Professional Documents

Culture Documents

RR Masomary Specification

Uploaded by

Vikas GautamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RR Masomary Specification

Uploaded by

Vikas GautamCopyright:

Available Formats

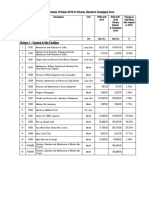

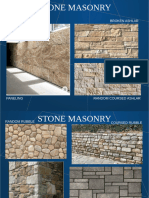

Section 607Rubble Masonry

607.1 General Description

This work includes constructing rubble masonry from classes such as coursed, random, and random range work, from roughly squared and dressed stone laid with or without mortar as specified on the Plans. 607.1.01 Definitions General Provisions 101 through 150. 607.1.02 Related References A. Standard Specifications Section 834Masonry Materials B. Referenced Documents General Provisions 101 through 150. 607.1.03 Submittals General Provisions 101 through 150.

607.2 Materials

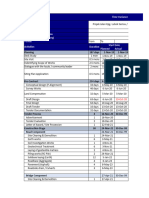

Ensure that materials meet the requirements of the following specifications: Material

Stone for Masonry Mortar and Grout

Section

834 834

607.2.01 Delivery, Storage, and Handling General Provisions 101 through 150.

607.3 Construction Requirements

607.3.01 Personnel General Provisions 101 through 150. 607.3.02 Equipment General Provisions 101 through 150. 607.3.03 Preparation General Provisions 101 through 150. 607.3.04 Fabrication General Provisions 101 through 150. 607.3.05 Construction Construct rubble masonry as follows: A. Shaping the Stone Roughly square the stones on joints, beds, and faces. At angles and ends of walls, use selected stone roughly squared and pitched to line. If specified, finish the corners or angles in exterior surfaces with a chisel draft.

Page 1

Section 607Rubble Masonry Before laying the stone in the wall, shape and dress it so that it will not loosen after it is placed. No dressing or hammering which will loosen the stone will be permitted after it is placed. B. Laying the Stone 1. 2. 3. 4. 5. 6. 7. Decrease the stone thickness from the bottom to the top of wall. Ensure that the headers in the heart of the wall are the same size as shown in the face and extend at least 12 in (300 mm) into the core or backing. Ensure that headers in walls 2 ft (600 mm) or less in thickness extend entirely through the wall. The headers shall occupy at least 20 percent of the face of the wall. Lay the masonry to line and in roughly leveled courses. Ensure that the bottom of the foundation is large, selected stones. Lay the courses with leaning beds parallel to the natural bed of the material. Regularly diminish the thicknesses of the courses, if varied, from the bottom to the top of the wall. Keep a surplus supply of stones at the site to select from. When mortar masonry is specified: a. b. c. d. e. Clean each stone and saturate it with water before setting it. Clean and moisten the bed that will receive it. Bed the stones in freshly made mortar with full joints. Carefully settle the stones in place before the mortar sets. Do not permit spalls in the beds. Ensure that the joints and beds have an average thickness of not more than 1 in. (25 mm). Ensure that the vertical joints in each course break with the adjoining courses at least 6 in. (150 mm). Do not place vertical joints directly above or below a header joint. If a stone is moved or if the joint is broken after the mortar has set, take the stone up and thoroughly clean the mortar from the bed and joints. Reset the stone in fresh mortar. Do not lay the masonry in freezing weather or when the stone contains frost, except by permission and subject to required conditions. NOTE: Do not lay the masonry in freezing weather or when the stone contains frost, except with permission. f. Whenever possible, properly point the face joints before the mortar sets. If joints cannot be pointed, rake them out to a depth of 1 in (25 mm) before the mortar sets. Do not smear the stone face surfaces with the mortar forced out of the joints or the mortar used in pointing. g. h. i. Thoroughly wet the joints pointed after the stone is laid with clean water and fill with mortar. Drive the mortar into the joints and finish with an approved pointing tool. Keep the wall wet while pointing. In hot or dry weather, protect the pointed masonry from the sun and keep it wet for at least three days after the pointing is finished. NOTE: Do not perform pointing in freezing weather or when the stone contains frost. j. 8. After the pointing is completed and the mortar is set, thoroughly clean the walls and leave them in a neat condition.

