Professional Documents

Culture Documents

Efficient Magnetic Localization and Orientation Technique For Capsule Endos

Uploaded by

Kumarivalli KannuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Efficient Magnetic Localization and Orientation Technique For Capsule Endos

Uploaded by

Kumarivalli KannuCopyright:

Available Formats

Efficient Magnetic Localization and Orientation

Technique for Capsule Endoscopy *

Chao Hu

1, 2, 3

, Max Qinghu Meng

2

, Mrinal Mandal

1

1

Department of Electrical and Computer Engineering, University of Alberta, Edmonton, AB T6G 2V4, Canada

2

Department of Electronic Engineering, The Chinese University of Hong Kong, Shatin, N.T. Hong Kong

3

Department of Electrical Engineering & Automation, Ningbo University, Ningbo, Zhejiang, 315211, PR China

hcsfds@ece.ualberta.ca, max@ee.cuhk.edu.hk, mandal@ece.ualberta.ca

Abstract -To build a new wireless robotic capsule endoscope

with external guidance for controllable and interactive GI tract

examination, a sensing system is needed for tracking 3D location

and 2D orientation of the capsule movement. An appropriate

sensing approach is to enclose a small permanent magnet in the

capsule. The magnet establishes a magnetic field around the

patients body. With the sensing data of magnetic sensor array

outside the patients body, the 3D location and 2D orientation of

the capsule can be calculated. Higher localization and orientation

accuracy can be obtained if more sensors and proper

optimization algorithm are applied. In this paper, different

nonlinear optimization algorithms are evaluated, and we have

found that Levenberg-Marquardt method provides higher

accuracy and faster speed. Simulations were done for

investigating the de-noise ability of this algorithm based on

different sensor arrays. Furthermore, the real experiment shows

that the results are satisfactory with high accuracy.

Index Terms - Wireless Capsule Endoscopy, Localization and

Orientation, Magnet, Optimization.

I. INTRODUACTION

One recent great breakthrough in endoscopy is the

development of wireless capsule endoscope. This new capsule

endoscope makes it possible for doctor to inspect the entire

gastrointestinal (GI) tract without causing much pain to the

patient, while the traditional endoscope cannot reach entire

small intestine and causes much discomfort. A clinical product,

known as M2A [1, 2], based on this technique, has been

developed by Given Image Ltd, and approved by U.S. Food

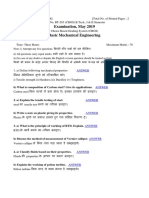

and Drug Administration [4]. Fig. 1 shows the composition of

the capsule endoscope, which is small (1128 mm) enough to

be swallowed. During the endoscopic test, the capsule moves

through the GI tract by natural peristalsis, while transmitting

out captured images using wireless technique.

However, M2A takes long time (between 20 to 36 hours)

to go through the entire human GI tract. In addition, it is

impossible for the doctor to control the capsules location and

orientation, and hence it is possible to miss capturing images

of some important spots. To address these limitations, we try

to make a new type of wireless robotic capsule endoscopic

system, where the capsule movement can be externally

* This project is supported by RGC Competitive Earmarked Research Grant

#CUHK4213/04E of the Hong Kong government, awarded to Max Meng.

Fig. 1 Wireless Capsule Endoscope

controlled [3,4]. Therefore, the capsule is guided to stop at any

important spots and is moved through unimportant areas in a

much faster pace. To realize such a system, an actuation and

guidance system is required. In our design, a small permanent

magnet is included in the capsule, which can be driven by

an externally applied magnetic field [5]. In order to realize

such external guidance and locomotion, it is a prerequisite that

the doctor know the location or orientation of the capsule.

Hence, a localization and orientation system of the capsule is

needed.

The M2A endoscopic system includes a localization module

[4, 6, 7]. The module is based on the RF (radio frequency)

signals received by eight antennas on the exterior of the human

abdomen corresponding to the emitting RF signals sent by the

capsule. The localization algorithm is based on the assumption

that the closest sensor receives the strongest signal. Because

the RF system is also used to transmit the captured images, this

module has the advantage that it does not need any additional

equipment. However, the measurement accuracy is too low

(average error is 37.7 mm [6, 7]), and we need to find more

efficient localization method.

Our implementation is to do magnetic localization using the

magnet enclosed in the capsule. Because human body has

magnetic permeability very similar to that of air, water, and

other non-ferromagnetic materials, it does not influence the

static magnetic field. Therefore, it is possible to achieve higher

localization accuracy with static magnetic method. A few

magnetic methods have been used for medical applications. For

example, it has been applied to monitor the movement of solid

oral dosage through GI tract by Weitschies et al [8]. Here the

magnetic measurement was realized by a commercial seven-

channel DC-SQUID device. Yoshiaki et al [9] used a magnetic

system consisting of a small magnet and four magnetic sensors,

3365 0-7803-8912-3/05/$20.00 2005 IEEE.

2005 IEEE/RSJ International Conference on Intelligent Robots and Systems

to measure both tooth rotation and rectilinear movements.

Akutagawa et al [10] used a magnet and a neural network

sensing system to measure the mandibular movement.

