Professional Documents

Culture Documents

M.tech Thermal Advanced RAC Chapter 1 VCC Cycles

Uploaded by

Patrice ThomasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M.tech Thermal Advanced RAC Chapter 1 VCC Cycles

Uploaded by

Patrice ThomasCopyright:

Available Formats

07-08-2012

1

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Basic Gas Cycles &

Vapour Compression

Refrigeration

Advanced Refrigeration & Air-Conditioning

M. Tech. Thermal Engineering

ME 0611 SEM - I

Dept. of Mechanical Engineering

ME 0611 SEM-I Advanced Refrigeration and Air-Conditioning

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Outline

Applications of Refrigeration.

Bell Coleman Cycle.

COP and Power Calculations

Vapour Compression Refrigeration System.

Presentation on T-S and P-h diagram.

Cascade Refrigeration System.

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

2

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Refrigeration

REFRIGERATION Science of producing and maintaining temperature below that of

surrounding / atmosphere.

REFRIGERATION Cooling of or removal of heat from a system.

Refrigerating System Equipment employed to maintain the system at a low temperature.

Refrigerated System System which is kept at lower temperature.

Refrigeration 1) By melting of a solid,

2) By sublimation of a solid,

3) By evaporation of a liquid.

Most of the commercial refrigeration production : Evaporation of liquid.

This liquid is known as Refrigerant.

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Refrigeration Circuit

Refrigeration Circuit

Evaporator

Compressor

Condenser Expansion

Valve

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

3

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

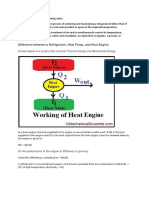

Refrigeration - Elements

Compressor

Condenser

Evaporator

Expansion

Valve

Wnet, in

Surrounding Air

Refrigerated Space

Q

H

Q

L

High Temp

Source

Low Temp

Sink

Q

H

Q

L

Wnet, in

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Refrigeration - Applications

1. Ice making.

2. Transportation of food items above and below freezing.

2. Industrial Air Conditioning.

4. Comfort Air Conditioning.

5. Chemical and related industries.

6. Medical and Surgical instruments.

7. Processing food products and beverages.

8. Oil Refining.

9. Synthetic Rubber Manufacturing.

10. Manufacture and treatment of metals.

11. Freezing food products.

12. Manufacturing Solid Carbon Dioxide.

13. Production of extremely low temperatures (Cryogenics)

14. Plumbing.

15. Building Construction.

Applications :

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

4

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. Applied Thermodynamics & Heat Engines

Refrigeration Systems

1. Ice Refrigeration System.

2. Air Refrigeration System.

2. Vapour Compression Refrigeration System.

4. Vapour Absorption Refrigeration System.

5. Adsorption Refrigeration System.

6. Cascade Refrigeration System.

7. Mixed Refrigeration System.

8. Thermoelectric Refrigeration System.

9. Steam Jet Refrigeration System.

10. Vortex Tube Refrigeration System.

Refrigeration Systems :

ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. Applied Thermodynamics & Heat Engines

Performance - COP

COP Ratio of Heat absorbed by the Refrigerant while passing through the Evaporator

to the Work Input required to compress the Refrigerant in the Compressor.

Performance of Refrigeration System :

- Measured in terms of COP (Coefficient of Performance).

If; R

n

= Net Refrigerating Effect. W = Work required by the machine.

Then;

W

R

COP

n

=

COP l Theoretica

COP Actual

COP lative = Re

Actual COP = Ratio of R

n

and W actually measured.

Theoretical COP = Ratio of Theoretical values of R

n

and W obtained by applying

Laws of Thermodynamics to the Refrigerating Cycle.

ME 0611 SEM-I

07-08-2012

5

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Performance - Rating

Rating of Refrigeration System :

- Refrigeration Effect / Amount of Heat extracted from a body in a given time.

Unit :

- Standard commercial Tonne of Refrigeration / TR Capacity

Definition :

- Refrigeration Effect produced by melting 1 tonne of ice from and at 0 C in 24 hours.

Latent Heat of ice = 336 kJ/kg.

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Air Refrigeration System

One of the earliest method.

Obsolete due to low COP and high operating cost.

Preferred in Aircraft Refrigeration due to its low weight.

Characteristic :

- Throughout the cycle, Refrigerant remains in gaseous state.

Air Refrigeration

Closed System Open System

Air refrigerant contained within

piping or components of system.

Pressures above atm. Pr.

Refrigerator space is actual room to be cooled.

Air expansion to atm. Pr. And then

compressed to cooler pressure.

Pressures limited to near atm. Pr. levels..

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

6

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Air Refrigeration System

1. Suction to compressor in Closed System may be at high pressures. Hence,

the size of Expander and Compressor can be kept small.

Closed System Vs. Open System :

2. In Open Systems, air picks up the moisture from refrigeration chamber. This

moisture freezes and chokes the valves.

3. Expansion in Open System is limited to atm. Pr. Level only. No such restriction

to Closed System.

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Reverse Carnot Cycle

3

2

1

4

Isotherms

Adiabatic

T

2

Expansion

Compression

T

1

P

r

e

s

s

u

r

e

Volume

P V Diagram

3 2

1 4

T

1

Expansion Compression

T

2

T

e

m

p

e

r

a

t

u

r

e

Entropy

1 4

T s Diagram

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

7

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

3 2

1 4

T

1

Expansion Compression

T

2

T

e

m

p

e

r

a

t

u

r

e

Entropy

1 4

Operation :

3 4 : Adiabatic Expansion.

Temp. falls from T

2

to T

1.

Cylinder in contact with Cold Body at T

1.

4 1 : Isothermal Expansion.

Heat Extraction from Cold Body.

1 2 : Adiabatic Compression.

Requires external power.

Temp. rises from T

1

to T

2.

Cylinder in contact with Hot Body at T

2

2 3 : Isothermal Compression.

Heat Rejection to Hot Body.

Reverse Carnot Cycle

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

3 2

1 4

T

1

Expansion Compression

T

2

T

e

m

p

e

r

a

t

u

r

e

Entropy

1 4

Heat extracted from cold Body : Area 1-1-4-4

= T

1

X 1-4

Work done per cycle : Area 1-2-3-4

= (T

2

T

1

) X 1-4

1 2

1

1 2

1

) 4 1 ( ) (

) 4 1 (

4 3 2 1

4 ' 4 ' 1 1

T T

T

X T T

X T

Area

Area

Done Work

Extracted Heat

COP

=

=

=

=

Reverse Carnot Cycle

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

8

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Example 1

A Carnot Refrigerator requires 1.3 kW per tonne of refrigeration to maintain a region at

low temperature of -38 C. Determine:

i) COP of Carnot Refrigerator.

ii) Higher temperature of the cycle.

iii) Heat delivered and COP, if the same device is used Heat Pump.

99 . 2

) sec/ 3600 ( ) 3 . 1 (

/ 000 , 14

3 . 1

1

= = = =

hr kW

hr kJ

kW

tonne

done Work

absorbed Heat

COP

refrig

.ANS

K T

K T

K

T T

T

COP

refrig

6 . 313

235

235

99 . 2

1

2 1 2

1

=

=

.ANS

Heat Delivered as Heat Pump ;

sec / 189 . 5 3 . 1

3600

/ 000 , 14

3 . 1 1 kJ

hr kJ

kW tonne

done Work absorbed Heat

= + = + =

+ =

.ANS

99 . 3

3 . 1

sec / 189 . 5

= = =

kW

kJ

done Work

delivered Heat

COP

HP

.ANS

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Example 2

A refrigerating system works on reverse Carnot cycle. The higher temperature in the

system is 35 C and the lower temperature is -15 C. The capacity is to be 12 tonnes.

