Professional Documents

Culture Documents

Work Schedule For Reference

Uploaded by

kevinmathew27Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Schedule For Reference

Uploaded by

kevinmathew27Copyright:

Available Formats

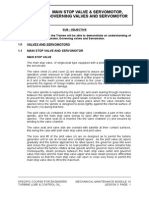

ACTIVITES :S.

NO DESCRIPTION GENERATOR:1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 FOUNDATION ANCHOR FASTNERS CHECK BEFORE CASTING FOUNDATION , FOUNDATION ANCHOR FASTENERS ALIGNMENT, LOCKING CHECK. BEFORE CASTING FOUNDATION CONCREETE OUTER COVER AS PER DRAWING MEASUREMENTS CHECK GT FOUNDATION CENTRE AXISIS PERMANENT MARKING FOUNDATION INSPECTION FOUNDATION CHIPPING FIXATOR POSITIONING , ALIGNMENT GTG STOOL DOWN FIXATOR GROUTING GT EQUIPEMENT LIFTING ARRANGEMENTS COMPLETION GTG BASE LEGS ASSEMBLY & TORQUE TIGHTENING GTG BOTTOM BASE CLEANING GTG BASE BOTTOM BLUE CONTACT CHECK GTG JACKING POST ASSEMBLY GTG PLACING ON FIXATOR GTG END SHIELDS ASSEMBLY OPENING AND CLEANING BEARINGS OPENONG AND MEASUREMENTS CHECK INNER /OUTER OIL DEFLECTOR MEASUREMENTS CHECK HYDROGEN SEAL MEASUREMENT , BLUE CONTACT CHECK HYDROGEN SEAL TO HOUSING BLUE CONTACT CHECK BEARING TO HOUSING BLUE CONTACT CHECK GTG END COVER OPENING & CLEANING END SHIELDS ASSEMBLY ON STATOR END SHIELD ALIGNMENT WITH STATOR DOWELL PIN MARKING & DRILLING BOTTOM HALF END SHIELDS LOWERING GTG ROTOR MEASUREMENTS CHECK, IR VALUE CHECK PREPARATIONS COMPLETION FOR ROTOR INSERTION ROTOR INSERTION 1 DURATION IN DAYS

PLANING START DATE END DATE

RESOURSES T&P

1 1 1 4 4 1 1 3 1 1 1 1 2 1 2 2 4 1 1 1 1 1 1 4 1 SURFACE PLATE CENTRE AXIS FRAMES PIANO WIRE

LIFT&SHIFT TORQUE WRENCH

EYE BOLTS , REMARS

ROTOR PULLING DEVICE

30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45

LOWER END SHIELDS FINALAISING , TORQUE TIGHTENING BEARINGS POSITIONING ROTOR LOWERING ON BEARING BEARING OIL CLEARANCE CHECK BEARING TO COVER INTERFERANCE CHECK GAS SHIELDA ASSEMBLY ROTOR BALDES ASSEMBLY FAN BLDES TO GAS SHIELDS CLEARANCE CHECK IN SIDE CLEANING CHECK WITH BOROSCOPIC TOP HALF END SHIELDS COMPOUND APPLY TOP HALF END SHIELDS ASSEMBLY AND BOLTS TORQUE TIGHTENING. INNER OIL DEFLECTOR ASSEMBLY AND CLEARANCE SETTING HYDROGEN SEALS ASSEMBLY , CLEARANCE CHECK AND IR VALUE CHECK BEARINGS INSTALLATION - BOTTOM HALF GTG ENCLOSURES ANCHOR BOLTS DRILLING , ASEMBLY. BEARINGS, SEAL BODY - IR VALUE CHECK TURBINE:FOUNDATION ANCHOR FASTNERS CHECK BEFORE CASTING FOUNDATION , FOUNDATION ANCHOR FASTENERS ALIGNMENT, LOCKING CHECK. GT FOUNDATION CENTRE AXISIS PERMANENT MARKING FOUNDATION INSPECTION FOUNDATION CHIPPING BASE PLATE BLUE MATCHING BASE PLATE MEASUREMENT CHECK FIXATOR POSITIONING , ALIGNMENT FIXATOR GROUTING BASE PLATE ALIGNMENT GT EQUIPEMENT LIFTING ARRANGEMENTS COMPLETION SCAFFOLDING PLATFORM ARRANGEMENTS GT LIFTING AND PLACING ON BASE JACK POST ASSEMBLY GT DROP TEST GT CENTRING EXHAUST DUCT STRUCTURE ERECTION 1

