Professional Documents

Culture Documents

Force Feed Systems

Uploaded by

puterinuritaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Force Feed Systems

Uploaded by

puterinuritaCopyright:

Available Formats

Force Feed Systems

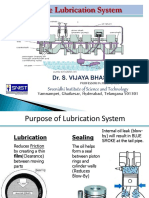

Except for petrol two-stroke, and small four-stroke auxiliary engines, most marine engines use a force feed lubrication system (Figure 23). Typical components of a force feed system are: oil supply tank or sump oil pump oil filter oil galleries feeding critical engine components oil cooler pressure and temperature gauges, if required. In the force feed lubrication system, oil is pumped from a sump or tank, filtered, andsupplied under pressure through oil galleries to critical components (bearings, etc.)of the engine. Less critical parts of the engine (gears, chains, etc.) are lubricated byoil splashed from bearings and other oil fed parts. The used oil drains into the sump of the engine, where it is returned to the oil pump or supply tank, to be used over and over again. Most force feed systems have the oil reserve stored in the sump of the engine (like car engines). These are called wet-sump lubrication systems. Others have the oil reserve stored in an external supply tank. These are called dry-sump systems The system in Figure 26 uses a wet sump. The oil supply is stored in the sump below the engine. A pump in the sump circulates the oil to the engine. After lubricating the engine, used oil drains back to the sump to be constantly re-circulated through the engine. Figure 27 shows a dry sump system oil is returned to the external oil tank by a scavenge pump. The scavenge pump is larger than the delivery pump to stop oil pooling in the sump. Dry sump systems have larger oil tank capacity, and are more reliable in heavy seas. The oil also remains cooler, and is less likely to leak past engine seals.

Figure 26: Wet-Sump Force Feed Lubrication System

Figure 27: Dry-Sump Force Feed Lubrication System

Notes

The oil delivery pump can develop extremely high pressures. A relief valve on the oil pump will open to limit the oil pressure, to prevent damage to the engine.

If the oil filter blocked up, no oil would get to the engine. The bypass valve will let unfiltered oil past a blocked filter to supply the engine. (Slightly dirty oil will do less damage than no oil at all.) Acids and contaminants build up in the oil. Always replace the oil and filters when indicated by the service schedule, or earlier if they need it. Use the correct type and grade of lubricant, and never mix them. Oils and greases with different chemical bases may interact and cause expensive damage. Lubrication of Two-Stroke Engines Diesel two-stroke engines normally have a conventional wet -sump force feed system as just described. Most two-stroke petrol engines are lubricated by petrol or outboard mix as it passes through the crankcase during induction. To ensure proper lubrication, and to prevent starting and running problems, you must make sure that: only the correct type of two-stroke oil is used the correct quantity of oil is added to the petrol the petrol and oil are thoroughly mixed together before being used A few high performance two-strokes, force feed a small amount of undiluted oil directly into the bearings and critical components from an oil supply tank. This is called oil injection. The used lubricating oil is eventually burned with the fuel, and the oil tank must be occasionally topped up to replace the lost oil. Straight petrol is used with oil-injected two-strokes.

Sistem Pengisian Udara

Kecuali untuk dua-stroke, dan kecil empat-stroke bantu mesin bensin, mesin-mesin kelautan yang kebanyakan menggunakan u2018force % yang memberi makan sistem pelumasan % u2019 (gambar 23). Komponen yang khas dari kekuatan yang memberi makan sistem adalah:

You might also like

- Amt 646 Midterm 1 Reciprocating Engine LubricationDocument48 pagesAmt 646 Midterm 1 Reciprocating Engine LubricationTyron CastroNo ratings yet

- Marine Diesel Engine Lubricating Oil SystemDocument8 pagesMarine Diesel Engine Lubricating Oil SystemAhmed SalemNo ratings yet

- Lubrication SystemDocument3 pagesLubrication Systemspencer philip cabaobaoNo ratings yet

