Professional Documents

Culture Documents

Final Report1

Uploaded by

prince_tutuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Report1

Uploaded by

prince_tutuCopyright:

Available Formats

[Type the document title]

Reciprocating Pump-from PO to GR[Type text]

Page 1

[Type the document title]

Reciprocating Pump-from PO to GR[Type text]

Page 2

[Type the document title]

ACKNOWLEDGEMENT

I am grateful to Bharat Pumps and Compressors Limited (BPC) for providing me the opportunity to undergo summer internship at their unit. This internship is a important part of the degree of Post Graduate Diploma Management for which I am currently enrolled at Institute of Management Technology, Nagpur. This training helped me to be associated with a heavy machinery manufacturing unit and understand their mode of operations. I would like to thank Mr.HPD BHATT from marketing department and my project guide Mr. ANUPAM BASU from production planning department (PEX) for providing me with valuable inputs at regular intervals. I would also like to thank the shop floor workers of BPC for sharing their experiences with me. Without them getting to know the nuts and bolts of production was not easy.

Rahul Pandey

Reciprocating Pump-from PO to GR[Type text]

Page 3

[Type the document title]

TABLE OF CONTENTS

EXECUTIVE SUMMARY................................................................................................. 4 Objectives of the Study........................................................................................................ 5 Methodology........................................................................................................................ 6 Introduction................................................ ......................................................................... 7 Project Overview...................................................................................................................14 Marketing Department......................................................................................................... 25 Purchase Department........................................................................................................... 30 Recommendations............................................................................................................... 49 Bibliography........................................................................................................................ 50

Reciprocating Pump-from PO to GR[Type text]

Page 4

[Type the document title]

EXECUTIVE SUMMARY

The report titled Reciprocating Pumps from Purchase order (PO) to gate receipt( GR) is an outcome of my extensive study and analysis of operations at a government manufacturing unit Bharat Pumps and Compressors. This unit is situated at Naini (Allahabad) and it specializes in manufacturing of reciprocating pumps, reciprocating compressors, centrifugal pumps and CNG cylinders. It has a vast variety of sub products within the above said products. My project talks of the operations of some of the major departments of the organization. Before joining BPC I had planned to concentrate on manufacturing processes only. But after joining I realized the importance of various other divisions as well. So instead of just studying operations at production department I studied the operation of whole organization taking RP as a example. So this report contains detailed operations of marketing division- order procurement, pricing strategy and sales promotion strategy. It also talks about procurement process- how vendors are identified, procedure adopted. The report goes on and talks about the production department and its importance, the processes involved in manufacturing of RP, time spent between two processes. At the end report has details about the store keeping practices and procedure followed at BPC. So overall this report has highlighted the operating activities of a typical manufacturing unit. It has helped me tremendously to see the application of the concepts of marketing and operations learnt in classroom in practical life.

Reciprocating Pump-from PO to GR[Type text]

Page 5

[Type the document title]

OBJECTIVES OF THE STUDY

The objectives of this study are as follow : To analyze the marketing Strategies & purchasing procedure of Bharat pumps and compressors limited. To understand coordination between all departments of Bharat pumps and compressors limited. To get the knowledge of public sector companies that how they work. To understand the planning procedure of manufacturing units. To get knowledge of stock keeping and Inventory control in BPCL. To apply the concepts of operations management read in class to practical use.

In order to achieve these objectives following steps were taken: Training was divided into manner so that I get some time to spend in each department of the company. This allowed me to understand their working and analyze whether they were in unison with other departments or not. Devote maximum time to marketing and production department of the company because these two are the most important part of the unit. Marketing brings in the order and production processes them. Company manufactures many products and for each it has a dedicated task force. So I concentrated on Reciprocating Pumps only for my ease of understanding

Reciprocating Pump-from PO to GR[Type text]

Page 6

[Type the document title]

METHODOLOGY

The information required for understanding the processes involved in procurement of purchase order to delivery of goods were obtained primarily by following methods : Study of previous product files : at the marketing and purchase department of the company I was provided with the previous product files which contained all communication with the client with respect to a particular product. It helped me in understanding how should we deal with customer in a B2B selling environment. The files had letters, right from initial enquiry to the last communication related to repair work needed (if any) for a particular machine. It was a secondary mode of data collection.

Study of processes involved in manufacturing of a reciprocating pump : my guide provided me with the manuals which contained all the steps needed in manufacturing. This was intended to make me familiar with the main steps involved in manufacturing of a reciprocating pump. It also helped me in getting some data for my report.

Direct information from the shop floor workers : any report related to manufacturing is incomplete without the inputs of the shop floor workers. So I observed them working on their jobs and also talked personally to them regarding their job. The objective was to identify whether they follow the manufacturing guidelines issued by the company or not.

Reciprocating Pump-from PO to GR[Type text]

Page 7

[Type the document title]

INTRODUCTION

Bharat Pumps and Compressors Limited inc. in 1970, under the ministry of heavy industries and public enterprise at Nain, the Trans Yamuna Area of Allahabad with the objectives to design, manufacture and supply of factory goods in the fluid handling filled including provision of services connected there with.

BPC which caters to the need of core sector of the economy such as oil exploration and exploitation, refineries, petro chemicals, chemicals and fertilizers, process industries, nuclear and thermal power plants, had its in earlier phase entered into technical collaboration with world renowned manufacturers to indigenously design and manufacture heavy duty centrifugal and

Reciprocating Pump-from PO to GR[Type text] Page 8

[Type the document title]

reciprocating pumps, reciprocating compressors and high pressures gas cylinders and other high tech oil field equipments such as cementing units, sucker rod pumps etc.

In very short span, the company absorbed the technology and established it self as a world renowned manufacturer of a wide range of high tech products. BPC has supplied its products to the total satisfaction of the customers in almost all national projects of company like ONGC, OIL, BPCL, IOCL, HPC, RCF, Nuclear Power Corporation, Dept. Of Atomic Energy, IPCL, etc. The company has a high credibility for quality of its products and acquired ISO 9001-2000, 14000, 18000(HASCP) certification COMPANYS VISION BUILDING TOMORROWS WORLD TODAY By providing Quality Engineering Products and Services through core competencies of our human resources and assets with focus on health and safety of power, society and environment.

