the above components, a diacetic acid salt of ethylenediamine is formed, which upon evaporation of water converts into N,N'-diacetylethylenediamine [3]. The latter, without isolation and purification, is treated with quick lime to give I. This compound is readily dehydrogenated in the presence of Raney nickel [2] or nonpyrophoric nickel [6] with the formation of II. We have also greatly improved the stages of nitration of II to III and hydroxyethylation of III to IV. Thus, by carrying out the nitration of II using a mixture of HNO 3 and H2SO 4 in the presence of Na2SO 4 and NaHSO4, we were able to increase the yield of III to 63-66% [5], as compared with 48-52% obtained in the nitration of II with inorganic nitrates [i]. The hydroxyethylation of III using ethylene oxide is conveniently carried out in a homogeneous medium consisting of H3PO 4 and AcOH [4] instead of HCOOH or AcOH [i0]. EXPERIMENTAL 2-Methyl-4,5-dihydroimidazole (2-Methylimidazoline, Lysidine~ I). A i- to 1.05-mole portion of AcOH (glacial or in the form of 20-85% aqueous solution) was added with water cooling and stirring to 0.5 mole of ethylenediamine (in the form of a 20-85% aqueous solution). The mixture was boiled with the simultaneous evaporation of water, while the temperature was increased to 220-240~ and at the end was heated for 30-40 min at 240-250~ *Communication 84 of the series "Studies in the series of imidazole." tDeceased. S. Ordzhonikidze All-Union Scientific Research Chemical Pharmaceutical Institute, Moscow~ Translated from Khimiko-farmatsevticheskii Zhurnal, Vol. 23, No. i0, pp. 1246-1248, October, 1989. Original article submitted January 4, 1989. 0091-150X/89/2310-0861512.50 9 1990 Plenum Publishing Corporation 861