1400-NM TORQUE WRENCH

1 2 1 1 1 1 1 2 6 1

0.5 LEAD WIRE

46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62

1 1 1 3 4 1 3 1 2 3

1 1 2 2

63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96

INLET PLENUM STRUCTURE ERECTION GT BOROSCOPIC GT VISUAL INSPECTION GT ROTOR LOCKING BEAM REMOVAL GT TRANSPORTING BEAM REMOVAL GT DIFFUSER END FACE CLEANING GT ROTOR COUPLING FACE MEASUREMENT CHECK LOAD COUPLING MEASUREMENT CHECK COUPLING BOLT MEASUREMENT CHECK EXHAUST DUCT BOTTOM HALF ERECTION ALL SPREADER BEAMS FABRICATION SS DIFFUSER ERECTION INLET PLENUM LOWER HALF ERECTION ACC MODULE ERECTION LUBE OIL PIPING ,COOLING&SEALING AIR, SUPPORTS ERECTION EXPANSION PIECE ERECTION BOTTOM CONE ERECTION PREPARATION FOR LOAD COUPLING INSTALLATION LOAD COUPLING INSTALLATION GT TO LOAD COUPLING BOLT TORQUE TIGHTENING TORQUE VALUE CHECK TOP CONE ERECTION INLET PLENUM MIDLE PIECE - 2ND PARTERECTION "C" WALLS ERECTION, EXHAUST DIFFUSER DUCT TOP ERECTION GT INLET PLENUM HORIZONTAL PIECE ERECTIONERECTION EXHAUST DUCT - TOP AND BOTTOM ALIGNMENT,BOLT TIGHTENING AND GAP CHECK EXHAUST DUCT - IN SIDE / OUT SIDE WEDING JOINT INSPECTION EXHAUST DUCT - IN SIDE / OUT SIDE WEDING , NDT GT TO GTG PRILIMINARY ALIGNMENT CHECK GT ENCLOSURE ERECTION(BEFORE COMPLETION OF COOLING ,SEALING, AIR EXTRACTION PIPING COMPLETION) BORO SCOPIC INSPECTION COMBUSTERS ASSEMBLY FUEL NOZZELES ASSEMBLY GT TRANSPORT BEAM

2 1 1 1

1 1 6 1 1 1 2 1 1

1 1 1 1

1 3 2

2 3 4 1

COMBUSTER CAN INSTALLATION. COMBUSTER CRANE ERECTION BEFORE TURBINE ENCLOSURE ROOF 98 ERECTION. 99 Change PM1 and PM4 orifices 100 TURBINE SIX POINT CHECK AFTER LUBE OIL CHECK. 97 101 GT ENCLOSUER FOUNDATION ANCHORS FIXING 102 COLLECTOR BASE PLACEMENT, ALIGNMENT 103 TURNING GEAR SOLE PLATE ERECTION, ALIGNMENT GT LUBE OIL FLUSHING Lube oil piping works: SEAL OIL PIPING to Gen and seal oil skid BDE loop seal pipe LIFT OIL PIPING to Generator Turning gear lube oil piping LIFT OIL PIPING to Turbine Lube oil piping to generator brgs Lube oil piping to turbine bearings IGV hyd/ trip oil piping GT Lube Oil Flushing preparation for temporary piping OIL FLUSHING BEARINGS NORMALAISIONING GT - GTG -TURNING GEAR FINAL ALIGNMENT GT - GTG FINAL ALIGNMENT FINAL ALIGNMENT OF GT- GTG- TURNING GEAR GT-GTG COUPLING BOLTS TORQUE TIGHTENING GT - GTG BEARINGS OIL CLEARANCE CHECK TOP HALF FINAL ASSEMBLY OUTER OIL DEFLECTOR ASSEMBLY GT BASE PLATE,GTG FIXATOR GROUTING

