Professional Documents

Culture Documents

EMI Texas Instruments - 4

Uploaded by

JavierOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EMI Texas Instruments - 4

Uploaded by

JavierCopyright:

Available Formats

Application NotesAN15

All Products

SLTA015A

(Revised 6/30/2000)

EMI Considerations for DC to DC Converters and Integrated Switching Regulators

Electromagnetic energy, whether intentionally or unintentionally generated, results in Electromagnetic Interference (EMI) with other equipment. Power Trends products are designed to minimize the amount of electromagnetic energy produced during normal operation. The permissible level of conducted and radiated EMI generated by any end product is regulated by a number of governing bodies throughout the world. Their function is to insure Electromagnetic Compatibility (EMC) of all electronic equipment. T assist designers o with compliance in the U.S. and European markets, Power Trends has designed and tested its products to several important standards. The table below shows a comparison of several key standards that define radiated emissions levels.

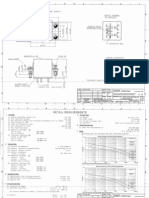

Table 13

Frequency Limits (MHz) Lower Upper 30 88 216 960 88 216 960 1000 .024 .80 1.59 4.77 88 20.17 88 216 960 10000 230 1000 1 30 470 1000 Radiated Emissions Limit for Class A (Industrial Equipment) dB(V/meter) @ 10 meters 39.1 43.5 46.4 49.5 88.6 56.2 - 20log (f) 58.2 66.2 - 40log (f) 39.1 43.5 46.4 49.5 40 47 Radiated Emissions Limit for Class B (Unrestricted Use) dB(V/meter) @ 3 meters 40.0 43.5 46.0 54.0 139 87.6 - 20log (f) 108.7 97.6 - 40log (f) 40.0 43.5 46.0 54.0 30* 37* 171.5 - 20log (f) 94.1 - 7.1log (f) 34* 40*

-dent test laboratory at an FCC approved open field test site. The results given here are for specific products that were chosen to be representative of a given product series. Since their circuit layouts are identical, the results for individual products within a series will not vary substantially.

PT3100/4100 Series The PT3100/4100 series was qualified for EMI at nominal input voltage and full output current. All products in the PT3100 series use the same PCB layout and magnetic components design.

Table 14

Specification FCC (CFR) Part 15 NWT-TR-001089 CISPR 22 VDE 0871 Test Results Pass Class B Pass Class B Pass Class B Pass Class A Pass Class B Conditions Electric Field tested at 10 meters Magnetic Field tested at 3 meters Electric Field tested at 10 meters Electric Field tested at 10 meters Magnetic Field tested at 3 meters Electric Field tested at 10 meters

Specification FCC (CFR) Title 47, Part 15, Subpart B

Bellcore .01 NWT-TR.024 001089 .80 Electric Field 1.59 Strength 4.77 1.59 20.17 88 216 960 CISPR 22 30 Electric Field 230 Strength VDE 0871 .01 Magnetic 1 Field Strength VDE 0871 30 Electric Field 470

PT78ST1 Series The PT78ST1 series was qualified for EMI at nominal input voltage and full output current. All products in the PT78ST1 series use the same PCB layout and magnetic component design.

Table 15

Specification FCC (CFR) Part 15 CISPR 22 VDE 0871 Test Results Pass Class B Pass Class B Pass Class B Conditions Electric Field tested at 10 meters Electric Field tested at 10 meters Magnetic Field tested at 3 meters Electric Field tested at 10 meters

PT6100 Series The PT6100 series was qualified for EMI at nominal input voltage and full output current. All products in the PT6100 series use the same PCB layout and magnetic component design.

Table 16

Specification Test Results Pass Class B Pass Class B Pass Class B Conditions Electric Field tested at 10 meters Electric Field tested at 10 meters Magnetic Field tested at 3 meters Electric Field tested at 10 meters FCC (CFR) Part 15 CISPR 22 VDE 0871

* Limit @ 10 meters Note: The conversion factor for 10 meter intensity to 3 meter intensity is 20log (10/3) or10.5dB(V/meter)

Power T rends products are carefully designed to minimize the amount of conducted and radiated EMI. All printed circuit board layouts are designed to minimize trace lengths and subsequent parasitics. Consideration is taken to eliminate ground loops and to control circuit rise times which are major contributors to radiated emissions. High-frequency ceramic capacitors are used on the input and the output to minimize conducted emissions. Thorough end-product testing is used to verify designs as electromagnetic compatible. The following tables summarize the results of Power Trends products tested in accordance with the above agency specifications. These tests were conducted by an indepen-

Although these results indicate a sound product design, radiated and conducted EMI must still be considered in the application of these products. Long traces and signal loops act as antennae that can easily receive and transmit high levels of EMI. When possible, use a multilayer board with a ground plane since this can add as much as 20dB of high frequency attenuation above a 2-sided board. Component location and routing should be checked and appropriate bypass capacitors should be selected. EMI filters and shielded cables are important when running long cables. Realizing its existence and understanding how emissions are generated and suppressed can greatly assist in improving reliability and reducing development costs, while complying with agency requirements.

