Professional Documents

Culture Documents

About Quality Management

Uploaded by

saloni3122Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

About Quality Management

Uploaded by

saloni3122Copyright:

Available Formats

About Quality management A quality management system is a management technique used to communicate to employees what is required to produce the

e desired quality of products and services and to influence employee actions to complete tasks according to the quality specifications. What Purpose Does a Quality Management System Serve? Establishes a vision for the employees. Sets standards for employees. Builds motivation within the company. Sets goals for employees. Helps fight the resistance to change within organizations. Helps direct the corporate culture.

Practices in Honda Honda's quality cycle By applying design and development expertise to design and development, production preparations, and production (mass production) in order to allow the creation of drawings designed to facilitate manufacturing and develop manufacturing control techniques that limit process variability, we are able to deliver a new level of outstanding quality.

System to enhance products quality We established a Quality Center to bring together the various components of our organization that are concerned with products quality data, allowing us to enhance our worldwide ability to both prevent quality issues and quickly detect and resolve them when they occur. Handling quality issues When we determine that product issues require action, we quickly report the issue to governmental authorities in accordance with individual countries' regulations.

Quality management education

In Japan, Honda offers a training curriculum divided into four courses according to in-house qualifications and the extent of individual workers' quality control responsibilities in order to improve associates' quality assurance skills.

Aiming for 120% products quality

"We have to aim for 120% product quality. If 99% of the products we make are perfect, that would seem

like a pretty good record. However, the customers who become the owners of the remaining 1% will surely consider their products 100% defective. It is unacceptable that even one customer in a thousandeven one customer in ten thousandshould receive a defective product. That's why we have to aim for 120%." When founder Soichiro Honda said this he defined the company's fundamental approach to quality: what it means to strive to be a company society wants to exist. Determined to meet or exceed the expectations of customers, Honda is taking new initiatives to reach ever-higher product quality standards. That is who we are. To strengthen customer trust by offering products founded in safety and offering a new level of outstanding quality, Honda has created a quality cycle that continuously enhances quality at every stage: design, development, production, sales and after-sales service.

Implementing the Global Honda Quality Standard (G-HQS)

As Honda's production and parts and materials sourcing expand globally, a shared global quality assurance standard is essential to ensuring that all Honda facilities continue to support 120% product quality. To address this need, Honda established the Global Honda Quality Standard (G-HQS) in April 2005. Based on the ISO 9001*1 and ISO/TS 16949*2 standards under which Honda facilities in Japan and around the world have been or are to be certified, the G-HQS serves to communicate the considerable knowledge Honda has gathered in producing quality products and help prevent issues from recurring. It will continue to conform to ISO certification standards. As of March 2012, all 46 Honda production facilities around the world have attained ISO certification. The G-HQS is designed to enhance the quality of Honda-brand products manufactured and sold worldwide. By ensuring that all facilities comply with these standards, we can better facilitate the interoperation of quality assurance systems at different worksites, contributing to quality assurance not only in production activities, but also in distribution and service. *1 ISO 9001: An international quality control and quality assurance standard *2 ISO/TS16949: An international quality management system standard for the automotive industry

47

You might also like

- NAPCOS Patrol Phase Exam 2Document8 pagesNAPCOS Patrol Phase Exam 2Freddie Evangelista100% (5)

- Significance of Knowledge Management at Toyota & Role of RFID within SCM of Manufacturing firmsDocument10 pagesSignificance of Knowledge Management at Toyota & Role of RFID within SCM of Manufacturing firmsSalman AsifNo ratings yet

- MAF251 Chapter 1Document19 pagesMAF251 Chapter 1Hasrul Daud100% (1)

- Lincoln Electric's Unique Management System Drives ProductivityDocument6 pagesLincoln Electric's Unique Management System Drives ProductivityKeresh HallNo ratings yet

- IHRM - Assignment-Udit GourDocument3 pagesIHRM - Assignment-Udit GourUdit GourNo ratings yet

- Group Assignment Logistic and Supply Chain Management ALS2023Document29 pagesGroup Assignment Logistic and Supply Chain Management ALS2023邢益润No ratings yet

