Professional Documents

Culture Documents

Helifix Cs03 Crack Stitching Repair Details

Uploaded by

Hemendra LalgiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Helifix Cs03 Crack Stitching Repair Details

Uploaded by

Hemendra LalgiCopyright:

Available Formats

CS03

Repair of a Crack Near a Corner in a Cavity Wall using HeliBars

METHOD STATEMENT

1. Using a twin-bladed, diamond-tipped wall chaser with vacuum attachment, cut slots into the horizontal mortar joints to the specified depth and at the required vertical spacing. Ensure that NO mortar is left attached to the exposed brick surfaces in order to provide a good masonry/grout bond. 2. Remove ALL dust and mortar from the slots and thoroughly flush with water. Where the substrate is very porous or flushing with water is inappropriate, use HeliPrimer WB. Ensure the slot is damp or primed prior to commencing step 6. 3. Cut the 6mm HeliBar to the required length and bend to fit in the slots. 4. Mix HeliBond cementitious grout using a power mixer and load into the Helifix Pointing Gun CS. 5. Fit the appropriate mortar nozzle. 6. Inject a bead of HeliBond grout, approx. 15mm deep, into the back of the slot. 7. Push the 6mm HeliBar into the grout to obtain good coverage. 8. Inject a second bead of HeliBond grout over the exposed HeliBar and iron it into the slot using a finger trowel. Inject additional HeliBond as necessary, leaving 10-15mm for new pointing. 9. The crack within the wall should be weather-proofed using an appropriate Helifix bonding agent e.g. HeliBond or CrackBond, depending on the width of the crack and the surface made good or left ready for any decoration. 10. Clean tools with clean, fresh water.

N.B. Pointing may be carried out as soon as is convenient after the HeliBond has started to gel.

RECOMMENDED TOOLING

For cutting slots up to 40mm deep........................................Twin bladed cutter with vacuum attachment For mixing HeliBond ................................3-jaw-chuck drill with mixing paddle For injection of HeliBond into slots ..............................Helifix Pointing Gun CS with mortar nozzle For smoothing pointing ...................................................Standard finger trowel

Specification Notes

The following criteria are to be used unless specified otherwise: A. Depth of slot into the masonry to be 35mm to 40mm. B. Height of slot to be equal to full mortar joint height, with a minimum of 8mm. For thin mortar joint specifications refer to the Helifix Technical Dept. C. HeliBar to be long enough to extend a minimum of 500mm either side of the crack or 500mm beyond the outer cracks if two or more adjacent cracks are being stitched using one rod. D. Normal vertical spacing is 450mm (6 brick courses). E. Where a crack is less than 300mm from the end of a wall or an opening the HeliBar is to be continued for at least 250mm around the corner and bonded into the adjoining wall. F. In hot conditions ensure the masonry is well wetted or primed to prevent premature curing of the HeliBond due to rapid de-watering. Ideally additional wetting of the slot, or priming with HeliPrimer WB, should be carried out just prior to injecting the HeliBond grout. G. Do not use HeliBond when the air temperature is +4C and falling or apply over ice. In all instances the slot must be thoroughly damp or primed prior to injection of the HeliBond grout. The above specification notes are for general guidance only and Helifix reserves the right to amend details/notes as necessary.

GENERAL NOTES

If your application differs from this repair detail or you require specific advice on your particular project, call the Helifix Technical Sales Team on 020 8735 5222. Our Technical Department can provide you with a full support service including:

G Advice, G

assistance and recommendations on all structural repair matters

Devising and preparing complete repair proposals for specific situations insurance-backed warranty via our Approved Installers scheme

G An

HELIFIX MASONRY REPAIR DETAILS April 2009

You might also like

- Design of FootingsDocument102 pagesDesign of FootingsTBCACCOUNTs100% (1)

- Sky DeckDocument44 pagesSky DeckEyob YimerNo ratings yet

- Diagnosing Defects in Historic BuildingsDocument10 pagesDiagnosing Defects in Historic BuildingsRafiq FitriNo ratings yet

- Preventing Annoying Floor Vibration: by Dr. Frank E. Woeste, P. EDocument4 pagesPreventing Annoying Floor Vibration: by Dr. Frank E. Woeste, P. EfraantoineNo ratings yet

- StructureMag DCA62012 StructuralSpecifications 1704Document4 pagesStructureMag DCA62012 StructuralSpecifications 1704PrateekPokharelNo ratings yet