Reciprocating Pump-from PO to GR[Type text] Page 9

[Type the document title]

COMPANYS MISSION OUR BUSINESS IS CLIENTS TOTAL SATISFACTION To provide excellent quality products and services to core sector industries with a special thrust on Oil and Gas, Petrochemicals, Refinery, Nuclear and Thermal power, fertilizer, and Public Transport Sectors. OBJECTIVES OF THE COMPANY To achieve a leading position in design, manufacture, testing, supply and erection of equipment for industry purposes. To lead in design, manufacture, testing and supply of nuclear pumps. To improve upon market share of centrifugal pumps for refineries, petrochemical, fertilizers sector and enter into power section. To develop export market of pumps, cylinders and services to earn foreign exchange. To develop a team of experts consisting of design engineering, quality control, production, erection and commissioning to make available consultancy services so as to guide and supervise plant performance of other companies. To develop the system capabilities in executing turnkey project.

MAIN PRODUCT OF COMPANY BPC has a large product range, serving almost all core sector industries: Centrifugal Pumps (as per latest edition of API 610) for Refinery and Petroleum Industry. Centrifugal Pumps for Nuclear Power plants. Reciprocating Pistons and Plunger Pumps as per API 674 latest edition. Reciprocating Fueling Machine Supply Pumps for Nuclear Power Plants High pressure liquid Ammonia Reactor Feed Pump High pressure seamless industrial cylinders. As per IS: 7285:BS970 High pressure compressed natural gas (CNG) cylinders for on-board applications. Compressed Natural gas (CNG) cascades

Page 10

Reciprocating Pump-from PO to GR[Type text]

[Type the document title]

RESEARCH AND DEVELOPMENT BPC technicians and engineers are frequently in contact with other organization operating and specialized research. It has contributed to the development of many project innovations and help to introduction of modern concepts. So has to keep BPC readdressed with the latest technology. MANPOWER In 1971, the no. of employees has not reached 200. Today it has 1200 employees. The higher technological level of production has achieved a corresponding increase in professional in knowledge of the employees. The aim has been achieved by employing higher qualified personnel and by organizing professional training and refresher courses for employees. Training of BPC technical staffs take place both at the overseas workshop of the company call lab orators as well as through organized in plant training program within the BPC. The welfare and development of its employees is nuclear of its personnel policy. MAJOR CLIENTS OF THE COMPANY Some of clients sector wise are: REFINARIES AND PETROCHEMICALS SECTOR Indian Oil Corporation Limited Hindustan Petroleum Corporation Limited Bharat Petroleum Corporation Limited Kochi Refinery Limited Numaligarh Refinery Mangalore Refinery and Petrochemicals Limited Chennai Petroleum Corporation Limited Tamilnadu Petro Products Limited Bongaigaon Refinery Indian Petrochemicals Corporation Limited

Page 11

Reciprocating Pump-from PO to GR[Type text]

[Type the document title]

Gas Authority of India Limited

OIL AND GAS SECTOR Oil and Natural Gas Corporation Limited Gas Authority of India Limited Oil India limited

Reciprocating Pump-from PO to GR[Type text]

Page 12

[Type the document title]

NUCLEAR POWER Dept. of Atomic Energy Bhabha Atomic Research Centre Nuclear Power Corporation Limited

FERTILIZERS AND CHEMICALS Tata Chemicals and Fertilizer Fertilizer Corporation Limited

Page 13

Reciprocating Pump-from PO to GR[Type text]

[Type the document title]

Hindustan Fertilizer and Chemicals Gujarat state Fertilizer Corporation Indo-Gulf Fertilizer and Chemical Madras Fertilizers Indian Farmers and Fertilizers Corporation (IFFCO) National Fertilizers Limited Bindal Agro fertilizers Chambal Fertilizers

Reciprocating Pump-from PO to GR[Type text]

Page 14

[Type the document title]

PROJECT OVERVIEW

The project is titled as Reciprocating Pumps- from purchase order (PO) to gate receipt (GR). it means that I have tried to study the various stages that reciprocating pump goes through. This includes processes from obtainment of purchase order by the marketing department till the issue of gate receipt by dispatch department. Initially I had planned to focus my study on operations part only of BPC but when I joined the company I realized that marketing was a very important department of the company. I felt that if I need to learn something from this internship then I must give attention to marketing as well. So my report has been divided into 2 parts. First part deals with the marketing operations of the company and second part with the study of processes involved in manufacturing of a reciprocating pump and their analysis with respect to the value stream mapping concepts learnt in class. As mentioned the first part deals with the marketing activities of BPC. 4 years ago BPC was a loss making unit of government of india but at present it is a highly profitable organization and recently a proposal has been sent to Government of India to include it in the list of NAVRATNA companies. What has lead to this tremendous turnaround? On enquiring with the employees I was told that the efficient handling of the marketing division by the new Managing Director Mr. A.K. Jain was one of the main reasons. So here I will be studying the marketing procedures followed at BPC keeping in mind the concepts of marketing mix studied. The second part of the report deals with the operating activities taking place in manufacturing of a reciprocating pump. The reason for choosing reciprocating pump as my product was that it was comparatively less complicated product. My guide suggested me to pick RP only. In his words RP is a product and all other are projects in themselves because they involve high degree of machining. I have developed a flowchart of work flow between different departments of the company and studied the time taken by each department. I had planned to study the shop floor operations too but I found them highly engineering based. Rather I studied the inventory management processes at the organization.