until water ceased to separate out. The technical grade N,N'-diacetylethylenediamine obtained (mp in a sample 176-177~ was cooled to 180-185~ 43 g (0.75 mole) of 97.5% calcium oxide was added, and the downward condenser was replaced by an air-cooled reflux condenser. Heating of the hot mass was continued at 220-265~ whereby I was soon formed and the whole mass began to boil (the bp of I is 197-200~ The mixture was boiled for 2 h, cooled to 185-190~ the reflux condenser was replaced by an air-cooled downward condenser, and I was distilled off at atmospheric or reduced pressure. Compound I can also be separated by dissolution of the mass in an anhydrous organic solvent (isopropanol, dichloroethane, diphenyl oxide, etc.). Yield 37-43 g (88-95%) of I, mp I01-I04~ which was suitable for the preparation of II without additional purification. According to the data in [14], the mp of I is I05~ 2-Methylimidazole (II). a) A 16.8-g portion of I was added to 0.7-3.3 g of moist (or alcohol-washed) Raney nickel paste. The mixture was rapidly heated to 170-175~ under an air-cooled reflux condenser, whereby a rapid evolution of hydrogen began. Heating was continued with a gradual increase in the temperature of the mass to 220~ (up to the cessation of evolution of hydrogen). The reaction time was 60-90 min, depending on the amount of the catalyst used. The mass was then cooled to 40-50~ 50-100 ml of ethanol and 0.5 g of activated charcoal were added, the mixture was boiled for 5-10 min, and filtered. The solvent was evaporated from the filtrate under vacuum to dryness, and the crystallized residue was dried at 40-50~ Yield 13.9-14.7 g (85-90~ of II, mp !39-142~ According to the data in [7, Ii, 13], the mp of II is 140-143~ b) A mixture of 50 ml of diphenyl oxide and 7.5 g of nickel formate dihydrate was heated in a flask with a downward air-cooled condenser for 1 h at 190-250~ up to cessation of distillation of water. The suspension of nonpyrophoric nickel catalyst thus obtained was cooled to 20-30~ and 47 g of I in 180 ml of diphenyl oxide, preliminarily heated to 180~ was added to the solution. The mixture was rapidly heated with stirring under an air-cooled reflux condenser to 220~ At this temperature a vigorous evolution of hydrogen began. The heating was continued with stirring and with increase of the temperature to 230~ for 2.5-3 h up to the complete cessation of the evolution of hydrogen. The mixture was then cooled to 155-165~ filtered, and the catalyst was washed on the filter with hot toluene (2 x 40 ml). The combined filtrate was cooled to 20~ the precipitate of II that separated out was filtered off, washed on the filter with cold toluene, and dried at 40-50~ Yield 41.3-41.8 g (90-91%) of II, mp 139-143~ Compound II obtained by methods a or b was suitable, without additional purification, for use in the synthesis of Ill. 2-Methyl-4(5)-nitroimidazole (III). A mixture of 276 ml of water, 352 ml of a 93% H2SO~, 576 g of anhydrous Na=SO~and 164 g (2 moles) of II was stirred under a reflux condenser, while heating the mass to 130~ A 252-mi portion of 99% HNO a (5.2 moles) was then added gradually to the hot solution from a dropping funnel with stirring and heating. A vigorous evolution of nitrogen oxides thus took place. The mixture was boiled for 4 h at 130-132~ whereby the evolution of nitrogen oxides ceased at the end of the heating~ The solution was cooled to 60-70~ poured with cooling and stirring into 1200 ml of water and neutralized with 25% aqueous ammonia to pH 4-5, while maintaining the mass at a temperature in the range of 30-40~ The mixture was then stirred for 30 min at the same temperature, and the precipitate that separated out was filtered off, washed with water, and dried at 60-70~ Yield 160-168 g (63-66%) of III, mp 252-254~ (decomp.). According to the data in [12], the mp is 254~ and according to the data in [7], the mp of the chemically pure compound is 261263~ Compound III is suitable for the synthesis of IV without additional purification. l-~-Hydroxyethyl-2-methyl-5-nitr0imidazole (IV~ Metronidazole). A 100-ml portion of Ac20 was added, with water cooling and stirring, to 76 ml of 85% H3PO 4 at such a rate that the temperature of the mixture did not rise above 70-90~ A 63.5-g portion (0.5 mole) of III was added to the mixture of H3PO 4 and AcOH obtained. The mass was stirred to the complete dissolution of III, then cooled to 25~ and at this temperature, 120 ml (2.5 moles) of ethylene oxide, preliminarily cooled to 0-50C, was added in the course of 1-1.5 h, with vigorous stirring and ice cooling. The reaction mixture was stirred for 2.5 h at 25-30~ and then was diluted with 800 ml of water, cooled to 2-5~ and held at this temperature for 4-5 h. The precipitate of unreacted III that separated out was filtered off, washed with water, and dried at 60-70~ Thus, 5.5-10 g (8.7-15.7%) of III was recovered, which was subsequently used in the next batch in the preparation of IV. The acid filtrate was made alkaline with 25% aqueous ammonia to pH I0 (about 200-230 ml), an additional 50 ml of 25% aqueous ammonia was added, and the mixture was allowed to stand for 10-14 h at 10~

862

The precipitate that separated out was filtered off, washed with water, and crystallized from 500-530 ml of distilled water with addition of 2 g of activated charcoal. The hot filtrate was cooled to 2-5~ held at this temperature for 10-12 h, the precipitate was filtered off, washed with distilled water, and dried at 70-80~ Yield 45 g (63.7%, based on reacted III) of IV, mp 160-161.5~ According to the data in [7, I0, ii], mp 158-161~ LITERATURE CITED i. 2. 3. 4. 5. 6o 7. 8. 9. i0. iio 12. 13. 14. 15. 16. USSR Inventor's Certificate No 164,289; Otkrytiya, No. 15 (1964). USS~ Inventor's Certificate No 176,912; Otkrytiya, No. 24 (1965). USSR Inventor's Certificate No 180,605; Otkrytiya, No. 8 (1966). USSR Inventor's Certificate No 201,416; Otkrytiya, No. 18 (1967). USSR Inventor's Certificate No 201,417; Otkrytiya, No. 18 (1967). USSR Inventor's Certificate No 201,418; Otkrytiya, No. 18 (1967). P. M. Kochergin, A. M. Tsyganova, L. S. Blinova, et al., Khim. Geterotsikl. Soedin., No. 6, 875-878 (1965)o Mo D. Mashkovskii, Drugs, 9th edn. [in Russian], Part 2, Moscow (1984), p. 343. Roumanian Patent No. 51,788 (1969); Chem. Abstr., 71, No. 124434e (1969). French Patent No. 1,379,915 (1964); Chem. Abstr., 62, No. 9145 (1965). G. N. Pershin, P. M. Kochergin, A. M. Tsyganova, et al., Med. Prom-st', No. i0, 12-16 (1964)0 R. Y. Fargher and F. L. Pyman, J. Chem. Soc., 115, 217 (1919). K. W. Kohlrauch and R. Seka, Chem. Ber., 71, 985 (1938). A. Ladenburg, Chem. Ber., 27, 2952-2957 (1894). B. Radziszewski, Chem. Ber., 15, 2706-2708 (1882). Bo Radziszewski, Chem. Bero, 16, 487-494 (1883).