Dry Rubble Masonry When laying dry rubble: a. b. Take care that each stone takes a firm bearing no less than in three separate points upon the underlying course. Ensure that face joints are no greater than 1 in (25 mm) wide.

Page 2

Section 607Rubble Masonry c. d. Chink the open front and rear joints with spalls fitted to take firm bearing upon the top and bottom surfaces throughout the length of the stone. Fill the interstices in the heart of the wall with spalls. When specified, thoroughly slush the open joint on the rear surfaces with mortar to prevent water from seeping through the joints.

C. Weep Holes Provide adequate drainage for retaining walls with weep holes as shown on the Plans or required by the Engineer. When backfilling at weep holes, build chimneys and french drains extending through the parts of the fill to be drained. The cost of chimneys, weep holes, and french drains is included in the Contract Price for rubble masonry. D. Copings Use copings, bridge seats, and back walls made from the materials shown on the Plans. If not otherwise specified, they shall be Class A concrete. Make concrete copings in sections at least 12 in (300 mm) thick and from 5 to 10 ft (1.5 to 3 m) long, extending the full width of the wall. Cast the sections in place or precast and set them in place in free mortar beds. 607.3.06 Quality Acceptance General Provisions 101 through 150. 607.3.07 Contractor Warranty and Maintenance General Provisions 101 through 150.

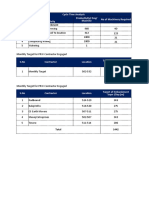

607.4 Measurement

This work is measured in cubic yards (meters) of accepted masonry. The dimensions shown on the Plans shall be used except for changes made by the Engineer. Excavation for rubble masonry is not measured for separate payment. 607.4.01 Limits General Provisions 101 through 150.

607.5 Payment

This work will be paid for at the Contract Price per cubic yard (meter) for mortar rubble masonry or dry rubble masonry complete in place. Payment will be made under:

Item No. 607 Item No. 607 Mortar rubble masonry Dry rubble masonry Per cubic yard (meter) Per cubic yard (meter)

607.5.01 Adjustments General Provisions 101 through 150.

Page 3

You might also like

- 3rd Running Bil 353 NH (Act)Document4 pages3rd Running Bil 353 NH (Act)mad21_No ratings yet

- Excel Midterm Activity Part 1 - Jewel Ann BenitezDocument34 pagesExcel Midterm Activity Part 1 - Jewel Ann BenitezMIKASANo ratings yet

- RFQ-1 PCLDocument14 pagesRFQ-1 PCLjeet bhalodiaNo ratings yet

- Cost Estimate Workshop Office R1 12.03.15Document69 pagesCost Estimate Workshop Office R1 12.03.15AbhishekKumarNo ratings yet

- Ammendment I JO TL (TE 03)Document26 pagesAmmendment I JO TL (TE 03)shanmugam.sNo ratings yet

- PC01 Budget For July, Aug, Sep'2021Document45 pagesPC01 Budget For July, Aug, Sep'2021Ashish BhartiNo ratings yet

- Balance CTC - Lily Lilac Tulip 19 20 - SWF - 08.01.2022Document51 pagesBalance CTC - Lily Lilac Tulip 19 20 - SWF - 08.01.2022UTTAL RAY100% (1)

- Geotechnical Scope of Work For ERL Unit-2Document75 pagesGeotechnical Scope of Work For ERL Unit-2smjohirNo ratings yet

- Prequalification checklist for civil subcontractorsDocument3 pagesPrequalification checklist for civil subcontractorsbureau servicesNo ratings yet

- Annexure - 1 Part D Subcontract Agreement (Sample Copy)Document6 pagesAnnexure - 1 Part D Subcontract Agreement (Sample Copy)Ahmed BoraeyNo ratings yet

