Professional Documents

Culture Documents

Asme Codes

Uploaded by

Karthikeyan VkOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme Codes

Uploaded by

Karthikeyan VkCopyright:

Available Formats

The Engineering ToolBox Resources, Tools and Basic Information for Engineering and Design of Technical A pplications!

Google Custom Search ASME/ANSI B16 - Standards of Pipes and Fittings The ASME B16 Standards covers pipes and fittings in cast iron , cast bronze, wro ught copper and steel Sponsored Links The ASME - American Society of Mechanical Engineers - ASME/ANSI B16 Standards co vers pipes and fittings in cast iron , cast bronze, wrought copper and steel. ASME/ANSI B16.1 - 1998 - Cast Iron Pipe Flanges and Flanged Fittings This Standard for Classes 25, 125, 250 Cast Iron Pipe Flanges and Flanged Fittin gs covers: (a) pressure-temperature ratings, (b) (c) (d) (e) (f) (g) sizes and method of designating openings of reducing fittings, marking, minimum requirements for materials, dimensions and tolerances, bolt, nut, and gasket dimensions and tests.

ASME/ANSI B16.3 - 1998 - Malleable Iron Threaded Fittings This Standard for threaded malleable iron fittings Classes 150, and 300 provides requirements for the following: (a) (b) (c) (d) (e) (f) (g) pressure-temperature ratings size and method of designating openings of reducing fittings marking materials dimensions and tolerances threading coatings

ASME/ANSI B16.4 - 1998 - Cast Iron Threaded Fittings This Standard for gray iron threaded fittings, Classes 125 and 250 covers: (a) (b) (c) (d) (e) (f) (g) pressure-temperature ratings size and method of designating openings of reducing fittings marking material dimensions and tolerances threading, and coatings

ASME/ANSI B16.5 - 1996 - Pipe Flanges and Flanged Fittings The ASME B16.5 - 1996 Pipe Flanges and Flange Fittings standard covers pressuretemperature ratings, materials, dimensions, tolerances, marking, testing, and me thods of designating openings for pipe flanges and flanged fittings. The standard includes flanges with rating class designations 150, 300, 400, 600, 900, 1500, and 2500 in sizes NPS 1/2 through NPS 24, with requirements given in

both metric and U.S units. The Standard is limited to flanges and flanged fitti ngs made from cast or forged materials, and blind flanges and certain reducing f langes made from cast, forged, or plate materials. Also included in this Standar d are requirements and recommendations regarding flange bolting, flange gaskets, and flange joints. ASME/ANSI B16.9 - 2001 - Factory-Made Wrought Steel Buttwelding Fittings This Standard covers overall dimensions, tolerances, ratings, testing, and marki ngs for wrought factory-made buttwelding fittings in sizes NPS 1/2 through 48 (D N 15 through 1200). ASME/ANSI B16.10 - 2000 - Face-to-Face and End-to-End Dimensions of Valves This Standard covers face-to-face and end-to-end dimensions of straightway valve s, and center-to face and center-to-end dimensions of angle valves. Its purpose is to assure installation interchangeability for valves of a given material, typ e size, rating class, and end connection ASME/ANSI B16.11 - 2001 - Forged Steel Fittings, Socket-Welding and Threaded This Standard covers ratings, dimensions, tolerances, marking and material requi rements for forged fittings, both socket-welding and threaded. ASME/ANSI B16.12 - 1998 - Cast Iron Threaded Drainage Fittings This Standard for cast iron threaded drainage fittings covers: (a) size and method of designating openings in reducing fittings (b) marking (c) materials (d) dimensions and tolerances (e) threading (f) ribs (g) coatings (h) face bevel discharge nozzles, input shafts, base plates, and foundation bolt holes (see Tables 1 and 2). ASME/ANSI B16.14 - 1991 - Ferrous Pipe Plugs, Bushings and Locknuts with Pipe Th reads This Standard for Ferrous Pipe Plugs, Bushings, and Locknuts with Pipe Threads c overs: (a) (b) (c) (d) (e) (f) (g) pressure-temperature ratings: size; marking; materials; dimensions and tolerances; threading; and pattern taper.

ASME/ANSI B16.15 - 1985 (R1994) - Cast Bronze Threaded Fittings This Standard pertains primarily to cast Class 125and Class 250 bronze threaded pipe fittings. Certain requirements also pertain to wrought or cast plugs, bushi ngs, couplings, and caps. This Standard covers: (a) (b) (c) (d) (e) (f) pressure-temperature ratings; size and method of designating openings of reducing pipe fittings; marking; minimum requirements for casting quality and materials; dimensions and tolerances in U.S. customary and metric (SI) units; threading.