Determine :

i) COP of Carnot Refrigerator.

ii) Heat rejected from the system per hour.

iii) Power required.

18 . 5

258 308

258

1 2

1

=

=

K K

K

T T

T

COP

refrig

.ANS

hr kJ Input Work

Input Work

hr kJ X

Input Work

tonne

Input Work

Effect frig

COP

refrig

/ 32558

/ 000 , 14 12 12

16 . 5

. Re

=

= = =

.ANS kW

hr kJ hr Input Work

Power 04 . 9

3600

/ 32558

3600

/

= = =

Heat Rejected / hr = Refrig. Effect / hr + Work Input / hr

= 12 x 14,000 (kJ/hr) + 32,558 (kJ/hr) = 2,00,558 kJ/hr. .ANS

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

9

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Example 3

Ice is formed at 0 C from water at 20 C. The temperature of the brine is -8 C. Find out

the kg of ice per kWh. Assume that the system operates on reversed Carnot cycle. Take

latent heat of ice as 335 kJ/kg.

46 . 9

265 293

265

1 2

1

=

=

K K

K

T T

T

COP

refrig

Heat to be extracted per kg of water ( to from ice at 0 C)

R

n

= 1 (kg) x C

pw

(kJ/kg.K) x (293 273) (K) + Latent Heat (kJ/kg) of ice

= 1 (kg) x 4.18 (kJ/kg.K) x 20 (K) + 335 (kJ/kg)

= 418.6 kJ/kg.

Also, 1 kWh = 1 (kJ) x 3600 (sec/hr) = 3600 kJ.

kg m

kJ

kg kJ X kg m

kJ done Work

kJ Effect frig

W

R

COP

ice

ice

n

refrig

35 . 81

3600

) / ( 6 . 418 ) (

46 . 9

) (

) ( . Re

= =

= =

.ANS

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Bell Coleman / Reverse Bryaton Cycle

Elements of this system :

1. Compressor.

2. Heat Exchanger.

3. Expander.

4. Refrigerator.

Work gained from Expander is used

to drive Compressor.

Hence, less external work is required.

Heat Exchanger

Cooling

Water

Refrigerator

Compressor Expander

Cold Air

Very Cold Air

Warm Air

Hot Air

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

10

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Bell Coleman / Reverse Bryaton Cycle

3

2

1

4

Isobars

Adiabatic

Expansion

Compression

P

r

e

s

s

u

r

e

Volume

P V Diagram

3

2

1

4

Expansion

Compression

T

e

m

p

e

r

a

t

u

r

e

Entropy

Isobars

Adiabatic

T s Diagram

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Bell Coleman / Reverse Bryaton Cycle

3

2

1

4

Expansion

Compression

T

e

m

p

e

r

a

t

u

r

e

Entropy

Isobars

Adiabatic

Heat Absorbed in Refrigerator :

) (

4 1

T T C m Q

P added

=

Heat Rejected in Heat Exchanger :

) (

3 2

T T C m Q

P rejected

=

If process changes from Adiabatic to Polytropic;

( )

1 1 2 2

1

V P V P

n

n

Q

comp

=

( )

4 4 3 3 exp

1

V P V P

n

n

Q

n

=

We know,

|

|

.

|

\

|

=

1

P

C R

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

11

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Bell Coleman / Reverse Bryaton Cycle

Net Work Done :

( )

( )

( )

1 2 3 4

4 3 1 2

4 4 3 3 1 1 2 2

exp

1

1

1

1

T T T T C m

n

n

T T T T R m

n

n

V P V P V P V P

n

n

W W W

P

n comp

+

|

|

.

|

\

|

=

+

=

+

=

=

For Isentropic Process :

( )

1 2 3 4

exp

T T T T C m

W W W

P

n comp

+ =

=

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Bell Coleman / Reverse Bryaton Cycle

COP :

( )

1 2 3 4

4 1

1

1

) (

T T T T C m

n

n

T T C m

W

Q

Q Q

Added Work

COP

P

P

net

added

added rejected

+

|

|

.

|

\

|

|

.

|

\

|

=

=

( )

1 2 3 4

4 1

1

1

) (

T T T T

n

n

T T

COP

+

|

|

.

|

\

|

|

.

|

\

|

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

12

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. Applied Thermodynamics & Heat Engines

Air Refrigeration Cycle - Merits / Demerits

Merits :

1. No risk of fire (as in case of NH

3

); as air is non flammable.

2. Cheaper (than other systems); as air is easily available.

3. Weight per tonne of refrigeration is quite low (compared to other systems).

Demerits :

1. Low COP (compared with other systems).

2. Weight of air (as Refrigerant) is more (compared to other systems).

ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. Applied Thermodynamics & Heat Engines

Example 4

A Bell Coleman refrigerator operates between pressure limits of 1 bar and 8 bar. Air is

drawn from the cold chamber at 9 C, compressed and then cooled to 29 C before

entering the expansion cylinder. Expansion and compression follow the law PV

1.35

= Const.

Calculate the theoretical COP.

For air, take = 1.4 and C

p

= 1.003 kJ/kg.

Polytropic Compression 1-2 :

K

bar

bar

K

P

P

T T

n

n

2 . 482

1

8

) 282 (

35 . 1

1 35 . 1 1

1

2

1 2

=

|

|

.

|

\

|

=

|

|

.

|

\

|

=

Polytropic Expansion 3-4 :

K T

bar

bar

T K

P

P

T T

n

n

6 . 176

1

8

) 302 (

4

35 . 1

1 35 . 1

4

1

4

3

4 3

=

|

|

.

|

\

|

=

|

|

.

|

\

|

=

3 2

1

4

PV

1.35

=C

P

r

e

s

s

u

r

e

Volume

P

2

= 8 bar

P

1

= 1 bar

282 K

302 K

ME 0611 SEM-I

07-08-2012

13

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. Applied Thermodynamics & Heat Engines

Heat Extracted from Cold Chamber :

kg kJ K K X kg kJ T T C

P

/ 7 . 105 ) 6 . 176 282 ( ) / ( 003 . 1 ) (

4 1

= = =

Example 4.cntd

Heat Rejected to Heat Exchanger :

kg kJ K K X kg kJ T T C

P

/ 7 . 180 ) 302 2 . 482 ( ) / ( 003 . 1 ) (

3 2

= = =

Net Work Done :

( )

( )

kg kJ W

K K K K kg kJ W

T T T T C m

n

n

W

net

net

P net

/ 8 . 82

282 2 . 482 302 6 . 176 ) / 003 . 1 (

4 . 1

1 4 . 1

1 35 . 1

35 . 1

1

1

1 2 3 4

=

+ |

.

|

\

|

=

+

|

|

.

|

\

|

27 . 1

/ 8 . 82

/ 7 . 105

= = =

kg kJ

kg kJ

done Work

absorbed Heat

COP

refrig

.ANS

ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. Applied Thermodynamics & Heat Engines

Example 5

An air refrigeration open system operating between 1 MPa and 100 kPa is required to

produce a cooling effect of 2000 kJ/min. temperature of the air leaving the cold chamber is

-5 C, and at leaving the cooler is 30 C. Neglect losses and clearance in the compressor

and expander. Determine :

i) Mass of air circulated per min. ii) Compressor Work, Expander Work, Cycle Work.

ii) COP and Power in kW required.