SYNTHESIS AND MICROBIOLOGICAL HYDROXYLATION OF 16~,I7~-DIHYDROXY-SUBSTITUTED 20-OXO-5~-PREGNANES M. L. Gerasimova, T. I. Gusarova, V. M. Ryzh~ova, T. M. Bykova, and L. M. Alekseeva UDC 615.357:577.175.53]. 012.1.017

At the present time, production of steroids, integrated microbiological hydroxylation, hydrolysis and dehydrogenation processes are being successfully used to provide a convenient path for the synthesis of corticosteroid preparations [i, 5]. In the preceding publications [7, 8] we reported studies of the influence of substituents at C(16), C(17) of the steroid on the transformation activity of the hydroxylating cultures of the microorganisms Curvalaria lunata ~ Tie~hemella orchidis, Cunnin~hamella blakesleeana~ Trichothecium roseum, and others~ The dependence of the direction of the hydroxylation on the structure of the substrate was studied on 16,17-substituted derivatives of the &4-pregnene series. To study the possibilities of using the 5~-pregnane derivatives for the synthesis of corticosteroids, we examined the microbiological transformation of 20-oxo-5~-pregnanes (I), containing substituents - the hydroxyl groups and the isopropylidenedioxy group - at C(16) and C(17). Data in the literature on the microbiological transformation of 5e-pregnane derivatives are sparse, and no data are available on the selective ll-~-hydroxylation. Derivatives of 3,20-dioxo-5~-pregnane - ll$,17~,21-trihydroxy-5~-pregnane-3,20-dione and its 17-acetate are steroid metabolites; the latter has anti-inflammatory and progestagenic activity. These compounds were obtained previously by hydrogenation of hydrocortisone and its acetate with hydrogen in the presence of a palladium catalyst at room temperature [6, 9]. S. Ordzhonikidze All-Union Scientific Research Chemical Pharmaceutical Institute, Moscow~ Translated from Khimiko-farmatsevticheskii Zhurnal, Vol. 23, No. 10, pp. 1259-1,2,63, October, 1989. Original article submitted July 15, 1988.

0091-150X/89/2310-0863512.50 9 1990 Plenum Publishing Corporation

863

You might also like

- Sintesis de Metronidazol A Partir de La Etilendiamina PDFDocument3 pagesSintesis de Metronidazol A Partir de La Etilendiamina PDFAstridChoqueNo ratings yet

- Synthesis 7 Hydroxy 4 Methyl CoumarinDocument4 pagesSynthesis 7 Hydroxy 4 Methyl CoumarinLam Khoa100% (1)

- 4 ChlorobutanolDocument2 pages4 Chlorobutanolsunil_vaman_joshiNo ratings yet

- 2hydroxy1,4 NaphthoquinoneDocument5 pages2hydroxy1,4 NaphthoquinoneZina ZinaNo ratings yet

- Organic Syntheses Collective Volume 3Document1,060 pagesOrganic Syntheses Collective Volume 3caltexas100% (5)

- Organic Syntheses Vol 03 - Clarke - WileyDocument56 pagesOrganic Syntheses Vol 03 - Clarke - Wileyqscwdvefb71100% (1)

- 3 (5) AminopyrazoleDocument4 pages3 (5) AminopyrazoleSanjayShirodkarNo ratings yet

- 2,4-Dimethyl-3,5-Dicarbethoxypyrrole: 2,4-Pyrroledicarboxylic Acid, 3,5-Dimethyl-, Diethyl EsterDocument3 pages2,4-Dimethyl-3,5-Dicarbethoxypyrrole: 2,4-Pyrroledicarboxylic Acid, 3,5-Dimethyl-, Diethyl EsterlibretasviejasNo ratings yet