ASME/ANSI B16.18 - 1984 (R1994) - Cast Copper Alloy Solder Joint Pressure Fittin gs This Standard for cast copper alloy solder joint pressure fittings designed for use with copper water tube, establishes requirements for: (a) (b) (c) (d) (e) (f) (g) Pressure-temperature ratings; Abbreviations for end connections; Sizes and method of designating openings of fittings; Marking; Material; Dimensions and tolerances; and Tests.

ASME/ANSI B16.20 - 1998 - Metallic Gaskets for Pipe Flanges-Ring-Joint, Spiral-W ould, and Jacketed This standard covers materials, dimensions, tolerances, and markings for metal r ing-joint gaskets, spiral-wound metal gaskets, and metal jacketed gaskets and fi ller material. These gaskets are dimensionally suitable for used with flanges de scribed in the reference flange standards ASME/ANSI B16.5, ASME B16.47, and API6A. This standard covers spiral-wound metal gaskets and metal jacketed gaskets f or use with raised face and flat face flanges. Replaces API-601 or API-601. ASME/ANSI B16.21 - 1992 - Nonmetallic Flat Gaskets for Pipe Flanges This Standard for nonmetallic flat gaskets for bolted flanged joints in piping i ncludes: (a) types and sizes; (b) materials; (c) dimensions and allowable tolerances. ASME/ANSI B16.22 - 1995 - Wrought Copper and Copper Alloy Solder Joint Pressure Fittings The Standard establishes specifications for wrought copper and wrought copper al loy, solder-joint, seamless fittings, designed for use with seamless copper tube conforming to ASTM B 88 (water and general plumbing systems), B 280 (air condit ioning and refrigeration service), and B 819 (medical gas systems), as well as f ittings intended to be assembled with soldering materials conforming to ASTM B 3 2, brazing materials conforming to AWS A5.8, or with tapered pipe thread conform ing to ASME B1.20.1. This Standard is allied with ASME B16.18, which covers cast copper alloy pressure fittings. It provides requirements for fitting ends suita ble for soldering. This Standard covers: (a) (b) (c) (d) (e) (f) (g) pressure temperature ratings; abbreviations for end connections; size and method of designating openings of fittings; marking; material; dimension and tolerances; and tests.

ASME/ANSI B16.23 - 1992 - Cast Copper Alloy Solder Joint Drainage Fittings (DWV) The Standard establishes specifications for cast copper alloy solder joint drain age fittings, designed for use in drain, waste, and vent (DWV) systems. These fi ttings are designed for use with seamless copper tube conforming to ASTM B 306, Copper Drainage Tube (DWV), as well as fittings intended to be assembled with so

ldering materials conforming to ASTM B 32, or tapered pipe thread conforming to ASME B1.20.1. This standard is allied with ASME B16.29, Wrought Copper and Wroug ht Copper Alloy Solder Joint Drainage Fittings - DWV. It provides requirements f or fitting ends suitable for soldering. This standard covers: (a) (b) (c) (d) (e) (f) (g) description; pitch (slope); abbreviations for end connections; sizes and methods for designing openings for reducing fittings; marking; material; and dimensions and tolerances.

ASME/ANSI B16.24 - 1991 (R1998) - Cast Copper Alloy Pipe Flanges and Flanged Fit tings This Standard for Classes 25, 125, 250, and 800 Cast Iron Pipe Flanges and Flang ed Fittings covers: (a) (b) (c) (d) (e) (f) (g) pressure temperature ratings, sizes and methods of designating openings for reduced fittings, marking, minimum requirements for materials, dimensions and tolerances, bolt, nut, and gasket dimensions, and tests.

ASME/ANSI B16.25 - 1997 - Buttwelding Ends The Standard covers the preparation of butt welding ends of piping component s to be joined into a piping system by welding. It includes requirements for wel ding bevels, for external and internal shaping of heavy-wall components, and for preparation of internal ends (including dimensions and tolerances). Coverage in cludes preparation for joints with the following. (a) no backing rings; (b) split or non continuous backing rings; (c) solid or continuous backing rings; (d) consumable insert rings; (e) gas tungsten are welding (GTAW) of the root pass. Details of preparation for any backing ring must be specified in ordering the component. ASME/ANSI B16.26 - 1988 - Cast Copper Alloy Fittings for Flared Copper Tubes This standard for Cast Copper Alloy Fitting for Flared Copper Tubes covers: (a) (b) (c) (d) (e) pressure rating; material; size; threading; marking.