3 2

1

4

PV

=C

P

r

e

s

s

u

r

e

Volume

P

2

= 1 MPa

P

1

= 100 kPa

268 K

303 K

Polytropic Expansion 3-4 :

K T

MPa

MPa

T K

P

P

T T

9 . 156

1 . 0

1

) 302 (

4

4 . 1

1 4 . 1

4

1

4

3

4 3

=

|

|

.

|

\

|

=

|

|

.

|

\

|

=

Refrig. Effect per kg :

kg kJ

K K X kg kJ

T T C

P

/ 66 . 111

) 9 . 156 268 ( ) / ( 003 . 1

) (

4 1

=

=

=

ME 0611 SEM-I

07-08-2012

14

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Example 5.cntd

min / 91 . 17

/ 66 . 111

min / 2000

. Re

. Re

kg

kg kJ

kJ

kg per Effect frig

Effect frig

= = =

Mass of air circulated per min :

.ANS

Polytropic Compression 1-2 : K

kPa

kPa

K

P

P

T T 4 . 517

100

1000

) 268 (

4 . 1

1 4 . 1 1

1

2

1 2

=

|

|

.

|

\

|

=

|

|

.

|

\

|

=

.ANS

Compressor Work :

( )

( )

min / 85 . 4486

268 4 . 517 ) / 287 . 0 ( min) / 91 . 17 (

1 4 . 1

4 . 1

1

1 2

kJ W

K K kg kJ kg W

T T R m W

comp

comp

comp

=

|

.

|

\

|

|

|

.

|

\

|

.ANS

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Expander Work :

( )

( )

min / 42 . 2628

9 . 156 303 ) / 287 . 0 ( min) / 91 . 17 (

1 4 . 1

4 . 1

1

exp

exp

4 3 exp

kJ W

K K kg kJ kg W

T T R m W

=

|

.

|

\

|

|

|

.

|

\

|

.ANS

Example 5.cntd

Cycle Work = W

cycle

= W

comp

W

exp

= 4486.85 kJ/min 2628.42 kJ/min = 1858.43 kJ/minANS

076 . 1

min / 43 . 1858

min / 2000 . Re

= = =

kJ

kJ

required Work

Effect frig

COP

refrig

.ANS

Power required :

kW

kJ

time

W

P

cycle

97 . 30

min sec/ 60

min / 43 . 1858

= = = .ANS

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

15

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Vapour Compression System

Elements of this system :

1. Compressor.

2. Condenser.

3. Expansion Valve.

4. Evaporator.

Vapour @ Pr. and Temp. (State 1)

Isentropic Compression :

Pr. and Temp. (State 2)

Condenser : Pr. Liquid (State 3)

Throttling : Pr. Temp. (State 4)

Evaporator : Heat Extraction from surrounding;

Pr. vapour (State 1).

1

2

3

4

1

2 3

4

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Vapour Compression System

Merits :

1. High COP; as very close to Reverse Carnot Cycle.

2. Running Cost is 1/5

th

of that of Air Refrigeration Cycle.

3. Size of Evaporator is small; for same Refrigeration Effect.

Demerits :

1. Initial cost is high.

2. Inflammability.

4. Evaporator temperature adjustment is simple; by adjusting Throttle Valve.

3. Leakage.

4. Toxicity.

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

16

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Vapour Compression System : T-s Diagram

Case A. Dry and Saturated Vapour after Compression :

Work done by Compressor

= W = Area 1-2-3-4-1

Heat Absorbed

= W = Area 1-4-g-f-1

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

Condensation

Compression

Evaporation

Expansion

T

2

T

1

3

4

2

1

Compressor Work,

(W)

Net Refrig. Effect,

(R

n

)

Sat. Vapour Line

Sat. Liq. Line

f g

1 2

4 1

1 4 3 2 1

1 4 1

h h

h h

Area

f g Area

Done Work

Absorbed Heat

COP

=

=

=

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Vapour Compression System : T-s Diagram

Case B. Superheated Vapour after Compression :

Work done by Compressor

= W = Area 1-2-2-3-4-1

Heat Absorbed

= W = Area 1-4-g-f-1

1 2

4 1

1 4 3 ' 2 2 1

1 4 1

h h

h h

Area

f g Area

Done Work

Absorbed Heat

COP

=

=

=

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

Condensation

Compression

Evaporation

Expansion

T

2

T

1

3

4

2

1

Compressor Work,

(W)

Net Refrig. Effect,

(R

n

)

Sat. Vapour Line

Sat. Liq. Line

f g

2

NOTE : h

2

= h

2

+ C

p

(T

sup

T

sat

)

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

17

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Vapour Compression System : T-s Diagram

Case C. Wet Vapour after Compression :

Work done by Compressor

= W = Area 1-2-3-4-1

Heat Absorbed

= W = Area 1-4-g-f-1

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

Condensation

Compression

Evaporation

Expansion

T

2

T

1

3

4

2

1

Compressor Work,

(W)

Net Refrig. Effect,

(R

n

)

Sat. Vapour Line

Sat. Liq. Line

f g

1 2

4 1

1 4 3 2 1

1 4 1

h h

h h

Area

f g Area

Done Work

Absorbed Heat

COP

=

=

=

NOTE : h

2

= (h

f

+ x.h

fg

)

2

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Vapour Compression System : P-h Diagram

Enthalpy, h

P

r

e

s

s

u

r

e

,

P

r

I

s

o

t

h

e

r

m

a

l

,

T

=

C

o

n

s

t

I

s

e

n

t

h

a

l

p

i

c

,

h

=

C

o

n

s

t

.

Isobaric,

P = Const

Sub-cooled

Liq. region

2 phase

region

Superheated

region

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

18

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Vapour Compression System : P-h Diagram

Enthalpy, h

P

r

e

s

s

u

r

e

,

P

r

1

2

3

4

Evaporation

Condensation

E

x

p

a

n

s

i

o

n

1 2

4 1

h h W

h h R

n

=

=

1 2

4 1

h h

h h

W

R

COP

n

= =

}

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Factors Affecting Vapour Compression System

A. Effect of Suction Pressure :

Enthalpy, h

P

r

e

s

s

u

r

e

,

P

r

1

2

3

4

1 4

2

P

1

P

2

1 2

4 1

h h

h h

W

R

COP

n

= =

COP of Original Cycle :

COP when Suction Pr. decreased :

( ) ( )

( ) ( ) ( )

2 ' 2 ' 1 1 1 2

' 1 1 4 1

' 1 ' 2

' 4 ' 1

h h h h h h

h h h h

h h

h h

W

R

COP

n

+ +

=

= =

Thus,

Refrig. Effect

Work Input

COP

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

19

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Factors Affecting Vapour Compression System

B. Effect of Delivery Pressure :

1 2

4 1

h h

h h

W

R

COP

n

= =

COP of Original Cycle :

COP when Delivery Pr. increased :

( ) ( )

( ) ( )

2 ' 2 1 2

4 ' 4 4 1

1 ' 2

' 4 1

h h h h

h h h h

h h

h h

W

R

COP

n

+

=

= =

Thus,

Refrig. Effect

Work Input

COP

Enthalpy, h

P

r

e

s

s

u

r

e

,

P

r

1

2

3

4

3

4

2

P

1

P

2

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Factors Affecting Vapour Compression System

C. Effect of Superheating :

1 2

4 1

h h

h h

W

R

COP

n

= =

COP of Original Cycle :

