Professional Documents

Culture Documents

Design of Cantilever Retaining Wall

Uploaded by

D.V.Srinivasa RaoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Cantilever Retaining Wall

Uploaded by

D.V.Srinivasa RaoCopyright:

Available Formats

DESIGN OF CANTILEVER RETAINING WALL

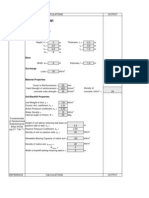

A)Data:Height of Retaining wall = Height of wall above G.L= Height of wall below G.L= Dry density of back fill material = Water content = Density of back fill soil&material ( Submerged unit weight) = Grade of concrete = Grade of steel = Ground water Table level (Below G.L) = Angle of shearing resistance of back fill material&material at toe portion () (As per report) = Angle of face of wall supporting earth with horizontal()(In degrees) (in anti clock wise direction) Slope of back fill() = Angle of wall friction () = Surcharge over the back fill in terms of height of back fill = Undrained Cohesion ( c) = Characteristic compressive strength = Tensile strength of steel = Unit weight of concrete = 4.50m 4.50m 0.00m 1600Kg/Cum 0.23m 1968Kg/Cum M25 Fe415 1.20m 32 87.5 0 16 1.20m 0Kg/sqm 25N/sqmm 415N/sqmm 2500Kg/Cum

B)Dimensions of the Cantilever wall(Assumed for preliminary design):Thickness of stem at bottom = Thickness of stem at top = Thickness of base slab = Breadth of beam = Depth of beam = Dia of Bored Cast-in situ straight pile assumed = Depth of pile = C/c spacing of piles in transverse direction = C/c spacing of piles in longitudinal direction = 0.40m 0.20m 0.40m 0.45m 0.60m 0.50m 5.00m 1.50m 2.00m

C)Design:i)Earth pressure calculations:Coefficient of active earth pressure by Coulomb's theory 2 Ka = sin sin(-) Sin(+) sin(+)sin(-) sin(+) From the above expression, Ka = Hence,maximum pressure at the base of the wall The pressure distribution along the height of the wall is as given below:Pressure due to Surcharge load = 0.3 Pa = 2656.80Kg/sqm

708.48 708.48

4.50m

2656.80

Total Active earth pressure force =

9165.96 1.76m

Height from the bottom of the wall =

The active earth pressure acts on the wall as shown below:-

CROSS SECTION DETAILS

200

18 . 55

92

600

2300

1000

500

Horizontal component of the earth pressure Ph = Vertical component of the earth pressure Pv = ii)Intial proportioning of the structure :-

5000

400

.54

1760

4500

8692.77Kg/m 2906.98Kg/m

In view of the very poor bearing capacity of the soil,either gravity or cantilever retaining walls are not economical.It is proposed to support the wall on base slab supported by longitudinal beams,which are supported on piles. As per the clause 5.6.2 of IS 2911(1)-1,the minimum spacing between friction piles should not be less than 3 times the diametre of the shaft,hence transverse spacing of 1.35m is adopted. Hence,total width of the pile cap = 2.30m 2.00m in longitudinal direction

Two rows of 450mm dia Bored cast-in-situ straight piles are proposed at spacing of

Computation of total vertical load on the pile :i)Self weight of pile = ii)Self weight of wall(2.00m length on two piles) = iii)Self weight of pile cap = iv)Self weight of beam = v)Weight of earth on heel side = vi)Weight of earth on toe side = 2453.13kg 3375.00kg 2300.00kg 500.00kg 8413.20kg 1003.68kg 18045.01kg

The total lateral load due to earth pressure on the wall = Deduct lateral force to be resisted by the pile cap-cum-beam system =

17385.55Kg -2361.60Kg 15023.95Kg

Hence,the pile needs to be designed for safe vertical load carrying capacity of Similarly,it needs to be designed for lateral load carrying capacity of ii)Design of pile :a)Safe vertical load carrying capacity:-