In this paper, we propose a localization and orientation

technique using a permanent magnet inside the capsule. The

magnetic field produced by the magnet is determined by its

location (3D) and orientation (2D). Therefore, we measure the

magnetic intensity and direction in some spatial points using a

few properly arranged sensors outside of the patients abdomen,

and determine the magnets (or capsules) location and

orientation by these sensor data. This idea was influenced by

the work reported by Prakash et al [11] and Schlageter et al

[12]. The system in [11] was used to localize a magnetic

marker in GI motility studies, based on the measurement data

of eight fluxgate magneto-meters. The system in [12] was built

with a 2D-array of 16 cylindrical Hall sensors and is used for

tracking the location and orientation of a general magnetic

marker. However, we cannot find detailed implementation

schemes and algorithms in these two papers, and it is our idea

to apply magnetic technique to track the capsule.

The magnetic intensity in a spatial point produced by the

magnet is a high-order nonlinear function of 5D magnets

location and orientation parameters. To solve such a problem,

an appropriate optimization method must be found, which

should have large tolerance of initial guess of the parameters,

fast speed, and strong de-noising ability. In addition, a reliable

magnetic sensing system should be built.

The organization of this paper is as follows. In section II,

we present the mathematical model of the magnetic field

produced by the permanent magnet, and evaluate several

nonlinear algorithms to determine the best algorithm in term of

calculation accuracy and speed. In section III, we present the

performance of the different sensor arrays, which is followed

by the conclusions in section IV.

II MATHMATIC MODEL AND MINIMIZATION ALGORITHMS

A. Mathematic Model

Fig. 2 shows a cylindrical magnet with length L, diameter b,

and a uniform magnetization

0

M M = (Amp/meter) on its

upper and bottom surfaces. Let P be the vector that represents

a spatial point p=(x

l

, y

l

, z

l

)

T

with respect to the magnet position

(a, b, c)

T

. The magnetic flux density at p can be calculated

using the following equation [13]

|

|

.

|

\

|

=

3

0

5

0 0

) ( 3

4

l l

T r

R R

M H P P H

B

|

|

.

|

\

|

=

3

0

5

0

) ( 3

l l

T

R R

N

H P P H

(1)

where

r

is the relative permeability of the medium,

0

is the

air magnetic permeability (Tm/A),

0

2

LM b M

T

= ,

4

0 T r

T

M

N = , and

0

H ==(m, n, p)

T

is the normalized vector

of the magnetic intensity of the magnet.

Assume that there are N sensors, with l-th sensor located at

(x

l

, y

l

, z

l

)

T

, 1 l N. The magnetic flux density at the l-th sensor

Fig. 2 Coordinate System for Magnets Localization

location can be represented by

N) , 1,2, l ( = + + = k j i B

lz ly lx l

B B B (2)

with three orthogonal components:

[ ]

+ +

=

3 5

) ( ) ( ) ( ) ( 3

l l

l l l l

T lx

R

m

R

a x c z p b y n a x m

N B

(3)

[ ]

+ +

=

3 5

) ( ) ( ) ( ) ( 3

l l

l l l l

T ly

R

n

R

b y c z p b y n a x m

N B

(4)

[ ]

+ +

=

3 5

) ( ) ( ) ( ) ( 3

l l

l l l l

T lz

R

p

R

c z c z p b y n a x m

N B

(5)

where

2 2 2

) ( ) ( ) ( c z b y a x R

l l l l

+ + = ,

In the proposed endoscopic system, the flux

intensities

lx

B ,

ly

B , and

lz

B are measured using the l-th

magnetic sensor located around position (

l l l

z y x , , )

T

, which is

known in advance. Note that there are six unknown parameters

(a, b, c, m, n, p). The flux intensity is invariant to the rotation

of the magnet along its major axis. Hence the magnets

orientation H

0

is in two dimensions. Therefore we add

following constraint for (m, n, p)

T

:

1

2 2 2

= + + p n m (6)

Equations (3)~(5) show the relationship between the flux

intensities at the l-th sensor and the magnet location and

orientation. For each sensor, we measure three magnetic

intensities

lx

B ,

ly

B , and

lz

B , and for N sensors, we obtain 3N

measured flux intensity values. Therefore, with two 3-axis

magnetic sensors or five 1-axis sensors, the six parameters of

the magnet location and orientation could be calculated by

solving (3)-(6).

Five sensors are the minimum to solve the 5 unknown

localization and orientation parameters. When N>5, the

solution is not unique (in the presence of noise), and we try to

obtain a solution of parameters (a, b, c, m, n, p) that minimize

an objective function. In this paper, we define an error

objective function as follows:

=

=

N

l

lx lx x

B B E

1

2 '

] [ (7)

3366

=

=

N

l

ly ly y

B B E

1

2 '

] [ (8)

=

=

N

l

lz lz z

B B E

1

2 '

] [ (9)

where

lx

B ,

ly

B , and

lz

B are defined by (3)~(5), and

'

lx

B ,

'

ly

B ,

and

'

lz

B are the three measured data of the l-th 3-axis

magnetic sensor. The total error is the summation of above

three errors.

z y x

E E E E + + = (10)

We need to find optimal parameters (a, b, c, m, n, p) to

minimize this error E. This is the least square error problem,

which can be solved by some minimization algorithms. To

evaluate the performance of an algorithm, we define two

parameters, localization error and orientation error as follows:

2 2 2

) ( ) ( ) (

t c t c t c p

c c b b a a E + + = (11)

2 2 2

) ( ) ( ) (

t c t c t c o

p p n n m m E + + = (12)

where (a

c

, b

c

, c

c

, m

c

, n

c

, p

c

) represent the calculated location

and orientation parameters, and (a

t

, b

t

, c

t

, m

t

, n

t

, p

t

) represent

the true location and orientation parameters of the magnet.