- FstgdstfesdrfDocument3 pagesFstgdstfesdrfapi-258706993No ratings yet

- Lubrication SystemDocument4 pagesLubrication SystembalramNo ratings yet

- Automotive Servicing NC Ii Service Lubricating SystemDocument21 pagesAutomotive Servicing NC Ii Service Lubricating SystemVanessa ParasNo ratings yet

- L.O LubricatingDocument2 pagesL.O LubricatingHaris HermanNo ratings yet

- Lubrication System 08me140Document5 pagesLubrication System 08me140zainriazNo ratings yet

- Lubrication Methods for MachineryDocument13 pagesLubrication Methods for Machinerysimba8661No ratings yet

- Jet Aircraft Engine Lubrication Systems: Types of LubricantsDocument4 pagesJet Aircraft Engine Lubrication Systems: Types of Lubricantsalfredsunny100% (1)

- AMTE-126 - Midterm Assignment#1Document5 pagesAMTE-126 - Midterm Assignment#1Maybelyn ConsignadoNo ratings yet

- Cooling and Lubrication of EnginesDocument6 pagesCooling and Lubrication of EnginesAmr EhabNo ratings yet

- Lube Oil System Construction and WorkingDocument7 pagesLube Oil System Construction and WorkingvijayNo ratings yet

- Lesson 9Document2 pagesLesson 9marpelNo ratings yet

- LubricationsDocument9 pagesLubricationsSamarth SNo ratings yet

- Aircrafft Lubrication SystemDocument8 pagesAircrafft Lubrication SystemshyamsundarsrNo ratings yet

- Lubricating Oil SystemDocument7 pagesLubricating Oil SystemLegen DaryNo ratings yet

- Lubricating Oil SystemDocument4 pagesLubricating Oil SystemAdnan ParkerNo ratings yet

- EMEg 5221chapter 10 11Document64 pagesEMEg 5221chapter 10 11Yoseph MershaNo ratings yet

- Compressor With Seal OilDocument7 pagesCompressor With Seal OilKamel NaimiNo ratings yet

- Lubrication System: Internal Combustion EnginesDocument24 pagesLubrication System: Internal Combustion EnginesAnonymous LFgO4WbIDNo ratings yet

- CompressorsDocument8 pagesCompressorsShariq Ali0% (1)

- Module 2 Btled 3Document16 pagesModule 2 Btled 3jovanalyn mananganNo ratings yet

- Engine Lubrication SystemDocument8 pagesEngine Lubrication SystemSunilNo ratings yet

- Compressor Lubrication Best PracticesDocument22 pagesCompressor Lubrication Best Practicesengrsurif100% (1)

- Lubrication System For An Ic EngineDocument23 pagesLubrication System For An Ic EngineTata VadiginaNo ratings yet

- ATS ComBased Training - PPTX MONDocument155 pagesATS ComBased Training - PPTX MONDEATHSTAR GAMINGNo ratings yet

- Qip Ice 23 Lubrication SystemsDocument24 pagesQip Ice 23 Lubrication SystemsMohan Kumar SNo ratings yet

- Lubrication and LubricantsDocument44 pagesLubrication and Lubricantspreethu02No ratings yet

- Auxiliary Units of CompressorDocument5 pagesAuxiliary Units of CompressoriaftNo ratings yet

- Jacking Oil SystemDocument7 pagesJacking Oil Systemcrespo123456100% (4)

- Lubrication SystemsDocument5 pagesLubrication SystemssaiNo ratings yet

- Lubrication SystemsDocument9 pagesLubrication SystemsCeno EdwinNo ratings yet

- Engine Lubrication SystemDocument2 pagesEngine Lubrication SystemYemaneDibetaNo ratings yet

- Engine Lubrication Systems and LubricantsDocument45 pagesEngine Lubrication Systems and LubricantsMuhammad Javed IqbalNo ratings yet

- Activity 1 ME LabDocument29 pagesActivity 1 ME LabIanNo ratings yet

- Engine Lubrication Purpose of Lubrication: K. V Karanth, M.I.T ManipalDocument3 pagesEngine Lubrication Purpose of Lubrication: K. V Karanth, M.I.T ManipalishanrathnakarNo ratings yet