ASME/ANSI B16.28 - 1994 - Wrought Steel Buttwelding Short Radius Elbows and Retu rns This Standard covers ratings, overall dimensions, testing, tolerances, and marki ngs for wrought carbon and alloy steel buttwelding short radius elbows and retur ns. The term wrought denotes fittings made of pipe, tubing, plate, or forgings. ASME/ANSI B16.29 - 1994 - Wrought Copper and Wrought Copper Alloy Solder Joint D rainage Fittings (DWV)

The standard for wrought copper and wrought copper alloy solder joint drainage f ittings, designed for use with copper drainage tube, covers: (a) (b) (c) (d) (e) (f) (g) Description, Pitch (slope), Abbreviations for End Connections, Sizes and Method of Designating Openings for Reducing Fittings, Marking, Material, Dimensions and Tolerances.

ASME/ANSI B16.33 - 1990 - Manually Operated Metallic Gas Valves for Use in Gas P iping Systems Up to 125 psig General This Standard covers requirements for manually operated metallic valves sizes NPS 1.2 through NPS 2, for outdoor installation as gas shut-off valves at the end of the gas service line and before the gas regulator and meter where the designated gauge pressure of the gas piping system does not exceed 125 psi (8.6 bar). The Standard applies to valves operated in a temperature environment betw een .20 degrees F and 150 degrees F (.29 degrees C and 66 degrees C). Design Thi s Standard sets forth the minimum capabilities, characteristics, and properties, which a valve at the time of manufacture must possess, in order to be considere d suitable for use in gas piping systems. ASME/ANSI B16.34 - 1996 - Valves - Flanged, Threaded, and Welding End This standard applies to new valve construction and covers pressure-temperature ratings, dimensions, tolerances, materials, nondestructive examination requireme nts, testing, and marking for cast, forged, and fabricated flanged, threaded, an d welding end, and wafer or flangeless valves of steel, nickel-base alloys, and other alloys shown in Table 1. Wafer or flangeless valves, bolted or through-bol t types, that are installed between flanges or against a flange shall be treated as flanged end valves. ASME/ANSI B16.36 - 1996 - Orifice Flanges This Standard covers flanges (similar to those covered in ASME B16.5) that have orifice pressure differential connections. Coverage is limited to the following: (a) welding neck flanges Classes 300, 400, 600, 900, 1500, and 2500 (b) slip-on and threaded Class 300 Orifice, Nozzle and Venturi Flow Rate Meters ASME/ANSI B16.38 - 1985 (R1994) - Large Metallic Valves for Gas Distribution The standard covers only manually operated metallic valves in nominal pipe sizes 2 1/2 through 12 having the inlet and outlet on a common center line, which are suitable for controlling the flow of gas from open to fully closed, for use in distribution and service lines where the maximum gage pressure at which such dis tribution piping systems may be operated in accordance with the code of federal regulations (cfr), title 49, part 192, transportation of natural and other gas b y pipeline; minimum safety standard, does not exceed 125 psi (8.6 bar). Valve se ats, seals and stem packing may be nonmetallic. ASME/ANSI B16.39 - 1986 (R1998) - Malleable Iron Threaded Pipe Unions This Standard for threaded malleable iron unions, classes 150, 250, and 300, pro vides requirements for the following: (a) design (b) pressure-temperature ratings (c) size

(d) (e) (f) (g) (h) (i) (j) (k) (l) (m)

marking materials joints and seats threads hydrostatic strength tensile strength air pressure test sampling coatings dimensions

ASME/ANSI B16.40 - 1985 (R1994) - Manually Operated Thermoplastic Gas The Standard covers manually operated thermoplastic valves in nominal sizes 1.2 through 6 (as shown in Table 5). These valves are suitable for use below ground in thermoplastic distribution mains and service lines. The maximum pressure at w hich such distribution piping systems may be operated is in accordance with the Code of Federal Regulation (CFR) Title 49, Part 192, Transportation of Natural a nd Other Gas by Pipeline; Minimum Safety Standards, for temperature ranges of .2 0 deg. F to 100 deg. F (.29 deg. C to 38 deg. C). This Standard sets qualificati on requirements for each nominal valve size for each valve design as a necessary condition for demonstrating conformance to this Standard. This Standard sets re quirements for newly manufactured valves for use in below ground piping systems for natural gas [includes synthetic natural gas (SNG)], and liquefied petroleum (LP) gases (distributed as a vapor, with or without the admixture of air) or mix tures thereof. ASME/ANSI B16.42 - 1998 - Ductile Iron Pipe Flanges and Flanged Fittings, Classe s 150 and 300 The Standard covers minimum requirements for Class 150 and 300 cast ductile iron pipe flanges and flanged fittings. The requirements covered are as follows: (a) (b) (c) (d) (e) (f) (g) pressure-temperature ratings sizes and method of designating openings marking materials dimensions and tolerances blots, nuts, and gaskets tests

