Professional Documents

Culture Documents

Research Paper

Uploaded by

Bharat ParasharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Research Paper

Uploaded by

Bharat ParasharCopyright:

Available Formats

Research J. Pharm. and Tech.

5(4): April 2012

ISSN 0974-3618 REVIEW ARTICLE

www.rjptonline.org

An Overview on Superdisintegrants

Department of Pharmaceutics, Manav Bharti University, Village - Laddo, P.O.- Sultanpur (Kumhar Hatti), Tehsil & Distt. Solan -173229 Himachal Pradesh. *Corresponding Author E-mail: uday7992@gmail.com

U. B. Mahajan*, Dr. Bharat Prashar.

ABSTRACT:

An oral solid dosage form should ideally disperse into the primary particles from which it was prepared. Tablets and capsules which need rapid disintegration, the inclusion of the right disintegrant is a prerequisite for optimal bioavailability. Superdisintegrants are used to improve the efficacy of solid dosage forms. This is achieved by decreasing the disintegration time which in turn enhances drug dissolution rate. Disintegrants are substances or mixture of substances added the drug formulation that facilitates the breakup or disintegration of tablet or capsule content into smaller particles that dissolve more rapidly than in the absence of disintegrants. Superdisintegrants are generally used at a low level in the solid dosage form, typically 1- 10 % by weight relative to the total weight of the dosage unit. The present study comprises the various kinds of superdisintegrants which are being used in the formulation to provide the safer, effective drug delivery with patient's compliance.

KEYWORDS: Superdisintegrants, polyplasdone, polymers.

The disintegrants have the major function to oppose the efficiency of the tablet binder and the physical forces that act under compression to form the tablet. The stronger the binder, the more effective must be the disintegrating agents in order for the tablet to release its medication. Ideally, it should cause the tablet to disrupt, not only into the granules from which it was compressed, but also into powder particles from which the granulation was prepared. Disintegrants are an essential component to tablet formulations. The ability to interact strongly with water is essential to disintegrant function. Combinations of swelling and/or wicking and/or deformation are the mechanisms of disintegrant action. Disintegrants are agents added to tablet and some encapsulated formulations to promote the breakup of the tablet and capsule slugs into smaller fragments in an aqueous environment there by increasing the available surface area and promoting a more rapid release of the drug substance. They promote moisture penetration and dispersion of the tablet matrix.

INTRODUCTION:

Tablet is the most popular among all dosage forms existing today because of its convenience of self administration, compactness and easy manufacturing; however hand tremors, dysphasia in case of geriatric patients, the underdeveloped muscular and nervous systems in young individuals and h case of uncooperative patients, the problem of swallowing is common phenomenon which leads to poor patient compliance. To overcome these drawbacks, mouth dissolving tablets (MDT) or orally disintegrating tablets; (ODT) has emerged as alternative oral dosage forms. These are novel types; of tablets that disintegrate/dissolve/ disperse in saliva within few seconds. According to European Pharmacopoeia, the ODT should disperse/disintegrate in less than three minutes. The basic approach used in development of MDT is the use of superdisintegrants like Cross linked carboxymelhylcellulose (Croscarmeliose), Sodium starch glycolate (Primogel, Explotab), Polyvinylpyrrolidone (Polyplasdone) etc. which provide instantaneous disintegration of tablet after putting on tongue, thereby releasing the drug in saliva. The bioavailability of some drugs may be increased due to absorption of drugs in oral cavity and also due to pregastric absorption of saliva containing dispersed drugs that pass down into the stomach. Moreover, the amount of drug that is subject to first pass metabolism is reduced as compared to standard tablets(1-3). Disintegrants are substances or mixture of substances added the drug formulation that facilitate the breakup or

Received on 05.12.2011 Accepted on 14.01.2012

Research J. Pharm. and Tech. 5(4): April 2012; Page 466-473

Modified on 23.12.2011 RJPT All right reserved

466

Research J. Pharm. and Tech. 5(4): April 2012

Swelling: Although not all effective disintegrants swell in contact with water, swelling is believed to be a mechanism in which certain disintegrating agents (such as starch) impart the Tablet disintegration has received considerable attention as disintegrating effect. By swelling in contact with water, the an essential step in obtaining fast drug release. The adhesiveness of other ingredients in a tablet is overcome emphasis on the availability of drug highlights the causing the tablet to fall apart. importance of the relatively rapid disintegration of a tablet as a criterion for ensuring uninhibited drug dissolution Porosity and Capillary Action (Wicking): behavior. Number of factors affects the disintegration Effective disintegrants that do not swell are believed to behavior of tablets. The development of fast dissolving or impart their disintegrating action through porosity and disintegrating tablets provides an opportunity to take an capillary action. Tablet porosity provides pathways for the account of tablet disintegrants. Recently new materials penetration of fluid into tablets. The disintegrant particles termed as superdisintegrant have been developed to (with low cohesiveness & compressibility) themselves act improve the disintegration processes. Selecting appropriate to enhance porosity and provide these pathways into the formulation excipients and manufacturing technology can tablet. Liquid is drawn up or wicked into these pathways obtain the design feature of fast disintegrating tablet. The through capillary action and rupture the interparticulate disintegrants have the major function to appose the bonds causing the tablet to break apart. efficiency of the tablet binder and the physical forces that act under compression to form the tablet. The stronger the Deformation: binder, the more effective must be the disintegrating agents Starch grains are generally thought to be elastic in nature in order for the tablet to release its medication. Ideally, it meaning that grains that are deformed under pressure will should cause the tablet to disrupt, not only into the granules return to their original shape when that pressure is removed. from which it was compressed, but also into powder But, with the compression forces involved in tableting, these grains are believed to be deformed more permanently particles from which the granulation was prepared. and are said to be energy rich with this energy being released upon exposure to water. In other words, the ability Method of addition of disintegrants: The requirement placed on the tablet disintegrant should be for starch to swell is higher in energy rich starch grains than it is for starch grains that have not been deformed clearly defined. The ideal disintegrant hasunder pressure. It is believed that no single mechanism is 1. Poor solubility responsible for the action of most disintegrants. But rather, 2. Poor gel formation it is more likely the result of inter-relationships between 3. Good hydration capacity these major mechanisms. 4. Good molding and flow properties 5. No tendency to form complexes with the drugs Disintegrants are essentially added to tablet granulation for Due to disintegrating particle/particle repulsive causing the compressed tablet to break or disintegrate when forces: Another mechanism of disintegration attempts to explain placed in aqueous environment. There are two methods of incorporating disintegrating the swelling of tablet made with non swellable disintegrants. Guyot-Hermann has proposed a particle agents into the tablet: repulsion theory based on the observation that non swelling Internal Addition (Intragranular) External Addition (Extragranular) particle also cause disintegration of tablets. The electric repulsive forces between particles are the mechanism of Partly Internal and External disintegration and water is required for it. Researchers In external addition method, the disintegrant is added to the found that repulsion is secondary to wicking38. sized granulation with mixing prior to compression. In Internal addition method, the disintegrant is mixed with Factors affecting action of disintegrants (6,7) Percentage of disintegrants present in the tablets. other powders before wetting the powder mixtures with the Types of substances present in the tablets. granulating fluid. Thus the disintegrant is incorporated within the granules. When these methods are used, part of Combination of disintegrants. disintegrant can be added internally and part externally. Presence of surfactants. This provides immediate disruption of the tablet into Hardness of the tablets. previously compressed granules while the disintegrating Nature of Drug substances. agent within the granules produces further erosion of the Mixing and Screening. granules to the original powder particles. The two step