- Actual Sysem Setup Alpha LubricatorDocument7 pagesActual Sysem Setup Alpha LubricatorRanjan DiptanshuNo ratings yet

- 06 Lubrication SystemDocument55 pages06 Lubrication Systemramalingeswarao annamdevulaNo ratings yet

- Compressor Lubrication Best PracticesDocument5 pagesCompressor Lubrication Best PracticeslubangjarumNo ratings yet

- Lubrication SystemsDocument13 pagesLubrication SystemsDhanu MalarNo ratings yet

- Engine Lubricating SystemsDocument21 pagesEngine Lubricating SystemsDeepak Dileep100% (1)

- Actual Sysem Setup: 2.2 System ExplanationDocument11 pagesActual Sysem Setup: 2.2 System Explanationtomsonthomas7No ratings yet

- Lubrication Systems for Industrial Gas TurbinesDocument7 pagesLubrication Systems for Industrial Gas TurbinesafegbuaNo ratings yet

- Lube Oil System.Document10 pagesLube Oil System.Muhammad luqmanNo ratings yet

- Lubrication SystemDocument15 pagesLubrication SystemNithinNo ratings yet

- Lubication Oil SystemDocument3 pagesLubication Oil SystemAustin UdofiaNo ratings yet

- SM 03 BDocument34 pagesSM 03 BMark OreschnickNo ratings yet

- Engine Lubrication SystemsDocument8 pagesEngine Lubrication SystemsMentsnot GetuNo ratings yet

- P - Automotive Lubrication System Service RevisedDocument22 pagesP - Automotive Lubrication System Service Reviseddmc constructionNo ratings yet

- Engine Lubrication SystemDocument45 pagesEngine Lubrication SystemSubodh KumarNo ratings yet

- Sistema de Lubricacion Emd 645Document21 pagesSistema de Lubricacion Emd 645Adriana Rojas VerasteguiNo ratings yet

- Lubricating System: What Is Engine Lubrication?Document4 pagesLubricating System: What Is Engine Lubrication?AsraNo ratings yet

- Lubrication SystemDocument4 pagesLubrication SystemArun BoseNo ratings yet

- DocumentDocument2 pagesDocumentBarnabas ProgressNo ratings yet

- Lubrication Systems For Petrol Engines (Automobile) PDFDocument16 pagesLubrication Systems For Petrol Engines (Automobile) PDFYuvarajNo ratings yet

- Adding Oil: Charging Pump and Simple FillingDocument4 pagesAdding Oil: Charging Pump and Simple FillingAnonymous rYwUkpNo ratings yet

- Oil System Over ViewDocument13 pagesOil System Over ViewbejoythomasNo ratings yet

- Single Unit Package System: Installation Split Air ConditionerDocument1 pageSingle Unit Package System: Installation Split Air ConditionerShubham SarkarNo ratings yet

- What is suction energy and how does it impact pump performanceDocument6 pagesWhat is suction energy and how does it impact pump performanceashumishra007100% (1)

- Fluid power motor calculationsDocument3 pagesFluid power motor calculationsأبو أسامة حمديNo ratings yet

- High Rise BLDG Water SupplyDocument22 pagesHigh Rise BLDG Water Supplykartik chopra64% (11)

- GP200SDocument155 pagesGP200SLina JiaNo ratings yet

- Manual de Partes Compresor SANDEMDocument25 pagesManual de Partes Compresor SANDEMLuis Panti EkNo ratings yet

- Cause and Effect Chart Cause and Effect Chart: (Unit-: BGP Inlet Facilities)Document6 pagesCause and Effect Chart Cause and Effect Chart: (Unit-: BGP Inlet Facilities)Riky FitriadiNo ratings yet

- Hydraulics Fundamentals Pipe Flow Velocity Diameter ProblemsDocument9 pagesHydraulics Fundamentals Pipe Flow Velocity Diameter ProblemsAngelo RosNo ratings yet

