Professional Documents

Culture Documents

API2

Uploaded by

chompink6900Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API2

Uploaded by

chompink6900Copyright:

Available Formats

TANK, API-650/653 Analysis Licensed To: Job: chilledWaterTank 05/21/12

COADE, Inc. @1994-2008 Time: 12:17:44

ID: 4369 Ver: 3.10

COADE Engineering Software, Inc. Copyright @ 1994-2008 API-650/653 TANK Design/Analysis Program Message File API-650 11th Edition, June 2007 API-653 3rd Edition, Addendum 2, Nov. 2005 Job: C:\Documents and Settings\All Users\Application Data\COADE, In Date: 5/21/12 Time: 12:18:01 Ver 3.10 Note, this file is created by the solution module, and is an "internal" file. All values shown in this file are presented in the internal units (English) of the program. This file is for data verification purposes only, this data should not be included in any formal reports. WIND DATA PER SECT 3.9.7.1 Wind Velocity in Miles/Hour: Velocity Factor, (V/120)**2: Wind Pressure, including 10% + 5 psf: Wind Profile Area in sq.ft.: Horizontal Wind Moment (ft-lb): Wind Shear Force (lb): MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Bottom Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Bottom Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature:

100.66 0.70367 26.785 581.25 0.30647E+06 15569. 1 0.90122 0.99479 22831. 28500. 1.0000 2 0.90122 0.99479 22831. 28500. 1.0000 3 0.90122 0.99479 22831. 28500. 1.0000 4 0.90122 0.99479 22831. 28500. 1.0000 5 0.90122 0.99479 22831. 28500. 1.0000 6 0.90122 0.99479 22831. 28500. 1.0000 7 0.90122 0.99479

TANK, API-650/653 Analysis Licensed To: Job: chilledWaterTank 05/21/12

Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used:

COADE, Inc. @1994-2008 Time: 12:17:44

22831. 28500. 1.0000 8 0.90122 0.99479 22831. 28500. 1.0000

ID: 4369 Ver: 3.10

MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: Thickness evaluation based on One Foot Method. "One Foot" Shell Course Thicknesses before Sect 3.6.1.1 check and round up. Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Design Test Design Test Design Test Design Test Design Test Design Test Design Test Design Test Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 0.1769 0.0437 0.1680 0.0371 0.1591 0.0305 0.1502 0.0238 0.1413 0.0172 0.1323 0.0106 0.1234 0.0040 0.1181 0.0000

Thickness(in) for each course. # DESIGN TEST USER INPUT 1 0.23622 0.23622 0.23622 2 0.19685 0.19685 0.23622 3 0.19685 0.19685 0.23622 4 0.19685 0.19685 0.23622 5 0.19685 0.19685 0.23622 6 0.19685 0.19685 0.23622 7 0.19685 0.19685 0.23622 8 0.19685 0.19685 0.23622 API-653 THICKNESS/CORROSION RESERVES Retiring Thickness Remaining Corrosion # Design Test Design Test (in) (in) (in) (in) 1 0.00000 0.00000 0.23622 0.23622 2 0.00000 0.00000 0.23622 0.23622 3 0.00000 0.00000 0.23622 0.23622 4 0.00000 0.00000 0.23622 0.23622 5 0.00000 0.00000 0.23622 0.23622 6 0.00000 0.00000 0.23622 0.23622 7 0.00000 0.00000 0.23622 0.23622 8 0.00000 0.00000 0.23622 0.23622 Allowed Fluid Heights (ft) for each course. # DESIGN TEST REQUIRED 1 66.226 176.38 33.465 2 44.484 147.15 28.543 3 44.484 147.15 23.622 4 44.484 147.15 18.701 5 44.484 147.15 13.780 6 44.484 147.15 8.8583 7 44.484 147.15 3.9370 8 44.484 147.15 0.00000

TANK, API-650/653 Analysis Licensed To: Job: chilledWaterTank 05/21/12

=========== ANNULAR BASE PLATE =========== ANNULAR BASE PLATE Table 5.1 limits were exceeded Annular bottom plate thickness Annular bot. plate width (in)

COADE, Inc. @1994-2008 Time: 12:17:44

ID: 4369 Ver: 3.10

COMPUTATION ERROR =========== COMPUTATION ERROR =========== during the computations for the (in) from Table 3-1 : per API650 3.5.2 : 0.15144E+10 0.15143E+10 0.15143E+10 19.685 0.15144E+10 19.685 0.60385 257.07 3.9430 1 8 7 6 5 4 3 2 1 37.569 4.9213 4.9213 4.9213 4.9213 4.9213 4.9213 4.9213 3.1198

0.00000 0.00000

SHELL WEIGHTS (with Nozzles) Computed weight of shell (lb): Computed corroded shell weight (lb): Insulation weight, in shell weight (lb Computed C.G. of shell (ft): Weight of shell Used (lb): C.G. of shell Used (ft):