For technical support and more information, see inside back cover or visit www.ti.com/powertrends

IMPORTANT NOTICE Texas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue any product or service without notice, and advise customers to obtain the latest version of relevant information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those pertaining to warranty, patent infringement, and limitation of liability. TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in accordance with TIs standard warranty. Testing and other quality control techniques are utilized to the extent TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily performed, except those mandated by government requirements. Customers are responsible for their applications using TI components. In order to minimize risks associated with the customers applications, adequate design and operating safeguards must be provided by the customer to minimize inherent or procedural hazards. TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other intellectual property right of TI covering or relating to any combination, machine, or process in which such semiconductor products or services might be or are used. TIs publication of information regarding any third partys products or services does not constitute TIs approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

You might also like

- Extenso MetersDocument22 pagesExtenso MetersJavierNo ratings yet

- Search Codes - WazeDocument2 pagesSearch Codes - WazeJavierNo ratings yet

- tt610 PDFDocument4 pagestt610 PDFJavierNo ratings yet

- CETAVER Adhesive Tape Specifications and ApplicationsDocument1 pageCETAVER Adhesive Tape Specifications and ApplicationsJavierNo ratings yet

- SS304 304L Data SheetDocument2 pagesSS304 304L Data SheetPrakash KumarNo ratings yet

- National Instr Tutorial 3092Document4 pagesNational Instr Tutorial 3092JavierNo ratings yet

- Mentorpaper 35429Document13 pagesMentorpaper 35429JavierNo ratings yet

- Topology Planning and Routing: Dean Wiltshire, SDD Product Architect - Mentor Graphics Corporation September 2006Document9 pagesTopology Planning and Routing: Dean Wiltshire, SDD Product Architect - Mentor Graphics Corporation September 2006JavierNo ratings yet

- Loctite 235564 Do It Right Users GuideDocument44 pagesLoctite 235564 Do It Right Users GuideJavierNo ratings yet

- Texas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesDocument32 pagesTexas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesJavierNo ratings yet

- Ethernet Train Bus ArticleDocument6 pagesEthernet Train Bus ArticleJavierNo ratings yet

- Therm6.3 10211 ValidationDocument7 pagesTherm6.3 10211 ValidationJavierNo ratings yet

- Loctite 235564 Do It Right Users GuideDocument44 pagesLoctite 235564 Do It Right Users GuideJavierNo ratings yet

- Design For AssemblyDocument19 pagesDesign For AssemblyJavierNo ratings yet

- Omnicon Sneak Analysis BrochureRevA8.5x11Document2 pagesOmnicon Sneak Analysis BrochureRevA8.5x11JavierNo ratings yet

- Safety Rules and Regulations Governing LRV - Cpuc General Order 143b - California STDDocument25 pagesSafety Rules and Regulations Governing LRV - Cpuc General Order 143b - California STDJavierNo ratings yet

- LC ThesisDocument73 pagesLC ThesisJavierNo ratings yet

- IUIa GiV EnglDocument3 pagesIUIa GiV EnglJavierNo ratings yet

- Understanding Boost Power StagesDocument32 pagesUnderstanding Boost Power StagesphanioletyNo ratings yet

- Mentor Paper 52590 BGA Fanout BreakoutDocument192 pagesMentor Paper 52590 BGA Fanout BreakoutMiriam DrathNo ratings yet

- Non Latching Relay - Leach InternationalDocument2 pagesNon Latching Relay - Leach InternationalJavierNo ratings yet

- Lessons in Electric Circuits, Volume I - DCDocument560 pagesLessons in Electric Circuits, Volume I - DCyoonghmNo ratings yet

- Overvoltage Protection in Railway ABBDocument32 pagesOvervoltage Protection in Railway ABBJavierNo ratings yet

- Texas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesDocument32 pagesTexas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesJavierNo ratings yet

- Omnicon Sneak Analysis BrochureRevA8.5x11Document2 pagesOmnicon Sneak Analysis BrochureRevA8.5x11JavierNo ratings yet