Thus,

Refrig. Effect

Work Input or

COP or

Enthalpy, h

P

r

e

s

s

u

r

e

,

P

r

1

2

3

4

1

2

P

1

P

2

( ) ( )

( ) ( ) ( )

1 ' 1 2 ' 2 1 2

1 ' 1 4 1

' 1 ' 2

4 ' 1

h h h h h h

h h h h

h h

h h

W

R

COP

n

+ +

+

=

= =

COP when Delivery Pr. increased :

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

20

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Factors Affecting Vapour Compression System

D. Effect of Sub-cooling :

1 2

4 1

h h

h h

W

R

COP

n

= =

COP of Original Cycle :

Thus,

Refrig. Effect

Work Input : SAME

COP

( ) ( )

( )

1 2

' 4 4 4 1

1 2

' 4 1

h h

h h h h

h h

h h

W

R

COP

n

+

=

= =

COP when Delivery Pr. increased :

Enthalpy, h

P

r

e

s

s

u

r

e

,

P

r

1

2

3

4

1

3

P

1

P

2

4

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Factors Affecting Vapour Compression System

E. Effect of Suction & Condenser Temperatures :

Now, Condenser Temp.

Evaporator Temp.

( )

( )

1 2

4 1

' 1 ' 4 ' 3 ' 2 ' 1

1 ' 4 4 ' 1 1

h h

h h

Area

f g Area

Done Work

Absorbed Heat

COP

>

=

+

|

=

COP of Modified Cycle :

COP of Original Cycle :

1 2

4 1

1 4 3 2 1

1 4 1

h h

h h

Area

f g Area

Done Work

Absorbed Heat

COP

=

=

=

COP

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

Condensation

Compression

Evaporation

Expansion

T

2

T

1

3

4

2

1

f g

1

4

2

3

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

21

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Vapour Compression System Mathematical Analysis

A. Refrigerating Effect :

( ) ) / (

4 1

kg kJ Heat d Superheate Heat Latent h h Q

evap

+ + =

= Amount of Heat absorbed in Evaporator.

B. Mass of Refrigerant :

= Amount of Heat absorbed / Refrigerating Effect.

( )

) sec / (

3600

000 , 14

4 1

tonne kg

h h

m

=

1 TR = 14,000 kJ/hr

C. Theoretical Piston Displacement :

= Mass of Refrigerant X Sp. Vol. of Refrigerant Gas (v

g

)

1

.

( )

( ) ) sec / (

3600

000 , 14

. .

3

1

4 1

tonne m v

h h

Displ Piston Th

g

-

=

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Vapour Compression System Mathematical Analysis

( )

( ) ) (

) / (

1 2

1 2

kW h h m P

kg kJ h h W

theor

comp

=

=

a) Isentropic Compression :

D. Theoretical Power Required :

( )

( ) ) (

1

) / (

1

1 1 2 2

1 1 2 2

kW V P V P

n

n

m P

kg kJ V P V P

n

n

W

theor

comp

=

a) Polytropic Compression :

E. Heat removed through Condenser :

( ) ) / (

3 2

kg kJ h h m Q

cond

=

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

22

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Example 7 Example 6

A refrigeration machine is required to produce ice at 0 C from water at 20 C. The

machine has a condenser temperature of 298 K while the evaporator temperature is 268

K. The relative efficiency of the machine is 50 % and 6 kg of Freon-12 refrigerant is

circulated through the system per minute. The refrigerant enters the compressor with a

dryness fraction of 0.6. Specific heat of water is 4.187 kJ/kg.K and the latent heat of ice is

335 kJ/kg. Calculate the amount of ice produced on 24 hours. The table of properties if

Freon-12 is given below:

Temperature

(K)

Liquid Heat

(kJ/kg)

Latent Heat

(kJ/kg)

Entropy of Liquid

(kJ/kg)

298 59.7 138.0 0.2232

268 31.4 154.0 0.1251

h

f1

= 31.4 kJ/kg

h

fg1

= 154.0 kJ/kg

h

f2

= 59.7 kJ/kg

h

fg2

= 138.0 kJ/kg

h

f3

= h

4

= 59.7 kJ/kg

m = 6 kg/min

rel

= 50 %

x

2

= 0.6

C

pw

= 4.187 kJ/kg.K

Latent Heat of ice

= 335.7 kJ/kg

}

Given :

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 6.cntd

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

298 K

268 K

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

kg kJ h x h h

fg f

/ 8 . 123 0 . 154 ) 6 . 0 ( 4 . 31

1 1

1

= + = + =

kg kJ h x h h

fg f

/ 2 . 133 0 . 138 ) 5325 . 0 ( 7 . 59

2 2

2 2

= + = + =

( )

5325 . 0

268

0 . 154

6 . 0 1251 . 0

298

0 . 138

2232 . 0

2

2

1

1

1 1

2

2

2 2

1 1 1 2 2 2

1 2

=

|

.

|

\

|

+ =

|

.

|

\

|

+

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+

- + = - +

=

x

x

T

h

x s

T

h

x s

s x s s x s

s s

fg

f

fg

f

fg f fg f

Isentropic Compression : 1-2

kg kJ h h

f

/ 7 . 59

3

4

= =

COP of Original Cycle :

( )

( )

82 . 6

/ 8 . 123 2 . 133

/ 7 . 59 8 . 123

1 2

4 1

=

= =

kg kJ

kg kJ

h h

h h

W

R

COP

n

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

23

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 6.cntd

Actual COP =

rel

X COP

theor

= 0.5 X 6.82 = 3.41

Heat extracted from 1 kg of water at 20 C to form 1 kg of ice at 0 C :

kg kJ

kg kJ

C X K kg kJ X kg

/ 74 . 418

) / ( 335

) ( ) 0 20 ( ) . / ( 187 . 4 ) ( 1

=

+

=

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

298 K

268 K

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

Now;

.ANS

( )

( )

hrs in tonne

X X

kg

kg kJ

kg kJ X kg

m

h h m

X m

W

R

COP

ice

ice

actual n

actual

24 661 . 0

1000

24 60 459 . 0

min / 459 . 0

41 . 3

/ 74 . 418

) / ( 8 . 123 2 . 133 ) ( 6

74 . 418

41 . 3

1 2

) (

= =

=

-

= = =

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 7

28 tonnes of ice from and at 0 C is produced per day in an ammonia refrigerator. The

temperature range in the compressor is from 25 C to -15oC. The vapour is dry and

saturated at the end of compression and an expansion valve is used. Assuming a

co-efficient of performance of 62% of the theoretical, calculate the power required to

drive the compressor. Take latent heat of ice = 335 kJ/kg.