- KEY DATADocument10 pagesKEY DATAabhishek negiNo ratings yet

- 2090-1600-Const-T-03 R1Document497 pages2090-1600-Const-T-03 R1sefpl_delhi100% (1)

- Estimate of RoadDocument17 pagesEstimate of RoadshambhuNo ratings yet

- L&T ECC P&M Cost EstimatesDocument5 pagesL&T ECC P&M Cost EstimateskaadalanNo ratings yet

- Time Variance Report 17.12.2020Document6 pagesTime Variance Report 17.12.2020Cliff Jude ZehnderNo ratings yet

- Standard Data Book (Road & Bridge)Document10 pagesStandard Data Book (Road & Bridge)Anonymous aNyCxZWNo ratings yet

- TIP-HSE-P03-02-F01 Contractor HSE - Containment For CCTVDocument1 pageTIP-HSE-P03-02-F01 Contractor HSE - Containment For CCTVVijayakumar KarunanidhiNo ratings yet

- METHOD STATEMENT OF EARTHWORKSDocument12 pagesMETHOD STATEMENT OF EARTHWORKSVladimir DovalNo ratings yet

- Pile Foundation ConstructionDocument36 pagesPile Foundation Constructionsunil_rathore20073921No ratings yet

- Instructions To Tenderers-Construction of Co2 & Chlorination BuildingDocument17 pagesInstructions To Tenderers-Construction of Co2 & Chlorination BuildingUMER SHARIFFNo ratings yet

- Schedule of Rates BarisalDocument138 pagesSchedule of Rates Barisal00152100% (3)

- Ganga Nagar Lab BuildingDocument19 pagesGanga Nagar Lab BuildingAyush TiwariNo ratings yet

- Construction of Mppschool Building at Ainapoor Tanda (V) of Doma (M)Document30 pagesConstruction of Mppschool Building at Ainapoor Tanda (V) of Doma (M)vanamgouthamNo ratings yet

- Invoice Copy: S.No Item Progress This Bill Contract (RS.)Document45 pagesInvoice Copy: S.No Item Progress This Bill Contract (RS.)muthupalaniappanNo ratings yet

- Rate Analysis-Norms 1Document10 pagesRate Analysis-Norms 1yamanta_rajNo ratings yet

- Fyp 070 FinalDocument190 pagesFyp 070 FinalSunil Kharbuja100% (1)

- Bill of QuantityDocument14 pagesBill of QuantityAshok KcNo ratings yet

- Triangle Construction 4th R.A. Bill For Township IIDocument81 pagesTriangle Construction 4th R.A. Bill For Township IItriangle269No ratings yet

- DSR - Vol2 - UPDATED - DEC - 2021Document8 pagesDSR - Vol2 - UPDATED - DEC - 2021srusti02No ratings yet

- DAR Vol 2Document1,371 pagesDAR Vol 2gyan_th9229No ratings yet

- Pile Foundations v1.00 Oct2010Document17 pagesPile Foundations v1.00 Oct2010Munteanu DanNo ratings yet

- S.No Description Total Quantity Foul Water Manhole Foul Water ChamberDocument2 pagesS.No Description Total Quantity Foul Water Manhole Foul Water ChamberSanthosh PalaniappanNo ratings yet

- VS Aos 09 01 13Document76 pagesVS Aos 09 01 13yogeshNo ratings yet

- Man HoursDocument2 pagesMan Hourserastus_petersNo ratings yet

- Covid Relief For ContractorsDocument7 pagesCovid Relief For ContractorsGobinder Singh VirdeeNo ratings yet

- Cycle Time EmbankmentDocument8 pagesCycle Time EmbankmentSreekanth SattirajuNo ratings yet

- Formatof Indenity BondDocument2 pagesFormatof Indenity BondSudhir SinhaNo ratings yet

- 201 A Sub BaseDocument1 page201 A Sub BaseCivil Engineering CalculationsNo ratings yet

- SPCL Offer 9 (New) - 03.12.09Document55 pagesSPCL Offer 9 (New) - 03.12.09ptn999No ratings yet