disintegration of tablet or capsule content into smaller particles that dissolve more rapidly than in the absence of disintegrants(4,5). Superdisintegrants are generally used at a low level in the solid dosage form, typically 1 10 % by weight relative to the total weight of the dosage unit. Examples of superdisintegrants are crosscarmelose, crosspovidone, sodium starch glycolate which represent example of a crosslinked cellulose, crosslinked polymer and a crosslinked starch respectively.

method usually produces better and more complete disintegration than the usual method of adding the disintegrant to the granulation surface only. Mechanism of tablet disintegration

467

Research J. Pharm. and Tech. 5(4): April 2012

Disintegants used in tabletting Starch Starch is the oldest and probably the most widely used disintegrant in the pharmaceutical industry. Regular cornstarch USP, has certain limitation and has been replaced to some extent by modified starches with specialized characteristics to serve specific functions. The mode of action of starch is that the disintegrant forms pathways throughout the tablet matrix that enable water to draw into the structure by capillary action, thus leading to disruption of tablet. Other concept relates to swelling of starch grains on exposure to water, a phenomenon that physically ruptures the particle particle bonding in tablet matrix. Choudhary et al (8) reported that pregelatinized starch is a modified starch prepared from potato starch and is used in piroxicam dispersible tablets. Different proportion of drug and disintegrants as in the ratio 1: 1, 1: 3, 1:9, were used to prepare dispersion. All the tablets disintegrated within 3 minutes. The possible mechanism responsible for increased dissolution rate from this tablet is rapid disintegration due to superior swelling capacity of pregelatinised starch. 2. Sodium Starch Glycolate ( Explotab and Primogel) These are modified starches with dramatic disintegrating properties and are available as explotab and primogel which are low substituted carboxy methyl starches. Explotab consisting of granules that absorb water rapidly and swell. The mechanism by which this action takes place involve rapid absorption of water leading to an enormous increase in volume of granules result in rapid and uniform disintegration. The natural predried starches swell in water to the extent of 10-20 percent and the modified starches increase in volume by 200-300 percent in water. This modified starch is that the disintegration time may be independent of compression force. (9)

was studied by Zhang et al. (12) The significantly faster antigen release rate and reduced time need for breaking the film due to the swelling force generated by incorporation of sodium starch glycolate in the beads. Sodium starch glycolate has outstanding water wicking capacity and good swelling property as observed in case of enteric coated antigen micro spheres. Zhao N and Augsburger LL (13) have investigated the efficiency of superdisintegrants in promoting tablet disintegration and drug dissolution under varied media pH. Significant reductions in the rate and extent of water uptake and swelling were observed for both sodium starch glycolate (Primojel) and croscarmellose sodium (Ac-DiSol) in an acidic medium (0.1 N HCl) 3. Cross-linked polyvinyl Pyrrolidone (Cross Povidone) Kornblurn et al (14) has reported the cross linked polyvinyl pyrrolidone and evaluated as tablet disintegrants and compared to starch USP and alginic acid. The capillary activity of cross povidone for water is responsible for its tablet disintegration property. Cross linked PVP has maximum moisture absorption and hydration capacity and can be considered for the selection of new disintegrant. They possess apparent binding property resulting in low percent of tablet friability, where it is employed as disintegrant even in low concentration 0.5 to 5 percent. Alesandro et al (15) formulated fast dissolving composition of ibuprofen tablet by using 0.5 10 % linear polyvinyl pyrrolidone with respect to ibuprofen. The tablet was completely in solution in 10 minutes.

The basic approach used in the development of the fastdissolving tablet is the use of superdisintegrants. Croscarmellose sodium, sodium starch glycolate, and crospovidone were screened in the present study, and on the basis of the results obtained in the preliminary screening studies, the batch containing crospovidone showed the The primogel and other disintegrants such as cross fastest disintegration.39 carmellose sodium, cross povidone and potato starch were used as super disintegrant and the effect of these on the Polyplasdone crospovidones dissolution rate of sparfloxacin tablet has been studied by Polyplasdone XL choudhary et al. (10) Polyplasdone XL 10 Unlike other superdisintegrants, which rely principally on swelling for disintegration, Polyplasdone disintegrants use a combination of mechanisms to provide rapid disintegration. Although Polyplasdone polymers swell by 95% to 120% upon contact with water, swelling is not the only mechanism for tablet disintegration. Swelling or swell volume is mainly a measure of the change in volume of the disintegrant after it is introduced to an aqueous solution and the system has reached equilibrium. However, swell volume does not measure the rate at which a disintegrant absorbs water and swells or the pressure generated by swelling. Polyplasdone polymers, with their porous particle morphology (Figures 2 and 3), rapidly absorb water (wicking) via capillary action. In addition, during tablet compaction, the highly compressible Polyplasdone particles become extremely deformed.