B. Localization and Orientation Algorithms

There exist several minimization algorithms to solve the

high-order nonlinear equations (7)~(10). To choose an

appropriate minimization algorithm, the following factors

must be considered:

1) A nonlinear optimization algorithm normally needs an

initial guess of the parameters, or their bounds, to begin the

search for the minimum. If the initial parameters are chosen

with large error, the algorithms may fail to give correct global

solution in case that there are many local minima. Therefore,

the chosen minimization algorithm should have large tolerance

of the initial guess of the parameters.

2) The minimization algorithm should be fast enough to

enable real time implementation.

3) The algorithm and system implementation should be

robust to the noises in the sensor data.

In this paper, we compare the performance of several

algorithms with respect to the localization error, orientation

error, and execution time. Our main objective here is to show

how these parameters change with the error level of the initial

guess of the parameters. We do the simulation with five x-axis

scheme as shown in Fig. 3, where S

1

~S

5

[S

1

=(0 0 0), S

2

=(0.1m

0 0), S

3

=(0 0.1m 0), S

4

=(-0.1m 0 0), S

5

=(0 -0.1m 0)] are the

locations of the five sensors, P

i

is the initial guess of the

magnets location, and P

t

(0.1m, 0.1m, 0.12m) is the true

magnets location. The error in the initial guess for magnets

location is defined by d = || P

i

- P

t

||.

In the following, we present several optimization

algorithms and their performances.

1. Powells Algorithm [14]

Powells algorithm is a local minimization method with

Fig. 3 Localization with 5 Sensors under Initial Guess of Magnets

Location which has error d with respect to true magnets location.

fast searching speed. In this algorithm, some searching

directions are defined based on quadratically convergent

method. With these directions, the multi-dimensional

minimization problem is changed to one-dimensional search

problem, and the minimized parameters are found when the

searches along these directions are completed. However, in our

trials, the calculation error of Powells algorithm is too large

to be acceptable. The localization error, orientation error, and

execution time are shown in Fig. 4, Fig. 5, and Fig. 6. It is

observed that the localization error reaches 8 cm under the

error levels (0.1 ~ 20 cm) of the initial location guess. The

orientation error reaches 30%. The average execution time is

0.367 second.

2. Downhill Simplex Algorithm [14]

The downhill simplex method is also a local minimization

method. Starting with an initial guess for the parameters, and

applying operation steps, e.g., reflection, expansion,

contraction and multi-contraction, the algorithm is then

supposed to make its own way downhill until it encounters a

minimum. As shown in Fig. 4, the results with downhill

simplex method are good with localization error smaller than

5mm when the initial guess error is smaller then 1.7 cm. When

the initial guess error is larger than 2.3 cm, the results are

unacceptable. Its average execution time is 0.290 second.

3. DIRECT [15]

DIRECT is an algorithm for finding the global minimum of

a multi-variant function subject to simple bounds. The

algorithm is a modification of the standard Lipschitzian

approach that eliminates the need to specify a Lipschitz

constant. The algorithm is called DIRECT because it is a

direct search technique and is an acronym for dividing

rectangles, a key step in the algorithm. As shown in Fig. 4, the

localization error is smaller than 10 mm under the location

level 0~20 cm of the search bounds. Also in Fig. 5 and Fig. 6,

we can see the orientation error is within 16 %, and its average

execution time is 0.503 second.

4. Multilevel Coordinate Search (MCS) [16]

MCS is similar to the DIRECT method for global

optimization based on multilevel coordinate search. Some

shortcomings of DIRECT are remedied in MCS so that it can

provide higher accuracy. The calculation errors using this

method are pretty small. As shown in Fig. 4 and Fig. 5, the

localization error is smaller than 0.2 mm, and orientation error

is smaller than 0.5%, under different values (0~20 cm) of the

3367

location bounds. However, the average execution time is 0.688

second, as shown in Fig. 6, which is longer than other methods.

5. Levenberg-Marquardt method [17]

The Levenberg-Marquardt method is a general nonlinear

downhill minimization algorithm. It dynamically mixes Gauss-

Newton algorithms and the gradient iterations. Both the

MATLAB functions lsqnonlin, the nonlinear least squares

solution, and fsolve, solving for roots of the nonlinear

equations, can provide the calculation of Levenberg-

Marquardt method. In our simulations, we have found that

lsqnonlin provides a marginally better accuracy than

fsolve. Excellent localization and orientation accuracy is

obtained with this algorithm. As shown in Fig. 4 and Fig.5, the

localization and orientation errors are zero when the error

levels of the initial guess of location are within 20 cm.