- What Is The Iso 9001Document2 pagesWhat Is The Iso 9001kiruhura Erick100% (1)

- TQM Presentation - Management Accounting & Performance AnalysisDocument58 pagesTQM Presentation - Management Accounting & Performance AnalysisAmirul HafizNo ratings yet

- Nestle - Corporate Governance and FDocument112 pagesNestle - Corporate Governance and FFarahaidaRRNo ratings yet

- Cultural analysis discussion questionsDocument4 pagesCultural analysis discussion questionsbokikg87No ratings yet

- Management of Services: Key Concepts and ClassificationsDocument9 pagesManagement of Services: Key Concepts and ClassificationsPRABHUDEVANo ratings yet

- HR Planning Aftab Automobile LimitedDocument11 pagesHR Planning Aftab Automobile LimitedMd. Shahnewaz KhanNo ratings yet

- Pib19063 - Case QCCS at Syarikat SDN BHDDocument4 pagesPib19063 - Case QCCS at Syarikat SDN BHDFAZIELLA MUSA100% (1)

- Inventory Management in Supply ChainDocument11 pagesInventory Management in Supply Chainparadise AngelNo ratings yet

- Marketing in Indian EconomyDocument15 pagesMarketing in Indian Economyshivakumar NNo ratings yet

- The Difference Between Auditors and Forensic AccountantsDocument1 pageThe Difference Between Auditors and Forensic AccountantsMohammed MickelNo ratings yet

- Final Examination (21355)Document13 pagesFinal Examination (21355)Omifare Foluke Ayo100% (1)

- Chapter 16 Case Application 1Document4 pagesChapter 16 Case Application 1Thư VõNo ratings yet

- Implementation of BCG Matrix in Malaysia CompanyDocument20 pagesImplementation of BCG Matrix in Malaysia CompanybubbleteaNo ratings yet

- Assignment 1Document3 pagesAssignment 1Abebe Nigatu100% (1)

- Strategic Management at Unilever BangladeshDocument18 pagesStrategic Management at Unilever Bangladeshiftekhar100% (1)

- The Effectiveness of ISO 9001 Implementation in Fo PDFDocument10 pagesThe Effectiveness of ISO 9001 Implementation in Fo PDFAbusaada2012No ratings yet

- Industry ProfileDocument20 pagesIndustry ProfileShanu shriNo ratings yet

- Vanish CaseDocument14 pagesVanish CaseLokesh KhatwaniNo ratings yet

- Chapter 19 Introduction To Management PearsonDocument3 pagesChapter 19 Introduction To Management PearsonRanin, Manilac Melissa SNo ratings yet

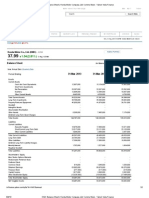

- HMC Balance Sheet - Honda Motor Company, LTD PDFDocument2 pagesHMC Balance Sheet - Honda Motor Company, LTD PDFPoorvi JainNo ratings yet

- Functions of RetailingDocument24 pagesFunctions of Retailingsurabhi01197500% (1)

- David sm17 Case Im 07Document23 pagesDavid sm17 Case Im 07César David Pérez AguilarNo ratings yet

- MGT162 160Document9 pagesMGT162 160Rijal RsNo ratings yet

- Common Size Analys3esDocument5 pagesCommon Size Analys3esSaw Mee LowNo ratings yet

- Investment and Portfolio Management, Chapter 1 Introduction To InvestmentDocument8 pagesInvestment and Portfolio Management, Chapter 1 Introduction To InvestmentAmbachew MotbaynorNo ratings yet

- Harley-Davidson's Focus StrategyDocument24 pagesHarley-Davidson's Focus Strategysaveen thapaNo ratings yet

- MGT321Document15 pagesMGT321Navid Al GalibNo ratings yet

- Toyota Situation AnalysisDocument3 pagesToyota Situation AnalysisSayed Riyaz0% (1)

- Boost Employee Commitment & Productivity with Job SatisfactionDocument1 pageBoost Employee Commitment & Productivity with Job SatisfactionHayati AhmadNo ratings yet