The tablets formulated by using these disintegrants were disintegrated within two minutes. The higher dissolution rates observed with superdisintegrants may be due to rapid disintegration and fine dispersion of particles formed after disintegration. Sallem et al (11) had studied the effect of four disintegrants on the dissolution of Terfenamide tablet containing the gas evolving disintegrant, CaCo3 . The four disintegrants improved disintegration and dissolution of the original formulation and their relative efficiency of improvement was in order of cross povidone> Ac-di-sol> Primogel> low substituted HPC. The fast disintegrants used were characterized by good hydration capacity. Cross povidone and primogel are known for their strong hydration capacities compared to the other fast disintegrants. The sodium starch glycolate was incorporated as a super disintegrant in the enteric coated antigen micro spheres and

468

Research J. Pharm. and Tech. 5(4): April 2012

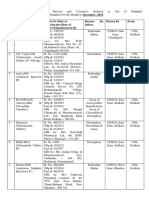

Product name Polyplasdone XL Polyplasdone XL-10

Typical Average Particle Size ( m) 110-140 25-40

Typical Surface Area (m2/g) 0.7 1.4

Bulk Density (g/cm3) 0.3 0.3

Tap Density (g/cm3) 0.4 0.5

As the deformed Polyplasdone particles come in contact with water that is wicked into the tablet, the Polyplasdone particles recover their normal structure and then swell, resulting in rapid volume expansion and high hydrostatic pressures that cause tablet disintegration.

Polyplasdone disintegrants are highly compressible, thus they are ideally suited for use with poorly compressible drug actives and in direct compression tablet processes. As Polyplasdone polymers are non-ionic, they will not form complexes with ionic drug actives that would slow drug release. Recent data show Polyplasdone disintegrants provide fastest dissolution with cationic drug actives in a model tablet formulation. 35 Polyplasdone XL-10 disintegrant is well suited for orally disintegrating and chewable tablet formulations. It provides rapid disintegration, smooth mouth feel and high tablet breaking force with low friability. 36 With poorly soluble drugs, Polyplasdone XL-10 crospovidone increases the rate and extent of dissolution. 37

4. Alginates Alginates are hydrophilic colloidal substances extracted from certain species of Kelp. Chemically they are available as alginic acid or salt of salt of alginic acid. Alginic acid is a polymer derived from seaweeds comprising Dmannuronic and L-glucoronic units. Its affinity for water Figure 2: Polyplasdone XL crospovidone particles are absorption and high sorption capacity make it an excellent porous and granular to enhance wicking of liquid into the disintegrant. It can be successfully used with ascorbic acid, particle multivitamins formulation. 5. Cellulose Cellulose such as purified cellulose, methylcellulose, crosslinked sodium carboxy methylcellulose (Ac-Di-Sol) and carboxy methyl cellulose are disintegrants to some extent depending on their ability to swell on contact with water. A crosslinked form of Ac-Di-Sol has been accepted as tablet disintegrant and it is essentially water insoluble. It has high affinity for water, which results in rapid tablet disintegration. (23) Botzolakis et al (16) have studied the wicking and swelling properties of pure disintegrants from plugs prepared under condition similar to those used in encapsulation of powder mixture into hard gelatin capsules. Use of Ac-Di-Sol exhibited the greatest wicking and swelling action followed by primogel and corn starch. The swelling property of pure disintegrant correlated best with the swelling of formulation mixtures and the efficiency of these materials in enhancing the dissolution of drug. Drug dissolution from the encapsulated dosage form can be improved significantly with the addition of disintegrating agents into the formulation. The efficiency of disintegrant employed, the nature of the matrix and the lubricant level. Augsburger et al (17) had shown the mechanism of action of disintegrants such as Ac-Di-Sol primogel, polyplasdone XL-10 and corn starch by rapid liquid absorption and swelling of disintegrant particles which fills the void spaces and cause the compact to disintegrate rapidly. Disintegrants,

Figure 3: Polyplasdone XL-10 crospovidone particles are smaller, but also porous and granular Applications Polyplasdone XL and XL-10 polymers provide rapid disintegration in oral solid dosage formulations. With its unique particle morphology, Polyplasdone crospovidone is the disintegrant of choice in the following applications: In wet granulation tablet processes, Polyplasdone XL-10 polymer, with its small average particle size, is highly effective at rapid disintegration when used intragranularly.

469

Research J. Pharm. and Tech. 5(4): April 2012

however, varied widely in their wicking and swelling properties and minimum concentration of disintegrant is necessary to produce primary particles upon disintegration and effectively improve drug dissolution. This study was thus designed to examine the behavior of disintegrant in their pure state and in hard gelatin capsule formulations. The intrinsic ability of disintegrant to absorb water and swelling was measured. Jagdish Singh (18) included a new range of sodium carboxymethyl cellulose (Nymzel types ZSB-10, ZSB16, ZSB-18) into Lorazepam tablet formulations to improve the disintegration, dissolution and bioavilability of drug. Sodium carboxy methylcellulose containing tablet disintegrated within 30 seconds. Bi et al (19) reported a rapidly disintegrating tablet with sufficient mechanical integrity as well as pleasant taste using cross-linked sodium carboxy methyl cellulose (AcDi-Sol) and tablettose. Ac-Di-Sol was one of the super disintegrant and has excellent disintegrant ability. It swells to a large extent when it comes in contact with water to disintegrate tablets and has fibrous nature that allows intraparticulate and extra particulate wicking of water even at low concentration level. Cousin et al, (20) formulated rapidly disintegrable multiparticular tablets containing carboxymethyl cellulose as a disintegrating agent and one swelling agent consisting of modified starch or microcrystalline cellulose. The tablets were disintegrated in the mouth in less than 60 seconds. 6. Microcrystalline Cellulose (Avicel pH -101, pH - 102, pH 105) Avicel exhibit very good disintegrant property when present in as low as 10 percent. It functions by allowing water to enter the tablet matrix by means of capillary pores, which break the hydrogen bonding between adjacent bundles of cellulose microcrystals. Tablets with excess avicel have a tendency to stick to the tongue due to rapid capillary absorption and dehydrating the most surface. Avicel has a fast wicking rate for water, hence this and starch makes an excellent combination for effective and rapid disintegration in tablet formulation (9) To develop a rapidly disintegrating tablet, a mixture of MCC and L-HPC was in the range of 8:2 9:1 shown shortest disintegration time.