Moreover, this method provides faster speed with average

execution time 0.106 second.

Comparing above results, we can conclude that:

1) The local minimization methods, e.g. Powells and

downhill simplex, are not suitable because Powells method

results large error and downhill simplex has too small

tolerance for initial guess parameters.

Fig.4 Localization Errors of Minimization Algorithms under Different

Error Level of the Initial guess of Magnet Location.

Fig.5 Orientation Errors of Minimization Algorithms under Different

Error Level of the Initial guess of Magnet Location.

Fig.6 Execution Time of Minimization Algorithms under Different

Error Level of the Initial guess of Magnet Location.

2) The global minimization methods, e.g. DIRECT and

MCS, can provide high search accuracy, but their execution

speed is low.

3) The Levenberg-Marquardt method is an appropriate

algorithm. It provides satisfactory tolerance for initial guess

parameters, and faster speed (<0.11 Second).

III. PERFORMANCE EVALUATION

The techniques discussed in section 3 are typically valid

when there is no noise in the sensors. However, in a practical

system, there are always some noises due to the influences in

the sensors, the amplification circuit, human body, and the

environment. In this section, we present the simulation results

for de-noising abilities of different sensor arrays, and the

results obtained by a real testing system with sixteen 1-, 2- and

3-axis Hall sensors. We use the MATLAB function lsqnonlin

to perform the optimization calculations.

A. Simulation Results of Sensor Array

Although five sensors is the minimum to solve the 5

unknown localization/orientation parameters, the noise

response of 5-sensor implementation (Fig. 7a) might often be

unacceptable. Fig. 8(a) shows the localization error using five

1-axis (only x-axis) sensors via random noises with level 0.1 to

25 (25 is about 2~3 % full output range of the sensors). The

localization error might reach 200 mm. To improve the

accuracy, we use a denser sensor arrangement. In our

implementation, nine and sixteen 1, 2, and 3-axis sensors are

also tried. As shown in Fig.7b, 7c, for nine-sensor case, the

sensors are uniformly arranged on the 200200 mm

2

square

plane; whereas for 16-sensors case, the sensors are uniformly

arranged on the 240240 mm

2

square plane.

(a) 5-sensors (b) 9-sensors (c) 16-sensors

Fig.7 Disposition of the Sensor Array

3368

Table 1 shows the resulting average localization error (mm)

and orientation error (in percentage, relative to the unit

orientation vector) via random noises, where the distance

between the magnet to the sensor plane is 12cm. Fig. 8(b), (c),

and (d) show the localization errors with the cases of five, nine,

and sixteen 3-axis sensors.

(a) Five 1-axis (x-axis) sensors

(b) Five 3-axis sensors

(c) Nine 3-axis sensors

(d) Sixteen 3-axis sensors

Fig. 8 Localization Error sensors via noise level

Table 1 Average Localization/Orientation Errors

via Noise Level 0.1:0.2:25

1-axis

(x-axis)

2-axis

(x & y axes)

3-axis

5-sensors 42.7mm;

17.9%

16.8mm;

16.6%

9.1mm;

8.2%

9-sensors 26.4mm;

27.1%

10.8mm;

9.3%

6.4mm;

6.0%

16-sensors 14.2mm;

15.8%

6.6mm;

5.8%

4.6mm;

4.5%

It is observed that higher localization accuracy is obtained

with larger number of sensors. For the case of sixteen 3-axis

sensors, the average localization error is 4.6mm for and

orientation error is 4.5%.

B. Real Experiment and Testing Results

We built a real experiment system, which includes

magnetic sensors, precision amplification circuit, stabilized

power source, AD Converters, and PC computer. The

magnetic sensors are made of 3-axis Hall sensors. We tried the

sixteen-sensor scheme such that there are sixteen groups of 1,

2, or 3-axis magnetic intensity data on the sixteen sensor

positions. Using the Levenberg-Marquardt algorithm (in

MATLAB function lsqnonlin), the localization and

orientation parameters are calculated.

Fig. 9 and Fig.10 show the localization and orientation

errors. We see that, for sixteen 1, 2, and 3-axis sensors

respectively, the localization/ orientation errors are smaller

than (21mm /33%), (16mm/25%), and (12.6mm/12%); and the

average localization/orientation errors are (7.8mm/6.14%),

(7.3mm/5.35%), and (5.6mm /4.26%). Fig. 11 and Fig.12

show the 3D and 2D (x and y plane) localization results with

sixteen 3-axis sensors, and its average execution time of each

sample is 0.137 second. These results are pretty satisfactory,

comparing with the RF method using in M2A. The latter has

87.0% samples with error smaller than 60 mm; and the

average error was 37.7 mm.

