Professional Documents

Culture Documents

34510193

Uploaded by

gutmontOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

34510193

Uploaded by

gutmontCopyright:

Available Formats

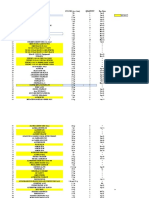

Specification for Contr. Job No.

: STORAGE TANKS TANK NUMBER: TQuantity required: Tank with fittings / fittings only / part of tank MECHANICAL DATA Contents : Flash point: C Roof construction : cone / dome / floating Fluid Class : I / II / III Floating roof, type : Internal Floating Cover m3 Gross capacity : seal : Code : Tank material : See sheet 4 Diameter : m Insulation shell/roof : yes / no thickness mm Height : m Location of fittings acc. to drawing: Climate : warm / cold / temperate / very cold FABRICATION AND INSPECTION REQUIREMENTS Construction acc. to DEP 34.51.01.31-Gen. Welding electrodes : Shell design : simple / progressive / suppliers option Welding schedule required : yes/no Tank to be extended with a windskirt : yes / no Inspection by : Hazard category : ERECTION DATA Erection required : yes / no Description of erection : acc. to DEP 64.51.01.31-Gen. FITTINGS AND MOUNTINGS PER TANK Mark Size Qty Drawing number

Location and description Shell, bottom Manhole Manhole Nozzle, inlet Nozzle, outlet Nozzle Nozzle Nozzle Centre drain for product Centre drain for water Side drain Internal gate valve Boss Name Plate with Bracket Ladder with cage Clean out door Spiral stair case Top curb angle Wind girder, top Wind girder, intermediate Holding down bolts with brackets Temperature gauge Free Vent

Remarks

Foam system Spare; with blind flange Spare; with blind flange Also applied for water

For floating roof tanks only

INFORMATION TO BE SUBMITTED WITH THE TENDER

REMARKS ON REVISIONS

Made by: Checked by: Appr. by:

EQUIPMENT : PLANT :

Rev. letter Date Sign

CONSIGNEE : Sheet No. 1 cont'd on sheet No. 2 Equipment No. Req. No.

Eng. by : Principal : DEP 34.51.01.93-Gen., June 2007

Requisition for Contr. Job No.: STORAGE TANKS - Cont. sheet FITTINGS AND MOUNTINGS PER TANK - Cont.'d Location and description Mark Size Qty Drawing number Remarks Cone/dome roof Railing around roof with / without painterbrackets Railing to centre of roof See note 1 Walkway between tanks Manhole Nozzle Nozzle Nozzle Nozzle Venting capacities in accordance Free vent with API Std. 2000 Pressure/vacuum valve Emergency venting for fire exposure Dip hatch Level gauge pole Radar level meaurement Walkway to centre of roof Skylights Centre safety point Foam nozzle Framework for safety chair Platform Dome-tank connection Tension ring Side wall Anti rotation cable connection Floating roof Supports Foam dam Shunts Rolling ladder with self-leveling treads Gauging platform Manhole, pontoon Manhole, deck, with p/v connections Guide/gauge pole-slotted Gauge well Roof drain with check valve Emergency drains Automatic bleeder valve Rim vent Dip hatch Guide/level gauge pole Description Safety Water spray Foam connections Earthing boss Earthing of floating roof REMARKS 1. 2. Safety cable to top of roof may be applied as well. Anti-slip patches to be placed on tank roof Min. water flow: 6.5 litre/min/m Sheet No. 2 cont'd on sheet No. 3 Equipment No. Req. No. Mark ACCESORIES PER TANK Size Qty Drawing number Remarks DEP 80.47.10.31-Gen. DEP 80.47.10.31-Gen. Note 2 Striker plate required

Striker plates required

Eng. by : Principal : DEP 34.51.01.93-Gen., June 2007

Requisition for Contr. Job No.: STORAGE TANKS - Cont. sheet ACCESORIES PER TANK - Cont'd Miscellaneous Level indicator Heating coil Swing pipe Extension pipe on inlet/outlet Erection key plates, etc. Electrodes (incl. 10 % spare) ENRAF Radar type

To be supplied by contractor To be supplied by contractor

SURFACE PREPARATION AND PRIMING AT MANUFACTURER'S WORKS PARTS : -External -Internal : -External -Internal Paint system No. Remarks on preparation and priming

Bottom plates

Shell plates

-Bott. rings -Lower 0.8 m -Top ring -Rest of shell

Roof sheets

: -External -Internal/underside

Roof trusses Pontoons - Interior Foam lines Stair treads Stairways, gangways, staggings, etc.