- An Improved Procedure For Synthesis of Dl-4-Hydroxy-3-Methoxymandelic Acid (DL - Ilvanillylll-Mandelic Acid, Vma)Document2 pagesAn Improved Procedure For Synthesis of Dl-4-Hydroxy-3-Methoxymandelic Acid (DL - Ilvanillylll-Mandelic Acid, Vma)Brandon TimmNo ratings yet

- Gabapentin hydrochloride process under 38 charsDocument6 pagesGabapentin hydrochloride process under 38 chars13201940100% (1)

- Synthesis of P2PDocument15 pagesSynthesis of P2PRiki Mandol83% (23)

- Process for producing phenoxypropionic acid methyl esters with high yields using half the molar amount of dimethyl sulfateDocument3 pagesProcess for producing phenoxypropionic acid methyl esters with high yields using half the molar amount of dimethyl sulfateSolomon EricksonNo ratings yet

- Patent Translate Method for 2,6-DiisopropylphenolDocument3 pagesPatent Translate Method for 2,6-DiisopropylphenolBen de LangeNo ratings yet

- A PhenylacetoacetonitrileDocument4 pagesA PhenylacetoacetonitrileNik OthmanNo ratings yet

- Preparation of Acrylyl Chloride Using Phosphorus OxychlorideDocument2 pagesPreparation of Acrylyl Chloride Using Phosphorus Oxychloride8612106535No ratings yet

- Alcohol FurfurilicoDocument5 pagesAlcohol Furfurilicojuan cruzNo ratings yet

- Studies on 4-Hydroxycoumarins. V. The Condensation of a,p-Unsaturated Ketones with 4-HydroxycoumarinDocument5 pagesStudies on 4-Hydroxycoumarins. V. The Condensation of a,p-Unsaturated Ketones with 4-HydroxycoumarinMarco Antonio MorenoNo ratings yet

- Synthesis of (3Z) Dodecenyl (E) 2 ButenoateDocument6 pagesSynthesis of (3Z) Dodecenyl (E) 2 ButenoatedangchihienNo ratings yet

- Unied States W 0: Patented Nov. 11, 1969Document2 pagesUnied States W 0: Patented Nov. 11, 1969Yeisson MoraNo ratings yet

- Increasing Yield in The Manufacturing of MPDSADocument3 pagesIncreasing Yield in The Manufacturing of MPDSAEditor IJSET0% (2)

- Synthesis of Acetophenone DerivativesDocument6 pagesSynthesis of Acetophenone DerivativesAwad SaidNo ratings yet

- Oxidations of NicotineDocument4 pagesOxidations of NicotineDon RegNo ratings yet

- Fatty Acid Derivatives of DiethanolamineDocument6 pagesFatty Acid Derivatives of DiethanolamineLeek AgoessNo ratings yet

- PD La H Y A Novel and Promising Catalyst For H - 2005 - Studies in Surface ScienDocument8 pagesPD La H Y A Novel and Promising Catalyst For H - 2005 - Studies in Surface ScienLindsey BondNo ratings yet

- Preparación de Nitroso Metil Urea PDFDocument4 pagesPreparación de Nitroso Metil Urea PDFJuanManuelAmaroLuisNo ratings yet

- The Synthesis Dihydroxyacetone Phosphate: in DelawareDocument3 pagesThe Synthesis Dihydroxyacetone Phosphate: in DelawareWhiteOak ComenziNo ratings yet

- Benzyl Cyanide: α-TolunitrileDocument3 pagesBenzyl Cyanide: α-TolunitrileEric M NevarezNo ratings yet

- Synthesis of 5-Hydroxyindole via Benzyloxy DerivativeDocument1 pageSynthesis of 5-Hydroxyindole via Benzyloxy DerivativeAnonymous FigYuONxuuNo ratings yet

- Preparation of Tungsten Trioxide WO3Document3 pagesPreparation of Tungsten Trioxide WO3aiensyafiqahNo ratings yet

- DEPOLYMERIZATION FUELSDocument5 pagesDEPOLYMERIZATION FUELSSarita RuizNo ratings yet

- Synthesis of 5 Cyano IndoleDocument6 pagesSynthesis of 5 Cyano IndolebsureshrajuNo ratings yet

