Professional Documents

Culture Documents

Work Instructions For Rolling of Plates

Uploaded by

Pravin PatilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Instructions For Rolling of Plates

Uploaded by

Pravin PatilCopyright:

Available Formats

DN WIND SYSTEMS INDIA PVT LTD

Document:

WORK INSTRUCTION FOR ROLLING OF PLATES

Responsibility:

Overall: Operating: Engineer (Production & QC) Machine Operator.

Instructions:

1. Process Instruction

1. 2. 3. 4. 5. Lift the plate with correct identification with the help of EOT crane. Load the plate to hydraulic table of machine. Use operating techniques for pre punching and rolling of plate as per Control chart. Start rolling as per instructions as displayed on Control Chart. Make sure the profile is matching to templates provided as per Control Chart only.

2. Process parameters & frequency of inspection.

1. Following parameters to be checked for quality,i. Top & Bottom side circumference. ii. Top & bottom side diameters (ovality). iii. Profile templates at both ends. iv. Root gap. v. Traceability of shell. vi. Visual. 2. Frequency of inspection 100% shells to be check for above mentioned parameters.

3. Specification & Tolerances

1. Dimensions to be maintain as per the corresponding section drawings. 2. Tolerances are as follows,i. Circumference - +6mm & -0mm ii. Diameter Max difference should be less than 1% of required diameter. iii. Profile template Should be within 0 to 3 mm. iv. Root gap to be maintain as per WPS requirements.

4. Points of OHS Concern

1. 2. 3. 4. 5. Assure the hydraulic Pressure is within limits as specified in machine specification. Use tool & tackles of proper capacity for lifting. Use Mask before start of cleaning of plate/shell with air. Use hand gloves while checking with templates and moving shell to next station. Ensure the Electrical supply is appropriate before starting the machine.

5. Points of Environmental Concern

1. Assure every week the hydraulic pipes are leak proof. 2. Collect and locate the removed scale metal to specified position only.

6. Points of Checking

1. 2. 3. 4. 5. 6. 7.

Reviewed by Signature: Reference No. : Issue. No. / Date:

Daily check for hoses and connections are proper Weekly checking of earthing connections for all the earthing pits and tables. Weekly checking for Roller lubricant. Fortnightly checking for hydraulic oil level. Half yearly checking of equipment fire fighting system. Ensure hoses of fire hydrant system are at place. Ensure availability of fire extinguishers.

Approved by Signature: Rev. No. / Date: Page 1 of 3

DNWSIPL/WI/03

01 / 15.01.2013

15.01.2013

DN WIND SYSTEMS INDIA PVT LTD

Document:

WORK INSTRUCTION FOR ROLLING OF PLATES

5. Points for Preventive Maintenance

1. 2. 3. 4. Half yearly tightening of earthing contacts to the earthing pits and tables. Weekly cleaning of switches and sensors. Half yearly cleaning of filters of hydraulic oil. Yearly cleaning of strainer of fire fighting system.

6. Points of Correction Action for deviations

1. 2. 3. 4. Press emergency button of the control unit of machine. In case of emergency, inform security, utility, safety officer & Plant Head. Operators are trained to handle emergency due to fatigue and machine failure. People not involved in fire fighting operation team directly, should quickly move through emergency exit routes & assemble at emergency assembly point.

7. Reaction Plan

1. 2. 3. 4. 5. In case of any non conformity, contact production supervisor In case of major deviation contact QC person. Stop the activity unless approval from QC. Mark according to color code (Hold/Reject) for non conforming objects. Raise internal non conformity (8D) report.

Documents:

No.

1. 2. 3.

Title

Process control chart Rolling plan Rolling Pressure chart

Location

Quality Department Quality Department Rolling Department

Retention

Up to next revision Up to next revision Up to next revision

Records:

No.

1. 2. 3. 4. 5. 6. 7.

Title

Tower dimension report (Register) Rolling book Breakdown Register Preventive Maintenance Register Production Register Accident record Register Internal 8D report

Location

Quality Dept. Production Dept. Maintenance Dept. Machine Operation Machine Shop Office Quality Dept. 3 years 3 years 3 years 3 years 1 Year 1 year 3 years

Retention

Material:

1. SMAW / GMAW welding machine 2. Welding rod / wire 3. Air compressor .

Reviewed by Signature: Reference No. : Issue. No. / Date:

Approved by Signature: Rev. No. / Date: Page 2 of 3

DNWSIPL/WI/03

01 / 15.01.2013

15.01.2013

DN WIND SYSTEMS INDIA PVT LTD

Document:

WORK INSTRUCTION FOR ROLLING OF PLATES

Instruments & Gauges:

1. 2. 3. 4. 5. Measuring tape (5M, 15M, 30M) Scale (6, 12) Right angle. Vernier gauge & thickness meter Rolling template.

