Professional Documents

Culture Documents

Application of Ac Drives in Steel Industries in India

Uploaded by

vishiwizardOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Ac Drives in Steel Industries in India

Uploaded by

vishiwizardCopyright:

Available Formats

APPLICATION OF AC DRIVES IN STEEL INDUSTRIES IN INDIA A CASE STUDY

V.VISHNUTEJA -1611210008 T.MOHANA-1611210003 M.Tech .Power Electronics & Drives, Dept. Of EEE SRM University, Chennai

INTRODUCTION:

The integrated steel plants are having very large capacity motors and power electronics devices, which are used during processing of steel. The process of manufacturing steel products from iron ore involves Raw material preparation, Primary reduction, Refining, Casting, Hot and Cold rolling, Surface coating etc. Energy such as gas and electric power is required in each of these processes. The motors used in the primary area (Coke oven, Blast furnace, Steel melting shop) do not require speed regulation of high order; on the other hand motors used in finishing mills require speed regulation of high accuracy In most of the steel plant applications, variable speed was obtained through DC motors driven four quadrant converters. During modernization, the DC motors and drives are replaced by AC motors and drives. AC drives are used mostly in primary area (Raw material handling, Sinter plant, Steel melting shop) in steel plant. Variable speed AC drives are used in soaking pits and reheat furnaces. AC motors of very high capacities (4 MW in Sinter plant and 14.4 MW in the prime mover of MG set in Plate Mill) are used in steel plants.

CASE STUDY -1: a. AC Drives for crane applications :

The basic requirement of crane drives are (i) Bi directional movement of the motors, (ii) Regenerative braking facilities, (iii) Controlled acceleration to reduce the load swing, (iv) Precise positioning of the load, (v) Torque at Zero speed and (vi) Safety features.

Conventional AC operated EOT cranes uses slip ring induction motor whose rotor windings are connected to power resistance in 4 to 5 steps by power contactors. VVVF drive, operated in four quadrant operation and consisting of one three phase forward converter, one three phase reverse converter and one transistor based inverter unit has been developed for crane application. RATINGS: 1. CRANE : Capacity: Main Hoist 30 T; Auxiliary Hoist: 5 T Current Collector: Gravity collector, Festoon with double collector arrangement. Speed: Traveling: 80 m/min Traversing: 40 m/min Main hoist: 8 m/min Aux. hoist: 20 m/min Each motor of the crane has to sustain 20 nos of start / stop operation in an hour. MOTOR RATINGS :

Long Travel Drive Specifications:

Motors: 2 Nos. with continuous output of 150 KVA and rated current of 165A VVVF drive capacity: 120 kVA; Overload capacity: 50% for 60 sec Type: Four quadrant operation with regenerative facility

Converter unit: 3 Phase thyristor bridge Inverter unit: 2 series connected power transistor with anti-parallel diode.

Benefits : i) ii) Savings in electrical power as there is no loss in rotor resistance Precise positioning of the hook at very low speed operation is possible. With rotor resistance control operator has to reverse the motor a few times for positioning iii) During braking, the drive regenerates and power is fed back to busbar through current collector iv) All controls and safety interlocks are done in a Programmable controller and thereby the panel size is small and high starting torque. b. AC Drives for Rolling Stand Motor : AC synchronous motors are used for driving the roughing stand rolls in a rolling mill. Synchronous motors are used when power requirement is very high and speed of rolling is low. The R0/V0 stand motors of Hot Strip Mill of Rourkela Steel Plant are synchronous motor. These motors are driven by cyclo converter .The Specifications of Motors are as follows 1. Capacity of R0 stand motors :3 MW x 2 Nos, 953 Volt, 1121 Amps, 70 RPM. 2. Capacity of V0 stand motors : 1 MW X 2 Nos at 953 volt. Cyclo converter output frequency is 5-15 Hz Benefits: i) Speed regulation is precise ii) The control system is having high dynamic response c. AC Drive requirement for Large Drive Machines : A. Exhauster of Sinter Plant II of Durgapur Steel Plant The Sinter Plant-II of DSP has two exhausters to suck air through sinter machine. The suction pressure is around 1500 mm WC. The installed electrical load is 21 MW. The average energy