18.05t 7.51t

To estimate the safe bearing capacity of pile, the ultimate bearing capacity of pile is calculated. Static formulae are used in estimating ultimate bearing capacity of pile. As per Appendix A of IS 2911(1)-1 Ultimate bearing capacity of a pile is given by , Qu = Q s + Q p Where Qs = Skin frictional resistance, Qp = End bearing resistance In the present case,the pile passes through the fine sand for a depth of 8.40m(As per soil testing report) Qs = fs x As fs = K Pdi tan Where, K = coefficient of earth pressure; Pdi = average effective overburden pressure in kgf/cm = angle of wall friction between pile and soil in degrees(To be taken equal to ) As = surface area of pile Effective overburden preesure at top of the pile = 960.00Kg/sqm

Effective overburden preesure at the level of pile tip = (Upto Water Table + After water table)

5598.40Kg/sqm

Average effective overburden pressure along pile shaft Pdi = Hence Qs = Qp = qp x Ap qp = Pdi (Nq-1) Where, Pdi = Effective overburden pressure at tip of the pile in kgf/cm Nq = Bearing capacity factor as per Fig.1 of IS 2911(1)-1 Ap = End bearing area of pile Nq = Pdi = Ap = 40 5598.4Kg/sqm 0.20sqm Hence,Qp = 43667.52kg 4822.52kg

3279.20Kg/m

Ultimate bearing capacity of pile =

48490.04kg

Applying a factor of safety of 2, allowable safe bearing capacity =

24.25t

b)Lateral load carrying capacity:Case1:- Pile considered as short fixed head pile embedded in cohesion less soil The pile considered as short restrained(Fixed head) pile embedded in cohesionless soil.As per Broom's theory,failure takes place when the load applied to the pile is equal to the ultimate lateral resistance of the soil Pu = 1.5 L d Kp Where, L = Length of embeddment d = Diametre of pile Kp = Coefficient of passive earth pressure Hence Pu = 100000.00kg 33.33t

2

Safe lateral load carrying capacity = (Applying a factor of safety of 3)

Case2:- Pile considered as short fixed head pile embedded in normally consolidated clay The lateral load capacity of the pile is estimated as per the layer of soil situated at the ground level, as it will have the major contribution in the lateral load capacity of pile. As the top most soil layer is normally consolidated clay,

T = (EI/h) E = 5000fck = I= For medium sand h = T= 1.71 2.500m 25000000

4 0.00307 m

5260.00KN/cum

From Figure 2 of IS: 2911 (Part 1)-19793, depth of fixity L f =

As the pile is short pile,the length of fixity is greater than the actual length,hence actual length is to be considered for design. Hence,lateral load capacity of fixed head pile is calculated as, Q = 12EIY/L3 where, Y = limiting lateral deflection of pile head = 5 mm for bridge substructures Hence Q = 294.72KN 29.47t

Load carrying capacity is taken as average of the above two values

31.40t

c)Structural design of pile:Now,the fixed end moment of the equivalent cantilever is given by Mu = Q(Lf)/2 = 9.39t-m =93.90KNm 77.00KNm 270.75KN 115.50KNm 0.75 0.03 0.043 0.037 0.15 1471.88sqmm 7.324243631

Applying a reduction factor of 0.82 as per IS 2911(PartI)-I,the moment = The pile is to be designed for axial load Pu = and moment of Mu = Assuming percentage of steel p = p/fck = Pu/fckD2 = Mu/fckD3 = d'/D = Area of steel required =

Using 16mm dia HYSD bars,No.of bars required for each pile = Hence provide 8 Nos of 16mm dia bars for each pile Provide 8mm ties at 200mm c/c Hence,the safe lateral load carrying capacity of pile is

31.40t

The passive earth pressure on grade beam = Kph = Passive earth pressure force for 2.0m length =