WIND GIRDER COMPUTATIONS Top Girder, required section modulus(in^3): Distance from top to intermediate wind girder (ft): Intermediate girder section modulus (in^3): TRANSFORMED SHELL COMPUTATIONS, Girder #: Trnsfrmd shell height below last girder(ft) Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): THIS GIRDER IS NOT NECESSARY !!! SEISMIC EVALUATION - FLUID WEIGHTS Computed operating fluid weight (lb): Computed test fluid weight (lb): Computed empty fluid weight (lb): WIND OVERTURNING STABILITY CHECK Weight for anchorage (lb): MDL (ft-lb): MF (ft-lb): MPI (ft-lb): MW (ft-lb): wa (lb/ft): Design tension load per bolt (lb): Estimated Number of anchors: Anchors not needed for Section 3.11

0.38413E+06 0.35666E+06 0.00000 0.15144E+10 0.11179E+11 0.45077E+06 12933. 0.14815E+06 1316.6 0.00000 0

You might also like

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- MEASURING LIFT AND DRAG OF A WINGDocument9 pagesMEASURING LIFT AND DRAG OF A WINGRaphael EfstathiouNo ratings yet

- Tutorial: CADINP Input LanguageDocument20 pagesTutorial: CADINP Input LanguageKeshav KumarNo ratings yet

- Tundra Navigation InstallDocument70 pagesTundra Navigation InstallradiobrainNo ratings yet

- ZF Astronic Bus Repair Manual Level 1-2-1337 751 101 2003Document8 pagesZF Astronic Bus Repair Manual Level 1-2-1337 751 101 2003Bette98% (48)

- 0 GRP Pipe Support Calculation Clamped Shoes Flange SupportsDocument29 pages0 GRP Pipe Support Calculation Clamped Shoes Flange SupportsmohdnazirNo ratings yet

- Analysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ADocument23 pagesAnalysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ANeeraj KumarNo ratings yet

- 07 - Balancing Redox in Acid or BasicDocument5 pages07 - Balancing Redox in Acid or BasicSupriyanto Bin PraptoutomoNo ratings yet

- Safe TutorialDocument364 pagesSafe TutorialKhaled Abdel SalamNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Fatigue Analysis of 6300 Liters Pressure Vessel by Using Cyclic ServiceDocument7 pagesFatigue Analysis of 6300 Liters Pressure Vessel by Using Cyclic ServiceFisul RahumanNo ratings yet

- Cleaner Production of Essential Oils by Steam DistillationDocument7 pagesCleaner Production of Essential Oils by Steam Distillationhagung100% (1)

- GE Turbine Fuel SpecsDocument24 pagesGE Turbine Fuel SpecsA H RanaNo ratings yet

- Service 3120740 05-23-08 ANSI EnglishDocument428 pagesService 3120740 05-23-08 ANSI EnglishAdriano Alves SilvaNo ratings yet

- GIS 66kV Manual PDFDocument53 pagesGIS 66kV Manual PDFsridhar3048100% (3)

- American Structural Design CalculationDocument295 pagesAmerican Structural Design CalculationIgnatius Samraj100% (1)

- Steel Pushover AnalysisDocument28 pagesSteel Pushover AnalysisDario Manrique Gamarra100% (1)

- DOE Exercise BookDocument35 pagesDOE Exercise BooksigmasundarNo ratings yet

- API RP 2A 21st 2000 Vs 2007-FatigueDocument16 pagesAPI RP 2A 21st 2000 Vs 2007-Fatiguesm8575No ratings yet

- Design For Test by Alfred L CrouchDocument117 pagesDesign For Test by Alfred L CrouchSrikanth100% (4)

- Structural analysis of 6-level modular accommodation unitDocument67 pagesStructural analysis of 6-level modular accommodation unitEduardo De Castro Cruz Jr.No ratings yet

- Nace Standards and Specifications Related Oil Natural Gas InfrastructureDocument5 pagesNace Standards and Specifications Related Oil Natural Gas InfrastructurePharmacist ShimaaNo ratings yet

- 05.1 Heat Flux Calculations Wind FreeDocument11 pages05.1 Heat Flux Calculations Wind FreegfgfNo ratings yet

- API 650 Tank Roof DesignDocument47 pagesAPI 650 Tank Roof DesignmarkfgtNo ratings yet

- 003-Heat ExchangerDocument299 pages003-Heat ExchangerVijayshanker GuptaNo ratings yet

- STAAD Pro analysis and design of air washer building structural elementsDocument28 pagesSTAAD Pro analysis and design of air washer building structural elementssunbo57% (7)

- Tank Venting Rate EstimationDocument3 pagesTank Venting Rate EstimationOmar KallufNo ratings yet

- Storing and Sanitation TechniquesDocument27 pagesStoring and Sanitation TechniquesMarjory Alga Omale100% (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Price Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost ItemDocument11 pagesPrice Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost Itemchompink6900No ratings yet