consumption at rated capacity is 13-14 MW, out of which 8 MW is consumed in the exhausters. The power line frequency varies from 49 to 53 Hz. When the frequency is high (say 53 Hz), motor speed increases to 1060 RPM and the blade speed increases to 1442 RPM. With this speed load on the exhauster motor increases and consequently stator current increases. When the current increases above safe limit, the motor trips. Such a trip causes a delay of around 1 hour. Each synchronous motor is rated for 4670 kVA, Stator 11kV, 244 A, Rotor 78 V, 295 A, Cos= 0.9. During high frequency, the load on the machine is reduced by closing the damper in the suction line. B. Compressors of Oxygen Plant of Durgapur Steel Plant: The capacity of oxygen plant is 700 t/day. The plant consists of two numbers of air separation units each of capacity 350 t/day. There are two air compressors for 2 air separation unit. Each air compressor is driven by synchronous motor of rating 11 kV, 6 MW, 0.9 pf lead. There are three oxygen compressors, driven by synchronous motor of rating 11 kV, 1700 kW, 0.9 pf lead. There are two nitrogen compressors driven by induction motor of rating 11 kV, 1320 kW. At higher frequency above 50 Hz, the plant becomes unstable. The plant is made stable by changing vent and by this way specific power consumption increases. There is no provision for regulating the speed of the compressors at higher frequency. Variable frequency drives to suit the above two mentioned motor capacities shall help to control the process by varying the supply frequency. CONCLUSION: As technology developed, AC drives replaced DC drives in industries requiring high precision of speed control and good dynamic performance. In a steel plant, power electronics plays an important role in process improvement and dimensional control of rolled products. Proper selection of drives not only saves electrical energy but also produce quality products. Advancements in the field of drives and control techniques are responsible for improvements in the quality and yield of steel products.

REFERENCES : 1. Applications of AC Motors and Drives in Steel Industries - A K Paul, I Banerjee, B K Santra and N Neogi-IEEE 2. Outlook for Low Power AC Drives in India- Scribd

You might also like

- Collaboration Live User Manual - 453562037721a - en - US PDFDocument32 pagesCollaboration Live User Manual - 453562037721a - en - US PDFIvan CvasniucNo ratings yet

- Ball Mill Drive Motor ChoicesDocument16 pagesBall Mill Drive Motor Choicessaiko_searchNo ratings yet

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- MsgSpec v344 PDFDocument119 pagesMsgSpec v344 PDFqweceNo ratings yet

- International Convention Center, BanesworDocument18 pagesInternational Convention Center, BanesworSreeniketh ChikuNo ratings yet

- Proposed Delivery For PAU/AHU Method Statement SEC/MS/3-25Document4 pagesProposed Delivery For PAU/AHU Method Statement SEC/MS/3-25Zin Ko NaingNo ratings yet

- Chaman Lal Setia Exports Ltd fundamentals remain intactDocument18 pagesChaman Lal Setia Exports Ltd fundamentals remain intactbharat005No ratings yet

- Bill of ConveyanceDocument3 pagesBill of Conveyance:Lawiy-Zodok:Shamu:-El80% (5)

- Application of AC Motors and Drives in Steel Industries: A K Paul, I Banerjee, B K Santra and N NeogiDocument5 pagesApplication of AC Motors and Drives in Steel Industries: A K Paul, I Banerjee, B K Santra and N NeogiMohamed Elsaid El ShallNo ratings yet

- Applying AC drives in steel industriesDocument6 pagesApplying AC drives in steel industriessiddsunnyNo ratings yet

- Variable Speed Units For Pumped Storage Power Plants: Page 1 of 9Document9 pagesVariable Speed Units For Pumped Storage Power Plants: Page 1 of 9raj sekharNo ratings yet

- Design and Simulation of Speed Control of Three Phase Induction Motor Using Power Electronics ConverterDocument52 pagesDesign and Simulation of Speed Control of Three Phase Induction Motor Using Power Electronics Converterzelalem wegayehu100% (1)

- 15EEE401 - II Ass - Aug 2018Document2 pages15EEE401 - II Ass - Aug 2018sriharshitha vegesnaNo ratings yet

- People Steel MillsDocument9 pagesPeople Steel Millsm4_mehdeeNo ratings yet

- Drives in Mechatronics1Document14 pagesDrives in Mechatronics1Durga PrasadNo ratings yet

- ست خطوات العاكس لقيادة المحرك التعريفي ثلاث مراحلDocument113 pagesست خطوات العاكس لقيادة المحرك التعريفي ثلاث مراحلMOUHSSINE BEN HAMMOUNo ratings yet

- AlernatorDocument47 pagesAlernatorMayank SrivastavaNo ratings yet

- VVVF DrivesDocument16 pagesVVVF DrivesIsradani MjNo ratings yet

- Types of Ac GeneratorDocument10 pagesTypes of Ac GeneratorJherel BerinNo ratings yet