3936.00Kg/sqm 2361.60Kg 2.36t 65.16t 17385.55Kg 17.39t < 65.16t

Hence,the total lateral load carrying capacity of the structure is The total lateral load due to active earth pressure = Hence safe. Centre to centre spacing between two rows of 500mm dia piles = Hence,the over all width of the base slab =

1.50m 2.30m

Design of wall or stem:Factored bending moment Mu = Effective depth required d = Over all depth provided = Mu/0.138fckb = 400.00mm 352.00mm 22960.26Kgm 257.98mm

Effective depth provided(Assuming 40mm cover) d = Mu/bd2 = 1.853

From table 2 of SP 16,percentage of steel required = Area of steel required = Hence provide 16mm dia HYSD bars@ 100mm c/c spacing Hence Ast provided = 2009.60sqmm

0.566 1992.32sqmm

Curtail 1/3rd of the reinforcement from half of the height Check for shear:Percentage of tension steel = Maximum shear force on the member = Factored Design shear force = Nominal shear stress tv =Vu/bd = Hence section is safe from shear strength point of view The design shear strength of concrete for the above steel percentage from Table 19 of IS 456 is 0.51 N/sqmm > 0.37 Hence,no shear reinforcement is required. Provide temperature re inforcement @ 0.12% Area required = 360.00sqmm 120.00sqmm 130.39KN 0.37 N/sqmm <2.8 N/sqmm (As per Table 20 of 1S 456) 0.57 86.93KN

Provide 1/3rd of above reinforcement on earthen side = Provide 8mm dia @ 300mm c/c on earthen side

Provide 2/3rd of above reinforcement on other side = Provide 8mm dia @ 200mm c/c on other side

240.00sqmm

Provide 10mm bars at 300mm c/c vertically on the outer face to support horizontal rods

Design of base slab:Thickness of base slab assumed = 0.40m

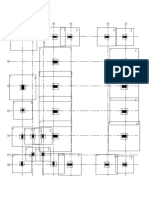

The loading on the base slab can be approximated as shown below:-

Wt.of wall =

3375.00Kg/m

33.75

Earth pressure = Wt.of earth =

8692.77Kg/m Self weight = 8856kg/m/m 1000.00kg/m/m 1.76m

RA 0.4 0.85 0.69 0.81

RB 0.4

Analysis is carried out assuming fixed supports to arrive at max.hogging moment,further supports are assumed to be hinged to arrive at max.sagging moments. After analysis, RA = RB = 12.540kN 141.170kN

The bending moment diagram is as shown below:-

100.12Knm

100.12Knm

Moment at A =

8.64Knm

Moment at B =

36.24Knm

Factored bending moment Mu = Effective depth required d = Over all depth provided = Mu/0.138fckb = 400.00mm

150.18Knm 208.64mm

Effective depth provided(Assuming 40mm cover) d = Mu/bd =

2

355.00mm

1.192 0.353 1253.15sqmm

From table 2 of SP 16,percentage of steel required = Area of steel required = Hence provide 16mm dia HYSD bars@ 150mm c/c spacing Hence Ast provided = Check for shear:Percentage of tension steel = Maximum shear force on the member = Factored Design shear force = Nominal shear stress tv =Vu/bd = Hence section is safe from shear strength point of view The design shear strength of concrete for the above steel percentage from Table 19 of IS 456 is 0.43 N/sqmm > 0.17 Hence,no shear reinforcement is required. 211.76KN 0.38 1339.73sqmm

141.17KN

0.60 N/sqmm <2.8 N/sqmm (As per Table 20 of 1S 456)

Provide same reinforcement at bottom also.Provide 10mm dia bars @150mm c/c at top&bottom as distribution reinforcement .