2 4 2 2 5 2 3 1" MAGNETIC GILTY MACHINE , DRILL BITS

104 105 106 107 108 109 110 111 112 113 114

20

PIPE BEND MACHINE

15 2

115 116 117 118 119 120 121

3 1 1 1 1 1 1 1 1 4

ALL AXIAL , REDIAL KEYS FINALMEASUREMENTS CHECK& ASSEMBLY COLLECTOR BASE PLATE & TURNING SOLE PLATE GROUTING AFTER 122 FINAL ALIGNMENT 123 ALL AUXILIARIE SKIDS , EQUIPEMENTS GROUTING GT EXHAUST

124 125 126 127 128 129 130

131 132 133 134 135

136 137 138 139 140 141 142 143 144 145 PEEC, LCI, EX compt floor platform and approach ladder(LITL) 146 Approach to inlet plenum, exhaust manhole(LITL) 147 Piping support structure DUCTS:148 Generator collector duct 149 VENTILATION DUCTS VENTILATIONS ASSEMBLY - if any 150 Accessory compt vent hood/ duct installation 151 152 153 154 AIR INLET FILTER HOUSE :Inlet plenum transition duct erection Inlet duct silncers duct erection Inlet duct erction Inlet duct elbow erection(lower)

GT EXHAUST STRUCTURE ERECTION GT DIFUSSER INSULATION - PINS WELDING SS DIFFUSER DUCT FLEX SEALS ASSEMBLY GT DIFUSSER - SS- OUT SIDE INSULATION GT EXHAUST DUCT LONGITUDINAL AXIS ,HORIZONTAL AXIS WELDING & NDT EXHAUST DUCT INSIDE INSULATION EXHAUST DUCT BELLOW JOINT ASSEMBLY& WELDING ,INSULATIONINSIDE INSULATION GT ENCLOSURE : AFTER COOLING,SEALING,EXTRACTION PIPING Turbine compartment enclosure Exhaust enclosure Load compartment enclosure Generator lagging Accoustic enclosures installation GT -GT , EQUIPEMENT PLATFORM ERECTION :Genarator floor platform and ladder(LITL) Turbine floor platform and approach ladder(LITL) Turbine floor platform (GE supplied) FILTER HOUSE STRUCTURE ERECTION Filter house floor platform and approach ladder(LITL) Filter house floor platform and ladder (GE supplied) Evaporative pump foundn. structure and ladder erection Ladder for Exhaust thermocouple around diffuser Access to Gen Terminal enclosure

CRANE

15

SCAFOLDING PIPES, CLAMPS

15

CRANE , HYDRA

15

CRANE & HYDRA

CRANE &HYDRA

155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179

Inlet duct elbow erection(upper) Inlet pluenum to turb Expansion joint and insulation Inlet pluenum to turb joint insulation and sealing Inlet pluenum to elbow Expansion joint installation FILTER HOUSE STRUCTURE ERECTION Filter house transition duct erections INLET PLENUM DUCT ERECTION FILTER HOUSE MODULES ERECTION FILTER HOUSE SAILENCERS ERECTION Evaporative pump erection Installation of bird screen to modules Support welding and weld of manifold on silencer duct IN SIDE FILTER HOUSE :Inside alignment of media and drift eliminator frames Verification of tack weld/ locking of all fastners clean air inside Evaporative media and drift eliminators installation Evaporative cooling system pump installation Inlet air filters installation Sealing checks between two modules/ joints Filter house: EVAPORATION COOLER Make up WATER SUPPLY- Non GE EVAPORATION COOLER BLOW DOWN PIPING- Non GE Inside and outside filter house -Evapo. Piping- GE PULSE AIR PIPING turb to APU and from APU to FH INLET BLEED HEAT PIPING turb to control valve GE IBH PIPING Cont valve to silencer duct Piping tubing for Eva. Cooler Water chem monitoring EQUIPEMENTS & SKIDS ERECTION Bearing Cooling air fan on turbine enclosure Turbine compartment Ventilation fans on turbine enclosure Accessory compartment Ventilation fans on access compt PHE ERECTION for LCI AC & DC REACTORS Inlet bleed head system control valve and support Air processing skid Install AC to PEECC CO2 FIRE PROF TANK / SKID ERECTION WATER WASH DRAIN TANK ERECTION