- US patent for cobalt extractant from nickel solutionsDocument3 pagesUS patent for cobalt extractant from nickel solutionsmtanaydinNo ratings yet

- A Study of Impurities in Intermediates and 3,4-Methylenedioxymethamphetamine (MDMA) Samples Produced Via Reductive Amination RoutesDocument17 pagesA Study of Impurities in Intermediates and 3,4-Methylenedioxymethamphetamine (MDMA) Samples Produced Via Reductive Amination RoutesandonovkaNo ratings yet

- Organic Chemistry Practical 3Document11 pagesOrganic Chemistry Practical 3Kah Jun100% (2)

- Sintese de TosMIC - Van LeusenDocument5 pagesSintese de TosMIC - Van LeusentiagovillaNo ratings yet

- DiazepamDocument7 pagesDiazepamjiskate77No ratings yet

- Atom Economical Synthesis of 4'-Methylpropiophenone by Friedel-Crafts Acylation of Toluene With Propionic Anhydride Over Solid Me So Porous Superacid UDCaT-5Document17 pagesAtom Economical Synthesis of 4'-Methylpropiophenone by Friedel-Crafts Acylation of Toluene With Propionic Anhydride Over Solid Me So Porous Superacid UDCaT-5S Bharadwaj ReddyNo ratings yet

- Organic Syntheses Collective Volume 1Document701 pagesOrganic Syntheses Collective Volume 1caltexas83% (6)

- Industrial process for OXICONAZOLE Dr krishnasarma Pathy step-I 2,2’4’-tri-choloroacetophenone,Imidazole reacted in presence of acetonitrile to form 1-(2,4-dichlorophenacyl)-imidazole (I).Which is then reacted with hydroxylamine. hydrochloride to give (Z)-1-(2,4-dichlorophenyl)-2-(1H-imidazol-1-yl) ethanone oxime (II). It is further reacted with 2,4-Dichlorobenzyl chloride in presence of sodium hydride to give (III) Oxiconazole and finally salt formation with nitric acidDocument10 pagesIndustrial process for OXICONAZOLE Dr krishnasarma Pathy step-I 2,2’4’-tri-choloroacetophenone,Imidazole reacted in presence of acetonitrile to form 1-(2,4-dichlorophenacyl)-imidazole (I).Which is then reacted with hydroxylamine. hydrochloride to give (Z)-1-(2,4-dichlorophenyl)-2-(1H-imidazol-1-yl) ethanone oxime (II). It is further reacted with 2,4-Dichlorobenzyl chloride in presence of sodium hydride to give (III) Oxiconazole and finally salt formation with nitric acidDrkrishnasarma pathy100% (1)

- Synthesis of Methylamine - OrgSynDocument5 pagesSynthesis of Methylamine - OrgSynzodd01No ratings yet

- Preparations of Hydriodic Acid (HI) 1Document7 pagesPreparations of Hydriodic Acid (HI) 1bigriverflowsNo ratings yet

- Working With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsDocument5 pagesWorking With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsmghaffarzadehNo ratings yet

- SYNTHESIS: To A Solution of 0.50 G 4-Acetoxyindole (See Preparation in TheDocument2 pagesSYNTHESIS: To A Solution of 0.50 G 4-Acetoxyindole (See Preparation in TheSmokeNo ratings yet

- SYNTHESIS: To A Solution of 0.50 G 4-Acetoxyindole (See Preparation in TheDocument2 pagesSYNTHESIS: To A Solution of 0.50 G 4-Acetoxyindole (See Preparation in TheSmokeNo ratings yet

- Organic Syntheses Collective Volume 2Document813 pagesOrganic Syntheses Collective Volume 2caltexas88% (8)

- Epoxidation of Methyl Oleate Using Heterogeneous CatalystDocument3 pagesEpoxidation of Methyl Oleate Using Heterogeneous CatalystYustinus KrisnaNo ratings yet

- Multistep Synthesis of 2-Chloro-4-BromoanilineDocument9 pagesMultistep Synthesis of 2-Chloro-4-Bromoanilinejcrider2100% (1)

- Method of Preparing S Nitrofurfural DiacetateDocument8 pagesMethod of Preparing S Nitrofurfural DiacetateKarla VTNo ratings yet