Design of beam:Breadth of the beam assumed = Depth of the beam assumed = UDL on beam :Due to self weight of slab = Due to weight of retained earth = 1150.00Kg/m 8413.20Kg/m 9563Kg/m 0.45m 0.60m

Twisting moment on beam :Due to earth pressure(Distributed to both beams) = 7653.42Kgm

2.00m

After analysis,the bending moment diagram is

31.90Knm

15.90Knm

Factored bending moment Mu = Torsional Moment 'T' in KN-m Equivalent bending moment Mt in KN-m Design Moment Me1 in KN-m Effective depth required d = Over all depth provided = Mu/0.138fckb = 600.00mm

47.85Knm 114.80Knm 157.57Knm 205.42Knm 363.75mm

Effective depth provided(Assuming 40mm cover) d = Mu/bd2 = 1.498

552.00mm

From table 2 of SP 16,percentage of steel required = Area of steel required = Hence provide 4 Nos of 20mm dia HYSD bars both at top&bottom Provide 2-12mm dia on each face as side face reinforcement Hence Ast provided = 1256.00sqmm 0.51

0.449 1115.32sqmm

Percentage of tension steel = Maximum shear force on the member = Factored shear force =

46.40KN 69.60KN 477.78KN 1.92 N/sqmm <2.8 N/sqmm (As per Table 20 of 1S 456)

Design shear force including equivalent shear due to torsion = Nominal shear stress tv =Vu/bd = Hence section is safe from shear strength point of view

The design shear strength of concrete for the above steel percentage from Table 19 of IS 456 is 0.49 N/sqmm Hence Vuc = Vus = Vu-Vuc = Vus/d = 6.45 KN/cm 85mm 356.06KN 121.72KN

Using 10mm dia two legged vertical stirrups,from table 62 of SP 16,the spacing required is

However,from safety point of view,provide 10mm dia 2 legged stirrups @ 80mm c/c

15306.84

DETAILS OF REINFORCEMENT

0.00 8mm bars@300mm c/c

10mm bars@300mm c/c 12mm bars@175mm c/c

8mm bars@200mm c/c

0.00m 0.15 0.30 0.15

1.80m

Beam size 0.375x0.50m Main steel:4-16mm both at top and bottom Shear steel:8mm stirrups@110mm c/c At bottom 10mm mat 150mm c/c

At top 10mm mat 150mm c/c

375mm DUR piles

5 Nos--12mm dia main 6mm dia stirrups at 300mm c/c

10mm bars@300mm c/c

8mm bars@200mm c/c

0.30m

1.75m

1.15m

0.85m

You might also like

- Reatining Wall With Sloping BackfillDocument16 pagesReatining Wall With Sloping BackfillSana UllahNo ratings yet

- Design of Pile FoundationDocument16 pagesDesign of Pile FoundationD SRINIVASNo ratings yet

- Cantilever Retaining Wall - RameswaramDocument23 pagesCantilever Retaining Wall - RameswaramD.V.Srinivasa RaoNo ratings yet

- Retaining Wall Design Final - From 12 To 8M Height Stone Mesonary - 24!12!18Document21 pagesRetaining Wall Design Final - From 12 To 8M Height Stone Mesonary - 24!12!18Shashank Srivastava100% (1)

- Retaining WallDocument6 pagesRetaining WallRahayu Jati PermanaNo ratings yet

- Design of Pier PDFDocument4 pagesDesign of Pier PDFChManikumarNo ratings yet

- Design Concrete Box CulvertsDocument9 pagesDesign Concrete Box CulvertsSUPERINTENDING ENGINEER100% (1)

- Retaining Wall With Pile FoundationDocument42 pagesRetaining Wall With Pile FoundationPrashant JhaNo ratings yet

- RCC RETAINING WALL Cantilever R1Document2 pagesRCC RETAINING WALL Cantilever R1Usama ChauguleNo ratings yet

- Design of Two Cell Box StructureDocument15 pagesDesign of Two Cell Box StructureHarish Kumar MahavarNo ratings yet

- Design of 2 Vents Box Culvert 2 X 4.5 X 3.50: General DataDocument55 pagesDesign of 2 Vents Box Culvert 2 X 4.5 X 3.50: General DataBhaskar ReddyNo ratings yet