Fig. 9 Localization error (mm) via Different Samples

for 1, 2, & 3-axis Sensors

3369

Fig. 10 Orientation error (relative to orientation vector)

via Different Samples for 1, 2, & 3-axis Sensors

Fig. 11 3D Localization Result

Fig.12 2D Localization Result

IV. CONCLUSIONS

An efficient magnetic technique is proposed for

localization and orientation of the capsule endoscope using a

permanent magnet. The detection system is composed of a

magnetic sensor array of five, or more number of, magnetic

sensors. Higher localization and orientation accuracy can be

obtained with denser sensor arrangement and the appropriate

optimization algorithm. Our experimental results show that

the Levenberg-Marquardt optimization method provides the

best performance in terms of calculation accuracy and

execution speed. In addition, a real test system has been built

by an array of sixteen 3-axis Hall sensors and results are

satisfactory with the localization error smaller than 10mm,

which is acceptable for tracking the capsule. In the future, we

will apply this system to the real localization and orientation

of the capsule in animal and human body. We are promising

for this localization and orientation system to be merged a

new system of the capsule endoscopy.

REFERENCES

[1] Gavriel Iddan, Gavriel Meron, Arkady Glukhovsky, and Paul Swain,

Wireless Capsule Endoscopy, Nature, Vol. 405, No. 6785, May, 2000,

pp.417.

[2] Gavriel J. Iddan, and C. Paul Swain, History and development of capsule

endoscopy, Gastrointestinal Endoscopy Clinics of North America,

14(2004), pp.1~9.

[3] Max Q.-H. Meng, Tao Mei, Jiexin Pu, Chao Hu, Xiaona Wang, and

Yawen Chan, Wireless Robotic Capsule Endoscopy: State-of-the-Art

and Challenges, Proceedings of the 5th World Congress on Intelligent

Control and Automation. Vol.6, June 15-19, 2004, pp.5561~5565.

[4] Zvi Fireman, Arkady Glukhovsky, and Eitan Scapa, Future of capsule

endoscopy, Gastrointestinal Endoscopy Clinics of North America,

14(2004), pp.219~227.

[5] M. Sendoh, K. Ishiyama, and K.-I. Arai, Fabrication of magnetic actuator

for use in a capsule endoscope, IEEE Trans.On Magnetics, vol.39, no.5,

September 2003, pp.3232~3234.

[6] Annette Fritscher-Ravens, and C. Paul Swain, The Wireless Capsule:

New Light in the Darkness, Digestive Diseases, 20(2002), pp.127~133.

[7] Doron Fischer, Reuven Schreiber, Daphna Levi, and Rami Eliakim,

Capsule endoscopy: the localization system, Gastrointestinal

Endoscopy Clinics of North America, 14(2004), pp.25~31.

[8] W. Weitschies, J. Wedmeyer, R. Stehr, and L. Trahms, Magnetic Markers

as a noninvasive tool to monitor gastrointestinal transit, IEEE

transactions on biomedical engineering, vol.41, no.2, 1994, pp.192~195.

[9] Yoshiaki Yamada, Noriaki Yoshida, Kazuhida Kobayashi, and Kiyotaka

Yamauchi, An application of magnet and magnetic sensor: measurement

system for tooth movement, IEEE Transactions on biomedical

engineering, vol.37, no.10, 1990, pp.919~923.

[10] M. Akutagawa, Y. Kinouchi, H. Nagashino, Application of neural

networks to a magnetic measurement system for mandibular movement,

Proceedings of the 19

th

annual international conference of the IEEE

Engineering in Medicine and Biology Society, Vol.20, No.4,

pp.1932~1935.

[11] N. Mani Prakash, and Francis A. Spelman, Localization of a magnetic

marker for GI motility studies: an in vitro feasibility study, Proceedings

of the 19

th

annual international conference of the IEEE Engineering in

Medicine and Biology Society, Oct.30-Nov.2, 1997, Chicago, IL. USA,

pp.2394~239.

[12] V. Schlageter, P.-A. Besse, R.S. Popovic, and P. Kucera, Tracking

system with five degrees of freedom using 2D-array of Hall sensors and a

permanent magnet, Sensors and Actuators A 92 (2001), pp.37~42.

[13] David K. Cheng. Field and Wave Electromagnetics: Static Magnetic

Fields. Addison-Wesley Publishing. 1989.

[14] Press, W.H., 1992, Numerical Recipes in C: The Art of Scientific

Computing, 2

nd

Edition, Cambridge University Press, Chapter 10.

[15] Mattias Bjorkman and Kenneth Holmstrom, Global Optimization Using

the DIRECT Algorithm in Matlab, Advanced Modeling and Optimization,

1(2), 1999, pp.17~29.

[16] Waltraud Huyer, and Arnold Neumaier, Global Optimization by

Multilevel Coordinate Search, Journal of Global Otimization, 14, 1999,

pp.331~355.

[17] Donald W. Marquardt, An Algorithm for Least-Squares Estimation of

Nonlinear Parameters, Journal of the Society for Industrial and Applied

Mathematics, Vol.11, No.2, 1963, pp.431~441.