- Internship Report Siemens Pakistan EnggDocument17 pagesInternship Report Siemens Pakistan Enggcapriconj100% (1)

- Assignment: National College Business AdministrationDocument4 pagesAssignment: National College Business AdministrationZubair Afzal Khan0% (1)

- Exam Docs Dipifr 2012Document2 pagesExam Docs Dipifr 2012aqmal16No ratings yet

- OB CaseStudyPresentationDocument12 pagesOB CaseStudyPresentationvichu_12684100% (1)

- North South University MKT627 (1) - Summer 2020 Quiz-1, Marks-10 Name: Tasnova Lutfor ID: 1825062090 SL No: (SL - 11)Document1 pageNorth South University MKT627 (1) - Summer 2020 Quiz-1, Marks-10 Name: Tasnova Lutfor ID: 1825062090 SL No: (SL - 11)Tasnova Lutfor 1825062090No ratings yet

- Group No 10 HRIS AssignmentDocument8 pagesGroup No 10 HRIS AssignmentWinifridaNo ratings yet

- Entrepreneurship ProjectDocument5 pagesEntrepreneurship Projectneha bagrechaNo ratings yet

- 2014 Perodua Improving Customer SatisfaDocument16 pages2014 Perodua Improving Customer Satisfanusra_t100% (1)

- Quality AwardsDocument28 pagesQuality Awardsrmanojbabu100% (1)

- Maf671 - Case SummaryDocument9 pagesMaf671 - Case SummarySheikh Are-kimNo ratings yet

- Memo Assignment QSDocument5 pagesMemo Assignment QSathirah jamaludinNo ratings yet

- Principles of Management Exam 1 NotesDocument4 pagesPrinciples of Management Exam 1 Notestruckjones100% (1)

- Mobilink Management ReportDocument76 pagesMobilink Management Reportibrahim_ghaznaviNo ratings yet

- TQM Kohinoor MillDocument21 pagesTQM Kohinoor MillEjaz Ahmed YousafzaiNo ratings yet

- Impact of HRM On Sales of NestleDocument4 pagesImpact of HRM On Sales of NestleAmmaar Dar0% (1)

- Case Study Pakistan Model Shariah Governance Framework PDFDocument17 pagesCase Study Pakistan Model Shariah Governance Framework PDFsyedtahaali100% (3)

- Herfindahl-Hirschman Index For Passenger Car Segment in IndiaDocument4 pagesHerfindahl-Hirschman Index For Passenger Car Segment in IndiaShreeni YeshodharanNo ratings yet

- Problems and Prospects of Garments IndustryDocument104 pagesProblems and Prospects of Garments IndustryYousufNo ratings yet

- INTI College-Assignment Report TMK2111Document27 pagesINTI College-Assignment Report TMK2111aurisiaNo ratings yet

- Microeconomics Assignment Chapter 4 QuestionsDocument2 pagesMicroeconomics Assignment Chapter 4 Questionshumair chauhdaryNo ratings yet

- Pest Analysis MTNLDocument9 pagesPest Analysis MTNLOltre777100% (1)

- Lesson 03Document11 pagesLesson 03arsha100% (1)

- Assessing financial performance of AEON and PARKSONDocument27 pagesAssessing financial performance of AEON and PARKSONPK LNo ratings yet

- BRM ReportDocument29 pagesBRM ReportMitisha GaurNo ratings yet

- Towards A Pedagogy of Human Rights EducationDocument14 pagesTowards A Pedagogy of Human Rights EducationPedro PabloNo ratings yet

- Smartphone and Exercise BenefitsDocument2 pagesSmartphone and Exercise BenefitskylaNo ratings yet

- Hotel ParisDocument2 pagesHotel ParisSuman ChaudharyNo ratings yet

- Implementing Rules of the National Service Training Program (NSTPDocument31 pagesImplementing Rules of the National Service Training Program (NSTPCrizza Rondina100% (1)

- ISO 45001 GuideDocument16 pagesISO 45001 GuideSoedarjoto SNo ratings yet

- Philippine Association of Service Exporters vs. TorresDocument4 pagesPhilippine Association of Service Exporters vs. TorresMae ThiamNo ratings yet