- DESIGN OPTIMIZATIONDocument223 pagesDESIGN OPTIMIZATIOND.V.Srinivasa RaoNo ratings yet

- Design of Box CulvertDocument21 pagesDesign of Box CulvertAnirbanBhattacharjeeNo ratings yet

- Design of Cantilever Retaining Wall: Preliminary ProportionsDocument6 pagesDesign of Cantilever Retaining Wall: Preliminary ProportionsMuhammed NaseefNo ratings yet

- Design of Pier Footing for Canal Trough StructureDocument15 pagesDesign of Pier Footing for Canal Trough StructureSandip UpNo ratings yet

- Turputallu 5m Span DesignDocument80 pagesTurputallu 5m Span DesignD.V.Srinivasa RaoNo ratings yet

- RCC Design Sheets 1Document437 pagesRCC Design Sheets 1Bang JoyNo ratings yet

- Retaining Wall DesignDocument120 pagesRetaining Wall DesignMohammed HanafiNo ratings yet

- Design of SyphonDocument7 pagesDesign of SyphonraghurmiNo ratings yet

- RR Masonary Retaing Wall DesignDocument41 pagesRR Masonary Retaing Wall DesignAbhay KumarNo ratings yet

- RCC RETAINING WALL H-5mDocument21 pagesRCC RETAINING WALL H-5mramanNo ratings yet

- Road Level 2.16m: 1.0 DiagramDocument16 pagesRoad Level 2.16m: 1.0 DiagramKrishna Dixit0% (1)

- Design of RCC Wing WallDocument6 pagesDesign of RCC Wing WallAnkit Singla100% (1)

- Rengali Right Canal Division No.-IiDocument18 pagesRengali Right Canal Division No.-IibirajajenaNo ratings yet

- TYP 01 1X2X2 With 0.70m FillDocument70 pagesTYP 01 1X2X2 With 0.70m FillHimanhsuNo ratings yet

- 3.abutment - WingsDocument12 pages3.abutment - WingsBilal A BarbhuiyaNo ratings yet

- 2 Cell Box 5 X 3m Service Road SectionDocument16 pages2 Cell Box 5 X 3m Service Road SectionUmar KarimiNo ratings yet

- Analysis of Random Rubble Stone Masonary Breast WallDocument3 pagesAnalysis of Random Rubble Stone Masonary Breast WallHarish Kumar MahavarNo ratings yet

- Design of Abutment PDFDocument4 pagesDesign of Abutment PDFChManikumarNo ratings yet

- Pure Water SumpDocument8 pagesPure Water SumpVarad Sonawadekar100% (1)

- Bucket DesignDocument6 pagesBucket Designוויסאם חטארNo ratings yet

- Abutment 45+705 110110Document106 pagesAbutment 45+705 110110AmbrishNo ratings yet

- Design of Bored Piles Is 2911-Part 1sec2Document5 pagesDesign of Bored Piles Is 2911-Part 1sec2Armaan GuptaNo ratings yet

- Slab Bridge Eg Han - 2 - 150321122706Document10 pagesSlab Bridge Eg Han - 2 - 150321122706Ebisa AdamuNo ratings yet

- Design of Retaining Wall HT 6.0 MDocument7 pagesDesign of Retaining Wall HT 6.0 Mkingsuk1980No ratings yet

- Drain Cum Retaining WallDocument12 pagesDrain Cum Retaining WallvivekNo ratings yet

- Flyover FaislabadDocument72 pagesFlyover Faislabadnespak06No ratings yet

- RCC RETAINING WALL DESIGN CALCULATIONSDocument84 pagesRCC RETAINING WALL DESIGN CALCULATIONSBharathiNo ratings yet

- Foundation DesignDocument24 pagesFoundation DesigneramitdhanukaNo ratings yet

- Design of Claritube SettlerDocument19 pagesDesign of Claritube SettlerGomatesh PatilNo ratings yet