Reciprocating Pump-from PO to GR[Type text]

Page 15

[Type the document title]

MARKETING DEPARTMENT

Definition of marketing:Marketing is defined by the American Marketing Association as the activity, set of institutions, and processes for creating, communicating, delivering, and exchanging offerings that have value for customers, clients, partners, and society at large. The term developed from the original meaning which referred literally to going to market, as in shopping, or going to a market to sell goods or services. Marketing practice tends to be seen as a creative industry, which includes advertising, distribution and selling. It is also concerned with anticipating the customers' future needs and wants, which are often discovered through market research. Seen from a systems point of view, sales process engineering views marketing as a set of processes that are interconnected and interdependent with other functions, whose methods can be improved using a variety of relatively new approaches. Depending upon the product and customer presence marketing can be achieved in many ways. For example to sell certain goods, like FMCG products, companies use direct marketing or retail marketing. But when we talk about BPC we realize that its a heavy engineering based industry. Its products are highly customized.BPC doesnt produce product in bulks or batches. Products are manufactured only after getting customer order. So the marketing activities are business to business oriented (B2B). its a very critical activity because failure on this front can result in loss worth crores of rupees to the organization.

Reciprocating Pump-from PO to GR[Type text]

Page 16

[Type the document title]

MARKETING DEPARTMENT OF BPCL Marketing department of BPCL is divided into two parts:1. Marketing of product 2. Marketing of spare parts MARKETING OF PRODUCT The department handles the marketing of all good that is produced by firms and marketing persons work hard to improve condition of marketing. Nature of marketing is as follows. Taking of order Preparation of product Selling/Sending of product Collections of payment.

Functional relation of Marketing Department with Other Departments All the department of BPCL is interconnected with each other, below is flow diagram of connection of marketing department with some of the other department of BPCL.

Reciprocating Pump-from PO to GR[Type text]

Page 17

[Type the document title] Flow Charts of nature of marketing

Demand Latter (Information of goods)

Design Department

Application Department

Estimation Department

Production Department (Good Prepared)

Marketing Department (Offer Accepted) Sending of Offer

Marketing Department

Sending of Goods

Marketing Department

(Collection of money)

Reciprocating Pump-from PO to GR[Type text]

Page 18

[Type the document title]

MARKETING OF SPARE PARTS For the marketing of spare parts company form a SPCD (Spare Parts Component Division) department because company has a good market of spare parts. Generally company used to do marketing of the spares component of own products.

Procedure For Marketing Of Spare Parts

1. Customer Floats Enquiries/Tender (Requirement are generated by customer) News Paper Internet Latter Post Fax Mode

2. Design Application Squinty of Requirement (OK or Minor Modification)

3. Engineering Estimation Department (Manufacturing Cost)

4. Preparation & Submission of Tender (Document to customer with minimum cost & stipulated due date)

Reciprocating Pump-from PO to GR[Type text]

Page 19

[Type the document title]

Marketing Cycles

Tender/Enquiries from customer

Marketing Department (Register all tender)

Design application Department

Design estimation Department

Marketing Department (Preparation of offer)

Offer Submitted to customer

Offer Negotiation Commercial terms & Condition Technical queries if any

P.O Placed by customer on suppliers/Manufacturers

Reciprocating Pump-from PO to GR[Type text]

Page 20

[Type the document title]

Work order issued to the respective department

Job Manufactured

Inspection & Testing

Packing

Departure to Customer

Equipment Erection & commissioning

Payment fallow up/collection (Marketing Department)

Trouble shooting If any

Reciprocating Pump-from PO to GR[Type text]

Page 21

[Type the document title]

POST ORDER MARKETING FUNCTION After getting the order the function of the marketing department does not end. This department also monitors the execution of order. After receiving the order the marketing department gives the order details to the design department to prepare indent, later on various other departments carry of the functions like purchases production planning and control shop and assembly technical section and lastly marketing department also carry on the function of dispatching erection and commissioning and spare parts maintenance. The finance and human resource departments all carry on their function in the carry of the manufacturing process. Not only order fetching in the beginning and seeing at the end is the function of marketing, but execution of orders is also its prime responsibilities. MARKETING STRATEGY The main marketing strategy of BPCL is CAPATIVE MARKETING STRATEGY. In this regard company used to sell their product at low profit or at no profit or at loss and put high price of spare part of that good to take out margin & losses. That is company used captive pricing strategy for the growth of sell of companys product. PROFIT AND GROWTH STRATEGIES Prior to the Liberalized Economic Policy, Public Sector Enterprises had the benefits of price and purchase preference (with no limits) in case of domestic bids and deemed export benefits in case of ICB bid with the increased competition from private sector cos. Into Indian Market. The following measures have to be adopted to counter external threats and offset our weaknesses. CREATION OF MARKETING CELL Marketing Cell is fully responsible for: Market Survey Data Bank maintenance for market demands, Business share, competitors data activities. To find market strategies of competitors, their strength and weaknesses. Arrangement of technical seminars for new projects.

Page 22

Reciprocating Pump-from PO to GR[Type text]

[Type the document title]

Updating market plans. Once the order is matured into order, the file will be taken over by contract execution group.

RELOOKING INTO PRICING POLICY In view of very tough market conditions and world wide recession and low order book position: Order will be booked on marginal cost basis. Review of pricing policy once order book position improves recovery overheads from spare parts.

SEPRATE COSTING CENTRE FOR DIFFERENT PRODUCTS Since machining facilities and labor requirement are different for different products, separate costing centers shell is created so that the each product price is competitive as compare to our competitors. PREORDER PURCHASING ACTIVITIES BY MARKETING To have competitive detailed offers for bought out and major casting. To have complete technical details of bought outs before finalized of order by the customer. Sub ordering time period will be reduced. Reduction in overall cost will be assured.

STRENGTHING OF BRANCH OFFICE For day to day dealing with customers and to have latest feedback on off ere and Competitors activities. To improve upon business activities with customers and consultants.

Reciprocating Pump-from PO to GR[Type text]

Page 23

[Type the document title]

AGGRESSIVE MARKETING Frequent interaction with end users and consultants. Impress upon customers to include conditions in favor of BPCL. To impress upon customers to recommend turn keys bidders for buying BPCL made equipments only. Marketing intelligence reports and takes immediate action on it.