Temp

(C)

Enthalpy (kJ/kg) Entropy of

Liquid

(kJ/kg.K)

Entropy of Vapour

(kJ/kg.K)

Liquid Vapour

25 100.04 1319.22 0.3473 4.4852

-15 -54.56 1304.99 -2.1338 5.0585

h

f1

= -54.56 kJ/kg

h

g1

= 1304.99kJ/kg

h

f2

= 100.04 kJ/kg

h

g2

= 1319.22 kJ/kg

h

f3

= h

4

= 100.04 kJ/kg

T

cond

= 25 C

T

evap

= -15 C

x

2

= 1.dry saturated vapour

COP

actual

= 0.62 (COP

theor

)

Latent Heat of ice

= 335.7 kJ/kg

}

Given :

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

24

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

( )

( )

91 . 8

23 . 1196 22 . 1319

04 . 100 23 . 1196

1 2

4 1

=

=

h h

h h

COP

l theoretica

COP of the Cycle :

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

298 K

258 K

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

Example 7.cntd

process c Isenthalpi kg kJ h h ..... / 04 . 100

4 3

= =

| |

kg kJ

h x h h

fg f

/ 23 . 1196

) 56 . 54 ( 99 . 1304 ) 92 . 0 ( ) 56 . 54 (

) (

1 1 1 1

=

+ =

+ =

( ) ( ) | |

92 . 0

1338 . 2 0585 . 5 ) 1338 . 2 ( 4852 . 4

2

1

1 1 1 2

1 2

=

+ =

- + =

=

x

x

s x s s

s s

fg f g

Isentropic Compression : 1-2

kg kJ h h

g

/ 22 . 1319

2 2

= =

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 7.cntd

Actual COP =

rel

X COP

theor

= 0.62 X 8.91

= 5.52

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

298 K

258 K

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

Actual R

n

= COP

actual

X Work done

= 5.52 X (h

2

h

1

)

= 5.52 X (1319.22 1196.23)

= 678.9 kJ/kg

Heat extracted from 28 tonnes of water at 0 C to form ice at 0 C :

) ( sec / 56 . 108

) (sec/ 3600 ) ( 24

) / ( 335 ) / ( 1000 ) ( 28

kW kJ

hr X hr

kg kJ X tonne kg X kg

=

=

Mass of refrigerant : kg

kg kJ

kJ

1599 . 0

) / ( 9 . 678

sec) / ( 56 . 108

= =

Total Work done by Compressor :

( )

) ( sec / 67 . 19

/ ) 23 . 1196 22 . 1319 ( ) ( 1599 . 0

1 2

kW kJ

kg kJ X kg h h X m

refrig

=

= =

.ANS

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

25

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 8

In a standard vapour compression refrigeration cycle, operating between an evaporator

temperature of -10 C and a condenser temperature of 40 C, the enthalpy of the

refrigerant, Freon-12, at the end of compression is 220 kJ/kg. Show the cycle diagram on

T-s plane. Calculate:

1. The C.O.P. of the cycle.

2. The refrigerating capacity and the compressor power assuming a refrigerant flow

rate of 1 kg/min.

You may use the extract of Freon-12 property table given below:

Temp (C) Pr (MPa) h

f

(kJ/kg) h

g

(kJ/kg)

-10 0.2191 26.85 183.1

40 0.9607 74.53 203.1

h

f1

= 26.85 kJ/kg

h

g1

= h

1

= 183.1 kJ/kg

h

f2

= 74.53 kJ/kg

h

g2

= 203.1 kJ/kg

h

f3

= h

4

= 74.53 kJ/kg

T

cond

= 40 C

T

evap

= -10 C

x

1

= 1.dry saturated vapour

h

2

= 220 kJ/kg

}

Given :

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 8.cntd

COP of Original Cycle :

( )

( )

94 . 2

/ 1 . 183 0 . 220

/ 53 . 74 1 . 183

1 2

4 1

=

= =

kg kJ

kg kJ

h h

h h

W

R

COP

n

.ANS

Refrigerating Capacity :

( ) ( )

min / 57 . 108

/ 53 . 74 1 . 183 ) ( 1

4 1

kJ

kg kJ X kg h h m

=

= =

.ANS

Compressor Power :

( ) ( )

kW

kJ

kg kJ X kg h h m

615 . 0

min / 9 . 36

/ 1 . 183 0 . 220 ) ( 1

1 2

=

=

= =

.ANS

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

40 C

-10 C

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

2

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

26

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 9

A Freon-12 refrigerator producing a cooling effect of 20 kJ/sec operates on a simple

cycle with pressure limits of 1.509 bar and 9.607 bar. The vapour leaves the evaporator

dry saturated and there is no undercooling. Determine the power required by the

machine. If the compressor operates at 300 rpm and has a clearance volume of 3% of

stroke volume, determine the piston displacement of the compressor. For compressor

assume that the expansion following the law PV

1.3

= Constant.

Temp

(

o

C)

P

s

(bar)

v

g

(m

3

/kg)

Enthalpy

h

f

(kJ/kg)

Enthalpy

h

g

(kJ/kg)

Entropy

s

f

(kJ/kg)

Entropy

s

g

(kJ/kg)

Specific

heat

(kJ/kg.K)

-20 1.509 0.1088 17.8 178.61 0.073 0.7082 ---

40 9.607 --- 74.53 203.05 0.2716 0.682 0.747

h

f1

= 17.8 kJ/kg

h

g1

= h

1

= 178.61 kJ/kg

h

f2

= 74.53 kJ/kg

h

g2

= 203.05 kJ/kg

h

f3

= h

4

= 74.53 kJ/kg

T

cond

= 40 C

T

evap

= -20 C

x

1

= 1.dry saturated vapour

h

2

= 220 kJ/kg

}

Given :

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 9.cntd

Refrigerating Capacity : ( ) ( )

sec / 192 . 0

/ 53 . 74 61 . 178 20

4 1

kg m

kg kJ X m kW h h m

=

= =

-

- -

( )

K T

T

T

T

C s s

s s

P

2 . 324

313

ln 747 . 0 682 . 0 7082 . 0

ln

2

2

' 2

2

' 2 1

2 1

=

|

.

|

\

|

+ =

|

|

.

|

\

|

+ =

=

Isentropic Compression : 1-2

( )

( ) ( )

kg kJ

K K kg kJ kg kJ

T T C h h

P

/ 4 . 211

0 . 313 2 . 324 . / 747 . 0 ) / ( 05 . 203

' 2 2 ' 2 2

=

+ =

+ =

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

313 K

253 K

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

2

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

27

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 9

.ANS

Power Required : ( ) ( )

kW

kg kJ X kg h h m

29 . 6

/ 61 . 178 4 . 211 sec) / ( 192 . 0

1 2

=

= =

-

Vol. Efficiency :

% 6 . 87

509 . 1

607 . 9

03 . 0 03 . 0 1

1

13 . 1 / 1

/ 1

=

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+ =

bar

bar

P

P

k k

n

S

d

vol

q

Vol of Refrigerant

at Intake :

sec / 02089 . 0

) / ( 1088 . 0 sec) / ( 192 . 0

3

3

m

kg m X kg

v m

g

=

=

- =

-

Piston Displ. Vol. :

( )

3

3

00477 . 0

) ( 300 876 . 0

min) (sec/ 60 sec) / ( 02089 . 0

) (

.

m

rpm

m

rpm

Vol Actual

vol

=

-

-

=

-

=

q

.ANS

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

313 K

253 K

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

2

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 10

A food storage locker requires a refrigeration capacity of 50 kW. It works between a

condenser temperature of 35 C and an evaporator temperature of -10 C. The refrigerator

is ammonia. It is sub-cooled by 5 C before entering the expansion valve by the dry

saturated vapour leaving the evaporator. Assuming a single-cylinder, single-acting

compressor operating at 1000 rpm with stroke equal to 1.2 times the bore, determine :

1. The power required.

2. The cylinder dimensions.

Properties of ammonia are :

Sat.

Temp.

(

o

C)

Pr.

(bar)

Enthalpy

(kJ/kg)

Entropy

(kJ/kg)

Sp. Vol.