- Designing Wood Schools: W D & B SDocument10 pagesDesigning Wood Schools: W D & B SAleksandar CherepnalkoskiNo ratings yet

- Deflection Limits For Floor Trusses: Revised 3/23/2017Document33 pagesDeflection Limits For Floor Trusses: Revised 3/23/2017lucasNo ratings yet

- Part 5 TilesDocument8 pagesPart 5 TilesFerdz ValenzNo ratings yet

- Materials Structures: BuildingDocument30 pagesMaterials Structures: BuildingVinicio FernandezNo ratings yet

- A Journal of Contemporaru Wood EngineeringDocument30 pagesA Journal of Contemporaru Wood EngineeringJose Martinez De MedinaNo ratings yet

- Row House Alternative 2Document1 pageRow House Alternative 2kushal nathNo ratings yet

- Gouts For Tile InstallationsDocument5 pagesGouts For Tile InstallationsSaud PathiranaNo ratings yet

- Corrosion Mitigation of Tanks: Chrissy HendersonDocument36 pagesCorrosion Mitigation of Tanks: Chrissy Hendersontania jessica gonzales giraldoNo ratings yet

- TJ 9003Document16 pagesTJ 9003AnthonyNo ratings yet

- When is blocking/bracing required within wood-frame wallsDocument3 pagesWhen is blocking/bracing required within wood-frame wallsSamia H. BhuiyanNo ratings yet

- KNS1042 Timber Part2 W11Document29 pagesKNS1042 Timber Part2 W11justine2109No ratings yet

- Weight Calculations Specific Weight (G/CM)Document15 pagesWeight Calculations Specific Weight (G/CM)Ranjeet Kumar ThakurNo ratings yet

- Oil Field Data HandbookDocument148 pagesOil Field Data HandbookUnknowneon100% (2)

- STP Equipment Layout 1: Control Room 1-02 Laboratory 1-01Document20 pagesSTP Equipment Layout 1: Control Room 1-02 Laboratory 1-01Archi Tonskie100% (1)

- How To Repair Plaster WallsDocument2 pagesHow To Repair Plaster WallsKumar SundaramNo ratings yet

- Revit SkillsDocument15 pagesRevit SkillsHemendra LalgiNo ratings yet

- 061000fl TrusjoistDocument25 pages061000fl TrusjoistabobeedoNo ratings yet

- Robot Getting Started Guide Eng 2011 Metric 2Document188 pagesRobot Getting Started Guide Eng 2011 Metric 2Dan Suciu100% (4)

- Summary of The International Existing Building CodeDocument4 pagesSummary of The International Existing Building Codefadapow4uNo ratings yet

- Timber Classification and StructureDocument44 pagesTimber Classification and Structurewan hazirahNo ratings yet

- Chapter 5-Prestressed Concrete DesignDocument51 pagesChapter 5-Prestressed Concrete DesignAzrai AzizNo ratings yet

- Defects in Buildings Construction - Structural & Non Structural Defects in ConstructionDocument5 pagesDefects in Buildings Construction - Structural & Non Structural Defects in ConstructionPrajakta RahateNo ratings yet

- Experimental Investigation of Structural Failure During The 2022 Fire SafetyDocument11 pagesExperimental Investigation of Structural Failure During The 2022 Fire SafetyDjibril GABRIELNo ratings yet

- Repair brickwork safely and effectivelyDocument8 pagesRepair brickwork safely and effectivelymoni_john_1No ratings yet

- Design and Analysis of Injection Mould with Hot Runner SystemDocument17 pagesDesign and Analysis of Injection Mould with Hot Runner SystemKiran KumarNo ratings yet

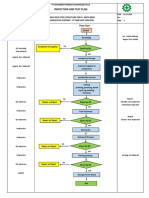

- Inspection and Test Plan: Flow Chart Start IncomingDocument1 pageInspection and Test Plan: Flow Chart Start IncomingSinden AyuNo ratings yet

- Autodesk Robot Structural Analysis Professional 2010 - Training Manual (Metric Version)Document178 pagesAutodesk Robot Structural Analysis Professional 2010 - Training Manual (Metric Version)ericfgNo ratings yet

- MS 1058 - Part 2 - 2005 PDFDocument23 pagesMS 1058 - Part 2 - 2005 PDFNurul Akma0% (1)

- Masonry Fire ResistenceDocument5 pagesMasonry Fire ResistenceJawad HussainNo ratings yet

- Maximum Span Tables: For Joists and RaftersDocument12 pagesMaximum Span Tables: For Joists and RaftersAntonio TorresNo ratings yet