3370

You might also like

- An Improved Magnetic Localization and Orientation Algorithm For Wireless Capsule EndoscopeDocument4 pagesAn Improved Magnetic Localization and Orientation Algorithm For Wireless Capsule Endoscopesun liangNo ratings yet

- De Oliveira 2021 J. Phys. Conf. Ser. 1826 012085Document8 pagesDe Oliveira 2021 J. Phys. Conf. Ser. 1826 012085Johnny Joe AguilarNo ratings yet

- A Sensor Fusion Algorithm For Cooperative LocalizationDocument8 pagesA Sensor Fusion Algorithm For Cooperative LocalizationVijaya YajnanarayanaNo ratings yet

- Improving Meg EegDocument6 pagesImproving Meg EegFrancisco Salto AlemanyNo ratings yet

- Sensors 15 19302 PDFDocument29 pagesSensors 15 19302 PDFLalo AngelNo ratings yet

- Engineering Clinics OpticDocument10 pagesEngineering Clinics OpticABDUL AHADU M 17BME063No ratings yet

- Research Article Microwave Tomography System For Methodical Testing of Human Brain Stroke Detection ApproachesDocument10 pagesResearch Article Microwave Tomography System For Methodical Testing of Human Brain Stroke Detection ApproachesChinaski BukowskiNo ratings yet

- Localizationmag10 (Expuesto)Document10 pagesLocalizationmag10 (Expuesto)mmssrrrNo ratings yet

- RRP Sample PaperDocument3 pagesRRP Sample PaperAna SpataruNo ratings yet

- ISO 9001:2008 Research Organization Tracks Coronary StructuresDocument6 pagesISO 9001:2008 Research Organization Tracks Coronary StructuresMuthumari AyyakannuNo ratings yet

- Kalvis M Jansons and Daniel C Alexander - Persistent Angular Structure: New Insights From Diffusion Magnetic Resonance Imaging DataDocument16 pagesKalvis M Jansons and Daniel C Alexander - Persistent Angular Structure: New Insights From Diffusion Magnetic Resonance Imaging DataTuhmaNo ratings yet

- Tomographic Diffraction Microscopt A Review of Inversion and Recent DevelpmentsDocument18 pagesTomographic Diffraction Microscopt A Review of Inversion and Recent DevelpmentsAsim AsrarNo ratings yet

- Sensors: Keeping A Good Attitude: A Quaternion-Based Orientation Filter For Imus and MargsDocument29 pagesSensors: Keeping A Good Attitude: A Quaternion-Based Orientation Filter For Imus and MargsmirkoNo ratings yet

- Sensors: Laser Sensors For Displacement, Distance and PositionDocument4 pagesSensors: Laser Sensors For Displacement, Distance and PositionLuis SánchezNo ratings yet

- Sensors: Lower Limb Wearable Capacitive Sensing and Its Applications To Recognizing Human GaitsDocument22 pagesSensors: Lower Limb Wearable Capacitive Sensing and Its Applications To Recognizing Human Gaitsmarius_haganNo ratings yet

- Magneto-Optical Tracking of Flexible Laparoscopic Ultrasound: Model-Based Online Detection and Correction of Magnetic Tracking ErrorsDocument26 pagesMagneto-Optical Tracking of Flexible Laparoscopic Ultrasound: Model-Based Online Detection and Correction of Magnetic Tracking ErrorsShinta MaharaniNo ratings yet

- Deploying Swarm Intelligence in Medical Imaging Identifying Metastasis, Micro-Calcifications and Brain Image SegmentationDocument11 pagesDeploying Swarm Intelligence in Medical Imaging Identifying Metastasis, Micro-Calcifications and Brain Image SegmentationSurbhi AnandNo ratings yet

- Cancellation of Unwanted Doppler Radar Sensor Motion Using Empirical Mode DecompositionDocument8 pagesCancellation of Unwanted Doppler Radar Sensor Motion Using Empirical Mode DecompositionJeong-geun KimNo ratings yet

- Fast AHRS Filter For Accelerometer Magnetometer AnDocument19 pagesFast AHRS Filter For Accelerometer Magnetometer AnhasanNo ratings yet

- Thesis PAPERDocument10 pagesThesis PAPERAhmed AbdelhadyNo ratings yet

- Sensors: A Sparse Reconstruction Algorithm For Ultrasonic Images in Nondestructive TestingDocument20 pagesSensors: A Sparse Reconstruction Algorithm For Ultrasonic Images in Nondestructive TestingBoulHich BoulHichNo ratings yet

- 3 D Vision Feedback For Nanohandling Monitoring in A Scanning Electron MicroscopeDocument24 pages3 D Vision Feedback For Nanohandling Monitoring in A Scanning Electron Microscopepurrab divakarNo ratings yet

- Sensors 11 09182Document25 pagesSensors 11 09182EduardoNo ratings yet

- Patient Adapted Augmented Reality System For Real-Time Echocardiographic ApplicationsDocument10 pagesPatient Adapted Augmented Reality System For Real-Time Echocardiographic ApplicationsGabriel KissNo ratings yet

- Applsci 08 01253Document15 pagesApplsci 08 01253Kundan karnNo ratings yet

- Estimation of IMU and MARG Orientation Using A Gradient Descent AlgorithmDocument7 pagesEstimation of IMU and MARG Orientation Using A Gradient Descent AlgorithmAchillesNo ratings yet

- Sensors: Accurate Orientation Estimation Using AHRS Under Conditions of Magnetic DistortionDocument17 pagesSensors: Accurate Orientation Estimation Using AHRS Under Conditions of Magnetic DistortionAndrewNo ratings yet