(m

3

/kg)

Sp. Heat

(kJ/kg.K)

Liquid Vapour Liquid Vapour Liquid Vapour Liquid Vapour

-10 2.9157 154.056 1450.22 0.82965 5.7550 --- 0.417477 --- 2.492

35 13.522 366.072 1488.57 1.56605 5.2086 1.7023 0.095629 4.556 2.903

h

1

= 1450.22 kJ/kg

h

2

= 1488.57 kJ/kg

h

f3

= 366.072 kJ/kg

T

cond

= 35 C

T

evap

= -10 C

x

1

= 1.dry saturated vapour

State 3 = Sub-cooled by 5 C

}

Given :

ME 0611 SEM-I Advanced Refrigeration and Air-Conditioning

07-08-2012

28

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 10.cntd

( )

( )

kg kJ

kg kJ kg kJ

T T C h h h

subcool sat liq P f

/ 29 . 343

) / ( 303 308 56 . 405 ) / ( 07 . 366

3 4 ' 3

=

=

= =

( )

K T

T

T

T

C s s s s

P

8 . 371

308

ln 903 . 2 2086 . 5 755 . 5

ln

2

2

' 2

2

' 2 1 2 1

=

|

.

|

\

|

+ =

|

|

.

|

\

|

+ = =

Isentropic Compression : 1-2

( )

( ) ( )

kg kJ

K K kg kJ kg kJ

T T C h h

P

/ 8 . 1673

0 . 308 8 . 371 . / 903 . 2 ) / ( 57 . 1488

' 2 2 ' 2 2

=

+ =

+ =

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

308 K

263 K

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

2

3

303 K

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 10.cntd

( ) ( )

sec / 04517 . 0

/ 29 . 343 22 . 1450

) ( 50

/

) ( 50

4 1

kg

kg kJ

kW

kg kJ h h

kW

m

=

=

=

-

Mass of Refrigerant :

Compressor Power :

( )

( )

kW

kg kJ X kg

h h m

1 . 10

/ 22 . 1450 8 . 1673 ) ( 04517 . 0

1 2

=

=

=

-

.ANS

Cylinder Dimensions :

( )

m m L

m D

kg m

rpm

D D

v

N

L D

kg m

g

228 . 0 ) 19 . 0 ( 2 . 1

19 . 0

/ 417477 . 0

60

) ( 1000

) 2 . 1 (

4 60 4

sec) / ( 04517 . 0

3

2 2

= - =

=

|

.

|

\

|

=

|

.

|

\

|

= =

-

t t

.ANS

.ANS

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

308 K

263 K

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

2

3

303 K

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

07-08-2012

29

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Comparison of Carnot Vs. VCC

Assumption : STATE 1 and STATE 3 are

common for both cycles.

A

1

A

1

: Additional Work required due to

superheated section

A

2

A

2

: Additional Work required, as no work

is recovered during expansion. A

3

A

3

: Loss in cooling effect due to throttling

as compared to isentropic expansion.

Advanced Refrigeration and Air-Conditioning

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

2

4

4

ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Comparison of Carnot Vs. VCC

on J/kg basis :

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

2

4

4

( ) ( )

' 2 1 3 ' 2 2 1

s s T h h A =

A

1

( )

' 4 3 2

h h A =

A

2

( )

' 4 4 3

h h A =

A

3

Areas A

2

and A

3

are EQUAL.

Throttling causes identical dual loss..!!!.

2 1 2 1

A A W W

comp

+ + =

3 1 4

A Q W

comp

=

Advanced Refrigeration and Air-Conditioning

( )

C

C

rev

R

W

A A

Q A

COP

COP

2 1

3

1

/ 1

+

+

= = q

ME 0611 SEM-I

07-08-2012

30

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg. Advanced Refrigeration and Air-Conditioning

Example 11

A refrigerant 12 theoretical single stage cycle operates between a condensing temperature

of 32.2 C and an evaporating temperature of -17.78 C. Assume a Carnot cycle operating

between the same temperatures. Determine :

1. Carnot cycle work of compression.

2. Carnot cycle refrigerating effect.

3. Excess work of compression due to superheat section.

4. Excess work of compression due to throttling.

5. Loss in refrigeration effect due to throttling.

6. Refrigeration efficiency.

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

3

4

2

1

Sat. Vapour Line

Sat. Liq. Line

f g

2

A

1

A

2

A

3

4

4

ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg. Advanced Refrigeration and Air-Conditioning

Example 11.cntd

1. ( )( )

( ) { } ( )

kg kJ

s s T T W

C

/ 986 . 22

033 . 247 7656 . 706 78 . 17 22 . 32

3 1 1 2

=

=

=

ANS.

2. ( )

( ) ( )

kg kJ

s s T Q

C

/ 332 . 117

033 . 247 7656 . 706 22 . 255

3 1 1

=

=

=

ANS.

( ) ( )

( ) ( )

kg kJ

s s T h h A

/ 1483 . 0

667 . 684 7656 . 706 22 . 305 43 . 200 33 . 207

' 2 1 3 ' 2 2 1

=

=

= 3.

ANS.

ME 0611 SEM-I

07-08-2012

31

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg. Advanced Refrigeration and Air-Conditioning

Example 11.cntd

( )

2653 . 0

889 . 80 7656 . 706

889 . 80 033 . 247

" 4 1

" 4 3

' 4

" 4 1 ' 4 " 4 ' 4 3

=

=

+ = =

s s

s s

x

s s x s s s

4. To evaluate A

2

, the value of h

4

is to be calculated.

ANS.

( )

( )( )

kg kJ

h h x h h

/ 242 . 62

817 . 19 73 . 179 2653 . 0 817 . 19

" 4 1 ' 4 " 4 ' 4

=

+ =

+ =

( )

( )

kg kJ

h h A

/ 438 . 4

242 . 62 78 . 66

' 4 3 2

=

=

=

ANS.

5. Since, A

3

= A

2

, we have A

3

= 4.438 kJ/kg.

ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg. Advanced Refrigeration and Air-Conditioning

6. Refrigerating efficiency can be calculated in 2 different ways :

Example 11.cntd

( ) ( )

( )

( ) ( )

( )

8 . 0

22 . 255 61 . 27

50 95 . 112

1 1 2

1 3 4 1

=

=

=

T h h

T T h h

R

q

ANS.

( ) ( )

8 . 0

986 . 22

438 . 4 1483 . 0

1

332 . 117 / 438 . 4 1

1

/ 1

2 1

3

=

+

+

=

+

+

=

C

C

R

W

A A

Q A

q

ANS.

OR by Equation :

ME 0611 SEM-I

07-08-2012

32

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg. Advanced Refrigeration and Air-Conditioning

Multistage Vapour Compression Cycle

To overcome the limitations of the single stage cycle.

At low Evaporator Temperatures, staging of Compressor is necessary

due to Vol. Efficiency in single stage cycles.

Compressor staging and vapour intercooling

to excessive discharge temperatures.

Also helps for COP.

ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg. Advanced Refrigeration and Air-Conditioning

Multistage Vapour Compression Cycle

Enthalpy, h

P

r

e

s

s

u

r

e

,

P

r

1

2

3

9

Evaporation

Condensation

E

x

p

a

n

s

i

o

n

4

5 6

7

8

Evaporator

LP

Compressor

1

2

HP

Compressor

4

5

Condenser

6

7

8

9

NOTE : Typical for AMMONIA and R12

__________

Flash

Intercooler

3

Water

Intercooler

ME 0611 SEM-I

07-08-2012

33

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 12

Calculate the power needed to compress 10 kg/min of Ammonia from saturated vapour at

1.4 bar to a condensing pressure of 10 bar :

(a) by single stage compression

(b) by two stage compression with intercooling by liquid refrigerant at 4 bar.