- Design of U Type Return Wall - 10.9mDocument15 pagesDesign of U Type Return Wall - 10.9mdipoksinghaNo ratings yet

- Detailed Design Calculations For 1 X 2.0M X 2.0M Size RCC Box CulvertDocument1 pageDetailed Design Calculations For 1 X 2.0M X 2.0M Size RCC Box Culvertnandu523No ratings yet

- Pipe CulvertDocument14 pagesPipe CulvertPraveen M balaramNo ratings yet

- Design of CulvertDocument9 pagesDesign of CulvertRupesh KoyandeNo ratings yet

- Abutment WellDocument576 pagesAbutment WellPrakash Singh RawalNo ratings yet

- Water Curent ForceDocument6 pagesWater Curent ForceShashank SrivastavaNo ratings yet

- Required Data: HydrologyDocument104 pagesRequired Data: HydrologyRoshan KejariwalNo ratings yet

- Slab CulvertDocument37 pagesSlab CulvertPayal MondalNo ratings yet

- Abut DesignDocument32 pagesAbut DesignSubir Kunda100% (2)

- Calculation of Safe Bearing Capacity of Soil: - Based On IS: 6403Document31 pagesCalculation of Safe Bearing Capacity of Soil: - Based On IS: 6403sourabh_gupta_54100% (1)

- Box CulvertDocument66 pagesBox CulvertRajendraNo ratings yet

- Project: Client: Made by Date Location: Subject: Checked Revision Job NoDocument2 pagesProject: Client: Made by Date Location: Subject: Checked Revision Job NothaoNo ratings yet

- Summary of Structural Calculation of 1-Barrel Box CulvertDocument30 pagesSummary of Structural Calculation of 1-Barrel Box CulvertTony Hartono BagioNo ratings yet

- Retaining Wall Design CalculationsDocument6 pagesRetaining Wall Design Calculationsdocument123456789100% (1)

- Transformer Foundation Along With Blast WallDocument11 pagesTransformer Foundation Along With Blast Wallkrmurali2000No ratings yet

- DESIGN OF GRAVITY RETAINING WALLDocument10 pagesDESIGN OF GRAVITY RETAINING WALLD.V.Srinivasa RaoNo ratings yet

- 230kV Equipment FoundationDocument4 pages230kV Equipment FoundationMian M Khurram100% (1)

- Worked Example - Retaining Wall Design - The Structural WorldDocument11 pagesWorked Example - Retaining Wall Design - The Structural WorldloishookiNo ratings yet

- Foundations - Theory and Design: Version 2 CE IIT, KharagpurDocument41 pagesFoundations - Theory and Design: Version 2 CE IIT, Kharagpurvenkatesh19701No ratings yet

- Design of Foundations PDFDocument41 pagesDesign of Foundations PDFolomizanaNo ratings yet

- Community K Parva-GF PlanDocument1 pageCommunity K Parva-GF PlanD.V.Srinivasa RaoNo ratings yet

- Design of Isolated Footing (Rf1 - 14&20) : Input DataDocument1 pageDesign of Isolated Footing (Rf1 - 14&20) : Input DataD.V.Srinivasa RaoNo ratings yet

- Old Designs ApprovedDocument14 pagesOld Designs ApprovedD.V.Srinivasa RaoNo ratings yet

- Community K Parva-FF PlanDocument1 pageCommunity K Parva-FF PlanD.V.Srinivasa RaoNo ratings yet

- Agriculture Building PlanDocument1 pageAgriculture Building PlanD.V.Srinivasa RaoNo ratings yet

- VJA Meeting Hall Detailed EstimateDocument56 pagesVJA Meeting Hall Detailed EstimateD.V.Srinivasa Rao100% (1)