SERVICES AND SPARE PARTS PROMPT AFTER SALES SERVICES AND SUPPLY OF SPARE PARTS. POSITNG OF SERVICE PERSONNEL AT MAJOR BUSINESS CENTRE. Taking up turnkey projects. Will help improve in order book positions as well as financial positions. Will also help to have more orders for as now most of the customers are going for turnkey jobs rather than having more vendors for different items. Tie ups will be arranged with reputed turnkey bidders.

OPTIMUM SELECTION Optimum selection of BPCL products as well as bought outs to meet customers requirements. ENTRY TO THERMAL POWER SECTORS Since 60% of total pump requirements are from power sectors, entry to this business

give business give additional business to the times 300 to 5oo lakhs initially. This will require Simplification of designs Procurement of casting and manufacturing will be done in batches. Tie ups with BHEL/DPCL and other turnkey contractors.

Reciprocating Pump-from PO to GR[Type text]

Page 24

[Type the document title]

IMPROVEMENT IN DELIVERIES BY CREATING SEPARATE MARKET CELL FOR REVIESW OF ORDER Production control sales otherwise

SALES PROMOTIONAL STARTEGIES Maintaining closing liaison with government and public sectors clients and customers. Participation in trade delegation trade fare and exhibition in India and abroad Organizing seminars and workshops for important users and consultants. Improve the customers satisfaction by (a) organizing camps at various sites for a limited period, listening to customers problems, resolving them and providing technical guidance. Presentation to customers before customers zero date through audio visual presentation. Tie ups with turnkey contractors. Scanning and circulation of tenders notices advertised in newspapers, government bulletin. MARKETING OBJECTIVES To achieve a leading position in design and manufacture. Testing, supply and creation of equipments of process industries. To be a leader in design, manufacture, testing 7 supplies of nuclear pumps... To improve up market share of centrifugal pumps for refineries, petrochemicals fertilizer sectors and others into power sectors. To develop a team of exports centrifugal pumps for engineering, quality control production and commission to make available consultancy services so as to guide and supervise plant performance of other companies. To develop system capabilities in executing turnkey projects.

Reciprocating Pump-from PO to GR[Type text]

Page 25

[Type the document title]

PURCHASE DEPARTMENT

PURCHASING: In ordinary sense purchasing means acquiring of materials tools etc by payment .But to the purchasing functions as acquired and new dimensional and modern purchasing may be defined as the function of procurement of materials with on objective of reducing the investment in the materials to facilitates the manufacturers comparatives position in the marketing . Purchasing is the process with includes for the function involves from the time unneeded is recognized then the receipts and the final exoticness of the materials so purchases. OBJECTIVE OF PURCHASING: We know that manufacturer organization can achieve its targets or goals is increased in profit margin until its various departments, such as production, sales are different sets of objective for different sets of objective for different department To maintain regular flow of materials of production departments.

To minimize capital investment in materials.

To make right purchase.

To avoid duplication waste and obsolescence.

To maintain good relation with outside supplier.

To maintenance of companies competitive position in the market.

Reciprocating Pump-from PO to GR[Type text]

Page 26

[Type the document title]

PURCHASE PROCEDURE: Principal of purchasing: Right quality, right quantity, right time, right price, right source and right place of delivery, six rules which constitute the purchase principal are also used also used in BPCL Naini, Allahabad.

Right Time

Right Price

Right Place

Right Quantity

Right source

Reciprocating Pump-from PO to GR[Type text]

Right Quantity

Page 27

[Type the document title]

SCOPE OF PURCHASING IN BPCL: This purchase manual lays down the direction and guidelines to be followed by purchase department, or any other department/Regional Offices/cost centers on matters relating procurement of materials, equipment and related services. A.OBJECTIVE OF PURCHASING: To purchase required materials, equipment or related services at the right time at an optimum price consistent with requirement in a transparent and fair manner with special focus on meeting customer commitments. B.PURCHASE POLICY: Procurement should be made from approved vendors/proven sources only. However, under exceptional circumstances procurement can be made from other than approved/proven vendors with the approval of head of purchases (not below the GM otherwise it will have approval of MD). Bulk buying & bunching of materials required for several contracts /indents shall be done to the maximum extent possible derive price advantage. There shall be continuous effort to regulate inventory levels. C. VENDOR APPROVAL: Vendor evaluation and approval shall be continuous and dynamic process. The criteria will be based on process and organizational capability, requisite facilities, financial soundness, quality system, delivery/quality performance and competitiveness etc. Procedure for registration and approval of vendors for production items & their periodic performance evaluation and feedback shall be as ISO PROCEDURE 461002.

Reciprocating Pump-from PO to GR[Type text]

Page 28

[Type the document title]

D.LIMITED TENDER: Limited tender shall normally be addressed to all approved vendors with the approval of the competent authority. If the number of approved vendor is six or more and all are addressed, it shall be treated as open tender as open tender for the purpose of delegation of power (Deemed open tender).In case of single acceptable offers, if it is considered necessary to proceed further in the same tender enquiry (reasons to be recorded) it shall be treated as single tender for further processing/delegation of powers (Deemed single tender against L.T). E.SINGLE TENDER: The single tender route shall be resorted to only in exceptional cases. Single tender may be invited due to any of the following reasons, (exceptional circumstances) duly certified by the Head of the Indenting Department, not below the rank of DGM: Proprietary in nature.

Purchase from collaborators or from their recommended vendors.

Customers contract requirement.

F.QUOTATION & OPENING OF TENDERS: Two part /Single part Bids: Generally to part bid system is preferred where bids are invited in two Parts viz. techno-commercial (Part I) and price (part-II) bids. The techno commercial bids are opened first, discussed and finalized after freezing the scope, technical specification and commercial terms and conditions and only then price bids of acceptable vendors shall be opened.