8: 2 9: 1 resulted in tablets with shortest disintegration time. Chaudhary et al (24) had formulated and evaluated dispersible tablets of poorly soluble drugs using MCC (pH 105) and potato starch. Higher dissolution rate were observed in tablets as compared to the dissolution rate of conventional tablets. 7. Ambrelite IPR 88 (Ion Exchange Resins) Ion exchange resin has ability to swell in the presence of water. When used as a disintegrant care must be taken that many resins have the ability to absorb drug particles. Anionic and Cationic resins have been used to absorb substances and release them when the charge changes.(9) 8. Gums Gums have been used as disintegrants because of their tendency to swell in water. They can display good binding characteristics (1 to 10 percent of tablet weight). This property can oppose the desired property of assisting disintegration and the amount of gum must be carefully titrated to determine the optimum level for the tablet. Common gums used as disintegrant include agar, locust bean, karaya, Pectin and tragacanth. Blank et al(25) described pharmaceutical dosage form which disintegrates rapidly in water, within 10 seconds, having an open matrix network structure comprised of mannitol and natural gum can be used particularly for oral administration to pediatric and geriatric patient. 9. Guar Gums It is naturally occurring gum (marketed under the trade name jaguar). It is free flowing, completely soluble, neutral polymer composed of sugar units and is approved for use in food. It is not sensitive to pH, moisture contents or solubility of the tablet matrix. It is not always pure white and sometimes varies in color from off-white to tan tends to discolor with time in alkaline tablets .(9)

10. Gum Karaya Karaya has the natural gum exudates from the traces of Sterculia urens belonging to family sterculiacea. Chemically the gum has an anionic polysaccharide, containing 43%. D-galacturonic acid, 13% D-galactose and MCC was used as disintegrating agent in the formulation of 15 percent L-rhamnose. The high viscosity nature of gum fast releasing compressed propranol hydrochloride limits its uses as binder and disintegrant in the development suppositories as reported by Malladi et al (21). The of conventional dosage form. concentration of MCC Shows faster drug release from suppository and evaluated their pharmacokinetics and Mohan Babu et al (26) has been reported the modified gum pharmacodynamics performance and compared the result karaya (Mgk) prepared from gum karaya (GK) by heat obtained with oral administration. treatment can be used as disintegrant (because of low viscosity). The viscosity and volatile acetyl value of Mg k Bi et al (22) and Watanabe et al (23) used microcrystalline was markedly less than GK. The formulation containing cellulose and Low substituted hydroxy propyl cellulose (L- Mgk absorb water readily, disintegrates and dissolves HPC) as disintegrants to prepare rapidly disintegrating rapidly due to its low viscosity and high swelling tablets. Ratio of the MCC and L- HPC was in the range of properties.

470

Research J. Pharm. and Tech. 5(4): April 2012

14. Isapghula Husk It is a natural substance as disintegrant. It consists of dried seeds of the plant known as plantago ovata. It contains mucilage which is present in the epidermis of the seeds. The mucilage is used as binding agent in the granulation of material for compressed tablets. Plantago ovata seeds husk has high swellability and gives uniform and slightly viscous Tablets containing Chitosan shows faster disintegration, solution hence it is used as thickening and suspending greater dissolution and are slightly softer than those agent. containing Chitin. An increment in concentration of these polymers causes markedly faster disintegration and better Gupta G.D. et al (30) has investigated the disintegrating dissolution. Tablet containing seven percent Chitosan property of the Isapghula husk, Cassia tora and Cassia disintegrate within one minute which was much faster than nodosa and the formulations were evaluated for the those containing sodium starch glycolate and cross standard of dispersible tablets and were compared with carmellose sodium. Moisture sorption and water uptake was marketed products. The study shown that the natural gums found the major mechanism of disintegration while used as disintegrants were effective in low (5%) dissolution related to swelling capacity. concentrations. Chitin and Chitosan as disintegrant in paracetamol tablets were evaluated and compared with four commonly used disintegrants such as corn starch, sodium starch glycolate, methyl cellulose and cross Carmellose sodium, reported by Ritthidet et al. (27) 12. Smecta Smecta is a clay mostly composed of smectile, a non fibrous Attapulgite, belonging to the family montomorillonite. Its layered leaf like structure consist of aluminium and octahydral layers sandwiched between tow tetrahydral silica layers. Smecta has a large specific area and high affinity for water. Smecta was found more adsorptive than other antdiarrheal clays, as fibrous attapulgite and kaolin. Smecta is evaluated as disintegrant in tablet made by compression and by wet granulation using lactose, dicalcium phosphate as water soluble and water insoluble fillers. An inorganic clay, magnesium aluminum silicate (Veegum), modified starch, Ac-di-sol and cross linked PVP as a disintegrants evaluated by Bhargava etal (28). Smecta performed well as a disintegrant in tablet superior to Veegum and starch, but inferior to Ac-di-sol and cross linked PVP. 13. Gellan Gum Gellan gum is a linear anionic polysaccharide, biodegradable polymer obtained from Pseudomonos elodea consisting of a linear tetrasaccharide repeat structure and use as a food additive. Antony et al (29) studied the Gellan gum as a disintegrant and the efficiency of gum was compared with other conventional disintegrants such as dried corn starch, explotab, avicel (pH 102), Ac-di-sol. And Kollidon CL. The disintegration of tablet might be due to the instantaneous swelling characteristics of gellan gum when it comes into contact with water and owing to its high hydrophilic nature. The complete disintegration of tablet was observed within 4 minutes with gellan gum concentration of 4 percent w/w and 90 percent of drug dissolved within 23 minutes. Ac-di-sol and Kollidone CL 15. Polacrillin Potassium (Tulsion 339) Tulsion (339) is a resin consisting of highly purified crosslinked polacrillin copolymer in potassium form. It is used as a tablet disintegrant and as a taste-masking agent for various drugs. When Tulsion-339 is used as disintegrant, it swells up at very fast rate upon contact with water or gastro intestinal fluid and act as an effective tablet disintegrant. It is to be added in a dry form in the proportion of 0. 5 to 5% of the total weight of tablet, amount may vary depending upon nature of tablet. Polacrillin Potassium is high molecular weight polymer so can't be absorbed by body tissues & is safe for human consumption. It has no any physiological action at recommended dosage & it is non-toxic. Specific features of Tulsion-339 as a disintegrant: Faster rate of swelling. No lump formation after disintegration / dispersion. High compatibility. With excipitients and common therapeutic agent. Does not stick to punches and clays. 16. Agar (31, 32) Agar is the dried gelatinous substance obtained from Gelidium Amansii (Gelidanceae) and several other species of red algae like, Gracilaria (Gracilariaceae) and Pterocadia (Gelidaceae). Agar is yellowish gray or white to nearly colorless, odorless with mucilaginous taste and is available in the form of strips, sheet flakes or coarse powder. Agar consists of two polysaccharides as agarose and agaropectin. Agarose is responsible for gel strength and Agaropectin is responsible for the viscosity of agar solutions. High gel strength of agar make it a potential candidate as a disintegrant.