- (2009) Repair Mortars For Historic Masonry PDFDocument13 pages(2009) Repair Mortars For Historic Masonry PDFAlida CrisNo ratings yet

- RI UST Regulations SummaryDocument84 pagesRI UST Regulations SummaryluisandradeNo ratings yet

- Brick / Masonry Foundatio NS: Click To Edit Master Subtitle StyleDocument11 pagesBrick / Masonry Foundatio NS: Click To Edit Master Subtitle StyleShruti JalodiaNo ratings yet

- Whatever Is Updated and RevisedDocument14 pagesWhatever Is Updated and RevisedWan Ah-LunNo ratings yet

- The Brownstone Guide: Maintenance & Repair Facts For Historic Property OwnersDocument12 pagesThe Brownstone Guide: Maintenance & Repair Facts For Historic Property OwnerspajinaNo ratings yet

- European Oak Grading Rules - 259 PDFDocument14 pagesEuropean Oak Grading Rules - 259 PDFmujic z100% (1)

- Actory Utual: General Information Wind and Wind UpliftDocument8 pagesActory Utual: General Information Wind and Wind Upliftspacex21No ratings yet

- UFC 3-570-06 - Cathodic Protection - (Draft)Document63 pagesUFC 3-570-06 - Cathodic Protection - (Draft)Johnny WalkerNo ratings yet

- European Oak Grading Rules 259Document14 pagesEuropean Oak Grading Rules 259Cristian Vacaru100% (1)

- 04-000-R1 Impressed Current Anodes SummaryDocument14 pages04-000-R1 Impressed Current Anodes SummaryGustavo OliveiraNo ratings yet

- Butterfly Valve Chamber: Top Plan Lower PlanDocument1 pageButterfly Valve Chamber: Top Plan Lower PlanmengineeringNo ratings yet

- ASCE 7-16 Live Load CDocument6 pagesASCE 7-16 Live Load CNgoc TonNo ratings yet

- 09C3A4USA033+Elite+Frame+Pool US EN SP V02Document28 pages09C3A4USA033+Elite+Frame+Pool US EN SP V02TasheenaNo ratings yet

- Impressed Current Cathodic Protection1Document2 pagesImpressed Current Cathodic Protection1swapneel_kulkarni100% (1)

- CP IntroductionDocument5 pagesCP IntroductionmunawarNo ratings yet

- R B WallsDocument8 pagesR B Wallsgtarun22guptaNo ratings yet

- Diving PDFDocument20 pagesDiving PDFTenaw AlamirewNo ratings yet

- Corrosion Protection of Tanks FRPDocument5 pagesCorrosion Protection of Tanks FRPaarmasp100% (1)

- Corrosion in Civil Engineering StructureDocument48 pagesCorrosion in Civil Engineering StructureSrikanth VihariNo ratings yet

- Tek 10-03Document4 pagesTek 10-03Thai DamNo ratings yet

- NASA Evaluates Criteria for Predicting Composite Delamination FailureDocument54 pagesNASA Evaluates Criteria for Predicting Composite Delamination Failuretrung4ad3100% (2)

- Roof TypesDocument152 pagesRoof TypesKerry GeohagenNo ratings yet

- Tpic 2011Document85 pagesTpic 2011garycwkNo ratings yet

- Abbreviations for Construction DrawingsDocument19 pagesAbbreviations for Construction DrawingsDenzil DanielNo ratings yet

- TFEC Timber Design Guide 17 Fire Resistance of Mass Timber StructuresDocument6 pagesTFEC Timber Design Guide 17 Fire Resistance of Mass Timber StructuresVelmohanaNo ratings yet

- Vermont Underground Storage Tank Installation ChecklistDocument7 pagesVermont Underground Storage Tank Installation ChecklistmhillebrennerNo ratings yet

- Maintenance and Repair Issues For Stone Cleaned Sandstone and GraniteDocument7 pagesMaintenance and Repair Issues For Stone Cleaned Sandstone and Granitekazuhiko_aikawaNo ratings yet

- Controlling Dampness in A Building ReportDocument35 pagesControlling Dampness in A Building ReportutkarshgayguwalNo ratings yet

- State Regulatory Code Specifics for Underground Storage TanksDocument27 pagesState Regulatory Code Specifics for Underground Storage TanksCossuNo ratings yet