- CI-PN-006 Construction Organ Plan - 0Document6 pagesCI-PN-006 Construction Organ Plan - 0ebsmsartNo ratings yet

- General Contractor Dredging ExperienceDocument34 pagesGeneral Contractor Dredging ExperienceBambang PermanaNo ratings yet

- New MES Schedule 2014 (Chepterwize)Document410 pagesNew MES Schedule 2014 (Chepterwize)Muhammad UmarNo ratings yet

- DAM ALLIED WORKS CONCRETE RATEDocument21 pagesDAM ALLIED WORKS CONCRETE RATEvpmohammedNo ratings yet

- Sanitary Rate 075 - 76 Siraha FinalDocument122 pagesSanitary Rate 075 - 76 Siraha FinalSirhali BuildersNo ratings yet

- RA BILL 9 For BD ROAD After Adding All BillDocument20 pagesRA BILL 9 For BD ROAD After Adding All BillnandiniNo ratings yet

- Rate Analysis - Khulna - Barisal - GopalganjDocument280 pagesRate Analysis - Khulna - Barisal - Gopalganjmd mohiuddinNo ratings yet

- Determination of EOT, Price Adjustment and Damages in Highway ProjectsDocument4 pagesDetermination of EOT, Price Adjustment and Damages in Highway ProjectsSanjeev KumarNo ratings yet

- Schedule of Rates for Earthworks and Small-Scale Water ResourcesDocument25 pagesSchedule of Rates for Earthworks and Small-Scale Water ResourcesMonirul Islam EstiakNo ratings yet

- Shutdown ScheduleDocument50 pagesShutdown ScheduleIopjuNo ratings yet

- Furnish Details in A Separate Sheet)Document4 pagesFurnish Details in A Separate Sheet)Parasuram BonangiNo ratings yet

- 005 - 24-09-2014 - Material ApprovalDocument1 page005 - 24-09-2014 - Material ApprovalMohammad UmmerNo ratings yet

- Daily Programme: Resource Availability / HSE StatisticsDocument8 pagesDaily Programme: Resource Availability / HSE StatisticsMohamed ThowfeekNo ratings yet

- NAWCPF-MSBI-NCPF-000-CV-RFQ-31072 - 001 - CPF-Civil Works-SOWDocument45 pagesNAWCPF-MSBI-NCPF-000-CV-RFQ-31072 - 001 - CPF-Civil Works-SOWMouhebNo ratings yet

- 072-73rate AnalysisKTMDocument388 pages072-73rate AnalysisKTMAmok BajracharyaNo ratings yet

- Material Reconciliation - PDF REVISEDDocument32 pagesMaterial Reconciliation - PDF REVISEDlinga2014No ratings yet

- Rate Analysis - Gujarat - Pkg-27 PDFDocument200 pagesRate Analysis - Gujarat - Pkg-27 PDFAayush AggarwalNo ratings yet

- Work Order for Culvert and Bridge ConstructionDocument5 pagesWork Order for Culvert and Bridge ConstructionLaxmipathi Rao LakkarajuNo ratings yet

- Stone MasonaryDocument59 pagesStone MasonaryNamrata Pal100% (1)

- StonemasonryDocument50 pagesStonemasonryVidya MohananNo ratings yet

- Specifications for excavation and stone masonryDocument16 pagesSpecifications for excavation and stone masonryRajan KumarNo ratings yet

- Unit-1 - Stone Masonry-Bmc Part-IDocument24 pagesUnit-1 - Stone Masonry-Bmc Part-IMukesh Kumar Shankhwar100% (1)

- Masonry (Basic Define Ti On)Document58 pagesMasonry (Basic Define Ti On)Tahir Yousafzai100% (2)

- Stone MassonaryDocument28 pagesStone MassonaryguneetNo ratings yet

- Performing Arts Centre Bengaluru by Sandhya S SarwananDocument53 pagesPerforming Arts Centre Bengaluru by Sandhya S SarwananSharvari GanpuleNo ratings yet