- Lah Nitroalkenes - Reverse AdditionDocument7 pagesLah Nitroalkenes - Reverse AdditionGindo Baroes WanNo ratings yet

- 2,3 Dimethoxy 4,5 Methylenedioxy Phenylacetone From IsodillapioleDocument2 pages2,3 Dimethoxy 4,5 Methylenedioxy Phenylacetone From IsodillapiolejolouisNo ratings yet

- Oxycodone From CodeineDocument7 pagesOxycodone From CodeineJi ChemNo ratings yet

- OS Coll. Vol. 2 P389-PhenylacetoneDocument5 pagesOS Coll. Vol. 2 P389-Phenylacetonesunil_vaman_joshi100% (2)

- Mdp2p PatentDocument4 pagesMdp2p PatentPelado JavierNo ratings yet

- Iso OriginalDocument2 pagesIso OriginalkakkienakkieNo ratings yet

- Experimental ProceduresDocument14 pagesExperimental ProceduresPrakas PalanychamyNo ratings yet

- Science - Adh1853 SMDocument44 pagesScience - Adh1853 SMgetahun esubalewNo ratings yet

- Working With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsDocument4 pagesWorking With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsYana PotemkinNo ratings yet

- Chapter VII Organic Reagents in Inorganic and Organic Chemistry PDFDocument26 pagesChapter VII Organic Reagents in Inorganic and Organic Chemistry PDFtravellerfellowNo ratings yet

- Piperidine SynthesisDocument4 pagesPiperidine Synthesisjiskate77No ratings yet

- A Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidFrom EverandA Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidNo ratings yet

- Witting Reaction by Suman BalyaniDocument22 pagesWitting Reaction by Suman BalyaniSuman Balyani50% (2)

- FrictionDocument3 pagesFrictionSuman BalyaniNo ratings yet

- Stereo PresentationDocument24 pagesStereo PresentationSuman BalyaniNo ratings yet

- Slow Learners How Are They Identified and SupportedDocument7 pagesSlow Learners How Are They Identified and SupportedSulvica Restiawaty100% (1)

- Cefditoren Side Chain: C H O O CHDocument2 pagesCefditoren Side Chain: C H O O CHSuman BalyaniNo ratings yet

- NBL Products & IntermediatesDocument7 pagesNBL Products & IntermediatesSuman BalyaniNo ratings yet

- Basics of Writing Patent Non-Infringement and Freedom-to-Operate OpinionsDocument0 pagesBasics of Writing Patent Non-Infringement and Freedom-to-Operate OpinionsSuman BalyaniNo ratings yet

- Classen Immunotherapies, Inc. v. Biogen Idec, 06-1634-1649Document57 pagesClassen Immunotherapies, Inc. v. Biogen Idec, 06-1634-1649Shailendra KumarNo ratings yet

- Tetrahedron 64 (2008) 8585-8603Document19 pagesTetrahedron 64 (2008) 8585-8603Suman BalyaniNo ratings yet

- Redox ReactionsDocument21 pagesRedox Reactionssudeepjoseph0% (2)

- The Patents Amendments) Rules 2005 (ENGLISH)Document52 pagesThe Patents Amendments) Rules 2005 (ENGLISH)Shakti DardiNo ratings yet

- J. Org. Chem. 1998, 63, 3471-3473Document3 pagesJ. Org. Chem. 1998, 63, 3471-3473Suman BalyaniNo ratings yet

- Organic Oxidation StatesDocument2 pagesOrganic Oxidation StatesSuman BalyaniNo ratings yet

- J. Chem. Soc., Perkin Trans. 1 1091Document7 pagesJ. Chem. Soc., Perkin Trans. 1 1091Suman BalyaniNo ratings yet

- Bio Org Chem Lett 2008Document4 pagesBio Org Chem Lett 2008Suman BalyaniNo ratings yet

- Awaking The Soul FinalDocument158 pagesAwaking The Soul FinalSuman BalyaniNo ratings yet

- Csgo BananagamingDocument7 pagesCsgo BananagamingMartim RochaNo ratings yet

- Infection and Infectious ProcessDocument44 pagesInfection and Infectious Processpandey omkarNo ratings yet

- How Chocolate is Made from Cacao BeansDocument3 pagesHow Chocolate is Made from Cacao BeansNur Anas Fatroni100% (3)