4 4

PAINTING SYSTEMS Blast clean to ISO 8501-1 grade SA 2 One layer shopprimer "Epikote" zinc primer (at workshop) Dry film thickness 30 m

Blast clean to ISO 8501-1 grade SA 2

Blast clean to ISO 8501-1 grade SA 2 One layer shopprimer type One layer One layer

Dry film thickness 30 m Dry film thickness 30 m Dry film thickness 30 m Total dry film thickness

Hot dip galvanising

Eng. by : Principal : DEP 34.51.01.93-Gen., June 2007

Sheet No. 3 cont'd on sheet No. 4 Equipment No. Req. No.

Requisition for STORAGE TANKS - Cont. sheet DESIGN DATA Description General Tank diameter Tank height Net capacity Nominal capacity Design pressure Design vacuum Design temperature Design windspeed Corrosion allowance Design density: Shell Roof Working density Aromatic content resistance Live load on roof: Floating roof / IFR Lowest position (measured at the shell) Higher position (cleaning and inspection) Highest position (cleaning and inspection)

Contr. Job No.:

m m m3 m3 mbar (ga) mbar (ga) C m/s mm kg/m3 kg/m3 kg/m3 % kN/m mm mm mm Seal at diameter of manhole

Gratings:

Description Plates Profiles Flanges Pipes Bolts/nuts Studbolts Nuts Gaskets

Material

Code

MATERIALS Inspection certificate (ISO 10474) 3.1B 2.2 3.1B 3.1B 3.1B 3.1B

Eng. by : Principal : DEP 34.51.01.93-Gen., June 2007

Sheet No. 4 Equipment No. Req. No.

You might also like

- SCR Mean - Metal - Temps For Heat Exchanger TubeDocument2 pagesSCR Mean - Metal - Temps For Heat Exchanger TubescranderiNo ratings yet

- Line Sizing ProcessDocument13 pagesLine Sizing ProcessEngr Theyji0% (1)

- API676 DatasheetDocument2 pagesAPI676 DatasheetLuvys Garcia MartinezNo ratings yet

- Ball Valves Data SheetDocument2 pagesBall Valves Data SheetJatin Vadhera VCSP100% (1)

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsDocument3 pagesSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- F.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellDocument9 pagesF.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellVINOD KAMBLENo ratings yet

- Standard Specification 3-26-2: 1. GeneralDocument2 pagesStandard Specification 3-26-2: 1. Generalhlagos123No ratings yet

- STD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureDocument27 pagesSTD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureNikunj KNo ratings yet

- 761-V-103 (Vessel With Demister), PDFDocument1 page761-V-103 (Vessel With Demister), PDFAlvin SmithNo ratings yet

- Flame ArresterDocument2 pagesFlame ArresterAariz KhanNo ratings yet

- J3X & JF3X PDFDocument2 pagesJ3X & JF3X PDFMukiara LuffyNo ratings yet

- BP Variable Catalog 09VDocument52 pagesBP Variable Catalog 09VPetros IosifidisNo ratings yet

- Flame ArresterDocument16 pagesFlame Arresteriran1362No ratings yet

- Tubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oDocument1 pageTubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oSIVANo ratings yet

- Engineering Group: Kuwait Oil Company (K.S.C.)Document14 pagesEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNo ratings yet

- MQ SP M 4015 PDFDocument25 pagesMQ SP M 4015 PDFjaseelNo ratings yet

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFDocument13 pagesComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFruponline1No ratings yet

- EGE11B21Document25 pagesEGE11B21Jhonny Rafael Blanco CauraNo ratings yet

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsNo ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- Tank Jet MixersDocument2 pagesTank Jet MixersGabriela Axinte100% (1)