Assume saturated liquid to leave condenser and dry saturated vapour to leave evaporator.

Advanced Refrigeration and Air-Conditioning

4

7

8

__________

2

Enthalpy, h

P

r

e

s

s

u

r

e

,

P

r

1

2

3

8

E

x

p

a

n

s

i

o

n

4

5 6

7

-27 C

-2 C

25 C

1.4 bar

10 bar

ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 12.cntd

From P h Chart for Ammonia, we get :

SINGLE STAGE :

h

6

= h

7

= -645.0 kJ/kg h

1

= 464.5 kJ/kg h

3

= 753.5 kJ/kg

h

5

= 623.5 kJ/kg.K h

2

= 602.5 kJ/kg h

4

= 498.0 kJ/kg

Higher stage compressor must compress 10 kg/min plus

the quantity of liquid which evaporates to de-superheat

the gas at 2.

The rate of Ammonia compressed can be computed by

making a heat and mass balance about intercooler.

4

(h

4

= 498 kJ/kg)

(0.9142 kg/min)

7

(h

6

= h

7

= -645 kJ/kg)

8

__________

2

(h

2

=602.5 kJ/kg)

(10 kg/min)

ME 0611 SEM-I Advanced Refrigeration and Air-Conditioning

07-08-2012

34

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

1. Heat Balance :

( ) ( ) ( ) ( ) 498 5 . 602 min / 10 645

4 6

- = - + - m kg m

2. Mass Balance :

( )

4 6

10 m m = +

( ) ( ) ( ) ( ) 4980 498 5 . 602 6025 645

6 6

+ - = - + - m m

Example 12.cntd

Property W/o Intercooling With Intercooling

1 2, 2 3 1 2, 2 4, 4 5

h

2

h

1

, kJ/kg 602.5 464.5 = 138 602.5 464.5 = 138

h

3

h

2

, kJ/kg 753.5 602.5 = 151 ---

h

5

h

4

, kJ/kg --- 623.5 498.0 = 125.5

Kg/min from 1 2 10 10

Kg/min from 2 3 10 ---

Kg/min from 4 5 --- 10.91426

Power (kJ/min), 1 2 10 X 138 = 1380 10 X 138 = 1380

Power (kJ/min), 2 3 10 X 151 = 1510 ---

Power (kJ/min), 4 5 --- 125.5 X 10.91426 = 1369.7

Total Power, (kJ/min) 2890 2747.7

ME 0611 SEM-I Advanced Refrigeration and Air-Conditioning

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Example 12.cntd

Thus,

Power requirement without liquid refrigerant intercooling = 2890 kJ/min

Power requirement with liquid refrigerant intercooling = 2747.7 kJ/min

ME 0611 SEM-I Advanced Refrigeration and Air-Conditioning

07-08-2012

35

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg. Advanced Refrigeration and Air-Conditioning

Multistage Vapour Compression Cycle

Evaporator

LP

Compressor

Water

Intercooler

__________

HP

Compressor

Condenser

1

2

3

4

5

6

7

8

9

Flash

Intercooler

Flash Intercooler :

Tank with fixed liquid level.

Liquid level maintained by a Float Valve

= Expansion Valve also.

Sat. Liquid at intermediate pressure is

expanded to Evaporator pressure.

Flash vapour @ Throttling is given as

suction to HP Compressor.

Vapour @ 3 is bubbled through orifices in

the Flash Intercooler and de-superheated

by evaporation of liquid.

Vapour @ suction to HP Compressor :

1. Flash Vapour.

2. Refrigerant in evaporator

3. Vapour due to evaporation of

liquid in intercooler.

ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg. Advanced Refrigeration and Air-Conditioning

Multistage Vapour Compression Cycle

Evaporator

LP

Compressor

Water

Intercooler

__________

HP

Compressor

Condenser

1

2

3

4

5

6

7

8

9

Flash

Intercooler

Disadvantages of Flash Intercooler :

Liquid refrigerant in tank is at

intermediate pressure and saturated.

1. Evaporator is above Intercooler.

2. Heat is absorbed in liquid line.

1. Some liquid evaporates ahead

of Expansion Valve.

2. Operation of Expansion Valve

is sluggish due to low pressure

differential.

ME 0611 SEM-I

07-08-2012

36

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Multistage Vapour Compression Cycle

NOTE : Typical for AMMONIA

Advanced Refrigeration and Air-Conditioning

Enthalpy, h

P

r

e

s

s

u

r

e

,

P

r

1

2

3

9

Evaporation

Condensation

E

x

p

a

n

s

i

o

n

4

5 6

7

8

Evaporator

LP

Compressor

Water

Intercooler

HP

Compressor

Condenser

1

2

3

4

5

6

7

8

9

_______

Shell-&-Coil

Intercooler

ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg. Advanced Refrigeration and Air-Conditioning

Multistage Vapour Compression Cycle

Evaporator

LP

Compressor

Water

Intercooler

HP

Compressor

Condenser

1

2

3

4

5

6

7

8

9

_______

Shell-&-Coil

Intercooler

Advantages of Shell-&-Coil Intercooler :

Subcools the liquid refrigerant.

Eliminates possibility of flash

liquid ahead the Expansion Valve.

Large pressure differential, as the

liquid is at Condenser pressure.

Limitation of Shell-&-Coil Intercooler :

Low COP, as not possible to

intercool the liquid as much as in

Flash Intercooler.

ME 0611 SEM-I

07-08-2012

37

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Multistage Vapour Compression Cycle

NOTE : Typical for R12 and R22

Advanced Refrigeration and Air-Conditioning

Evaporator

LP

Compressor

HP

Compressor

Condenser

1

2

4

5

6

7

8

9

_______

Shell-&-Coil

Liquid

Intercooler

3

Enthalpy, h

P

r

e

s

s

u

r

e

,

P

r

1

2

3

9

Evaporation

Condensation

E

x

p

a

n

s

i

o

n

4

5 6

7

8

ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Multistage Vapour Compression Cycle

Advanced Refrigeration and Air-Conditioning

Evaporator

LP

Compressor

HP

Compressor

Condenser

1

2

4

5

6

7

8

9

_______

Shell-&-Coil

Liquid

Intercooler

3

Vapour from LP Compressor is not

intercooled.

Vapour from LP Compressor is

mixed with refrigerant from

Intercooler.

In stead of Float Valve, a Thermostatic

Expansion Valve is used.

ME 0611 SEM-I

07-08-2012

38

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Multistage Vapour Compression Cycle

Advanced Refrigeration and Air-Conditioning

Enthalpy, h

P

r

e

s

s

u

r

e

,

P

r

1

2

3

9

Evaporation

Condensation

E

x

p

a

n

s

i

o

n

4,10,11

5 6

7,12

8

Low Temp

Evaporator

LP

Compressor

HP

Compressor

Condenser

1

2

4

5

6

7

8

9

_______

Shell-&-Coil

Liquid

Intercooler

3

Water

Intercooler

High Temp

Evaporator

10

11

12

ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg.

Multistage Vapour Compression Cycle

Advanced Refrigeration and Air-Conditioning

No. of stages of Compression :

Economic as well as Practical Considerations.

R12, R22 and Ammonia : Single Stage

Evaporator Temp above 30 C.

R12, R22 : Single Stage more successful at lower temp than that for Ammonia.

Two Stage : Evaporator Temp between 60 C to 30 C.

Three Stage : Evaporator Temp below 65 C.