- SAN BEDA UNIVERSITY - COLLEGE OF LAW PUBLIC INTERNATIONAL LAW PART II ACTORSDocument4 pagesSAN BEDA UNIVERSITY - COLLEGE OF LAW PUBLIC INTERNATIONAL LAW PART II ACTORSRedd LapidNo ratings yet

- Adp National Employment Report December2021 Final Press ReleaseDocument5 pagesAdp National Employment Report December2021 Final Press ReleaseRafa BorgesNo ratings yet

- Social Media and Its Impact On Personal Development NewDocument2 pagesSocial Media and Its Impact On Personal Development NewRanti HarviNo ratings yet

- Third Text 6 Magiciens de La Terre 1989Document94 pagesThird Text 6 Magiciens de La Terre 1989Mirtes OliveiraNo ratings yet

- Guidance monitoring and evaluation tool of Doña Pepeng Elementary SchoolDocument36 pagesGuidance monitoring and evaluation tool of Doña Pepeng Elementary SchoolNhayram NaresNo ratings yet

- Service marketing strategiesDocument2 pagesService marketing strategiesAshiqul IslamNo ratings yet

- Product Satisfying FeaturesDocument7 pagesProduct Satisfying FeaturesFaithy CuajotorNo ratings yet

- A Study On The Method of Designing Kiken Yochi Training Sheets (Hazard Prediction Training Sheets) in Medical ServiceDocument7 pagesA Study On The Method of Designing Kiken Yochi Training Sheets (Hazard Prediction Training Sheets) in Medical ServiceirmanNo ratings yet

- Mega Mini Cross Stitch: 900 Super Awesome Cross Stitch Motifs by Makoto OozuDocument3 pagesMega Mini Cross Stitch: 900 Super Awesome Cross Stitch Motifs by Makoto Oozulinky np0% (8)

- George Markert ResumeDocument2 pagesGeorge Markert ResumeInlanderChrisNo ratings yet

- G2Q1 - FIL - Sina Estella at Lisa at Isang Linggo Sa Klase Ni Gng. Reyes - 033016 - FINALDocument24 pagesG2Q1 - FIL - Sina Estella at Lisa at Isang Linggo Sa Klase Ni Gng. Reyes - 033016 - FINALGina Balbuena100% (1)

- TECHNOLOGY FOR EFFECTIVE LEARNING ENVIRONMENTSDocument14 pagesTECHNOLOGY FOR EFFECTIVE LEARNING ENVIRONMENTSCeleste De VeraNo ratings yet

- The Geneva ConventionDocument31 pagesThe Geneva ConventionJuan FranciscoNo ratings yet

- Course - 2.008x - EdXDocument4 pagesCourse - 2.008x - EdXahmedidrees1992No ratings yet

- Business Plan Format by SEDADocument13 pagesBusiness Plan Format by SEDATumiso MabokelaNo ratings yet

- 99.blis Revised Assignment 2017-2018 EnglishDocument26 pages99.blis Revised Assignment 2017-2018 EnglishRavi KantNo ratings yet

- Entrep 1Document40 pagesEntrep 1shayesssNo ratings yet

- Dominique HinnenDocument1 pageDominique Hinnenapi-452098057No ratings yet

- SAQ OF THE PLACE OF ART IN EDUCATION - Nandalal Bose (Class Xi of Wbchse) - Sure Success Tutorial HomeDocument8 pagesSAQ OF THE PLACE OF ART IN EDUCATION - Nandalal Bose (Class Xi of Wbchse) - Sure Success Tutorial HomeSurajit DasNo ratings yet

- Bs Notes KombazDocument434 pagesBs Notes KombazCladious ZvokurevaNo ratings yet

- Neo-Functionalism and Civil Religion TheoriesDocument4 pagesNeo-Functionalism and Civil Religion TheoriesJul 480weshNo ratings yet

- Aircraft TypeDocument1 pageAircraft TypeMahmoud Al-TamimiNo ratings yet

- 01 Melsoft GT Works3 Quick Guide - L08189engaDocument58 pages01 Melsoft GT Works3 Quick Guide - L08189engavuitinhnhd9817No ratings yet