ASME/ANSIB16.44 - 1995 - Manually Operated Metallic Gas Valves for Use in House Piping Systems This Standard applies to new valve construction and covers quarter turn manually operated metallic valves in sizes NPS 1/2-2 which are intended for indoor insta llation as gas shutoff valves when installed in indoor gas piping between a gas meter outlet & the inlet connection to a gas appliance. ASME/ANSI B16.45 - 1998 - Cast Iron Fittings for Solvent Drainage Systems The Standard for cast iron drainage fittings used on self-aerating, one-pipe Sol vent drainage systems, covers the following: (a) (b) (c) (d) (e) (f) (g) (h) description sizes and methods for designating openings for reducing fittings marking material pitch design dimensions and tolerances tests

ASME/ANSI B16.47 - 1996 - Large Diameter Steel Flanges: NPS 26 through NPS 60 This Standard covers pressure-temperature ratings, materials, dimensions, tolera nces, marking, and testing for pipe flanges in sizes NPS 26 through NPS 60 and i n ratings Classes 75, 150,0300, 400, 600, and 900. Flanges may be cast, forged, or plate (for blind flanges only) materials. Requirements and recommendations re garding bolting and gaskets are also included. ASME/ANSI B16.48 - 1997 - Steel Line Blanks The Standard covers pressure-temperature ratings, materials, dimensions, toleran ces, marking, and testing for operating line blanks in sizes NPS 1/2 through NPS 24 for installation between ASME B16. 5 flanges in the 150, 300, 600, 900, 1500 , and 2500 pressure classes. ASME/ANSI B16.49 - 2000 - Factory-Made Wrought Steel Buttwelding Induction Bends for Transportation and Distribution Systems This Standard covers design, material, manufacturing, testing, marking, and insp ection requirements for factory-made pipeline bends of carbon steel materials ha ving controlled chemistry and mechanical properties, produced by the induction b ending process, with or without tangents. This Standard covers induction bends f or transportation and distribution piping applications (e.g., ASME B31.4, B31.8, and B31.11) Process and power piping have differing requirements and materials that may not be appropriate for the restrictions and examinations described here in, and therefore are not included in this Standard. Sponsored Links Search the Engineering ToolBox Google Custom Search Related Topics Codes and Standards - Piping codes and standards - ASME, ANSI, ASTM, AGA, AP I, AWWA, BS, ISO, DIN and more.. Related Documents ANSI - American National Standards Institute - ANSI provides a forum for dev elopment of American national standards ANSI B16.5 - Maximum Pressure and Temperature Ratings - Non-shock pressure ( psig) and temperature ratings for steel pipe flanges and flanged fittings ASME - American Society of Mechanical Engineers - ASME is one of the leading organizations in the world developing codes and standards Bolt Stretching - Bolt stretch according Hooke's Law Bronze Flanges - ASME/ANSI 150 lb - Flange diameters, thickness, bolt circle s, numbers and diameters of bolts for ASME/ANSI B16.15 - Cast Bronze Threaded Fi ttings - 150 lb Bronze flanges with plain faces Carbon and Stainless Steel Flanges - ASME/ANSI Class 600 - ASME/ANSI B16.5-1 996 Pipe Flanges and Flanged Fittings - Class 600 Flanges - outside and inside d iameters, bolt circles, numbers and diameters of bolts Carbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19 - Pipe sizes, inside and outside diameters, wall thickness, schedules, weight and weight of p ipe filled with water - Metric Units Cast Iron Flanged Pipe Fittings - Working Pressures - Maximum working pressu re of cast iron pipe fittings - flanged fittings according ANSI B16.1 Cast Iron Flanges - ASME/ANSI Class 125 - ASME/ANSI B16.1 - 1998 - Cast Iron Pipe Flanges and Flanged Fittings - Class 125 Flanges - outside and inside diam eters, bolt circles, numbers and diameters of bolts Cast Iron Flanges - ASME/ANSI Class 25 - ASME/ANSI B16.1 - 1998 - Cast Iron Pipe Flanges and Flanged Fittings - Class 25 Flanges - outside and inside diamet ers, bolt circles, numbers and diameters of bolts