- Module 4 Drives and Mechanisms Elements of CNC Machine Tools: Electric MotorsDocument47 pagesModule 4 Drives and Mechanisms Elements of CNC Machine Tools: Electric MotorsDhanish KumarNo ratings yet

- Lecture 6Document31 pagesLecture 6amanuel abrehaNo ratings yet

- Three-Phase Squirrel-Cage Induction Motor Drive Analysis Using LabVIEWDocument26 pagesThree-Phase Squirrel-Cage Induction Motor Drive Analysis Using LabVIEWCarlos Roberto Amaya Rodriguez100% (1)

- ElectricalDocument157 pagesElectricalnaguNo ratings yet

- (VT Ranganathan) Course Notes On Electric DrivesDocument119 pages(VT Ranganathan) Course Notes On Electric DrivesPowerranger2.0No ratings yet

- History of CLW: Chittaranjan Locomotive Works. CLW Is The Proud Recipient of The SafetyDocument10 pagesHistory of CLW: Chittaranjan Locomotive Works. CLW Is The Proud Recipient of The SafetyRahul SinhaNo ratings yet

- Electric Motor Selection and UsesDocument3 pagesElectric Motor Selection and UsesFisher MadamNo ratings yet

- Variable Frequency Drive or VFDDocument4 pagesVariable Frequency Drive or VFDramsingh2613No ratings yet

- Industrial Drives and ControlDocument10 pagesIndustrial Drives and ControlMohit SanandiyaNo ratings yet

- Introduction To Electric DrivesDocument75 pagesIntroduction To Electric DrivesVikas PooniaNo ratings yet

- Effect of Mine Hoist Drives On The Electrical Power Supply SystemDocument6 pagesEffect of Mine Hoist Drives On The Electrical Power Supply SystemGlenn Adalia BonitaNo ratings yet

- Variable Frequency DrivesDocument17 pagesVariable Frequency DrivesVinay Tarsem Lal100% (1)

- Direct Current (DC) Motors: OperationDocument6 pagesDirect Current (DC) Motors: OperationckyprianouNo ratings yet

- 129 - Ent 204Document12 pages129 - Ent 204Polutan ElvinNo ratings yet

- Chapter 1 - ADocument23 pagesChapter 1 - AAHMAD ASRI ABD SAMATNo ratings yet

- ميكاترونكسDocument6 pagesميكاترونكسAhmed M. MuradNo ratings yet

- Doubly-Fed Electric Machine - WikipediaDocument5 pagesDoubly-Fed Electric Machine - WikipediavineeshNo ratings yet

- Essential Requirements of Railway Traction SystemsDocument66 pagesEssential Requirements of Railway Traction SystemsAkshay KatharNo ratings yet

- MINI PROJECT DC Main DrivesDocument35 pagesMINI PROJECT DC Main DrivesSriram MogalapalliNo ratings yet

- Module 5Document20 pagesModule 5yakomi suraNo ratings yet

- Synchronous Motor Drive SeminarDocument19 pagesSynchronous Motor Drive SeminarSwarup MadduriNo ratings yet

- Induction Motors Fed by PWM MV7000 Converters Enhance Electric Propulsion PerformanceDocument9 pagesInduction Motors Fed by PWM MV7000 Converters Enhance Electric Propulsion Performancemlkz_01No ratings yet

- Intellegint LoadsheddingDocument22 pagesIntellegint LoadsheddingrohithNo ratings yet

- Electrical Ac & DC Drives: S.Sumalatha G.Lakshmi PrasannaDocument20 pagesElectrical Ac & DC Drives: S.Sumalatha G.Lakshmi PrasannageniunetNo ratings yet

- LCIs and Syn Motors Applied To Roller Mills - Zayechek - 2000Document10 pagesLCIs and Syn Motors Applied To Roller Mills - Zayechek - 2000Parameswararao BillaNo ratings yet

- Overview of CLW and its LocomotivesDocument12 pagesOverview of CLW and its LocomotivesRahul SinhaNo ratings yet

- Chapter 4 DC MachineDocument101 pagesChapter 4 DC Machinekelemyas ayalew100% (2)

- The Advantages and Hazards of DC MotorsDocument6 pagesThe Advantages and Hazards of DC MotorsGalco IndustrialNo ratings yet

- Electric Traction - ReferenceDocument19 pagesElectric Traction - ReferenceShrestha SanjuNo ratings yet

- Lecture No 2Document25 pagesLecture No 2Walid salamaNo ratings yet

- Igbt DC DriverDocument5 pagesIgbt DC Driverjimy_312No ratings yet

- Dewatering Pump Installation and CommissioningDocument22 pagesDewatering Pump Installation and CommissioningOdejobi Oluseyi JonathanNo ratings yet