- 2018 IspscDocument103 pages2018 IspscAnubhav MishraNo ratings yet

- SP15 99Document1 pageSP15 99Orlando Manriquez LNo ratings yet

- Corrosionengg 151021181918 Lva1 App6891Document133 pagesCorrosionengg 151021181918 Lva1 App6891pm2013100% (1)

- Impressed Current CP Quality Control and Inspection Report FormDocument1 pageImpressed Current CP Quality Control and Inspection Report FormBiswasNo ratings yet

- Helifix Complete Crack Stitching Repair DetailsDocument14 pagesHelifix Complete Crack Stitching Repair DetailsHemendra LalgiNo ratings yet

- Crack Stitching A Solid Wall Using HelibarsDocument1 pageCrack Stitching A Solid Wall Using HelibarsMisterphylNo ratings yet

- Ge Getting Started With GSADocument4 pagesGe Getting Started With GSAHemendra LalgiNo ratings yet

- Tata - ComFlor Brochure 201Document40 pagesTata - ComFlor Brochure 201pushpak2312No ratings yet

- Helifix Crackstitching Product InfosheetDocument1 pageHelifix Crackstitching Product InfosheetHemendra LalgiNo ratings yet

- Helifix Complete Crack Stitching Repair DetailsDocument14 pagesHelifix Complete Crack Stitching Repair DetailsHemendra LalgiNo ratings yet

- Helifix Cs04 Crack Stitching Repair DetailsDocument1 pageHelifix Cs04 Crack Stitching Repair DetailsHemendra LalgiNo ratings yet

- Ge Getting Started With GSADocument4 pagesGe Getting Started With GSAHemendra LalgiNo ratings yet

- Determining The Time of Setting of Portland CementDocument3 pagesDetermining The Time of Setting of Portland CementRizette PaloganNo ratings yet

- Standard VCS 5737,: Volvo Car CorporationDocument9 pagesStandard VCS 5737,: Volvo Car CorporationWei Yue ZhuanNo ratings yet

- MARAFIQ Pipe Specification Rev 1Document17 pagesMARAFIQ Pipe Specification Rev 1jaseelNo ratings yet

- Surface Preparation and Protective CoatingDocument19 pagesSurface Preparation and Protective CoatingnitinNo ratings yet

- Not For Production Use (For Reference Only) : ASTM A778-01Document1 pageNot For Production Use (For Reference Only) : ASTM A778-01Abu Bakr AsharefNo ratings yet

- 164 - Pragna PaperDocument16 pages164 - Pragna Paperucsproject2017No ratings yet

- Mechanical Properties of Al-14Si-2.5Cu-0.5Mg Aluminum-Silicon P/M AlloyDocument5 pagesMechanical Properties of Al-14Si-2.5Cu-0.5Mg Aluminum-Silicon P/M AlloySathwikRaoNo ratings yet

- REBARS - IK - ManufacturersDocument528 pagesREBARS - IK - ManufacturersTheoNo ratings yet

- Terminal CabinetDocument66 pagesTerminal CabinetChristine May CagaraNo ratings yet

- Intro to Concrete Structures DesignDocument42 pagesIntro to Concrete Structures DesignTanvirH.ChowdhuryNo ratings yet

- Engineering Utilities 2Document8 pagesEngineering Utilities 2Vanissa MontillaNo ratings yet

- Planning, Analyzing and Designing of Staff Quaters Building by Using STAAD ProDocument12 pagesPlanning, Analyzing and Designing of Staff Quaters Building by Using STAAD ProInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- PolyethyleneDocument31 pagesPolyethyleneHesham chemecology100% (1)

- Free Stock Hight TensileDocument1 pageFree Stock Hight TensileIRWANNo ratings yet

- Quantity Estimation of Building Basic Health UnitDocument30 pagesQuantity Estimation of Building Basic Health UnitWintun73No ratings yet

- Adm Specification PDFDocument10 pagesAdm Specification PDFsumeshmhrNo ratings yet

- 577roof Bolt TypesDocument15 pages577roof Bolt TypesOmar HelalNo ratings yet

- gr110 200 PDFDocument65 pagesgr110 200 PDFMuthu MohammadNo ratings yet

- EN 760 (Flux-SAW)Document2 pagesEN 760 (Flux-SAW)HoangNo ratings yet

- CoreTen Brochure PDFDocument2 pagesCoreTen Brochure PDFRashid MohammedNo ratings yet

- Brick TableDocument1 pageBrick TablewilliamNo ratings yet

- InstrumentsDocument10 pagesInstrumentsRomyna Mae GalangNo ratings yet