30

ABOVE 125 TON CRANE CONTINUES REQUIRED FOR ONLY AIR INLET FILTER HOUSE

180 181 182 183 184 185 186 187 188 189

190 Accessory compt vent fan installation 191 TURNING GEAR POSITIONING 192 BUS DUCT ERECTION H2,CO2 SKIDS ASSEMBLY 193 H2 cyliners 194 CO2 cyliners 195 H2,CO2 supply MANIFOLDS ASSEMBLY. 196 H2,CO2 valve MANIFOLDS . 197 FLOAT TRAP ERECTION 198 HUMIDITY SENSOR ERECTION 199 H2 Control cabinet 200 H2 Control Control valve 201 Liquid level detector 202 H2 flow totaliser 203 Humidity SENSOR 204 SEAL OIL SKIDS ERECTION& GROUTING 205 Seal oil pressure indicators, junction box on generator 206 Final alignment turbine to generator 207 Final alignment generator to turning gear 208 Install turbine and generator keys/ pins/ found hardwares 209 Install load coupl bols gen end 210 Install load coupl guard 211 Check turning gear manual movement/ rotation 212 Install turning gear coupling and guard

15

CRANE & HYDRA

PIPING

H2, CO2 PIPING 213 H2, CO2 PIPING between skids and to Generator 214 H2, CO2 PIPING to filling cylinders 215 H2/CO2 vent to atmosphere CO2 FIRE PROT PIPING216 CO2 FIRE PROT PIPING- Exhaust and bearing tunnel(GE) 217 CO2 FIRE PROT PIPING- inside turbine compt (GE) 218 CO2 FIRE PROT PIPING- inside accessory and load compt (GE) 219 CO2 FIRE PROT PIPING- Turb to CO2 supply skid( Non GE) COOLING WATER PIPING: GT 220 COOLING WATER PIPING- Supply/ Ret To Gen, Acc, Turb- Non GE THREED MACHIEN, THREED GUAGE

PIPE BEND MACHINE

20

PIPE CUTTING MACHINE, PIPE BEND

221 222 223 224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239 240 241 242 243 244 245 246 247 248 249

COOLING WATER PIPING- CW supply and return To Gen cooler-Non GE COOLING WATER PIPING- CW supply and return to lube oil cooler(non GE) COOLING WATER PIPING- CW supply and return to Turb- GE( turb legs, FD cooling water) COOLING WATER PIPING- CW supply and return to Turb( turb legs, FD cooling water)-NON GE LCI COOLING WATER PIPING( GE and Non GE) WATER WASHING PIPING- GE and Non GE FUEL GAS PIPING: FUEL GAS PIPING- supply to accessory compt-Non GE FUEL GAS PIPING- accessory compt to turb-Pm1, PM4, D5-GE FUEL GAS PIPING- Pm1, PM4, D5 headers to combustor -GE DRAIN PIPING FALSE START DRAIN PIPING and tubing- GE DRAIN PIPING - NON GE Exhaust plenum drain piping(GE) Water wash DRAIN PIPING (Non GE to tank) Drain piping from CS, Low point drains(Non GE) AIR PIPING Insrument air supply line to GT and skids(LITL) AIR EXTRACTION PIPING-GE PURGE AIR PIPING-GE COOLING & SEALING AIR PIPING, bearing Cooling air -GE Air processing skid-GT to skid piping(GE) Air processing skid-Skid to filter house piping(Non GE) Inelt bleed heat piping to silencer skid(non GE) VENT PIPING FLUE GAS VENT TO ATMOSPHERE HIGHT-non GE Mist eliminator/ vapor fan vent piping H2/ CO2 vent to safe height COSTOMER INTER CONNECTION PIPING- CW/ FG/ Air/ drain Performance tubing Performance tubing- inlet bell mouth and inlet duct Tubing to CO2 dampers, perf equip, instruments, DLN, drain Prestart up checks Install DLN tunning kit, connect tubing- DLN TA Install performance test equipments