Reciprocating Pump-from PO to GR[Type text] Page 29

[Type the document title]

For commercially off the materials where technical specifications and requirements are

clear, single part bid system may be followed. G.OPENING OF TENDERS: All tenders shall be opened at a specified place and appointed date and time by representatives of purchase & finance departments in the presence of representatives of vendors who would like to be present. Proper records of proceedings of tender opening shall be maintained. H.REPEAT ORDERS: Repeat ordering against order placed earlier on Open or Limited Tender basis (not single or deemed single tender basis) without calling for fresh tenders may be resorted to, with recorded reasons and approval of authority of the original order, provided there is no downward price trend and it should give benefit in delivery. Quantity discount/reduction in price offered by the vendor due to reduced effort on his part (design/marketing efforts etc.) shall neither be treated as downward price trend nor as negotiation. The repeat order can be placed up to the value of original order, however, value of repeat order can be up to two times in case where the original order did not exceed Rs 5 lacks i.e. value of order of two times basis would not exceed Rs 10 lacks. Subject to this condition, the repeat order can be for any number of time but within two years from the data of original order. However for low value item up to Rs.1000/- each and total value not exceeding Rs.10, 000/-, no such restriction shall be applicable.

Reciprocating Pump-from PO to GR[Type text]

Page 30

[Type the document title]

PRODUCTION DEPARTMENT

Production is one of the most important department of any manufacturing unit. A organizations fortune depends upon how efficiently the production department is handled and managed by the managers responsible for its operations. Managers at PEX have to be very careful and vigilant because apart from managing their department they inturn are managing whole operations of the unit. This is the hub of activities at BPCL. All departments report to PEX. Purchase Design Marketing

PEX

PEX

Shop

Packing

Stores

It performs the dual function of planning activities and then ensuring that the planned activities are executed properly. The primary planning activities are: Annual turnover planning Material planning Shop activities Sales order work program

Reciprocating Pump-from PO to GR[Type text]

Page 31

[Type the document title]

The executing functions are: Indenting Material monitoring as well as positioning Shop loading Issue of vouchers for WIP products Packing list

The operations of this department are so widespread that the work has been divided into a team of 2 managers. All departments generally have 1 manager but PEX has 2. One deals with centrifugal pumps, reciprocating compressors and shop activities. The other manager takes care of reciprocating pumps, work in progress (WIP) and stock section. As mentioned earlier my focus of study will be based on reciprocating pump only. So let us understand in brief about a reciprocating pump. A pump is a device used to move fluids, such as gases, liquids or slurries. A pump displaces a volume by physical or mechanical action. One common misconception about pumps is the thought that they create pressure. Pumps alone do not create pressure; they only displace fluid, causing a flow. Adding resistance to flow causes pressure. Pumps fall into two major groups: positive displacement pumps and rotodynamic pumps. Their names describe the method for moving a fluid. Reciprocating pumps are those which cause the fluid to move using one or more oscilating pistons, plungers or membranes (diaphragms).Reciprocating-type pumps require a system of suction and discharge valves to ensure that the fluid moves in a positive direction. Pumps in this category range from having "simplex" one cylinder, to in some cases "quad" four cylinders or more. Most reciprocating-type pumps are "duplex" (two) or "triplex" (three) cylinder. Furthermore, they can be either "single acting" independent suction and discharge strokes or "double acting" suction and discharge in both directions. The pumps can be powered by air,

Reciprocating Pump-from PO to GR[Type text] Page 32

[Type the document title]

steam or through a belt drive from an engine or motor. This type of pump was used extensively in the early days of steam propulsion (19th century) as boiler feed water pumps. Though still used today, reciprocating pumps are typically used for pumping highly viscous fluids including concrete and heavy oils and special applications demanding low flow rates against high resistance. BPC has the following manufacturing capacity:

Maximum Power Maximum Pressure Maximum Capacity Fluids Handled

1700 KW 2 675 kg/cm 3 315 M /Hr Drilling Mud, Cementing Slurry, Crude Oil steam, Condensate, Heavy Water, Fatty Acids, Ammonia Carbonate, Liquid Ammonia, Water Injection

Reciprocating Pump-from PO to GR[Type text]

Page 33

[Type the document title]

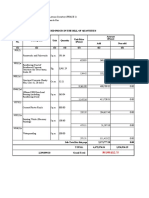

Activity time schedule for a reciprocating pump:

Recd of customer PO (mktg) 2 Release of SO ( mktg) 25 Issue of DPI (design) 3 45 Clearance of DPI ( msx)

Issue of BM/KL drgs (design)

Clearance of DPI ( pex) 2 Send DPI to purchase 20 PO placement ( mpx) 90 Material received in stores (msx)

Reciprocating Pump-from PO to GR[Type text] Page 34

[Type the document title]

2 DRS clearance ( msx) 3 SRV clearance (stores) 2 Docket loading (pex) 2 Material loading to shop (pex) 30 Processing of material (pex) 10 Vedor operation 2 Mat send to WIP by feeder 7 Mat collected by assembly

Reciprocating Pump-from PO to GR[Type text]

Page 35

[Type the document title]

10 Assembly 2 Internal utilization 2 Testing 2 Packing 1 Dispatch

Here the numbers besides arrow represent the ideal number of days the process should take to complete. Ideally a reciprocating pump should be ready to be delivered 229 days after receipt of purchase order. However when I studied the previous delivery files I noticed that mostly the delivery was possible after the scheduled date.

Reciprocating Pump-from PO to GR[Type text]

Page 36

[Type the document title]

To find out the real delivery time I studied previous 6 delivery files. Here are their delivery period details: 1) ONGC Mehsana --2) IOCL Jamnagar ---3) ONGC Dibrugarh --305 days 250 days 260days

4) ONGC Srirangapatnam- 256 days 5) HPCL Mumbai --232 days

6) Bongaigaon refinery -- 275 days

It clearly indicates that BPC has not been able to manufacture pumps in accordance with the standard time frame. This has led to severe monetory loss to company many times because in almost all agreements clause of late delivery and subsequent penalty is mentioned. Generally the penalty varies from 5 % to 10% of total cost. For a product whose cost runs in crores of rupees this penalty is significant. Lets highlight the negative impact of a late delivery : Monetory loss Loss of goodwill Increase in backlog of products When I tried to ascertain the reasons for frequent delay in production I came across following reasons: Old machinery: BPC has a vast variety of heavy machines. Some of them are very old and worned out. They do not give the output that is required to keep pace with the schedule. Workers mindset : BPC is a govt. firm. The mindset of its employee is that whether they work or not they will be paid. So they are not motivated enough to give their best performance.