- Spe 77-104 Check Valves To Bs 1868Document8 pagesSpe 77-104 Check Valves To Bs 1868zeke2611No ratings yet

- Pfaudler Din Be Reactors 1Document42 pagesPfaudler Din Be Reactors 1Nancy GarciaNo ratings yet

- Ball Valve SpecDocument35 pagesBall Valve SpecsandystaysNo ratings yet

- Burst PR Calculation PDFDocument1 pageBurst PR Calculation PDFAranga KeerthiNo ratings yet

- Standard Specification For Mechanical AgitatorsDocument11 pagesStandard Specification For Mechanical AgitatorsJITENDER KUMARNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument52 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesAsif ChougleNo ratings yet

- Piping Class - AS20Document2 pagesPiping Class - AS20Дмитрий РыбаковNo ratings yet

- Tank Storage Istanbul 2011Document53 pagesTank Storage Istanbul 2011cristinelb100% (1)

- Nom 009 Ener 2014Document12 pagesNom 009 Ener 2014Mauricio RodriguezNo ratings yet

- Tema Online Study Notes PDFDocument10 pagesTema Online Study Notes PDFumerhayatNo ratings yet

- Tech. Spec. For Heat ExchangersDocument5 pagesTech. Spec. For Heat Exchangerssanjay421No ratings yet

- V 21302 - Rev.2 CDocument133 pagesV 21302 - Rev.2 Cpandiangv100% (1)

- Ex ProtectionDocument44 pagesEx ProtectionAnil MarkaleNo ratings yet

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 pageTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1No ratings yet

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Document22 pages15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuNo ratings yet

- Gasket Paking ListDocument1 pageGasket Paking ListIrwansyah MuchtarNo ratings yet

- Pip Vessp002-2014Document9 pagesPip Vessp002-2014d-fbuser-93320248No ratings yet

- Hoja de Datos Sistema Aire Comprimido ReferencialDocument18 pagesHoja de Datos Sistema Aire Comprimido ReferencialchepeluchounNo ratings yet

- TQ - Air Fin Cooler (CS) - ModificationDocument6 pagesTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNo ratings yet

- Process Industry Practices Structural: PIP STE01100 Constructability Design GuideDocument22 pagesProcess Industry Practices Structural: PIP STE01100 Constructability Design Guideeng laythNo ratings yet

- Sizing of Expansion Tank For Hot Oil SystemDocument3 pagesSizing of Expansion Tank For Hot Oil Systemkarthick100% (1)

- Cost Air CoolersDocument1 pageCost Air CoolersSteve WanNo ratings yet

- Guide To Steam Tracing and Condensate CollectionDocument34 pagesGuide To Steam Tracing and Condensate CollectionRAMNo ratings yet

- RASCHIG-JAEGER Reactor Internals - BulletinDocument8 pagesRASCHIG-JAEGER Reactor Internals - BulletinapitbhuNo ratings yet

- Boiler Performance & Technical Data JT-K13467-E01-0Document15 pagesBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- Head Surface AeaDocument7 pagesHead Surface AeaShashi Kant KumarNo ratings yet

- Column Data Sheet Distillation Column (T-2010)Document12 pagesColumn Data Sheet Distillation Column (T-2010)John Patrick Sanay NunezNo ratings yet

- H-652 Ecc Specification For Piping Design - 01Document17 pagesH-652 Ecc Specification For Piping Design - 01vermaakash22100% (1)

- Easyheat s27 - 02 SarcoDocument8 pagesEasyheat s27 - 02 SarcoMarcelo ResckNo ratings yet

- The Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeDocument3 pagesThe Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeSrihari KodimelaNo ratings yet

- Limpet Reaction Vessel PDFDocument1 pageLimpet Reaction Vessel PDFarajamani78No ratings yet

- Storage Tank Venting CalculationDocument1 pageStorage Tank Venting Calculationام يمنى ايمنNo ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988From EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86From EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86No ratings yet

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsFrom EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsNo ratings yet

- Vertical CompressDocument47 pagesVertical CompressAskar InanNo ratings yet

- Vertical CompressDocument47 pagesVertical CompressAskar InanNo ratings yet

- Engineering Example CalculationDocument78 pagesEngineering Example Calculationkae kaeNo ratings yet