- Iwnicki 01 12Document63 pagesIwnicki 01 12JavierNo ratings yet

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchJavierNo ratings yet

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchJavierNo ratings yet

- WP BScan For Designers enDocument5 pagesWP BScan For Designers enJavierNo ratings yet

- Imeko WC 2012 TC4 O18Document5 pagesImeko WC 2012 TC4 O18JavierNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- A Review of Bharat Nirman ProgrammeDocument3 pagesA Review of Bharat Nirman Programmevivek559No ratings yet

- Practice Notes FOR Quantity SurveyorsDocument7 pagesPractice Notes FOR Quantity SurveyorsYasirNo ratings yet

- AeroCRS 5.95-Premier AirlinesDocument1 pageAeroCRS 5.95-Premier AirlinesmohamedNo ratings yet

- Fmi-Hd BR PDFDocument16 pagesFmi-Hd BR PDFmin thantNo ratings yet

- 3 Axis AccelerometerDocument9 pages3 Axis AccelerometerResearchDesignLabNo ratings yet

- Chapter 3 Views in ASP - NET CoreDocument23 pagesChapter 3 Views in ASP - NET Coremohammadabusaleh628No ratings yet

- Prova ScrumDocument11 pagesProva ScrumJoanna de Cassia ValadaresNo ratings yet

- History of Titan Watch IndustryDocument46 pagesHistory of Titan Watch IndustryWasim Khan25% (4)

- Design and Construction of Water Supply SchemeDocument126 pagesDesign and Construction of Water Supply SchemeShreyansh SharmaNo ratings yet

- Hofa Iq Limiter Manual enDocument8 pagesHofa Iq Limiter Manual enDrixNo ratings yet

- Dokumen - Tips Md110-ForumDocument317 pagesDokumen - Tips Md110-ForumMiguel Ángel CoriaNo ratings yet

- Bend Steel in Steel BarDocument3 pagesBend Steel in Steel BarMir Masood ShahNo ratings yet

- Condrada v. PeopleDocument2 pagesCondrada v. PeopleGennard Michael Angelo AngelesNo ratings yet

- Digital Payments in IndiaDocument6 pagesDigital Payments in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Djiwandono, Indonesian Financial Crisis After Ten Years: Some Notes On Lessons Learned and ProspectsDocument12 pagesDjiwandono, Indonesian Financial Crisis After Ten Years: Some Notes On Lessons Learned and ProspectsMuhammad Arief Billah100% (1)

- List of Family Outing EpisodesDocument7 pagesList of Family Outing EpisodesFanny KesumaliaNo ratings yet

- January 2023: Top 10 Cited Articles in Computer Science & Information TechnologyDocument32 pagesJanuary 2023: Top 10 Cited Articles in Computer Science & Information TechnologyAnonymous Gl4IRRjzNNo ratings yet

- 12V Laptop ChargerDocument12 pages12V Laptop ChargerSharon Babu0% (1)

- 325W Bifacial Mono PERC Double Glass ModuleDocument2 pages325W Bifacial Mono PERC Double Glass ModuleJosue Enriquez EguigurenNo ratings yet

- TopGearDocument188 pagesTopGearbarborina10% (1)

- Marc Sans, Barcelona ActivaDocument17 pagesMarc Sans, Barcelona ActivaPromoting EnterpriseNo ratings yet

- SMB GistDocument7 pagesSMB GistN. R. BhartiNo ratings yet

- Soft ListDocument21 pagesSoft Listgicox89No ratings yet

- Agency Certificate of Compliance: IGHRS Update As of June 30, 2022Document2 pagesAgency Certificate of Compliance: IGHRS Update As of June 30, 2022Dacanay RexNo ratings yet

- Innovative Uses of Housing Lifting Techniques-JIARMDocument16 pagesInnovative Uses of Housing Lifting Techniques-JIARMPOOJA VNo ratings yet

- (IJCST-V4I2P61) :akshika Aneja, Garima SodhiDocument4 pages(IJCST-V4I2P61) :akshika Aneja, Garima SodhiEighthSenseGroupNo ratings yet

- Royal Harare Golf Club: An Oasis of Excellence in The Midst of Political and Economic DevastationDocument24 pagesRoyal Harare Golf Club: An Oasis of Excellence in The Midst of Political and Economic DevastationCompleatGolferNo ratings yet

- MCB, MCCB, ElcbDocument3 pagesMCB, MCCB, ElcbMonirul Islam0% (1)

- Tata MotorsDocument13 pagesTata MotorsAshwin Sood100% (3)

- 09 e 4150 C 0305 CB 1 A 37000000Document217 pages09 e 4150 C 0305 CB 1 A 37000000Dani GarnidaNo ratings yet