- Medical Physics - 2017 - O Brien - Relative Dosimetry With An MRlinac Response of Ion Chambers Diamond and DiodeDocument14 pagesMedical Physics - 2017 - O Brien - Relative Dosimetry With An MRlinac Response of Ion Chambers Diamond and DiodeANANTHARAMAN AYYALUSAMY.N.K.No ratings yet

- Magnetic Field Due To Brain ActivityDocument23 pagesMagnetic Field Due To Brain ActivitySuhas SureshNo ratings yet

- Duma 15 Handheld Scanning Probes For OCTDocument13 pagesDuma 15 Handheld Scanning Probes For OCTMainakNo ratings yet

- 2014 NUVAissisDocument9 pages2014 NUVAissisAngel ManriqueNo ratings yet

- Optimizing Sensor Deployment for IoT Using CPSO and ABC AlgorithmsDocument6 pagesOptimizing Sensor Deployment for IoT Using CPSO and ABC AlgorithmsHemanth S.NNo ratings yet

- TVG Survey Hawaii QASDocument10 pagesTVG Survey Hawaii QASgiovanni byceNo ratings yet

- Taulu JAP 05Document10 pagesTaulu JAP 05FayazKhanPathanNo ratings yet

- Multi-Target Tracking Using Ant-Colony Optimization For Static Sensor NetworksDocument4 pagesMulti-Target Tracking Using Ant-Colony Optimization For Static Sensor NetworksInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Novel and Compatible Sensing Coil For A Capsule in Wireless Capsule Endoscopy For Real Time LocalizationDocument4 pagesA Novel and Compatible Sensing Coil For A Capsule in Wireless Capsule Endoscopy For Real Time Localizationsun liangNo ratings yet

- A Novel Calibration Method For Non-Orthogonal ShafDocument10 pagesA Novel Calibration Method For Non-Orthogonal ShafNur jannah anna JannahNo ratings yet

- Era Paper1Document6 pagesEra Paper1john_j7No ratings yet

- Computers in Biology and Medicine: B. Nayebifar, H. Abrishami MoghaddamDocument8 pagesComputers in Biology and Medicine: B. Nayebifar, H. Abrishami MoghaddamMohammad RofiiNo ratings yet

- Resume C-ArmDocument4 pagesResume C-Armp27838121011No ratings yet

- Edge Detection and Classification in X-Ray Images. Application To Interventional 3D Vertebra Shape ReconstructionDocument8 pagesEdge Detection and Classification in X-Ray Images. Application To Interventional 3D Vertebra Shape ReconstructionfarancakNo ratings yet

- Application of Gps in Power SystemDocument2 pagesApplication of Gps in Power SystemRavinder KumarNo ratings yet

- Sensors 20 05329Document25 pagesSensors 20 05329sunil kumar sharmaNo ratings yet

- Ubiccjournalvolume2no3 4 43Document12 pagesUbiccjournalvolume2no3 4 43Ubiquitous Computing and Communication JournalNo ratings yet

- Three-Dimensional Localization Algorithm of Wireless Sensor Networks Base On Particle Swarm OptimizationDocument6 pagesThree-Dimensional Localization Algorithm of Wireless Sensor Networks Base On Particle Swarm OptimizationVasu PasupuletiNo ratings yet

- Chapter-2 Laser MeterDocument9 pagesChapter-2 Laser MeterLee Robert OlivarNo ratings yet

- SLAMBOT: Structural Health Monitoring Robot Using Lamb WavesDocument19 pagesSLAMBOT: Structural Health Monitoring Robot Using Lamb WavesJose De GouveiaNo ratings yet

- Data Processing Method For Geomagnetic DataDocument6 pagesData Processing Method For Geomagnetic DataGeophysicstes abdalla ismailNo ratings yet

- Elasticity Detection of IMT of Common Carotid ArteryDocument4 pagesElasticity Detection of IMT of Common Carotid Arterypurushothaman sinivasanNo ratings yet

- Adamov_2019_J._Phys.__Conf._Ser._1368_022001Document10 pagesAdamov_2019_J._Phys.__Conf._Ser._1368_022001Shadi AtriNo ratings yet

- Conic-Spiraleur: A Miniature Distal Scanner For Confocal MicrolaparoscopeDocument13 pagesConic-Spiraleur: A Miniature Distal Scanner For Confocal MicrolaparoscopeAnjireddy ThatiparthyNo ratings yet

- Satellite Image Processing Using Radiometric Resolution & Spectral ResolutionDocument11 pagesSatellite Image Processing Using Radiometric Resolution & Spectral ResolutionIJRASETPublicationsNo ratings yet

- Optical MagDocument6 pagesOptical MagonynhoNo ratings yet

- TOA Based Positioning of Medical ImplantsDocument5 pagesTOA Based Positioning of Medical ImplantsHadi RadNo ratings yet

- Remote Sensing: Radiometric Calibration Methodology of The Landsat 8 Thermal Infrared SensorDocument19 pagesRemote Sensing: Radiometric Calibration Methodology of The Landsat 8 Thermal Infrared SensorAstrolabeNo ratings yet