20

PIPE CUTTING MACHINE, PIPE BEND MACHINE

PIPE CUTTING MACHINE, PIPE BEND MACHINE

10

PIPE CUTTING MACHINE, PIPE BEND MACHINE

10

PIPE CUTTING MACHINE, PIPE BEND MACHINE

PIPE CUTTING MACHINE, PIPE BEND MACHINE

250 251 252 253 254 255 256 257 258 259 260 261 262

Final inspection of filter house, inlet plenum and duct Final inspection of exhaust, bearing tunnel and turb compt Unit on turning gear Unit crank False fire check Emergency trip check Unit on FSNL Synchroniser check and unit synchronisation Unit on load Unit run for steam blowing/ combined cycle DLN tunning Unit on Base load Performance test OIL FLUSHING START DATE GT ON TURNING GEAR FIRST CRANCKING : : :

You might also like

- Power Plant EfficiencyDocument27 pagesPower Plant EfficiencyAnupam XessNo ratings yet

- คู่มือบำรุงรักษา root blowerDocument17 pagesคู่มือบำรุงรักษา root blowervarayutjNo ratings yet

- Pumps and System CurvesDocument22 pagesPumps and System CurvesgusgifNo ratings yet

- 11.SOP Condensate PumpDocument7 pages11.SOP Condensate PumpDodik NugrohoNo ratings yet

- Integrated Automobile Car Jack (IAJ)Document35 pagesIntegrated Automobile Car Jack (IAJ)Lorenz SchmidNo ratings yet

- Bis BFP Oil FlushingDocument19 pagesBis BFP Oil FlushingShailenderNo ratings yet

- February 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsDocument4 pagesFebruary 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsKarim MuhammedNo ratings yet

- RWPL TG Capital Overhauling Scope of JobDocument8 pagesRWPL TG Capital Overhauling Scope of JobSreekanthMylavarapuNo ratings yet

- Curriculum Vitae: Career ObjectiveDocument3 pagesCurriculum Vitae: Career ObjectiveShashank JaiswalNo ratings yet

- List of CHP EquipmentsDocument7 pagesList of CHP EquipmentsbrockNo ratings yet

- 57-62 1m809 - Eng72dpiDocument6 pages57-62 1m809 - Eng72dpiAbhinav TewariNo ratings yet

- Mechanical Engineer CVDocument3 pagesMechanical Engineer CVRaj AryanNo ratings yet

- Lesson Main Stop Valve & Servomotor, Governing Valves and ServomotorDocument41 pagesLesson Main Stop Valve & Servomotor, Governing Valves and Servomotormister pogiNo ratings yet

- Boiler FundamentalsDocument39 pagesBoiler FundamentalsaksjnNo ratings yet

- Catalogo Medidor Gt3Document12 pagesCatalogo Medidor Gt3luis_d_mNo ratings yet

- Commissioning Manual DH-6155: Descon Engineering LTDDocument102 pagesCommissioning Manual DH-6155: Descon Engineering LTDHammad AhmedNo ratings yet

- Punch List Analysis SampleDocument3 pagesPunch List Analysis SampleBramNo ratings yet

- Brewery Plant Progress StatusDocument4 pagesBrewery Plant Progress StatusMukesh KumarNo ratings yet

- PUMPS Lecture 2024Document37 pagesPUMPS Lecture 2024aidenpierce8876No ratings yet

- Checklist For Material SubmittalDocument2 pagesChecklist For Material SubmittalMohammed NadeemNo ratings yet

- MEP 1 Shafting SystemDocument19 pagesMEP 1 Shafting SystemYohannes DennisNo ratings yet

- 5 Parallel and Series Pump Operation 5Document15 pages5 Parallel and Series Pump Operation 5Omar AhmedNo ratings yet

- Fuel Supply System System in S.I EngineDocument47 pagesFuel Supply System System in S.I EngineSanjay HedgeNo ratings yet

- Different Type of Air Standard (Otto and Diesel Cycle)Document23 pagesDifferent Type of Air Standard (Otto and Diesel Cycle)Irteza HossainNo ratings yet

- Vacuum Breaker ValveDocument2 pagesVacuum Breaker ValveRaghunath YeturiNo ratings yet

- Crude Oil Price Trends in Global MarketDocument28 pagesCrude Oil Price Trends in Global MarketRITESH MADRECHA100% (1)