11. Chitin and Chitosan These are obtained from marine sources. Chitin a structural constituents in the sheels of crutacean and insect has an acylated polyamine, which is biodegradable and non toxic. It is the most abundant natural polymer after cellulose.

showed very similar pattern of disintegration and in vitro dissolution rates. With the same concentration tablet made with starch showed 220 minutes. From this result gellan gum has proved itself as a superior disintegrant.

471

Research J. Pharm. and Tech. 5(4): April 2012

Application of various commercially used combinations of modified cellulose/starch used in odts Superdisintegrant and Disintegrants Applications Brand Common Name Classification Functional Properties Name Category CLCrospovidone Kollidon Ac-DiSol Croscarmellose Sodium Explotab Sodium starch Primojel glycolate Explotab Sodium starch V17 glycolate Explotab Sodium starch CLV glycolate L-HPC Hydroxypropyl cellulose(low substituted) Starch Starch, 1500 Pre-gelatinized Avicel Microcrystalline cellulose Polyvinyl-pyrrolidone Cellulose, carboxy-methyl ether, sodium salt crosslinked Sodium carboxymethyl starch Tablet super disintegrant Tablet and capsule disintegrant

Tablet and capsule super disintegrant (Cross linked substituted Carboxy- Super methyl ether) sodium disintegrant carboxymethyl starch (Cross linked low substituted Super Carboxy-methyl ether) Sodium disintegrant carboxymethyl starch Cellulose, 2-hydroxypropyl Tablet and ether capsule super disintegrant Pregelatinized Diluent , binder starch and disintegrant Cellulose Tablet & capsule diluent, Tablet disintegrant

Swelling (18% in 10s), (45% in 20s) Wicking and 88% swelling (12% in 10s), (23% in 20s) Swelling capacity -----(300 times) More swelling than Explotab Swelling Swelling (13% in 10s), (50% in 20s) Hygroscopic Hygroscopic, swelling(12% in 10s), (18% in 20s) ----------37% 22% 18%

EMC at 25C/ 90%RH 62%

Typical Uses Disintegrant (Dry and Wet granulation) Disintegrant for capsules, tablets and granules Disintegrant (Dry and Wet granulation) Disintegration & dissolution aid. Not for use in wet Granulation Use in wet granulation and high shear equipment Disintegrant and Binder in wet granulation Binder/diluent & disintegrant Binder/diluent, lubricant and disintegrant

Ito et al (33) investigated the use of agar powder as a disintegrating agent for the development of rapidly disintegrating oral tablets. Agar was chosen because it absorbs water and swell significantly but do not become gelatinous in water at physiological temperature. 17. Gas Evolving disintegrants Another approach for the disintegration of tablet is inclusion of citric acid and tartaric acid along with the sodium bicarbonate, sodium carbonate, potassium bicarbonate or calcium carbonate. These react in contact with water to liberate carbon dioxide that disrupts the tablet. Onali et al (34) described the process of making rapidly disintegrating tablets. The tablets consisting of malic acid or effervescence base, calcium carbonate as an active ingredient (antacid) and cornstarch as a bulking agent and disintegrating agent. The tablets prepared from these ingredients disintegrated within 20 second. Categories of drugs in which the superdisintegrants are used :Analgesics and Anti-inflammatory Agents, Anthelmintics, Anti-Arrhythmic Agents, Anti-bacterial Agents, Anticoagulants, Anti-Epileptics, Anti-Fungal Agents, Anti-Gout Agents, Anti-Hypertensive Agents, Anti-Malarials, AntiMuscarinic Agents, Anti-Neoplastic Agents And Immunosuppressants, Anti Protozoal Agents, Anti-Thyroid Agents, Anxiolytic, Sedatives, Hypnotics And Neuroleptics, Tj-Blockers, Cardiac Inotropic Agents, Corticosteroids, Diuretics, Anti-Parkinsonian Agents, Gastro-Intestinal Agents, Histamine H,-Receptor Antagonists, Lipid Regulating Agents, Local Anaesthetics, Neuro -Muscular

Agents, Nitrates And Other Anti-Anginal Agents, Nutritional Agents, Opioid Analgesics, Oral Vaccines, Proteins, Peptides And Recombinant Drugs, Sex Hormones, Stimulants. Tablet disintegration has received considerable attention as an essential step in obtaining fast drug release. Disintegration remains a powerful influence and precursor for drug absorption. Disintegration of tablet or capsule is depending upon the type and quantity of disintegrants. The development of fast dissolving or disintegrating tablets provides an opportunity to take an account of tablet disintegrants. Therefore, there is a huge potential for the evaluation of new disintegrants or modification of an existing disintegrants into superdisintegrants, so as to formulate fast dissolving dosage form.