- Fractal Music, Hypercards & More Mathematical Recreations From Scientific American Magazine - Martin Gardner - EnglishDocument334 pagesFractal Music, Hypercards & More Mathematical Recreations From Scientific American Magazine - Martin Gardner - EnglishValaki Aki100% (5)

- Implants and Their Use in Beef Cattle Production Oklahoma State UniversityDocument26 pagesImplants and Their Use in Beef Cattle Production Oklahoma State UniversitysegurahNo ratings yet

- Quantitative NMR Spectroscopy For The Prediction of Base Oil PropertiesDocument7 pagesQuantitative NMR Spectroscopy For The Prediction of Base Oil PropertiesSiddhartha MitraNo ratings yet

- Phreeqc 3 2013 ManualDocument519 pagesPhreeqc 3 2013 ManualpauloalpeNo ratings yet

- Micronutrients in Hair LossDocument9 pagesMicronutrients in Hair LossIkbal Adi SaputraNo ratings yet

- T B E T P: HE OOK OF Cclesiastes OR HE ReacherDocument16 pagesT B E T P: HE OOK OF Cclesiastes OR HE ReacherDarkillangel Forlorn OmenNo ratings yet

- Convert server power supply into ham radio power supplyDocument5 pagesConvert server power supply into ham radio power supplyTrentungcaysoBombodealop100% (1)

- Ansys FileDocument4 pagesAnsys Filejlmeseguer508No ratings yet

- AAP 851 Vamp 30 Repair Manual 195212 OCRDocument210 pagesAAP 851 Vamp 30 Repair Manual 195212 OCRNicholasNo ratings yet

- Ansys RecordDocument58 pagesAnsys RecordMr.kaththi perfectNo ratings yet

- Yank 1943jul09 PDFDocument24 pagesYank 1943jul09 PDFjohn obrienNo ratings yet

- Developing The Whole PersonDocument17 pagesDeveloping The Whole PersonDaphne LavardoNo ratings yet

- Class Timetable Summary for Periods 1-5Document14 pagesClass Timetable Summary for Periods 1-5عبدالرحمن فهمي الشريفNo ratings yet

- Patient Information: Corp.: Bill To:: Doc. No: LPL/CLC/QF/2806Document1 pagePatient Information: Corp.: Bill To:: Doc. No: LPL/CLC/QF/2806Modi joshiNo ratings yet

- BASE METAL ALLOYS FOR DENTAL APPLICATIONSDocument85 pagesBASE METAL ALLOYS FOR DENTAL APPLICATIONSmeghaNo ratings yet

- Floor JansenDocument8 pagesFloor JansenDeyan Ivanov100% (1)

- Laws of Thermodynamics - NewDocument20 pagesLaws of Thermodynamics - NewPeter CheaNo ratings yet

- Kerala Govt Schemes Help Paddy Farmers With Crop Insurance, Flood ProtectionDocument6 pagesKerala Govt Schemes Help Paddy Farmers With Crop Insurance, Flood ProtectionRahulNo ratings yet

- Samsung YP-ST5 - Quick GuideDocument2 pagesSamsung YP-ST5 - Quick GuidegarneliNo ratings yet

- Assighment 3Document7 pagesAssighment 3Samih S. BarzaniNo ratings yet

- Introduction To Experimental PsychologyDocument27 pagesIntroduction To Experimental PsychologyJhonel NautanNo ratings yet

- Ea (Dyn)Document9 pagesEa (Dyn)Dr.Biswajit jenaNo ratings yet

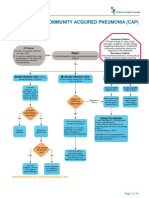

- Complicated Community Acquired Pneumonia Clinical PathwayDocument14 pagesComplicated Community Acquired Pneumonia Clinical PathwayFaisalMuhamadNo ratings yet

- D 4123-Indirect Tension Test For Resilient Modulus of BitumiDocument4 pagesD 4123-Indirect Tension Test For Resilient Modulus of BitumianjanaNo ratings yet

- Catalogue Wastewater Treatment SolutionsDocument49 pagesCatalogue Wastewater Treatment SolutionsmentolNo ratings yet

- Lámina ParacetamolDocument2 pagesLámina ParacetamolAndrea Alvarado RoNo ratings yet