- PV Elite Heat Exchanger CalculationsDocument99 pagesPV Elite Heat Exchanger CalculationscbousmuNo ratings yet

- Full TextDocument341 pagesFull Textcevapcic100No ratings yet

- Pump Branch DesignDocument7 pagesPump Branch DesignMarcelo PerettiNo ratings yet

- Non-Circular Pressure Vessels SquareDocument27 pagesNon-Circular Pressure Vessels SquareAbhilash Kurian100% (1)

- Agitator Design: HP CalculationDocument32 pagesAgitator Design: HP CalculationJose Heli Vallejos CoronadoNo ratings yet

- Ventilation SpreadsheetDocument1 pageVentilation SpreadsheetgutmontNo ratings yet

- Demand Controlled VentilationDocument58 pagesDemand Controlled VentilationgutmontNo ratings yet

- Design For Piping Support PDFDocument138 pagesDesign For Piping Support PDFgutmontNo ratings yet

- PIP STE03360 Horizontal Vessel JUL07Document42 pagesPIP STE03360 Horizontal Vessel JUL07Nithirut Kampanya100% (4)

- Dieselfirepump DFMmetricizedversionDocument16 pagesDieselfirepump DFMmetricizedversiongutmontNo ratings yet

- Layout of Piping Systems and Process EquipmentDocument452 pagesLayout of Piping Systems and Process Equipmentjumkung67% (3)

- Standards For Duct Sizing and Duct Details 022506Document10 pagesStandards For Duct Sizing and Duct Details 022506cordells100% (2)

- Standard Design Details KapitolineDocument359 pagesStandard Design Details KapitolineMohamed100% (2)

- Pipe Sizing Charts Tables.12890822Document29 pagesPipe Sizing Charts Tables.12890822forevertay2000No ratings yet

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- Layout of Piping Systems and Process EquipmentDocument452 pagesLayout of Piping Systems and Process Equipmentjumkung67% (3)

- Heat Exchanger Mechanical Design Calculations Per ASME & TEMA - by Abdel Halim GalalaDocument136 pagesHeat Exchanger Mechanical Design Calculations Per ASME & TEMA - by Abdel Halim Galalagutmont100% (3)

- Transformer Room Ventilation CalculationDocument2 pagesTransformer Room Ventilation Calculationgutmont100% (9)

- Static Cal 8m Dia CR Tank r2Document22 pagesStatic Cal 8m Dia CR Tank r2rahul_anil100% (1)

- 6314 Henderson NV MechanicalDocument10 pages6314 Henderson NV MechanicalgutmontNo ratings yet

- Nuclear Power Corporation of India LTD (Npcil) Kakarapara Atomic Power Project - Units 3&4Document6 pagesNuclear Power Corporation of India LTD (Npcil) Kakarapara Atomic Power Project - Units 3&4gutmontNo ratings yet

- Stairwell & Lift Pressurization CalculationsDocument31 pagesStairwell & Lift Pressurization CalculationsAneng2890% (10)

- Dewpoint in Compressed Air FAQDocument4 pagesDewpoint in Compressed Air FAQamirthalingam_b671No ratings yet

- M-2-3 Hangers and SupportsDocument214 pagesM-2-3 Hangers and SupportsSeungmin PaekNo ratings yet

- Discharge PR Drop Pipe SizeDocument5 pagesDischarge PR Drop Pipe SizeAvinash VasudeoNo ratings yet

- Ashrae D 21513 20100324Document226 pagesAshrae D 21513 20100324Hristina Stanojkovska25% (4)

- Standards For Duct Sizing and Duct Details 022506Document10 pagesStandards For Duct Sizing and Duct Details 022506cordells100% (2)

- Lipids: Fats, Oils, Steroids and Their ImportanceDocument3 pagesLipids: Fats, Oils, Steroids and Their ImportanceEvangeline Galac AbrilNo ratings yet