- Stone MasonryDocument8 pagesStone MasonryjembuildersupplyNo ratings yet

- Road Inventory January 2022Document13 pagesRoad Inventory January 2022ASSESSOR LGUTUAONo ratings yet

- UNIT 14 Stories 2012021001 Luh Desi PurnamawatiDocument7 pagesUNIT 14 Stories 2012021001 Luh Desi PurnamawatiDesi PurnamaNo ratings yet

- 2 - Types of Stone, Brick and Block Masonry-2000Document20 pages2 - Types of Stone, Brick and Block Masonry-2000asadNo ratings yet

- Antronec: City of ArtisansDocument26 pagesAntronec: City of ArtisanssilentiborNo ratings yet

- PIPE CULVERT WITH CUSHION (1X1.2m) - (1x900) - 13+140-2Document1 pagePIPE CULVERT WITH CUSHION (1X1.2m) - (1x900) - 13+140-2Chandan VatsNo ratings yet

- Specific Surface Area and its effect on Concrete StrengthDocument12 pagesSpecific Surface Area and its effect on Concrete Strengthmohannad eliassNo ratings yet

- Seminar On Stone MasonryDocument5 pagesSeminar On Stone MasonryVaibhav BabbarNo ratings yet

- Construction of Stone Masonry-Code of Practice: Indian StandardDocument8 pagesConstruction of Stone Masonry-Code of Practice: Indian Standardsaifullah629No ratings yet

- Is 1597-2-1992 Ashlar MasonaryDocument11 pagesIs 1597-2-1992 Ashlar MasonaryBaba Maisam ShabirNo ratings yet

- REVITALISASI DRAINASE & CPHMA 5.000 KM (BBPJN JATENG DIY) - 07082020 - Rev3 EDIT77Document9 pagesREVITALISASI DRAINASE & CPHMA 5.000 KM (BBPJN JATENG DIY) - 07082020 - Rev3 EDIT77soraya anisaNo ratings yet

- Koridor Koridor: Gspublisherversion 0.0.100.100Document1 pageKoridor Koridor: Gspublisherversion 0.0.100.100tishebraNo ratings yet

- Design and Construction of Stone BuildingDocument2 pagesDesign and Construction of Stone BuildingMuhafeez GoolabNo ratings yet

- Traditional and Contemporary Practices in The UK Stone IndustryDocument48 pagesTraditional and Contemporary Practices in The UK Stone IndustrySimon Brown100% (1)

- Unit 2Document17 pagesUnit 2Deepti Chandrasekhar100% (1)

- Designa Schist ManualDocument22 pagesDesigna Schist Manualbinod2500No ratings yet

- Stone MasonaryDocument23 pagesStone MasonaryParth AnajwalaNo ratings yet

- PlasticDocument233 pagesPlasticaniruddhia4mNo ratings yet

- Group 7 English Descriptions - v1.0Document212 pagesGroup 7 English Descriptions - v1.0Rizwan GhaniNo ratings yet

- Stone & Brick Mas. Con. Vyomkesh BhosleDocument19 pagesStone & Brick Mas. Con. Vyomkesh BhosleVyomkesH BHOSLENo ratings yet

- Tindivanam Quarry Distance ChartDocument2 pagesTindivanam Quarry Distance Chartshashank147No ratings yet

- Stone Masonry: - Ashlar Masonry - Rubble MasonryDocument23 pagesStone Masonry: - Ashlar Masonry - Rubble MasonryYogendra PatilNo ratings yet

- Henry TaylorDocument3 pagesHenry TaylorNuno Dias RoqueNo ratings yet

- Behind The Postmodern FacadeDocument360 pagesBehind The Postmodern Facadekosti7No ratings yet

- Essential Stone Masonry TechniquesDocument47 pagesEssential Stone Masonry TechniquesSantosh MakadNo ratings yet

- Viveda Wellness Retreat Case StudyDocument13 pagesViveda Wellness Retreat Case StudyJayNo ratings yet