- Feed Pumps, Feed Injectors, Feed Regulators, Feed Heaters, Air Heaters and Steam AccumulatorsDocument74 pagesFeed Pumps, Feed Injectors, Feed Regulators, Feed Heaters, Air Heaters and Steam Accumulatorsbanukiran sambojuNo ratings yet

- Modern Resume Examples TemplateDocument3 pagesModern Resume Examples TemplateAlexa PilgrimNo ratings yet

- 1 Meters For Liquids, Gases, and Solids in Suspension: Table 1: Applicability of Flow Metering TechnologiesDocument15 pages1 Meters For Liquids, Gases, and Solids in Suspension: Table 1: Applicability of Flow Metering Technologiespk_zhotNo ratings yet

- UNIT 1 Routine Maintenance Check On Gas TurbineIIIDocument3 pagesUNIT 1 Routine Maintenance Check On Gas TurbineIIImuaz_aminu1422No ratings yet

- Steam O&MDocument28 pagesSteam O&MmadiNo ratings yet

- Boiler Notes 2Document42 pagesBoiler Notes 2Balakrishnan KannanNo ratings yet

- Feedwater SystemDocument70 pagesFeedwater SystemishanpahwaNo ratings yet

- Handling Precautions While Installing ButterFly ValveDocument10 pagesHandling Precautions While Installing ButterFly ValveDefenceDogNo ratings yet

- Master Mechanical Engineering - Design Heat Recovery Steam Generator (HRSG) Combined Cycle Power PlantsDocument4 pagesMaster Mechanical Engineering - Design Heat Recovery Steam Generator (HRSG) Combined Cycle Power PlantsAlessandro BalduzziNo ratings yet

- Introduction To Magnetic Flow MetersDocument11 pagesIntroduction To Magnetic Flow MetersNïkĦïl ДkДvØØrNo ratings yet

- Boiler ParameterDocument2 pagesBoiler ParameterFieNo ratings yet

- Hydraulic TestDocument3 pagesHydraulic TestSaurabh BarangeNo ratings yet

- Power Plant Inspection, Repair, and Testing: Learning ObjectivesDocument30 pagesPower Plant Inspection, Repair, and Testing: Learning ObjectivessamiNo ratings yet

- Dead Weight TestersDocument5 pagesDead Weight TestersShrikant EkboteNo ratings yet

- Start-Up Checklist for CompressorsDocument3 pagesStart-Up Checklist for CompressorsgustavoespinosamNo ratings yet

- Hydraulic Actuator SpecificationsDocument3 pagesHydraulic Actuator SpecificationsRizky RamadhaniNo ratings yet

- Preparing Electrical Load SchedulesDocument7 pagesPreparing Electrical Load SchedulesMila GamidoNo ratings yet

- Summer Training ReportDocument24 pagesSummer Training Reportruman ahmadNo ratings yet

- Engineering Management ProposalDocument64 pagesEngineering Management ProposalWee Chek100% (1)

- Equipment and ToolsDocument15 pagesEquipment and ToolsMathias OnosemuodeNo ratings yet

- Annexure IIIDocument674 pagesAnnexure IIItakari divisionNo ratings yet

- Resume: Professional ExperienceDocument3 pagesResume: Professional ExperienceShankker KumarNo ratings yet

- My Latest CV - EngineerDocument3 pagesMy Latest CV - EngineersasibhushanNo ratings yet

- BSR Energy Management HandbookDocument38 pagesBSR Energy Management HandbookMuhammad Fakhar ZamanNo ratings yet

- Test Paper (Steam Turbines) : Page 1 of 4Document4 pagesTest Paper (Steam Turbines) : Page 1 of 4msaqibraza93No ratings yet

- C7Document72 pagesC7victorhernandezrega94% (35)

- 2000H Service Wheel Loader 993KDocument4 pages2000H Service Wheel Loader 993KmhmdtrainingNo ratings yet

- Polyol & Tdi PumpsDocument40 pagesPolyol & Tdi Pumpsrozichka100% (1)

- 1682 SlidDocument185 pages1682 SlidLuis CornejoNo ratings yet

- CIBI of GT # 5 Frame VI at IOCL VadodaraDocument3 pagesCIBI of GT # 5 Frame VI at IOCL Vadodaramahesh_rathoreNo ratings yet