Cast Iron Flanges - ASME/ANSI Class 250 - ASME/ANSI B16.1 - 1998 - Cast Iron Pipe Flanges and Flanged Fittings - Class 250 Flanges - outside and inside diam eters, bolt circles, numbers and diameters of bolts Cast Iron Threaded Pipe Fittings - Working Pressures - Maximum working press ure of cast iron pipe fittings - threaded fittings according ANSI B16.4 Comparing American and British Piping Standards - Comparing US American (AST M) and British (BSi) piping standards - specifications, grades and material desc riptions Copper Tubes DWV - Drain, Waste and Vent - Dimensions of copper tube ASTM 30 6 DWV - Drain Waste and Vent Dimensions Butt-Welding Fittings - Butt-Welding Fittings - B16.9 - dimension s Malleable Iron Threaded Fittings - Pressure-Temperature Ratings - ASME/ANSI B16.3 - 1998 - Malleable Iron Threaded Fittings - Pressure-Temperature Ratings Pipe Flanges and Gasket Dimensions - Gasket dimensions for pipe flanges and flange fittings ASME B16.5 Pipe Flanges and Flange Fittings Engineering ToolBox - SketchUp Edition - Online 3D modeling! 3D Engineering ToolBox - draw and model technical applications Engineering ToolBox - SketchUp Edition - enabled for use with the amazing, fun a nd free Google SketchUp Translate the ToolBox Arabic - Chinese (Simplified) - Chinese (Traditional) - Dutch - French - German - Italian - Japanese - Korean - Portuguese - Russian - Spanish - - Select Your o wn language . . About the ToolBox We appreciate any comments and tips on how to make The Engineering ToolBox a bet ter information source. Please contact us by email editor.engineeringtoolbox@gmail.com if You find any faults, inaccuracies, or otherwise unacceptable information. The content in The Engineering ToolBox is copyrighted but can be used with NO WA RRANTY or LIABILITY. Important information should always be double checked with alternative sources. All applicable national and local regulations and practices concerning this aspects must be strictly followed and adhered to. Advertise in the ToolBox If you want to promote your products or services in the Engineering ToolBox - pl ease use Google Adwords. 3D Engineering ToolBox - draw and model technical applications! 2D Engineering T oolBox - create and share online diagram drawing templates! Engineering ToolBox Apps - mobile online and offline engineering applications! Home Acoustics Air Psychrometrics Basics Combustion Drawing Tools Dynamics Economics Electrical Environment Fluid Mechanics Gas and Compressed Air

HVAC Systems Hydraulics and Pneumatics Insulation Material Properties Mathematics Mechanics Miscellaneous Physiology Piping Systems Process Control Pumps Standards Organizations Steam and Condensate Thermodynamics Water Systems Convert Units Temperature oC oF Length m km in ft yards miles nautical miles Volume m3 liters in3 ft3 us gal Velocity m/s km/h ft/min ft/s mph knots Pressure Pa (N/m2) bar mm H2O kg/cm2 psi inches H2O Flow

m3/s m3/h US gpm cfm Free Industry Downloads Official Medical Design Briefs Control Engineering Engineering Standards Engineering Standards Mobile Edition! printer friendly Sponsored Links Free Industry Downloads Asia Electronics Industry Vision Systems Design EDN Engineering Standards Engineering Standards

You might also like

- CRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiaDocument4 pagesCRGO Strips India, CRGO Transformer Laminations, CRGO Core IndiaKarthikeyan VkNo ratings yet

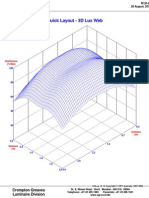

- Quick Layout - 3D Lux WebDocument1 pageQuick Layout - 3D Lux WebKarthikeyan VkNo ratings yet

- The Easy WayDocument80 pagesThe Easy WayKarthikeyan Vk100% (1)

- Transformer SizingDocument7 pagesTransformer SizingKarthikeyan VkNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Trusted Cloud Computing by Helmut Krcmar, Ralf Reussner, Bernhard Rumpe (Eds.)Document335 pagesTrusted Cloud Computing by Helmut Krcmar, Ralf Reussner, Bernhard Rumpe (Eds.)Hari HaranNo ratings yet