Reciprocating Pump-from PO to GR[Type text]

Page 37

[Type the document title]

MANUFACTURING OF RECIPROCATING PUMP Till now we discussed about the departmental processes involved in manufacturing of reciprocating pumps. Now we will see the manufacturing activities which are performed. The work can be divided into 6 major parts. they are : Engineering Procurement Fabrication and Constuction Inspection Packing/ shipment Final book

Let us discuss each process in brief: Engineering : it is the initial phase of manufacturing of an RP. It consists of initial submission of drawings by the design department. This design is sent to client for approval.once the final design is approved it come back to PEX. It looks for the list of parts required in the manufacturing. The list is sent to stores to check for the available parts in stock. The final list of products unavailable is sent to purchase department for procurement. This whole process is expected to be completed in 20% of the time available from the date of PO received to CDD(contractual date of delivery). Procurement : BPC does not manufacture all parts of an RP. Most of the parts are either BO(bought out finished) or SB (semi bought out finished). Some of the major BO parts are crank shaft, extension rod, discharge manifold, suction manifold, discharge dampner with charging hose assembly. Some of the SB parts are frame, connectiong rods, fluid end assembly, stuffing box. These parts need machining before they can be assembled and fitted. The procurement is done by purchase department in the manner mentioned before. 30% of total processing time is allotted to procurement process. Fabrication and construction : this is the main process when job is loaded on machines and operated upon. Certain parts are manufactured inhouse like the base plate, certain extension rods. All the materials required for the constructions are bought out from stores and assembled as and when required. This part involves lot of labour intensive hours and hence accounts for 40% of net processing time.

Page 38

Reciprocating Pump-from PO to GR[Type text]

[Type the document title]

Inspection : Once the RP is ready it is put on test bed to check for any fault during manufacturing. Inspection is carried out by the representatives of the clients at the factory site. If they find the product as per the terms and conditions mentioned in the PO it is approved by the client to prepare for shipment. However if he finds the product unsatisfactory then the product may have to be send to shop again to make the necessary changes. Generally 5% of total time is set aside for this operation. Packing/shipment : this is the final stage of manufacturing at the shop floor. Product is meant to be transported to all over india. Some products are also shipped abroad. So its very essential to ensure a safe packing. Company arranges for a high abusive resistant packing to ensure safe delivery to designated destination. It sets aside 3% of total time for this. Final book : this is the process of finalizing the paper work associated with the product. Excise and custom duty needs to be remitted as per norms. clerance from states road departments needs to be obtained to ensure penalty free travelling. Product needs to be insured. All this paper work takes the 2% of total time.

Reciprocating Pump-from PO to GR[Type text]

Page 39

[Type the document title]

Materials management is the branch of logistics that deals with the tangible components of a supply chain. Specifically, this covers the acquisition of spare parts and replacements, quality control of purchasing and ordering such parts, and the standards involved in ordering, shipping, and warehousing the said parts. The other major component of materials management is standards compliance. There are standards that are followed in supply chain management that are critical to a supply chain's function. For example, a supply chain that uses just-in-time or lean replenishment requires absolute perfection in the shipping of parts and material from purchasing agent to warehouse to place of destination. Systems reliant on vendor-managed inventories must have up-to-date computerized inventories and robust ordering systems for outlying vendors to place orders on. Materials management typically insures that the warehousing and shipping of such components as are needed follows the standards required to avoid problems. This component of materials management is the fastest changing part, due to recent innovations in SCM and in logistics in general, including outsourced management of warehousing, mobile computing, and real-time logistical inventories. In bpcl they deal with the two measure component of material management I) Store Keeping Inventory Control

II)

STORE KEEPING

MEANING OF STORE A Store is one who caresses the store lying under his control. The dictionary meaning of term an individual who is a man of working class type and who maintains the store. Further a storekeeper is taken as a person who executes the retail orders of the foreman just like a shop assistant serves the customer at the counter. Some taken the term as a store- labor. But with the

Reciprocating Pump-from PO to GR[Type text]

Page 40

[Type the document title]

advancement of technical and scientific knowledge, the sphere of industry, trade and commerce has also we depend; and with the increasing importance of storekeeper.

STORE-KEEPING Store keeping refers to the safe custody of all item of material stocked in the storeroom for which the storekeeper acts as a trustee. The simple means that the material Carried into the store are to be stored I the storeroom in a such manner that. 1. The possibility of their being stolen or damaged due to fire or any other causes reduced, and.

2. They can be easily located and issued whenever required for use in and outside the storeroom, store keeping, thus may mean physical storage of material carried into the store room in a scientific manner with a view to.

3. Saving them from all kinds of damages, and losses and .

4. Exercising over all control over their movement.

OBJECTIVE OF STORE KEEPING The objective of storekeeping can broadly be categorized under following heads. 1. Minimization of the cost of production;

2. Providing efficient service;

Reciprocating Pump-from PO to GR[Type text] Page 41

[Type the document title]

3. Establishing coordination between the various department of the organization; and

4. Advising the management;

PROCEDURE ADOPTED IN BPCL FOR STORING OF DIFFERENT TYPES OF MATERIALS The store of BPCL is classified in three sections, which are given below:A. Receiving Cell B. Custody Cell C. Transport or Traffic Cell

A. RECEIVING CELL Receiving cell performs the following activities: 1. Receiving purchase department 2. Material receipt against challan, G.R. notes. 3. Preparation of materials arrival stores report. 4. Preparation of DRS (Daily receipt Stores) based on suppliers challan. 5. Clearance of DRS after unpacking of the package and physical checking of material as per DRS 6. Preparation of SRV with the help of cleared DRS and purchase order. 7. Preparation of DR (Shortage/Damage/Access) Report. 8. Intimation of supplier regarding shortage and damage if any.