- Tracking The Vector Acceleration With A Hybrid Quantum Accelerometer TriadDocument44 pagesTracking The Vector Acceleration With A Hybrid Quantum Accelerometer TriadPiotr MatybaNo ratings yet

- Tomography Techniques For Acoustic Emission Monitoring: ECNDT 2006 - We.3.6.2Document13 pagesTomography Techniques For Acoustic Emission Monitoring: ECNDT 2006 - We.3.6.2FarzadNo ratings yet

- (X) Small Object Detection and Tracking - Algorithm, Analysis and Application (2005)Document10 pages(X) Small Object Detection and Tracking - Algorithm, Analysis and Application (2005)Hira RasabNo ratings yet

- Recognition of Polyps in The Images of Wireless Capsule EndosDocument4 pagesRecognition of Polyps in The Images of Wireless Capsule EndosInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Theoretical method to increase the speed of continuous mapping in a three-dimensional laser scanning system using servomotors controlFrom EverandTheoretical method to increase the speed of continuous mapping in a three-dimensional laser scanning system using servomotors controlNo ratings yet

- Syl LB Hms 240809Document102 pagesSyl LB Hms 240809sharma_anand73No ratings yet

- SP Racing F3 FC Board(Deluxe) internal OSD Specification and SetupDocument5 pagesSP Racing F3 FC Board(Deluxe) internal OSD Specification and SetupibyselfNo ratings yet

- NetAct Plan Editor 4.9-4 CNDocument4 pagesNetAct Plan Editor 4.9-4 CNAshraf JarjeesNo ratings yet

- Seminar ReportDocument12 pagesSeminar ReportNupurNo ratings yet

- GC Catalogue 2015 - 2017Document104 pagesGC Catalogue 2015 - 2017Джи СиNo ratings yet

- Remove the first element from a Redis list with LPOPDocument3 pagesRemove the first element from a Redis list with LPOPSantosh KambleNo ratings yet

- CFO To Chief Future OfficerDocument24 pagesCFO To Chief Future OfficerSuccessful ChicNo ratings yet

- NCERT Solutions For Class 7 English Supplementary Chapter 10 An Alien HandDocument2 pagesNCERT Solutions For Class 7 English Supplementary Chapter 10 An Alien HandMubeena TayyabiNo ratings yet

- Content-Based Image Retrieval System Using SketchesDocument50 pagesContent-Based Image Retrieval System Using SketchesHoney Merrin SamNo ratings yet

- Ang Alamat NG Gubat Bob OngDocument3 pagesAng Alamat NG Gubat Bob OngSunshine SungaNo ratings yet

- Q4-Hinge Theorem-ActivityDocument2 pagesQ4-Hinge Theorem-ActivityEmelie HernandezNo ratings yet

- Ifw Process GimDocument24 pagesIfw Process Gimmyownhminbox485No ratings yet

- Design & Analysis of Mono Composite Leaf SpringDocument5 pagesDesign & Analysis of Mono Composite Leaf Springijsret100% (1)

- SDO City of Malolos-Math5-Q4M1-Area of A Circle-Ramirez EWDocument25 pagesSDO City of Malolos-Math5-Q4M1-Area of A Circle-Ramirez EWKris Bernadette David100% (1)

- Using Sales and Operations PlanningDocument136 pagesUsing Sales and Operations PlanningJose Lara100% (1)

- BoilerDocument7 pagesBoilerXie ShjNo ratings yet

- Quarter 1 Revision SheetsDocument7 pagesQuarter 1 Revision Sheetsghada kamalNo ratings yet

- Computer NetworksDocument4 pagesComputer NetworksMainul HossainNo ratings yet

- MyFax User GuideDocument47 pagesMyFax User Guidesanjaya 黄保元No ratings yet

- 1st Bay Area Mathematical Olympiad February 23, 1999Document2 pages1st Bay Area Mathematical Olympiad February 23, 1999Karn KumarNo ratings yet

- What's in The Light: Bel Air Family Investment Awarded Silver Spoon AwardDocument14 pagesWhat's in The Light: Bel Air Family Investment Awarded Silver Spoon AwardlrbrennanNo ratings yet

- Methodology of Education Research MCQSDocument12 pagesMethodology of Education Research MCQSRAFIULLAHNo ratings yet

- Tool ShopDocument6 pagesTool ShopJiwithe NidahaseNo ratings yet

- Personality TypesDocument20 pagesPersonality TypesGURNEESHNo ratings yet

- BT 203 Basic Mechanical Engineering May 2019 PDFDocument2 pagesBT 203 Basic Mechanical Engineering May 2019 PDFKunta PatleNo ratings yet

- Data Mining Course Learn Analytics RDocument5 pagesData Mining Course Learn Analytics RAntonio AlvarezNo ratings yet

- Booklet First Step 2023Document73 pagesBooklet First Step 2023Jose Leonardo Nuñez EscobarNo ratings yet

- 1 HN 1 To 4000Document308 pages1 HN 1 To 4000K SachinNo ratings yet

- Ap Art CrashcourseDocument19 pagesAp Art Crashcourseapi-298825724No ratings yet

- ASTM C 1260 Expansion LimitsDocument12 pagesASTM C 1260 Expansion Limitsheisin1865No ratings yet