CONCLUSION:

REFERENCES:

1. 2. 3. 4. 5. 6. 7. 8.

Habib, W., Khankari, R., Hontz, J., Fast-dissolving drug delivery systems, critical review in therapeutics, Drug Carrier Systems, 2000, 17(1):61- 72. Chang, R., Guo, X., Burnside, B. A. , Couch, R., Fast-dissolving tablets, Pharm. Tech., 2000, 24(6):52-58. Dobetti, L., Fast-Melting Tablets: Developments and Technologies, Pharm. Tech., (Suppl.),2001, 44-50. Handbook of Pharmaceutical excipients , Ainley Wade and Paul J. Wedder eds, 2nd Ed, 1994 Grasono Alesandro et al, US Patent 6,197,336 2001 Schimidt P.C. and Brogramann B., Acta. Pharm. Technol,1988 (34), 22. Cohen Y., and Lach J.L., J. Pharm. Sci., (52)122, 1963 Chaudhari K.P.R, Rao Rama N., Indian Drugs, Vol 35 (6), 368 to 371, 1988.

472

Research J. Pharm. and Tech. 5(4): April 2012 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. Liberman H.A., Lachman L. and Schawstr J.B., Pharmaceutical Dosage forms, tablets, vol 2, 1989, 173-177 Chudhari K. P.R., & Radhika, Int. J. Pharm. Excipts, 2000 (4), 181-184 Sallem E., Ibrahim H., Dahab R. A., Drug Dev. Ind. Pharm., 1998, Vol 24 (6), 501-507 Ihang J. A., & Christensen J. M., Drug Dev Ind Pharn, 1996, Vol 22 (8), 833-839 Zhao N, Augsburger LL. AAPS PharmSciTech. 2005; 06(01) Korunubhum S. S., Batopak S. B., J. Pharm Sci, 1973, Vol 62 (1), 43-49 Grasono, Alessandro et al, U S Patent 6,197,336 2001 Botzalakis J. E., & Dngsburger L L., Drug Dev Ind Pharn, 1988, Vol 14 (9), 1235-1248 Botzalakis J. E., & Dngsburger L L., Drug Dev Ind Pharn, 1988, Vol 14 (1), 29-41 Jagdish Singh., Drug Dev Ind Pharn, 1992, Vol 18 (3), 375-383 Bi. Y. X., Sunanda H., Yonezawa Y., Drug Dev Ind Pharn, 1999, Vol 25(5), 571-581 Cousin et al., Rapidly Disintegrable multiparticular Tablets., U S Patnet, 5, 464, 632 (1995) . Malladi, Sastry. S. P., Diwan P. V. Drug Dev Ind Pharn, 1993, Vol 19(9), 1089-1096 Bi et al. Rapidly Disintegrable multiparticular Tablets., Chem Pharma Bull., 1995, Vol 18(9), 1308-1310 Watanable Y. et al, Chemical pharm Bull, 2001, Vol 49(2), 134139 Chaudhary K. P. R., & Sujata Rao., Indian J. Pharm. Sci., 1992(2) 31 32 Blank et al., Fast Dissolving dosage form, US Patent 4,946,684 (1990) Mohan Bau, G.V.M. Prasad, Ramanna Murthy K. V., Int. J. Pharm. Excipients, 2000 (4) 185 191 Ritthidej G.C., Chomoto P., Pammangusa S., Drug Dev Ind Pharm., 1994, Vol 20(13), 2109 2114 Bhargava H. N., Shah D., Oza B. J., Drug Dev Ind Pharm., 199, Vol 17(158), 2093 2102 Antony P. J., and Sanghavi N. M., Drug Dev Ind Pharm., 1997, vol 23(4), 413 415 Gupta G. D., and Gaud R. S., Indian J. Pharm Sci., 2000, Vol 62(5), 339 342 Kokate C. K., Purohit A. P., and Gokhale S. B., Pharmacognosy II nd Ed, Nirali Prakashan, India, 1999, 109 136 Budavani S. O., Neil N. J., Smith A., The Merck Index, An Encyclopedia of Chemicals, Drugs and Biologicals, 29th Ed. Published by Merck Research Laboratories, Division of Merck & Co. Inc., 1996, 181 Ito A., Sugihara M., Chem. Pharm. Bull., Vol 44(11) 1996, 2132 2136 Onali Aomer, Fast Melt Tablets and Method of Making Same. US Patent 5,807,577 (1998). J. Balasubramaniam, K. Bindu, V.U. Rao, D. Ray, R. Haldar, and A.W. Brzeczko, Effect of Superdisintegrants on Dissolution of Cationic Drugs, Dissolution Technologies, Vol 15 (2), 18-25 (2008). W. Camarco, R. Dipan, A. Druffner, Selecting Superdisintegrants for Orally Disintegrating Tablet Formulations, Pharm Tech Supplement, 2006, pp.s28-s37. J. Balasubramaniam, T. Bee, Influence of Superdisintegrants on the Drug Dissolution from Oral Solid-Dosage Forms, Pharm Tech Excipient Supplement, S4-S14 (2009). Lachman L, Liberman HA. Theory and Practice of Industrial Pharmacy, Third Edition, 1990, pp 293-294. M. Gohel, AAPS PharmSciTech 2004; Vol 5 (3) Article 36, pp 16.

33. 34. 35.

36. 37. 38. 39.