Reciprocating Pump-from PO to GR[Type text] Page 42

[Type the document title]

9. SRV raised in nine copies in different series: a. Capital goods (1) b. Raw Material Goods (2) c. Casting and Forging (3) d. Component Group and Standard Bought out (4) e. Tolling Item (5) f. Consumable item and safety allied items (6) g. Cashes (69) h. Stationary Item (65) i. Electrical Item j. Offloading and Machinery (8) k. Cash purchase item (95) l. Sending of SRV to Q.C.X. Deptt. For Inspection of Materials (10) m. Hand overing of rejected materials to rejection stores (11) n. Preparation of rejected report & intimation to supplier (12) o. Dispatch of rejected material to supplier after setting suitable replacement (13) P. Distribution of SRV copies to various deptt (14) q. Filling of Cleared along with other paper (DRS Challans) in purchase order file (15)

Reciprocating Pump-from PO to GR[Type text]

Page 43

[Type the document title]

B. CUSTODY CELL:

In this cell following activities are performed; 1. Handling of materials to various custody groups along with SRV. 2. Storage and preservation of materials. 3. Posting of SRV in bin cards. 4. Tendering of SIV by user deptt. For issue of materials. 5. Issue of materials with control of SIV of SIV Control Register. 6. Dispatch of SIV (after issue of materials) of user as well as finance deptt. 7. Return of posted and cleared SRV back to receiving section. 8. Stock verification

C. Transport or Traffic Cell.

Transport section performed following activates: 1. Consignee section copy of GR notes along with other relevant paper from purchase department. 2. Entry of GR notes in GR Control Register. 3. Collection of materials from transports Go-down and Handling it over to receiving cell. 4. Receipt of sale Order from commercial. 5. Receipt of release order for dispatch. 6. Marketing arrangement of funds for excise only duty. 7. Arranging mode of transport.

Reciprocating Pump-from PO to GR[Type text] Page 44

[Type the document title]

8. Preparation of challan, Invoice and Outward materials gate pass. 9. Intimation to supplier directly or through communication regarding dispatch of materials. 10. Transporters billing activities.

VARIOUS FUNCTION OF STORE IN B.P.C.L. NAINI,

A. RECEIPT OF MATERIALS:

Receipt of purchase orders its filing and maintaining record.

Receipt of materials in store.

Finding and maintaining records of receipt documents E.g. Challans bills etc.

Entry of vouchers in daily receipt books

Getting the quality of items verified.

Reciprocating Pump-from PO to GR[Type text]

Page 45

[Type the document title]

Posting of items from daily receipt books in stocks, books.

B. ISSUE OF MATERIALS

Issue of materials to different department against SIV

Posting of SIV in stock books.

Posting of tools and plant register

C. PRESERVATION OF MATERIALS

Regular checking of physical condition of materials.

To adopt all necessary process for preservation of materials.

D. CHECKING OF CONSUMPTION REGISTERS

Maintaining records of consumption registers issued.

Checking of consumption registers.

Reciprocating Pump-from PO to GR[Type text]

Page 46

[Type the document title]

E. PHYSICAL CHECKING OF STORE

Preparing list of items balance as per stock books

Checking as per physical stock

Determining shortage and excess and its adjustment

F. ANNUAL STOCK VERIFICATION ALL THE LABS WORK SHOP

Making arrangement for annual physical stock verification of each lab and shop.

Follow up of stock verification and detaining verification report.

Maintaining records and making arrangement for removal discrepancy where found

G. CHECKING OF CHANGE LIST OF TIMER TO TIME Inviting proposal for write off.

Arranging the process of write off by the committee constitution for this purpose.

Reciprocating Pump-from PO to GR[Type text]

Page 47

[Type the document title]

Putting the report of write off from the stock of concern lab/work shop and from store record. H. DISPOSAL OF UNSERVICEABLE AND SCRAPE MATERIALS Preparing the list of items to disposed.

Sorting the items according to the method of disposal

Inviting tenders completing the process of disposal.

II. INVENTORY CONTROL

Inventory control refers to the process whereby in investment in materials and parts carried in stock in regulated within predetermined limits set in accordance with inventory policy established by the management. The activities of inventory control thus include the following: 1. Determination of limits of inventories to be held. 2. Determination of inventory policies. 3. Setting out of investment pattern and its regulation as per individual and collective requirements. 4. Follow up to examine the working of the inventory policy and effecting changes as and when needed.

Objectives of Inventory Control

Controlling of materials of controlling of inventory is very essential for production and finance control in any organization the effective control aims. The inventory control has been seeking

Reciprocating Pump-from PO to GR[Type text] Page 48

[Type the document title]

new and better control techniques to cope the complexities, masses of data and tight deadlines that are characterized by the highly competitive business environment of today. Inventory control has been struggling between too much and too little, too soon or too late that is what we can call inventory control in other works controlling the cost of inventories. Tow primary objectives of inventory control are: To minimize idling of men, machines which may arise due to shortage of raw materials, suppliers and spares parts to provide efficient and smooth service to the customers. To keep to minimum, (I) Capital (cash) back up or investment on inventories, and (II) inventory carrying cost, i.e., expenses involved in storing and handling inventories. The first objective requires holding large inventories i.e. making inventories (stock) as big as possible, whereas the second of objective requires holding only sufficient inventories. Both these objectives are, therefore, in conflict with each other. The challenge of inventory con troll is to balance these conflicting objectives. Inventory control tries this problem by striking an optimum inventory holding cost for each organization.