- Entrepreneurial Intentions of Cavite Business StudentsDocument12 pagesEntrepreneurial Intentions of Cavite Business StudentsKevin Pereña GuinsisanaNo ratings yet

- Adjectives Weekly Plan1Document10 pagesAdjectives Weekly Plan1RItta MariaNo ratings yet

- DISADVANTAGESDocument3 pagesDISADVANTAGESMhd MiranNo ratings yet

- Attribute Achievement FormDocument15 pagesAttribute Achievement FormMiguel MenesesNo ratings yet

- Move Over G7, It's Time For A New and Improved G11: Long ShadowDocument16 pagesMove Over G7, It's Time For A New and Improved G11: Long ShadowVidhi SharmaNo ratings yet

- ADD MATH ProjectDocument13 pagesADD MATH Projectmegazat27No ratings yet

- Sles-55605 C071D4C1Document3 pagesSles-55605 C071D4C1rgyasuylmhwkhqckrzNo ratings yet

- Ôn tập và kiểm tra học kì Tiếng anh 6 ĐÁP ÁNDocument143 pagesÔn tập và kiểm tra học kì Tiếng anh 6 ĐÁP ÁNThùy TinaNo ratings yet

- Nozzle F Factor CalculationsDocument5 pagesNozzle F Factor CalculationsSivateja NallamothuNo ratings yet

- What Is Gross Income - Definition, Formula, Calculation, and ExampleDocument7 pagesWhat Is Gross Income - Definition, Formula, Calculation, and ExampleKapil SharmaNo ratings yet

- Lab 1 Boys CalorimeterDocument11 pagesLab 1 Boys CalorimeterHafizszul Feyzul100% (1)

- Colorimetric Determination of ManganeseDocument16 pagesColorimetric Determination of ManganeseidaayudwitasariNo ratings yet

- Eurapipe ABS Pipe - Fittings ManualDocument52 pagesEurapipe ABS Pipe - Fittings ManualLê Minh ĐứcNo ratings yet

- 09 Lift Cylinder Drift (Bulldozer) - CheckDocument2 pages09 Lift Cylinder Drift (Bulldozer) - CheckFredy Manrique AstoNo ratings yet

- Alarm Management Second Ed - Hollifield Habibi - IntroductionDocument6 pagesAlarm Management Second Ed - Hollifield Habibi - IntroductionDavid DuranNo ratings yet

- Research Chapter 1Document7 pagesResearch Chapter 1Aryando Mocali TampubolonNo ratings yet

- Counter Circuit Types, Components and ApplicationsDocument22 pagesCounter Circuit Types, Components and Applicationsnavin_barnwalNo ratings yet

- 8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features DescriptionDocument3 pages8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features Descriptionedward3600No ratings yet

- 3.6 God Provides Water and Food MaryDocument22 pages3.6 God Provides Water and Food MaryHadassa ArzagaNo ratings yet

- aCTION PLAN IN HEALTHDocument13 pagesaCTION PLAN IN HEALTHCATHERINE FAJARDONo ratings yet

- Fundamental of Computer MCQ: 1. A. 2. A. 3. A. 4. A. 5. A. 6. ADocument17 pagesFundamental of Computer MCQ: 1. A. 2. A. 3. A. 4. A. 5. A. 6. AacercNo ratings yet

- Vox Latina The Pronunciation of Classical LatinDocument145 pagesVox Latina The Pronunciation of Classical Latinyanmaes100% (4)

- Linear Circuit Analysis (ELEN-1100) : Lecture # 13: More On Mesh Current AnalysisDocument11 pagesLinear Circuit Analysis (ELEN-1100) : Lecture # 13: More On Mesh Current AnalysisPhD EENo ratings yet

- Parts of A Computer With Their FunctionsDocument19 pagesParts of A Computer With Their FunctionsJaried SumbaNo ratings yet

- LEONI Dacar® 110 enDocument1 pageLEONI Dacar® 110 engshock65No ratings yet

- PP 12 Maths 2024 2Document21 pagesPP 12 Maths 2024 2Risika SinghNo ratings yet

- Numerical Solution of Ordinary Differential EquationsDocument31 pagesNumerical Solution of Ordinary Differential Equationschandu3072002100% (1)

- Youtube SrsDocument23 pagesYoutube Srsabhinandan PandeyNo ratings yet

- Teaching and Learning in the Multigrade ClassroomDocument18 pagesTeaching and Learning in the Multigrade ClassroomMasitah Binti TaibNo ratings yet