473

You might also like

- Super DisintegrantsDocument19 pagesSuper Disintegrantsvikaskiran60No ratings yet

- Containment of High-Potency Products in a GMP EnvironmentDocument3 pagesContainment of High-Potency Products in a GMP EnvironmentAnkush PandeyNo ratings yet

- OriginalDocument32 pagesOriginalAlexandra MilenkovicNo ratings yet

- Impact of Cross ContaminationDocument8 pagesImpact of Cross ContaminationYousifNo ratings yet

- Answer 1 Tablet Coating ValidationDocument9 pagesAnswer 1 Tablet Coating ValidationPankaj JaatNo ratings yet

- An Overview On Tablet CoatingDocument4 pagesAn Overview On Tablet Coatingronahaniifah11No ratings yet

- Pharmaceutical EngineringDocument24 pagesPharmaceutical EngineringKedai Kado UnikNo ratings yet

- Aseptic Process TechnologyDocument19 pagesAseptic Process TechnologyHimanshu ShahuNo ratings yet

- Aseptic Processing Case StudyDocument28 pagesAseptic Processing Case Studykavya nainitaNo ratings yet

- Quality by Design For Biotechnology Products-Part 2 - Process Development ForumDocument7 pagesQuality by Design For Biotechnology Products-Part 2 - Process Development ForumGyro9No ratings yet

- Portfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesFrom EverandPortfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesPete HarpumNo ratings yet

- HBEL GuidelineDocument4 pagesHBEL GuidelineRenuka KrishnanNo ratings yet

- 51 PDFDocument3 pages51 PDFChetalee NaikNo ratings yet

- Basic Principles of GMP: GMP For Sterile Pharmaceutical ProductsDocument19 pagesBasic Principles of GMP: GMP For Sterile Pharmaceutical Productsabhijit_gothoskar6039No ratings yet

- 2.9.1. Disintegration of Tablets and CapsulesDocument3 pages2.9.1. Disintegration of Tablets and CapsulesPikiy PutriNo ratings yet

- Bioburden USP PDFDocument4 pagesBioburden USP PDFKatyaSNNo ratings yet

- Quality Management Systems A Complete Guide - 2021 EditionFrom EverandQuality Management Systems A Complete Guide - 2021 EditionNo ratings yet

- An Inside Look at USP71Document22 pagesAn Inside Look at USP71Dante IulliNo ratings yet

- SOP For HPLC Shimadzu LabSolutionsDocument6 pagesSOP For HPLC Shimadzu LabSolutionsfawaz khalilNo ratings yet

- CDER Microbiologist Perspective on Sterility AssuranceDocument52 pagesCDER Microbiologist Perspective on Sterility AssuranceKraken UrNo ratings yet

- Pilot Scaleup Techniques For Solid Dosage Form - An Overview For TabletsDocument7 pagesPilot Scaleup Techniques For Solid Dosage Form - An Overview For TabletsAsifNo ratings yet

- Forced DegradationDocument8 pagesForced DegradationBiyaya San PedroNo ratings yet

- Tier 1 CVSDocument23 pagesTier 1 CVSCHETHAN K SNo ratings yet

- Industrial Training PRESENTATION (Benazir)Document6 pagesIndustrial Training PRESENTATION (Benazir)Benazir ShuguftaNo ratings yet

- Line Clearence Ravi 17oct14Document31 pagesLine Clearence Ravi 17oct14pooja singhNo ratings yet

- Limit Test For Heavy MetalsDocument19 pagesLimit Test For Heavy MetalsnutrimakeNo ratings yet

- BP702T Ip IiDocument29 pagesBP702T Ip IiTurbo ChargedNo ratings yet

- CGMP Responsibilities Quality Control Head DepartmentDocument36 pagesCGMP Responsibilities Quality Control Head DepartmentAdelio MercadejasNo ratings yet

- Justification of LimitsDocument6 pagesJustification of LimitsRulli SulaemanNo ratings yet

- MM-CHPA Voluntary Codes and Guidelines Stability TestingDocument9 pagesMM-CHPA Voluntary Codes and Guidelines Stability TestingPranav PatelNo ratings yet

- Media Fill For Validation of A Good Manufacturing - ARTIGODocument9 pagesMedia Fill For Validation of A Good Manufacturing - ARTIGOBiancaNo ratings yet

- Quality by Design Approaches For Topical Dermatological Dosage FormsDocument19 pagesQuality by Design Approaches For Topical Dermatological Dosage FormsDoinița UrsuNo ratings yet

- Regulatory Toxicology OverviewDocument100 pagesRegulatory Toxicology OverviewHarsh KoshtiNo ratings yet

- Computers in Pharmaceutical Research and Development:: A General OverviewDocument21 pagesComputers in Pharmaceutical Research and Development:: A General OverviewMohammed AzarudeenNo ratings yet

- Aseptic ProcessingDocument13 pagesAseptic ProcessingAshok Kumar100% (1)

- Alconox Detergent Cleaning ValidationDocument12 pagesAlconox Detergent Cleaning ValidationstanlesNo ratings yet

- Tablets Quality ControlDocument18 pagesTablets Quality ControlThangabalan Than100% (2)

- Powders & Granules TextDocument12 pagesPowders & Granules Textabdullah2020No ratings yet

- Usp Review AlbuterolDocument82 pagesUsp Review Albuterolsrayu2603No ratings yet

- FOB2-3 TS - Technical Manual - Section 2 - Installation SpecificationsDocument10 pagesFOB2-3 TS - Technical Manual - Section 2 - Installation SpecificationsmaghraouiNo ratings yet

- Veena SeminarDocument41 pagesVeena SeminarVeena PatilNo ratings yet

- Pi 053 1 Hbel Qa PDFDocument7 pagesPi 053 1 Hbel Qa PDFM. S. ChikkamaniNo ratings yet

- WHO IVB 14.07 EngDocument14 pagesWHO IVB 14.07 EnggineNo ratings yet

- Comprehensive Quality by Design for Pharmaceutical Product Development and ManufactureFrom EverandComprehensive Quality by Design for Pharmaceutical Product Development and ManufactureGintaras V. ReklaitisNo ratings yet

- Guidance For Industry - ATP - PremisesDocument13 pagesGuidance For Industry - ATP - PremisesFISHNo ratings yet

- Pharmaceutical MicrobiologyDocument16 pagesPharmaceutical MicrobiologyIslam TareqNo ratings yet