Reciprocating Pump-from PO to GR[Type text]

Page 49

[Type the document title]

RECOMMENDATIONS

Through out the duration of my internship at BPC one thing which was very evident was the excessive dependence on paperwork for all purposes. I had talks with the recently recruited employees of the BPC and they all were of the opinion that paperwork should be minimized. The need for an integrated ERP service is very much required. I understand that implementing it in a government setup is not an easy task but then it must be mentioned that this is a global arena now. Competitors with better equipped technology can be a concern for the company. ERP implementation should be done in a phased manner to enable proper absorption among all the employees. Coming to the production process I find that BPC need to invest in modernization. I had talks with shop floor workers and most of them, expectedly, were against any form of modernization. But talking to higher officials revealed that modernization is in their agenda. Its because of the fear of workers of losing their jobs, implementing it was proving to be a tough task. Management needs to convince the work force about the benefits of modernization.

Reciprocating Pump-from PO to GR[Type text]

Page 50

[Type the document title]

BIBLIOGRAPHY

1) Manuals and files at the marketing department, purchase department, production department and stores of BPC.

2) Operation management by Chase, Jacobs, Aquilano, Agarwal (11th edition)

3) Marketing Management by Philip Kotler

4) Utilizing simulation to enhance value stream mapping : a manufacturing case application by Thomas Mcdonald, Eileen M.Van Aken & Antonio F.Rentes

4) Website of BPC www.bpcindia.ac.in and other search engines like www.google.com

Reciprocating Pump-from PO to GR[Type text]

Page 51

[Type the document title]

Reciprocating Pump-from PO to GR[Type text]

Page 52

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Durga's Interview QuestionsDocument22 pagesDurga's Interview QuestionsRaJu SinGh82% (11)

- ISA RP60.3 Human Engineering For Control CentersDocument22 pagesISA RP60.3 Human Engineering For Control CentersDaniel Arrieta DarrásNo ratings yet

- Category (23) - Drilling of Shallow Oil/Water Wells, Workover and Ancillary ServicesDocument4 pagesCategory (23) - Drilling of Shallow Oil/Water Wells, Workover and Ancillary ServicesHarsh TiwariNo ratings yet

- Petex DOF BrochureDocument15 pagesPetex DOF BrochureJeevan BabuNo ratings yet

- Business Process ModelingDocument89 pagesBusiness Process ModelingAhsan Zaman100% (2)

- SIP PresentationDocument23 pagesSIP Presentationprince_tutuNo ratings yet

- Summers Presentation - Bharti AirtelDocument19 pagesSummers Presentation - Bharti Airtelprince_tutuNo ratings yet

- Mcnroe ChemicalsDocument43 pagesMcnroe Chemicalsprince_tutuNo ratings yet

- Mahindra FinanceDocument35 pagesMahindra Financeprince_tutu100% (1)

- Bajaj Final Sip ReportDocument51 pagesBajaj Final Sip Reportprince_tutu100% (1)

- 15.project Attendence Managemnt SystemDocument33 pages15.project Attendence Managemnt SystemAAAJAYNo ratings yet

- Ch03 TurbanDocument38 pagesCh03 TurbanIndi FebriNo ratings yet

- Lawaan Cemetery Part 2Document17 pagesLawaan Cemetery Part 2Mark Joseph ArellanoNo ratings yet

- The Critical Success Factors in Customer Relationship Management (CRM) (ERP) ImplementationDocument15 pagesThe Critical Success Factors in Customer Relationship Management (CRM) (ERP) ImplementationSatya Sai KiranNo ratings yet

- Mohamed Badr CVDocument2 pagesMohamed Badr CVMohamed BadrNo ratings yet

- Alok KadamDocument5 pagesAlok KadamJohnathan RoweNo ratings yet

- OSS ReferenceDocument336 pagesOSS ReferenceMonish R Nath50% (2)

- IntergrafDocument6 pagesIntergrafripac100% (1)

- Export PDS To Smart 3D User's GuideDocument6 pagesExport PDS To Smart 3D User's Guidedaisyduck2013No ratings yet

- Bloomberg Businessweek USADocument84 pagesBloomberg Businessweek USAalexe012No ratings yet

- General Considerations For Residential Considerations in Singapore Residential PropertyDocument54 pagesGeneral Considerations For Residential Considerations in Singapore Residential PropertyhosamlockNo ratings yet

- Ch11Integer Goal ProgrammingDocument54 pagesCh11Integer Goal ProgrammingAngelina WattssNo ratings yet

- List of BAPIsDocument35 pagesList of BAPIsthiago.alves.85No ratings yet

- Rai Quo NK 001 0124Document5 pagesRai Quo NK 001 0124yudii.hidayatNo ratings yet

- Honda Sales ProjectDocument72 pagesHonda Sales Projectsurendar100% (2)

- STD1 Crimping Chart March 2020 Final 2Document1 pageSTD1 Crimping Chart March 2020 Final 2Bernd RichterNo ratings yet

- (Type The Document Title) : Acquisition of Jaguar & Land Rover by Tata MotorsDocument46 pages(Type The Document Title) : Acquisition of Jaguar & Land Rover by Tata Motorsravneet050% (2)

- SAP-TO BE Financial Statement VersionDocument10 pagesSAP-TO BE Financial Statement VersionsivasivasapNo ratings yet

- Logistics Section 01 IntroductionDocument40 pagesLogistics Section 01 IntroductionNgọc Nhung Vũ100% (2)

- Bajaj PULSUR 220 DTS - OkokDocument75 pagesBajaj PULSUR 220 DTS - OkokSubramanya DgNo ratings yet

- MBA 6011 Partial Mod 19 2013Document11 pagesMBA 6011 Partial Mod 19 2013sumithaps66469No ratings yet

- Airworks TeaserDocument8 pagesAirworks TeaserNavin GuptaNo ratings yet

- GANTT Chart and Opertn BRK DwnsDocument10 pagesGANTT Chart and Opertn BRK DwnsJyoti PathrejaNo ratings yet

- Portable Machine MM2000iDocument3 pagesPortable Machine MM2000ijromero_rpgNo ratings yet

- Urban Planning With GisDocument9 pagesUrban Planning With GisMostaque AhmedNo ratings yet

- Raju - Reliability EngineerDocument2 pagesRaju - Reliability EngineerMadhuseptember2022No ratings yet