Photos:

Pre-punching

Rolling

Inspection

Reviewed by Signature: Reference No. : Issue. No. / Date: Approved by Signature: Rev. No. / Date: Page 3 of 3

DNWSIPL/WI/03

01 / 15.01.2013

15.01.2013

You might also like

- Weld MapDocument4 pagesWeld MapSatish Keskar50% (2)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Welding Consumables Control RegisterDocument5 pagesWelding Consumables Control RegisterAli Mhaskar100% (2)

- Electrode Baking RegisterDocument1 pageElectrode Baking RegisterSuresh Rathod100% (4)

- Shell Rolling ProcedureDocument26 pagesShell Rolling ProcedureKingston Rivington100% (1)

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- Fit-Up Inspection Report PDFDocument1 pageFit-Up Inspection Report PDFAlfian Imaduddin100% (1)

- Attachment 22 - (SECL-PIP026) Welding Consumable Issue SlipDocument5 pagesAttachment 22 - (SECL-PIP026) Welding Consumable Issue SlipRjeb mohamedNo ratings yet

- List of Qualified WeldersDocument3 pagesList of Qualified WeldersdavNo ratings yet

- Indcon Projects Electrode Qualification Procedure IOCL Gas PipelineDocument11 pagesIndcon Projects Electrode Qualification Procedure IOCL Gas PipelineAkhilesh Kumar67% (3)

- Welding Consumable Baking Register PDFDocument1 pageWelding Consumable Baking Register PDFKandula Raju100% (1)

- WPS SUMMARYDocument10 pagesWPS SUMMARYbhavin178No ratings yet

- W10 Work Instructions For WeldingDocument1 pageW10 Work Instructions For WeldingMunazar Hussain100% (2)

- QC WELDING WORKS CHECKLIST Rev.0Document2 pagesQC WELDING WORKS CHECKLIST Rev.0Rajesh Kumar Ravi100% (2)

- Welding Safety ChecklistDocument2 pagesWelding Safety ChecklistSaid Elsamna100% (1)

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- Project quality control form QCF307Document1 pageProject quality control form QCF307minhnnNo ratings yet

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Weld Inspection ReportDocument5 pagesWeld Inspection ReportFord Katim100% (2)

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNo ratings yet

- Acceptance CriteriaDocument1 pageAcceptance CriteriaRamzi Dol Abdul Wahid50% (2)

- Updated Layered Welding Audit ChecklistDocument1 pageUpdated Layered Welding Audit Checklistcarey stewart100% (1)

- DPT Report - FormatDocument1 pageDPT Report - Formatskc0% (1)

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz Aydin100% (1)

- Sop For Fabrication of Fuel TankDocument3 pagesSop For Fabrication of Fuel TankVinod Kumar Verma75% (8)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Weld Map Details Joints and SpecificationsDocument22 pagesWeld Map Details Joints and Specifications9913489806100% (2)

- Procedure For Receipt, Storage and Handling of Welding Consumable (Rev 1)Document8 pagesProcedure For Receipt, Storage and Handling of Welding Consumable (Rev 1)dee1985100% (2)

- Valid SOP: Standard Operating ProceduresDocument10 pagesValid SOP: Standard Operating ProceduresShahid Raza100% (2)

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

- Welder, Welding Operator Qualification Test ReportDocument2 pagesWelder, Welding Operator Qualification Test Reportkarthik sundaramNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Welding Consumable and Storage ProcedureDocument10 pagesWelding Consumable and Storage Procedurehasan_676489616100% (1)

- Work Instructions For Arc Welding Machine: ReferenceDocument1 pageWork Instructions For Arc Welding Machine: Referencevivek sureshNo ratings yet

- Welding Procedure Specification and Procedure Qualification RecordDocument2 pagesWelding Procedure Specification and Procedure Qualification RecordNatdanai NorawanNo ratings yet

- Electrode Baking ProcedureDocument3 pagesElectrode Baking ProcedureAkhilesh Kumar90% (10)

- Inspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsDocument1 pageInspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsmukeshayoorNo ratings yet

- Welder Id SampleDocument1 pageWelder Id Sampledevendrasingh202157% (7)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- Welding Machine Preventive Maintenance RecordDocument1 pageWelding Machine Preventive Maintenance RecordChethan100% (2)

- WPQR Welding Procedure Qualification RecordsDocument3 pagesWPQR Welding Procedure Qualification Recordsramesh rajaNo ratings yet

- WPS Format For ASME IX - WQTDocument1 pageWPS Format For ASME IX - WQTThe Welding Inspections CommunityNo ratings yet

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- Welder TrainingDocument13 pagesWelder Trainingויליאם סן מרמיגיוסNo ratings yet

- Stage Wise Inspection ReportDocument2 pagesStage Wise Inspection ReportKarthi Keyan100% (2)

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- PQRDocument2 pagesPQRalokbdasNo ratings yet

- MPT Report FormatDocument1 pageMPT Report FormatRoshan ThomasNo ratings yet

- Dish End InspectionDocument2 pagesDish End InspectionTomy George80% (5)

- Electrode Handling Procedure - Simple - SMAWDocument7 pagesElectrode Handling Procedure - Simple - SMAWGalih Suksmono Adi0% (1)

- Saep 1146Document8 pagesSaep 1146Ronanki RaviNo ratings yet

- Mechanical Running Test Procedure for Instrument Air CompressorDocument7 pagesMechanical Running Test Procedure for Instrument Air CompressorkhozaqiNo ratings yet

- AC7102.1D Nadcap Audit Criteria For BrazingDocument11 pagesAC7102.1D Nadcap Audit Criteria For BrazingrsjfidderNo ratings yet

- Work Instruction On Tube ExpansionDocument40 pagesWork Instruction On Tube Expansionjayaarnav100% (1)

- API Inspection Categories Drilling RIG Equipment HoistingDocument5 pagesAPI Inspection Categories Drilling RIG Equipment Hoistingmalikpdj100% (6)

- MJR For 30M Maintenance Check of Check ValvesDocument9 pagesMJR For 30M Maintenance Check of Check Valvesxtremewhiz100% (1)

- Standard Appointment Letter for Management StaffDocument6 pagesStandard Appointment Letter for Management Staffashish_2410No ratings yet

- Procedure For Incoming InspectionDocument3 pagesProcedure For Incoming InspectionPravin Patil67% (3)

- 5S PosterDocument1 page5S PosterPravin PatilNo ratings yet

- Nik Weld ParameterDocument5 pagesNik Weld ParameterHarmish BhattNo ratings yet

- Tower No.:-Section No.:-: SR - No. Operation Date Time Sign RemarkDocument1 pageTower No.:-Section No.:-: SR - No. Operation Date Time Sign RemarkPravin PatilNo ratings yet

- IPL 2013 ScheduleDocument1 pageIPL 2013 SchedulePravin PatilNo ratings yet

- Top Car BrandsDocument14 pagesTop Car BrandsPravin PatilNo ratings yet

- Warehouse ProcedureDocument2 pagesWarehouse ProcedurePravin Patil0% (1)

- SIPAT WeldingDocument60 pagesSIPAT WeldingPravin PatilNo ratings yet

- Z-Test of SteelDocument1 pageZ-Test of SteelPravin PatilNo ratings yet

- Welding Parameter Record SheetDocument2 pagesWelding Parameter Record SheetPravin Patil100% (1)

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsDocument24 pagesPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishNo ratings yet

- Introduction To Chemical Reactor Engineering - Problems PDFDocument75 pagesIntroduction To Chemical Reactor Engineering - Problems PDFJojie-Ann Alabarca100% (1)

- Arora 2003 - VIPDocument6 pagesArora 2003 - VIPMaria Laura Viola AugustoNo ratings yet

- FTJ Series Product Guide PDFDocument12 pagesFTJ Series Product Guide PDFJhon SendokNo ratings yet

- A2 Biology Nerve Impulse ExamDocument16 pagesA2 Biology Nerve Impulse ExamDeborah HenniganNo ratings yet

- Three Dimensional Numerical Simulation of Shell and Tube Heat Exchangers Part I Foundation and Fluid Mechanics PDFDocument19 pagesThree Dimensional Numerical Simulation of Shell and Tube Heat Exchangers Part I Foundation and Fluid Mechanics PDFAltamash MunirNo ratings yet

- Aerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionDocument16 pagesAerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionAlberto De La CruzNo ratings yet

- Global Warming TextsDocument3 pagesGlobal Warming TextsAnonymous NbKeZIGDVMNo ratings yet

- Hardtop XP (Azad)Document5 pagesHardtop XP (Azad)Anonymous f1NlMPnNo ratings yet

- MNL 67-2009 PDFDocument128 pagesMNL 67-2009 PDFlolo100% (2)

- Applying Vat Dyes to Cotton FibersDocument3 pagesApplying Vat Dyes to Cotton FibersMuhammad Jawad Ul RehmanNo ratings yet

- A Comparative Study of ZnO-PVP and ZnO-PEG Nanoparticles ActivityDocument8 pagesA Comparative Study of ZnO-PVP and ZnO-PEG Nanoparticles ActivityVũ Hải NamNo ratings yet

- UTM Arau Prepares 4-BromobenzophenoneDocument7 pagesUTM Arau Prepares 4-BromobenzophenoneMay Lee100% (1)

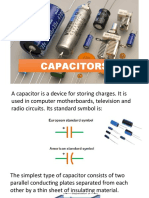

- CapacitorsDocument25 pagesCapacitorsAlbert Rosete0% (1)

- Vapor-Phase Hydrogen Peroxide Resistance of Environmental IsolatesDocument5 pagesVapor-Phase Hydrogen Peroxide Resistance of Environmental IsolatesMohamed FetouhNo ratings yet

- Gasket Assembly Stress Recommendations: Compressed Sheet, GRAPH-LOCK®, GYLON® and Gylon Epix™Document1 pageGasket Assembly Stress Recommendations: Compressed Sheet, GRAPH-LOCK®, GYLON® and Gylon Epix™dilo0987No ratings yet

- Decolorization and Organic Removal From Palm Oil Mill Effluent by Fenton's ProcessDocument5 pagesDecolorization and Organic Removal From Palm Oil Mill Effluent by Fenton's Processagungtiyo21No ratings yet

- Refinery Wastewater Treatment TrainingDocument27 pagesRefinery Wastewater Treatment TrainingHariajahNo ratings yet

- Etch Rates For Micromachining Processing PDFDocument2 pagesEtch Rates For Micromachining Processing PDFJohnathanNo ratings yet

- Cold Lime Soda Softening ProcessDocument10 pagesCold Lime Soda Softening ProcessSaurabh JadhavNo ratings yet

- Syllabus:-Biomolecules, Cell: The Unit of Life, Structural Organisation in AnimalsDocument9 pagesSyllabus:-Biomolecules, Cell: The Unit of Life, Structural Organisation in AnimalsEXCEPTIONAL FOCUSNo ratings yet

- 2013 12 Handbok Fittings ENG WebDocument72 pages2013 12 Handbok Fittings ENG WebVictor BiacoloNo ratings yet

- Culverts DesignDocument21 pagesCulverts DesignNani CherryNo ratings yet

- Material Properties of EPDM, NBR, and FPM Rubber Seals - Technical - Resources - BLUCHERDocument3 pagesMaterial Properties of EPDM, NBR, and FPM Rubber Seals - Technical - Resources - BLUCHERManish Pareek100% (1)

- Alternative-Refrigerants R22 GBDocument12 pagesAlternative-Refrigerants R22 GBMon PerezNo ratings yet

- 128 Salicylic Rohdia MSDSDocument13 pages128 Salicylic Rohdia MSDSWike Wingtias ArnesaNo ratings yet

- Ammonia: Latent Heat of OFDocument34 pagesAmmonia: Latent Heat of OFCastoriadisNo ratings yet

- ADMIX CATALOG 2015 16 WEB Links PDFDocument248 pagesADMIX CATALOG 2015 16 WEB Links PDFdan0427No ratings yet

- Synthesis, Properties, and Applications of Magnetic Iron Oxide NanoparticlesDocument24 pagesSynthesis, Properties, and Applications of Magnetic Iron Oxide NanoparticlessimoNo ratings yet

- 442-032 PDF PDFDocument12 pages442-032 PDF PDFCalNo ratings yet

- Chemistry 9 Chap 1 Long QADocument17 pagesChemistry 9 Chap 1 Long QAAkbar Ali AhmedNo ratings yet