- Lecture - 4 Mixing PDFDocument36 pagesLecture - 4 Mixing PDFKazi Nafis UllahNo ratings yet

- Development and Manufacturing of Injectable (Parenteral) Drug Products UnitDocument10 pagesDevelopment and Manufacturing of Injectable (Parenteral) Drug Products UnitParul SrivastavaNo ratings yet

- MHRA Questions and Answers For Specials Manufacturer's Con326474 PDFDocument44 pagesMHRA Questions and Answers For Specials Manufacturer's Con326474 PDFSharma PokkuluriNo ratings yet

- LAB 130 Stability Management Procedure SampleDocument3 pagesLAB 130 Stability Management Procedure SampleOdunlamiNo ratings yet

- Pharmaceutical Microbiology LabsDocument27 pagesPharmaceutical Microbiology LabsThuy LeNo ratings yet

- GMP Trends-1Document177 pagesGMP Trends-1skvemulaNo ratings yet

- Cleaning Validation White PaperDocument7 pagesCleaning Validation White PaperAngga PratamaNo ratings yet

- Applying QBD Principles For The Development of A Pharmaceutical Dosage FormDocument31 pagesApplying QBD Principles For The Development of A Pharmaceutical Dosage FormSneha KaduNo ratings yet

- Liquid Dosage FormDocument29 pagesLiquid Dosage FormALIMAH MOSARWANo ratings yet

- Pharmaceutical Industrial Safety HazardsDocument77 pagesPharmaceutical Industrial Safety Hazardsdankshavali shaikNo ratings yet

- Cleaning Validation in Pharmaceutical IndustriesDocument5 pagesCleaning Validation in Pharmaceutical IndustriesAbhishek RajNo ratings yet

- Why The Swab Matters in Cleaning ValidationDocument3 pagesWhy The Swab Matters in Cleaning ValidationYehuda Rahmanu PuteraNo ratings yet

- Clean RoomDocument16 pagesClean RoomApoloTrevinoNo ratings yet

- Daftar PustakaDocument6 pagesDaftar PustakaummiheryanaNo ratings yet

- Topical NSAIDs for ElderlyDocument4 pagesTopical NSAIDs for ElderlyOktarisaNo ratings yet

- Community Pharmacy Symptoms, Diagnosis and Treatment by Paul RutterDocument489 pagesCommunity Pharmacy Symptoms, Diagnosis and Treatment by Paul RutterNhi Nguyễn75% (8)

- Classics in Chemical Neuroscience: ChlorpromazineDocument10 pagesClassics in Chemical Neuroscience: ChlorpromazineLisa MariaNo ratings yet

- Bandung pharmacy price list for prescription drugsDocument13 pagesBandung pharmacy price list for prescription drugsJar JarNo ratings yet

- Devi Datt Joshi Auth. Herbal Drugs and Fingerprints Evidence Based Herbal DrugsDocument261 pagesDevi Datt Joshi Auth. Herbal Drugs and Fingerprints Evidence Based Herbal DrugsStella AguirreNo ratings yet

- DPRI 2017 Edition Guide for Government Procurement of Essential MedicinesDocument23 pagesDPRI 2017 Edition Guide for Government Procurement of Essential MedicineskrisconradNo ratings yet

- Cadila Pharmaceuticals.1Document19 pagesCadila Pharmaceuticals.1Sahil ShahNo ratings yet

- Arroz Con Mango PDFDocument197 pagesArroz Con Mango PDFVanshika JainNo ratings yet

- Otc Advisor PainDocument24 pagesOtc Advisor Painfarzad100% (2)

- Drug Alert For The Month of December 2016Document3 pagesDrug Alert For The Month of December 2016amit545No ratings yet

- FluroquinolonesDocument29 pagesFluroquinolonestummalapalli venkateswara rao0% (1)

- Sil HTC CarryoverDocument4 pagesSil HTC CarryoverKhoranaNo ratings yet

- Protokol Kemoterapi WilmsDocument5 pagesProtokol Kemoterapi WilmsrantiadrianiNo ratings yet

- Supreme Court Rules No Injunctive Relief After Patent ExpirationDocument2 pagesSupreme Court Rules No Injunctive Relief After Patent Expirationmisslee misseunNo ratings yet

- Food and Drug Interactions A General ReviewDocument15 pagesFood and Drug Interactions A General ReviewDaniela AndreiNo ratings yet

- Effective Home Remedies With HerbsDocument23 pagesEffective Home Remedies With HerbsAlexandru Vasile100% (1)

- Biocon India Group: Prof. R. SrinivasanDocument12 pagesBiocon India Group: Prof. R. SrinivasanNithin kumarNo ratings yet

- Rajiv Gandhi University of Health Sciences, Bangalore, KarnatakaDocument13 pagesRajiv Gandhi University of Health Sciences, Bangalore, KarnatakaR HariNo ratings yet

- PsilocybinDocument2 pagesPsilocybinJackson James WoodNo ratings yet

- PBF ObatDocument4 pagesPBF Obatrisha maysaraNo ratings yet

- Ers 2015Document358 pagesErs 2015Dejan ŽujovićNo ratings yet

- 8435 Leche en PolvoDocument12 pages8435 Leche en PolvomaveloNo ratings yet

- 1 BDDSDocument27 pages1 BDDSVatsal PandyaNo ratings yet

- PromethazineDocument14 pagesPromethazinePapaindoNo ratings yet

- Acute Pain Management GuideDocument65 pagesAcute Pain Management GuideMohamed KhatibNo ratings yet

- Organizational Transformation in Pharmaceutical IndustryDocument21 pagesOrganizational Transformation in Pharmaceutical IndustryMahiya QaziNo ratings yet

- RKO bulan juni apotek Vanisa obat penjualan dan persediaanDocument10 pagesRKO bulan juni apotek Vanisa obat penjualan dan persediaanressamahendraNo ratings yet

- Sulphite SensitivityDocument3 pagesSulphite SensitivityKrishan BhanotNo ratings yet

- Marketing Plan B6 BioconDocument9 pagesMarketing Plan B6 BioconRitvik DineshNo ratings yet