- VCE BIOLOGY UnitDocument24 pagesVCE BIOLOGY Unitjess_heathNo ratings yet

- Infrome NDocument15 pagesInfrome NJose Miguel Solano RiveraNo ratings yet

- Fundamentals of Gas-Liquid-Solid FluidizationDocument34 pagesFundamentals of Gas-Liquid-Solid Fluidizationfaisal58650100% (1)

- PESSI Tenders Medicines Interferon SyringesDocument77 pagesPESSI Tenders Medicines Interferon SyringesAsim IdreesNo ratings yet

- Corrugated Box: Prepared by Sneha A. Chavan Department of Pharmaceutics M Pharm !ST Year II SemesterDocument29 pagesCorrugated Box: Prepared by Sneha A. Chavan Department of Pharmaceutics M Pharm !ST Year II SemesterPreetha PalaniswamyNo ratings yet

- O-Rings - & - Seals - Metric O-Ring & Retaining RingDocument1 pageO-Rings - & - Seals - Metric O-Ring & Retaining RingRoberto MardonesNo ratings yet

- The Rammelsberg Massive Sulphide Cu-Zn-Pb-BaDocument17 pagesThe Rammelsberg Massive Sulphide Cu-Zn-Pb-Badayyoos56No ratings yet

- High-strength heat resistant cement groutDocument4 pagesHigh-strength heat resistant cement groutSHAIK ASIMUDDINNo ratings yet

- KAP 3002 Chemical Safety Chater 1bDocument37 pagesKAP 3002 Chemical Safety Chater 1bSyahirah MisarihNo ratings yet

- Combined CyclesDocument17 pagesCombined CyclesMuhammad HarisNo ratings yet

- Naming and Writing Formulae of Coordination Compounds - HandoutsDocument11 pagesNaming and Writing Formulae of Coordination Compounds - HandoutsJayr SibayanNo ratings yet

- LouversDocument22 pagesLouversTareq AbdellatifNo ratings yet

- Detect Concrete Corrosion with Hammer TestsDocument50 pagesDetect Concrete Corrosion with Hammer TestsSumit Singh ThakurNo ratings yet

- Photosynthesis and RespirationDocument4 pagesPhotosynthesis and RespirationChristian BaleNo ratings yet

- Acetic AnhydrideDocument1 pageAcetic AnhydrideCarlos Vargas de MontoyaNo ratings yet

- Edexcel Intl A Levels Biology Unit 3 Wbi13 v1Document6 pagesEdexcel Intl A Levels Biology Unit 3 Wbi13 v1seif nimer100% (1)

- WCH06 01 Que 20180125Document16 pagesWCH06 01 Que 20180125Yuan XintongNo ratings yet

- Chemical Stock UpdatedDocument21 pagesChemical Stock UpdatedPraise and worshipNo ratings yet

- (Open Drugs) A Complete MDMA Synthesis For The First Time ChemistDocument13 pages(Open Drugs) A Complete MDMA Synthesis For The First Time Chemistfelipecam586% (7)

- Year 10 Chemistry Revision Schedule BookletDocument8 pagesYear 10 Chemistry Revision Schedule BookletDermot ChuckNo ratings yet

- Norox Mekp-925hDocument2 pagesNorox Mekp-925hEngTamerNo ratings yet

- Polarity and Intermolecular Forces Lab SheetDocument9 pagesPolarity and Intermolecular Forces Lab SheetLama AshiNo ratings yet

- HCL (Carlroth) PDFDocument16 pagesHCL (Carlroth) PDFMinjdeDiosNo ratings yet

- Null 1Document26 pagesNull 1Peter MukunzaNo ratings yet

- DUROXYN EF 900 60X - EN - LetterDocument2 pagesDUROXYN EF 900 60X - EN - LetterFabio Enrique Gomez RamirezNo ratings yet

- ThermodynamicsDocument30 pagesThermodynamicsNeha Kaur SinhaNo ratings yet

- 852XDocument4 pages852XAlp PalaNo ratings yet

- Low Temperature Cure Strategies For Powder Coatings - IndiaDocument12 pagesLow Temperature Cure Strategies For Powder Coatings - IndiawolfkynNo ratings yet

- Cobalt-Chromium AlloysDocument1 pageCobalt-Chromium AlloysPinto PintoNo ratings yet