ME 0611 SEM-I

07-08-2012

39

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg. Advanced Refrigeration and Air-Conditioning

Cascade Refrigeration System

Entropy, s

T

e

m

p

e

r

a

t

u

r

e

,

T

3a

4a

2a

1a

2a

3b

4b

2b

1b

2b

Evaporator

LP

Compressor

1a

2a 3a

4a

HP

Compressor

1b

2b

Condenser

3b

4b

Cascade

Condenser

ME 0611 SEM-I

Basic Vapour Compression and Vapour Absorption Refrigeration

M. Tech. Thermal Engg. Advanced Refrigeration and Air-Conditioning

Cascade Refrigeration System

Evaporator

LP

Compressor

1a

2a 3a

4a

HP

Compressor

1b

2b

Condenser

3b

4b

Temperatures below -65 C

Two Independent Systems.

Cascade Condenser : Heat Exchanger

Advantage :

Possibility of Multistaging each stage!!!

Limitation :

Efficiency loss due to Temperature

Overlap in Cascade Condenser.

Applications :

1. Liquefaction of Petroleum Vapour.

2. Liquefaction of Air / Atm. Gases.

3. Manufacture of Dry Ice.

ME 0611 SEM-I

07-08-2012

40

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. ME 0611 SEM-I Advanced Refrigeration and Air-Conditioning

It is one of the oldest Refrigeration System.

Production of Low ( Cryogenic) Temperature Applications.

Two or more Refrigeration Cycles operate in series.

Cascade Refrigeration System

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. ME 0611 SEM-I

Thermodynamic Cycle

Advanced Refrigeration and Air-Conditioning

07-08-2012

41

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. ME 0611 SEM-I

Experimental Setup for Cascade System

Advanced Refrigeration and Air-Conditioning

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. ME 0611 SEM-I

Experimental Setup for Cascade System

Advanced Refrigeration and Air-Conditioning

07-08-2012

42

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. ME 0611 SEM-I

Performance of Cascade System

Advanced Refrigeration and Air-Conditioning

Sr. No. Parameter Value Parameter Value

1. T

e

,CO2 -50

0

C T

e

,NH3 -20.96

0

C

2. T

c

,CO2 -17.48

0

C T

c

,NH3 29.72

0

C

3. COP,CO2 2.40 COP,NH3 2.14

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. ME 0611 SEM-I Advanced Refrigeration and Air-Conditioning

Comparison Multistage VCC

07-08-2012

43

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. ME 0611 SEM-I Advanced Refrigeration and Air-Conditioning

Precooled Linde Hampson Cycle

(1)

Makeup Gas

Heat Exchanger

Heat Exchanger

J T Valve

J T Valve

Main

Compressor

Refrigerant

Compressor

Cooling

Water

Liquid

(2)

(3)

(4)

(5)

(f)

(g)

(6)

(1)

(a)

(a)

(b)

(c)

(d)

3

4

T

e

m

p

,

T

Entropy, s

1 2

5

6

f g

Refrigerant

Boiling

Point

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. ME 0611 SEM-I Advanced Refrigeration and Air-Conditioning

Cascade System for Air Liquefaction

Makeup Gas

Liquid N

2

Cooling Water

Ammonia, NH

3

Ethylene, C

2

H

4

Methane, CH

4

07-08-2012

44

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Cascade System for LNG Liquefaction

ME 0611 SEM-I Advanced Refrigeration and Air-Conditioning

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. ME 0611 SEM-I Advanced Refrigeration and Air-Conditioning

Advantages / Limitations

Temperature Overlap in Cascade Condenser .

Limitation :

Advantages :

It permits the use of Two / more different Refrigerants, depending on

their Boiling Points.

Inclusion of Intercooling between every two stages is possible, so it

improve performance of system.

Each cycle is operating separately ( i.e. Pr, Freq, compressor Input

Power, etc).

07-08-2012

45

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg.

Thank You !

Advanced Refrigeration and Air-Conditioning ME 0611 SEM-I

Basic Gas Cycles and Vapour Compression Refrigeration

M. Tech. Thermal Engg. Applied Thermodynamics & Heat Engines

References

Randall Barron, Cryogenic Systems, Oxford University Press, 2

nd

ed.,

1981, pp. 69 85.

Roy J. Dossat, Principles of Refrigeration, Thomson Press, 2

nd

SI ed., pp.

542 548.

Aurora S. C. and Domkundwar S. , Refrigeration and Air Conditioning,

Dhanpat Rai & Sons, Delhi, 8

th

ed. pp. 1 4.

Cengel Y. & Boles C. , Thermodynamics, Tata McGraw Hill Publication,

Sixth ed., pp. 636-638.

ME 0611 SEM-I

You might also like

- INTRO REFRIGERATIONDocument60 pagesINTRO REFRIGERATIONadityanarang147100% (1)

- CHAPTER 2 - AIR REFRIGERATION CYCLE (Compatibility Mode) PDFDocument12 pagesCHAPTER 2 - AIR REFRIGERATION CYCLE (Compatibility Mode) PDFVarun SinghNo ratings yet

- R&ACDocument66 pagesR&AC19-309 Khaleel ur RahmanNo ratings yet

- Lcture 1 R&ACDocument95 pagesLcture 1 R&ACzetseatNo ratings yet

- Part I Refrigeration Chapter 1Document43 pagesPart I Refrigeration Chapter 1eskewt0% (1)

- Digital Notes on Refrigeration and Air Conditioning SystemsDocument76 pagesDigital Notes on Refrigeration and Air Conditioning Systemsdipsankar chatterjeeNo ratings yet

- Rac Lab ManualDocument30 pagesRac Lab ManualPrakharGupta100% (1)

- Thermodynamics 2 - Chapter 5 Part1Document29 pagesThermodynamics 2 - Chapter 5 Part1Amir SallehNo ratings yet

- EjectorDocument9 pagesEjectorManuel Gallegos CalderónNo ratings yet

- 803 Rac (Me-803) Exp. ManualDocument47 pages803 Rac (Me-803) Exp. ManualAnonymous z3RsdPToNo ratings yet

- RAC Assignment No. 1Document3 pagesRAC Assignment No. 1Ankur SachdevaNo ratings yet

- RAC Assign 1Document2 pagesRAC Assign 1Arun BeniwalNo ratings yet

- An Analysis of The Performance of An Ejector RefriDocument6 pagesAn Analysis of The Performance of An Ejector RefriHalvor JohnsenNo ratings yet

- Air Cycle Refrigeration SystemDocument30 pagesAir Cycle Refrigeration SystemtsegayNo ratings yet

- 1Document10 pages1Amit KumarNo ratings yet

- Introduction To Refrigeration & Air Conditioning: Applied Thermodynamics & Heat EnginesDocument60 pagesIntroduction To Refrigeration & Air Conditioning: Applied Thermodynamics & Heat EnginesHarry TarusNo ratings yet

- Air Conditioning 1Document17 pagesAir Conditioning 1Esmail AnasNo ratings yet

- Power Engineering And: Refrigeration (22562)Document23 pagesPower Engineering And: Refrigeration (22562)Kunal AhiwaleNo ratings yet

- Difference Between A Refrigerator, Heat Pump, and Heat EngineDocument11 pagesDifference Between A Refrigerator, Heat Pump, and Heat EngineBiswajit PatraNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv SharmaNo ratings yet

- AT 0 Lab Report PDFDocument7 pagesAT 0 Lab Report PDFerlanggasulaiman90No ratings yet