- Bule Hora University Department of Ece Eceg 4222 Power Electronics & Electric DrivesDocument14 pagesBule Hora University Department of Ece Eceg 4222 Power Electronics & Electric DrivesBilisuma DamiteNo ratings yet

- .0 .0 Tensors - Fluid - Dynamics - CreteDocument8 pages.0 .0 Tensors - Fluid - Dynamics - CreteRabei RomulusNo ratings yet

- Unit - 1Document12 pagesUnit - 1222 PiyushNo ratings yet

- CIA - I Question Bank With Answers SOLID STATE DRIVESDocument4 pagesCIA - I Question Bank With Answers SOLID STATE DRIVESdeepakraghavanNo ratings yet

- AC vs DC Motor Components and DifferencesDocument13 pagesAC vs DC Motor Components and DifferencesrikechNo ratings yet

- Electric Drives Control TechniquesDocument2 pagesElectric Drives Control Techniquessriharshitha vegesnaNo ratings yet

- DC Motor Speed Control: Bayan University For Science & TechnologyDocument12 pagesDC Motor Speed Control: Bayan University For Science & TechnologyAltayeb AbdulhameedNo ratings yet

- Speed Control of DC MotorDocument31 pagesSpeed Control of DC Motorabhinav. alpheus651997No ratings yet

- Wind Energy Training Ch#5Document34 pagesWind Energy Training Ch#5Munseb AliNo ratings yet

- Power Electronics: Lecture Notes of Power Electronics CourseFrom EverandPower Electronics: Lecture Notes of Power Electronics CourseNo ratings yet

- Integration of Large Scale Wind Energy with Electrical Power Systems in ChinaFrom EverandIntegration of Large Scale Wind Energy with Electrical Power Systems in ChinaNo ratings yet

- Hardware Inloop Simulation IEEE LabVIEWDocument1 pageHardware Inloop Simulation IEEE LabVIEWvishiwizardNo ratings yet

- Op - XT546 246 346 - Op288 V03Document2 pagesOp - XT546 246 346 - Op288 V03vishiwizardNo ratings yet

- ACM2 TAU Datasheet enDocument5 pagesACM2 TAU Datasheet envishiwizardNo ratings yet

- Part Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisDocument6 pagesPart Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisIjabiNo ratings yet

- Maxwell 2dDocument7 pagesMaxwell 2dvishiwizardNo ratings yet

- Engineered PlasticsDocument61 pagesEngineered Plastics고병석No ratings yet

- LJLVJK LVJJV LKJVDocument5 pagesLJLVJK LVJJV LKJVvishiwizardNo ratings yet

- 50 SCS Automotive Coatings - Rev0913Document4 pages50 SCS Automotive Coatings - Rev0913vishiwizardNo ratings yet

- Electric Vehicle Motor Design NotesDocument131 pagesElectric Vehicle Motor Design NotesvishiwizardNo ratings yet

- TRL Definitions PDFDocument1 pageTRL Definitions PDFBHARadwajNo ratings yet

- ReadmeDocument4 pagesReadmevishiwizardNo ratings yet

- FAB Resistivity White PaperDocument8 pagesFAB Resistivity White PapervishiwizardNo ratings yet

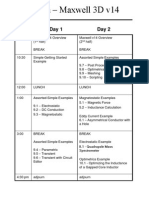

- Maxwell 3D v14 Training AgendaDocument1 pageMaxwell 3D v14 Training AgendavishiwizardNo ratings yet

- 5 SmanualDocument16 pages5 SmanualMark ThomasNo ratings yet

- Recent Advances in Materials For Use in Permanent Magnet Machines - A ReviewDocument7 pagesRecent Advances in Materials For Use in Permanent Magnet Machines - A ReviewvishiwizardNo ratings yet

- Jeas 1012 787Document5 pagesJeas 1012 787vishiwizardNo ratings yet

- Electrical Resin BenefitsDocument2 pagesElectrical Resin BenefitsvishiwizardNo ratings yet

- Nit 3600 1Document5 pagesNit 3600 1vishiwizardNo ratings yet

- Lit Survey RamamurthyDocument9 pagesLit Survey RamamurthyvishiwizardNo ratings yet

- Wittich2011 SonkusaleVanderveldeDocument1 pageWittich2011 SonkusaleVanderveldevishiwizardNo ratings yet

- Presentation 1Document1 pagePresentation 1vishiwizardNo ratings yet

- Big Energy Series 11.5.2012 Qing-Chang ZhongDocument1 pageBig Energy Series 11.5.2012 Qing-Chang ZhongvishiwizardNo ratings yet