- Description Size Cat. Usage Description Ft-Lbs N-M: Torque Specification NumberDocument5 pagesDescription Size Cat. Usage Description Ft-Lbs N-M: Torque Specification NumberSuperlativo IgvNo ratings yet

- 797B Off-Highway Truck Component DiagramDocument133 pages797B Off-Highway Truck Component DiagramgustavoNo ratings yet

- Subaru Added Security BrochureDocument6 pagesSubaru Added Security BrochureGreg JohnsonNo ratings yet

- HDPEChapter 04Document19 pagesHDPEChapter 04kevinmathew27No ratings yet

- PLASTICOSDocument61 pagesPLASTICOSJohn TorrezNo ratings yet

- Chapter 2 - Inspection, Tests and Safety For PE PipesDocument27 pagesChapter 2 - Inspection, Tests and Safety For PE PipesPeter ShiuNo ratings yet

- Above Ground Applications For PE PipeDocument22 pagesAbove Ground Applications For PE PipebugerkngNo ratings yet

- PREF 0104 Tool Kit 106L1971G019 Qty./Turbine 1: Parts ListDocument1 pagePREF 0104 Tool Kit 106L1971G019 Qty./Turbine 1: Parts Listkevinmathew27No ratings yet

- Plastic Pipe - PE - Chapter01Document9 pagesPlastic Pipe - PE - Chapter01garisa1963No ratings yet

- Print Version Lead Auditor ModuleDocument90 pagesPrint Version Lead Auditor Modulekevinmathew27No ratings yet

- Chapter 07Document39 pagesChapter 07kevinmathew27No ratings yet

- 035rev23 - Exam Dates - AICIP 2013Document1 page035rev23 - Exam Dates - AICIP 2013kevinmathew27No ratings yet

- 035rev23 - Exam Dates - AICIP 2013Document1 page035rev23 - Exam Dates - AICIP 2013kevinmathew27No ratings yet

- PREF 0009 Tool Kit, Noz Remov Stg1 106L1351G002 Qty./Turbine 1Document1 pagePREF 0009 Tool Kit, Noz Remov Stg1 106L1351G002 Qty./Turbine 1kevinmathew27No ratings yet

- A23-28 656seriesDocument6 pagesA23-28 656serieskevinmathew27No ratings yet

- 6535Document3 pages6535kevinmathew27No ratings yet

- Parts List for Station Tool Kit 107L2726G001Document1 pageParts List for Station Tool Kit 107L2726G001kevinmathew27No ratings yet

- V 6584 R 8Document4 pagesV 6584 R 8kevinmathew27No ratings yet

- Equipment Erection PDFDocument13 pagesEquipment Erection PDFkasturisunilkumar86% (7)

- Gek 116357Document4 pagesGek 116357kevinmathew27No ratings yet

- PREF 0010 Tool Kit, Rotor Jacking 106L1350G003 Qty./Turbine 1Document1 pagePREF 0010 Tool Kit, Rotor Jacking 106L1350G003 Qty./Turbine 1kevinmathew27No ratings yet

- C 1section IIDocument17 pagesC 1section IIkevinmathew27No ratings yet

- 3756RDocument22 pages3756Rkevinmathew27No ratings yet

- 5037Document8 pages5037kevinmathew27No ratings yet

- Parts List for FIXTURE,LINR REMOVAL-COM 103E3723G003Document1 pageParts List for FIXTURE,LINR REMOVAL-COM 103E3723G003kevinmathew27No ratings yet

- 3681Document51 pages3681kevinmathew27No ratings yet

- ADocument2 pagesACharles DanielNo ratings yet

- 2458 2Document31 pages2458 2kevinmathew27No ratings yet

- Pet Norske Veritas As: Certificate of TrainingDocument1 pagePet Norske Veritas As: Certificate of Trainingkevinmathew27No ratings yet

- Reformation Voice News Paper February 2013Document8 pagesReformation Voice News Paper February 2013kevinmathew27No ratings yet

- Sg072 - Pipeline Nov 14 LR 1Document2 pagesSg072 - Pipeline Nov 14 LR 1kevinmathew27No ratings yet