- Valtech Industries - Manufacturer From Saki Vihar Road, Mumbai, India About UsDocument1 pageValtech Industries - Manufacturer From Saki Vihar Road, Mumbai, India About UsRKGUPTANo ratings yet

- Gas Turbine EngineDocument44 pagesGas Turbine EngineManas BatraNo ratings yet

- 19a QEV QuickExhaustValves June2013Document7 pages19a QEV QuickExhaustValves June2013RahimNo ratings yet

- Pratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3015442Document2 pagesPratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3015442Sebastian Ossa OssaNo ratings yet

- NPSH and Pump Cavitation - E Shashi Menon - ScienceDirectDocument17 pagesNPSH and Pump Cavitation - E Shashi Menon - ScienceDirectrosliyu100% (1)

- Bomba Rexroth 2Document32 pagesBomba Rexroth 2Ruben Gomez CcorahuaNo ratings yet

- S12 Water Flushing CircuitDocument26 pagesS12 Water Flushing CircuitLuan MaxNo ratings yet

- Prac 2 Without AnswersDocument6 pagesPrac 2 Without AnswersTitsarosal ThomasNo ratings yet

- FLUID TRANSPORT EQUIPMENTDocument8 pagesFLUID TRANSPORT EQUIPMENTKeanu EspinaNo ratings yet

- RTA-34 Fuel Injection System Modifications and MaintenanceDocument12 pagesRTA-34 Fuel Injection System Modifications and MaintenanceCatalin CataNo ratings yet

- Restriction Orifice RO Flow Control Instrument PDFDocument8 pagesRestriction Orifice RO Flow Control Instrument PDFRaphael212219No ratings yet

- RH200 Engine & Pump Drive GearboxDocument26 pagesRH200 Engine & Pump Drive GearboxLuis jopi67% (3)

- Certificado FM - Valvula Angular de 1.5 - BreccoDocument1 pageCertificado FM - Valvula Angular de 1.5 - BreccoMeli SanchezNo ratings yet

- Chapter:3 Tyep of Reciprocating Pump 3.1: Classification of Reciprocating PumpDocument10 pagesChapter:3 Tyep of Reciprocating Pump 3.1: Classification of Reciprocating PumpParth VyasNo ratings yet

- SR - No. Part No. Description Brand ModelDocument5 pagesSR - No. Part No. Description Brand Modelramsey222No ratings yet

- LKH-35 Centrifugal Pump: Spare Parts ListDocument4 pagesLKH-35 Centrifugal Pump: Spare Parts ListJavier Conesa OutedaNo ratings yet

- EXPERIMENT 2: Absorption of Carbon Dioxide in WaterDocument4 pagesEXPERIMENT 2: Absorption of Carbon Dioxide in WaterAzrol Azmir Long67% (6)

- Inspection Checklist: Project R-Con Ta-2015 at QP Refinery, Mesaieed Tag # DateDocument2 pagesInspection Checklist: Project R-Con Ta-2015 at QP Refinery, Mesaieed Tag # DateishtiaqNo ratings yet

- STLE2018 - CMF VI - Session 6B - P. Rabbat - BASF PAG-Based Finished Lubricant Solutions PDFDocument18 pagesSTLE2018 - CMF VI - Session 6B - P. Rabbat - BASF PAG-Based Finished Lubricant Solutions PDFHiMichael LiangNo ratings yet

- Equipos Reg Vacio y DosificadoresDocument32 pagesEquipos Reg Vacio y Dosificadoresjorge valdesNo ratings yet

- Hydraulics / Hydraulique / Hidrá Ulica: Vapormatic Quality Replacement Parts Suitable For Massey Ferguson ApplicationsDocument54 pagesHydraulics / Hydraulique / Hidrá Ulica: Vapormatic Quality Replacement Parts Suitable For Massey Ferguson ApplicationsRetropartes AcevedoNo ratings yet

- Basic Pneumatic Circuitry: For Control and AutomationDocument134 pagesBasic Pneumatic Circuitry: For Control and AutomationMuh KhairanNo ratings yet