- Brushless Motor FundamentalsDocument13 pagesBrushless Motor FundamentalsvishiwizardNo ratings yet

- Sensors Used in HEVDocument4 pagesSensors Used in HEVvishiwizard100% (1)

- How to Check a MOSFETDocument2 pagesHow to Check a MOSFETvishiwizardNo ratings yet

- FTF Aut f0234Document38 pagesFTF Aut f0234vishiwizardNo ratings yet

- Cam DesignDocument13 pagesCam DesignvishiwizardNo ratings yet

- A Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesDocument1 pageA Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesvishiwizardNo ratings yet

- Motor Primer1Document2 pagesMotor Primer1vishiwizardNo ratings yet

- Sona SPEED CatalogueDocument13 pagesSona SPEED CataloguevishiwizardNo ratings yet

- Trinath Chigurupati, A095 576 649 (BIA Oct. 26, 2011)Document13 pagesTrinath Chigurupati, A095 576 649 (BIA Oct. 26, 2011)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- Flare Finance Ecosystem MapDocument1 pageFlare Finance Ecosystem MapEssence of ChaNo ratings yet

- John GokongweiDocument14 pagesJohn GokongweiBela CraigNo ratings yet

- Tyron Butson (Order #37627400)Document74 pagesTyron Butson (Order #37627400)tyron100% (2)

- Department of Labor: kwc25 (Rev-01-05)Document24 pagesDepartment of Labor: kwc25 (Rev-01-05)USA_DepartmentOfLaborNo ratings yet

- Abb Drives: User'S Manual Flashdrop Mfdt-01Document62 pagesAbb Drives: User'S Manual Flashdrop Mfdt-01Сергей СалтыковNo ratings yet

- SE Myth of SoftwareDocument3 pagesSE Myth of SoftwarePrakash PaudelNo ratings yet

- Green Management: Nestlé's Approach To Green Management 1. Research and DevelopmentDocument6 pagesGreen Management: Nestlé's Approach To Green Management 1. Research and DevelopmentAbaidullah TanveerNo ratings yet

- ADSLADSLADSLDocument83 pagesADSLADSLADSLKrishnan Unni GNo ratings yet

- Overall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarDocument2 pagesOverall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarVishak ThebossNo ratings yet

- 4Q Labor Case DigestsDocument53 pages4Q Labor Case DigestsKaren Pascal100% (2)

- Legal Techniques (2nd Set)Document152 pagesLegal Techniques (2nd Set)Karl Marxcuz ReyesNo ratings yet

- Novirost Sample TeaserDocument2 pagesNovirost Sample TeaserVlatko KotevskiNo ratings yet

- Alfa Laval Complete Fittings CatalogDocument224 pagesAlfa Laval Complete Fittings CatalogGraciele SoaresNo ratings yet

- 6vortex 20166523361966663Document4 pages6vortex 20166523361966663Mieczysław MichalczewskiNo ratings yet

- The SAGE Handbook of Digital JournalismDocument497 pagesThe SAGE Handbook of Digital JournalismK JNo ratings yet

- Hardened Concrete - Methods of Test: Indian StandardDocument16 pagesHardened Concrete - Methods of Test: Indian StandardjitendraNo ratings yet

- Fundamentals of Corporate Finance Canadian Canadian 8th Edition Ross Test Bank 1Document36 pagesFundamentals of Corporate Finance Canadian Canadian 8th Edition Ross Test Bank 1jillhernandezqortfpmndz100% (22)

- BS EN 364-1993 (Testing Methods For Protective Equipment AgaiDocument21 pagesBS EN 364-1993 (Testing Methods For Protective Equipment AgaiSakib AyubNo ratings yet

- Globalisation - Theories of Digital CommunicationDocument12 pagesGlobalisation - Theories of Digital CommunicationDiya Patel-10SNo ratings yet

- An4856 Stevalisa172v2 2 KW Fully Digital Ac DC Power Supply Dsmps Evaluation Board StmicroelectronicsDocument74 pagesAn4856 Stevalisa172v2 2 KW Fully Digital Ac DC Power Supply Dsmps Evaluation Board StmicroelectronicsStefano SalaNo ratings yet

- Sop EcuDocument11 pagesSop Ecuahmed saeedNo ratings yet

- Marketing ManagementDocument14 pagesMarketing ManagementShaurya RathourNo ratings yet

- EU Letter To Liz Truss 2016Document2 pagesEU Letter To Liz Truss 2016MadeleineNo ratings yet