- 31FL5541Document56 pages31FL5541Sunthron SomchaiNo ratings yet

- CN60 10TTDocument84 pagesCN60 10TTjalage5043No ratings yet

- FINAL Korea Japan China For GCE Blue Maritime Presentation PDFDocument61 pagesFINAL Korea Japan China For GCE Blue Maritime Presentation PDFyeNo ratings yet

- BOEING B757-The Cali Accident (Part 1)Document8 pagesBOEING B757-The Cali Accident (Part 1)Miran MirNo ratings yet

- GRP Lamination Processing - Instructions PDFDocument34 pagesGRP Lamination Processing - Instructions PDFmuhammadkashikNo ratings yet

- 1st Grade Spelling Word ListDocument15 pages1st Grade Spelling Word ListAnonymous TswlBz100% (2)

- Manhole Cover Assembly, Bolted, Semi-Flush, Oiltight and WatertightDocument6 pagesManhole Cover Assembly, Bolted, Semi-Flush, Oiltight and WatertightSaif Ullah KhanNo ratings yet

- Chemical Tanker Cargo Operations Training SyllabusDocument68 pagesChemical Tanker Cargo Operations Training SyllabusMannie VasquezNo ratings yet

- Safe Motorcycle Riding TipsDocument8 pagesSafe Motorcycle Riding TipsRista Nya DendiNo ratings yet

- Railway Signalling Installation and Quality Hand BookDocument284 pagesRailway Signalling Installation and Quality Hand BookVijay Khanchi100% (21)

- BMW z4 BrochureDocument35 pagesBMW z4 BrochureGooglymooNo ratings yet

- 5Document65 pages5indrajeetNo ratings yet

- Draft SPECIFICATION For Power Quality RestorerDocument44 pagesDraft SPECIFICATION For Power Quality RestorerPavanNo ratings yet

- STPO Wo. DELDocument9 pagesSTPO Wo. DELDurgesh KadamNo ratings yet

- IDFC Indian Infrastructure - ChallengesDocument18 pagesIDFC Indian Infrastructure - ChallengesSudarshan SubhashNo ratings yet

- Intralogistics Automation in The Automotive IndustryDocument12 pagesIntralogistics Automation in The Automotive IndustrycyrilNo ratings yet

- Section 300 Earthwork Erosion Control and DrainageDocument50 pagesSection 300 Earthwork Erosion Control and DrainagePapiya Chakraborty100% (1)

- MCC DSR Rate AnalysisDocument280 pagesMCC DSR Rate AnalysisAbhijeet VardheNo ratings yet

- Mandatory Mandatory MandatoryDocument133 pagesMandatory Mandatory MandatoryArnauRodriguezVernetNo ratings yet

- TSB Belt TensionerDocument3 pagesTSB Belt TensionerrxhughesNo ratings yet

- Pengaruh Kualitas Layanan Jasa Terhadap Brand ImageDocument17 pagesPengaruh Kualitas Layanan Jasa Terhadap Brand ImageSukmadwi HartantiNo ratings yet

- Bus & Cable Car Simulator – San Francisco Gameplay GuideDocument39 pagesBus & Cable Car Simulator – San Francisco Gameplay GuideDanialNo ratings yet

- Managing Products and Services OperationsDocument11 pagesManaging Products and Services OperationsAnne PecadizoNo ratings yet

- Ingles Basico - 2023Document11 pagesIngles Basico - 2023mctsiamasNo ratings yet

- GTR - Manual - PCDocument74 pagesGTR - Manual - PCJOrdi jorNo ratings yet

- Process Pressure Vessels and Piping SystemsDocument5 pagesProcess Pressure Vessels and Piping SystemsEn NdyNo ratings yet

- Parts Catalogue: '19 ER300 AKF/AKFA (CL) (Z300)Document87 pagesParts Catalogue: '19 ER300 AKF/AKFA (CL) (Z300)Yeison Cartagena BedoyaNo ratings yet

- Basics of Aero in MotorsportDocument28 pagesBasics of Aero in MotorsportRanjit PenmetsaNo ratings yet

- 2 Sample SHS G11 Research Paper by Turingan, JohnDocument42 pages2 Sample SHS G11 Research Paper by Turingan, JohnJedí BelanoNo ratings yet

- E-RIDE User's GuideDocument16 pagesE-RIDE User's GuideAyesha KhanNo ratings yet