- RCC Drain DesignDocument1 pageRCC Drain DesignD.V.Srinivasa RaoNo ratings yet

- STP Gollapudi SectionsDocument1 pageSTP Gollapudi SectionsD.V.Srinivasa RaoNo ratings yet

- Community Pathanaguluru PLANDocument1 pageCommunity Pathanaguluru PLAND.V.Srinivasa RaoNo ratings yet

- DPRC Kanuru GF PDFDocument1 pageDPRC Kanuru GF PDFD.V.Srinivasa RaoNo ratings yet

- Women's Hostel Building Grid Line PlanDocument1 pageWomen's Hostel Building Grid Line PlanD.V.Srinivasa Rao100% (1)

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterD.V.Srinivasa RaoNo ratings yet

- Kankipadu Mandal AMC RecordingDocument23 pagesKankipadu Mandal AMC RecordingD.V.Srinivasa RaoNo ratings yet

- DPRC at Kanuru FF Plan - RevisedDocument1 pageDPRC at Kanuru FF Plan - RevisedD.V.Srinivasa RaoNo ratings yet

- 21 Column ProformaDocument2 pages21 Column ProformaD.V.Srinivasa RaoNo ratings yet

- VRO Bldg. FinalDocument84 pagesVRO Bldg. FinalD.V.Srinivasa RaoNo ratings yet

- DPRC 1st Floor Plan RevisedDocument1 pageDPRC 1st Floor Plan RevisedD.V.Srinivasa RaoNo ratings yet

- Muslim's Shadikhana Community Hall Plan & Soil ReportDocument8 pagesMuslim's Shadikhana Community Hall Plan & Soil ReportD.V.Srinivasa RaoNo ratings yet

- Proposals For Improvements To Rubbish Roads: S.No Mandal Grampanchayat Name of The Road LengthDocument4 pagesProposals For Improvements To Rubbish Roads: S.No Mandal Grampanchayat Name of The Road LengthD.V.Srinivasa RaoNo ratings yet

- Working Women's HostelDocument21 pagesWorking Women's HostelD.V.Srinivasa RaoNo ratings yet

- Government of Andhrapradesh Panchayat Raj Engineering DepartmentDocument2 pagesGovernment of Andhrapradesh Panchayat Raj Engineering DepartmentD.V.Srinivasa RaoNo ratings yet

- Footing Lay-Out 20tDocument1 pageFooting Lay-Out 20tD.V.Srinivasa RaoNo ratings yet

- Design of Two Way and One Way Slabs for MMS BuildingDocument4 pagesDesign of Two Way and One Way Slabs for MMS BuildingD.V.Srinivasa RaoNo ratings yet

- Balive Bridge EstimateDocument77 pagesBalive Bridge EstimateD.V.Srinivasa Rao100% (1)

- Design of Typical Community HallDocument52 pagesDesign of Typical Community HallD.V.Srinivasa Rao0% (1)

- ANALYSIS & DESIGNDocument7 pagesANALYSIS & DESIGND.V.Srinivasa RaoNo ratings yet

- Kavity StadiumDocument21 pagesKavity StadiumD.V.Srinivasa RaoNo ratings yet

- D.V.Srinivasa Rao: Csi Bridge 2014, Bentley Leap Bridge Enterprise, Staad BeavaDocument5 pagesD.V.Srinivasa Rao: Csi Bridge 2014, Bentley Leap Bridge Enterprise, Staad BeavaD.V.Srinivasa RaoNo ratings yet

- Design of Typical Community HallDocument52 pagesDesign of Typical Community HallD.V.Srinivasa Rao0% (1)

- RCC Combined Footing DesignDocument21 pagesRCC Combined Footing DesignD.V.Srinivasa Rao67% (3)

- MSO Bro Bauwerkslager A4 E OnlineDocument32 pagesMSO Bro Bauwerkslager A4 E OnlineBarben Group CorpNo ratings yet

- LOCAL FIELDS IN MESOSCOPIC MEDIADocument178 pagesLOCAL FIELDS IN MESOSCOPIC MEDIAaffinitaNo ratings yet

- Steam Pipe SizingDocument16 pagesSteam Pipe SizingsamvendanNo ratings yet

- Graphene at Fifteen: Ruquan Ye and James M. TourDocument7 pagesGraphene at Fifteen: Ruquan Ye and James M. Touralihamid hamediNo ratings yet

- CE 362 - Topic 1 - Student'sDocument76 pagesCE 362 - Topic 1 - Student'sJohn Joseph SuanNo ratings yet

- SpheronDocument1 pageSpheronPLASTIC LAB CBDNo ratings yet

- Materials Data HandbookDocument112 pagesMaterials Data HandbookmadelineNo ratings yet

- Nitriding & Nitrocarburising: Mikael Fällström Bodycote AGI NEEDocument51 pagesNitriding & Nitrocarburising: Mikael Fällström Bodycote AGI NEEPushparaj Vignesh100% (1)

- Basicsof XRDDocument64 pagesBasicsof XRDsriharivelaga100% (9)

- List of Timoshenko BooksDocument6 pagesList of Timoshenko BooksUdhamNo ratings yet

- MMC4v6a ENDocument3 pagesMMC4v6a ENalexNo ratings yet

- Determining Natural Convection Heat Transfer Coefficient of Human BodyDocument8 pagesDetermining Natural Convection Heat Transfer Coefficient of Human BodyNora GuzmanNo ratings yet

- La Metalografia A ColorDocument81 pagesLa Metalografia A ColorLENDNo ratings yet

- Design Example of Reinforce Concrete BeamsDocument60 pagesDesign Example of Reinforce Concrete BeamsMario FrankistaNo ratings yet

- Interview QuestionsDocument2 pagesInterview QuestionsAdeel AhmedNo ratings yet

- Doina Dimonie PDFDocument31 pagesDoina Dimonie PDFEstudiante2346No ratings yet

- Shape ManufacturingDocument3 pagesShape ManufacturingAditya GagraniNo ratings yet

- LRFD Compression Member DesignDocument267 pagesLRFD Compression Member DesignAnonymous 7MdZQn1No ratings yet

- Materials Selection For A Carbon Fibre FrameDocument11 pagesMaterials Selection For A Carbon Fibre FramePablo Jaramillo100% (1)

- Bus Bar Current Carrying CapacityDocument8 pagesBus Bar Current Carrying CapacityMichael Zhang0% (1)

- (NATO Science For Peace and Security Series C - Environmental Security) Igor Linkov, Jeffery A. Steevens-Nanomaterials - Risks and Benefits (NATO Science For Peace and Security Series C - Environm-1Document454 pages(NATO Science For Peace and Security Series C - Environmental Security) Igor Linkov, Jeffery A. Steevens-Nanomaterials - Risks and Benefits (NATO Science For Peace and Security Series C - Environm-1Joel Cano100% (1)

- SKRCT Composite Materials Question BankDocument2 pagesSKRCT Composite Materials Question Bankumanathmech_75899977No ratings yet

- Pump and Piping DesignDocument79 pagesPump and Piping DesignPraveenNo ratings yet

- Introduction To Electron Microscopy and MicroanalysisDocument56 pagesIntroduction To Electron Microscopy and MicroanalysisPerlita2013100% (1)

- Antimony in SGCIDocument5 pagesAntimony in SGCIIPSITNo ratings yet

- Datasheet WSE250-2P2431 6044705 enDocument7 pagesDatasheet WSE250-2P2431 6044705 enZaendhal's De'Ricky ÁlvarêsNo ratings yet

- Steel column base connection designDocument17 pagesSteel column base connection designFarhan DanishNo ratings yet

- Drag Force ReportDocument8 pagesDrag Force ReportMateus RodriguesNo ratings yet

- Sol Help Models MemsDocument11 pagesSol Help Models Memsabhinav10729No ratings yet