- A1) Evaluate The Quality Control Program at Polaroid Prior To Project GreenlightDocument8 pagesA1) Evaluate The Quality Control Program at Polaroid Prior To Project Greenlightnicasavio2725No ratings yet

- 154 Loesche Mills For Cement Raw Material E 2016Document28 pages154 Loesche Mills For Cement Raw Material E 2016faheemqcNo ratings yet

- CSP00138 (GEN-Tutorial) Pushover Analysis As Per Eurocode 8 2004Document24 pagesCSP00138 (GEN-Tutorial) Pushover Analysis As Per Eurocode 8 2004bosnia76100% (1)

- Transporte IntermodalDocument8 pagesTransporte IntermodalDavid LatorreNo ratings yet

- LIFT OFF ModuleDocument28 pagesLIFT OFF ModulericardoNo ratings yet

- Advance Production EngineeringDocument48 pagesAdvance Production EngineeringClaudia Toding AlloNo ratings yet

- Tutorial Pressure VesselDocument19 pagesTutorial Pressure Vesseltahseenahsan100% (1)

- Beggs & Brill MethodDocument9 pagesBeggs & Brill Methodmatrix69No ratings yet

- DesignBuilder v4.2 ASHRAE140 2Document113 pagesDesignBuilder v4.2 ASHRAE140 2Yusuf AhdaNo ratings yet

- PV Elite Vessel Analysis Program: Input DataDocument9 pagesPV Elite Vessel Analysis Program: Input DataAhmed Ammar YasserNo ratings yet

- DOE Applications in IndustryDocument27 pagesDOE Applications in IndustryAzue RamliNo ratings yet

- Make Up Water.r1Document54 pagesMake Up Water.r1Ranu JanuarNo ratings yet

- Daily Exam 4 OpenDocument4 pagesDaily Exam 4 OpenEswaranNo ratings yet

- Sump TankDocument65 pagesSump TankAgus MarpaungNo ratings yet

- Gas Eng MOHAMED BAKRI OSMANDocument11 pagesGas Eng MOHAMED BAKRI OSMANhoa864611No ratings yet

- V6000 Kombi-F-II, Kombi-F: Flanged Balancing and Shutoff ValvesDocument20 pagesV6000 Kombi-F-II, Kombi-F: Flanged Balancing and Shutoff ValvesmateuscristianosantoNo ratings yet

- EN 3-2005 Example 001Document7 pagesEN 3-2005 Example 001Anitha Hassan KabeerNo ratings yet

- DesigningPlantFoundations TRNC01913 1 0001Document26 pagesDesigningPlantFoundations TRNC01913 1 0001rex torboNo ratings yet

- Performance Evaluation of A Air Conditioner According To Different Test Standards PDFDocument9 pagesPerformance Evaluation of A Air Conditioner According To Different Test Standards PDFIAEME PublicationNo ratings yet

- AA SM 028 Fastener FlexibilityDocument20 pagesAA SM 028 Fastener Flexibilitykrishbalu17No ratings yet

- ANSI AHRI Standard 1360 I-P 2013 With Addendum 1 PDFDocument15 pagesANSI AHRI Standard 1360 I-P 2013 With Addendum 1 PDFdimaomarNo ratings yet

- Design Analysis Project Title Here: Created byDocument21 pagesDesign Analysis Project Title Here: Created byTonic89No ratings yet

- Split stream dearator vessel design calculationsDocument26 pagesSplit stream dearator vessel design calculationsArt G. EnziNo ratings yet

- Recipe Function: Mitsubishi Electric CorporationDocument18 pagesRecipe Function: Mitsubishi Electric Corporationkurakura langitNo ratings yet

- Coupling UW16.2 KL Ver 1.1Document4 pagesCoupling UW16.2 KL Ver 1.1gopaltryNo ratings yet

- Assignment 1 - ProsperDocument9 pagesAssignment 1 - ProsperMuhammad Amirullah SanadiNo ratings yet

- Process Integration AnalysisDocument4 pagesProcess Integration AnalysisUdaya ZorroNo ratings yet

- Saddle support and anchor bolting loads for ship moduleDocument12 pagesSaddle support and anchor bolting loads for ship modulemsraja77No ratings yet

- Group Technology: Pgdie 41Document31 pagesGroup Technology: Pgdie 41Saikat SahaNo ratings yet

- Calculation note for compressor shelter steel structure designDocument54 pagesCalculation note for compressor shelter steel structure designmaniaxpdfNo ratings yet

- Feed Forward Cascade ControlDocument10 pagesFeed Forward Cascade ControlMiNiTexasNo ratings yet

- Ge Seismic DET-463Document4 pagesGe Seismic DET-463rober2222No ratings yet

- FOUNDATION TANK DESIGN CALCULATIONDocument82 pagesFOUNDATION TANK DESIGN CALCULATIONRamadhani MgsNo ratings yet

- T0220 PDFDocument35 pagesT0220 PDFChristian Andres PantojaNo ratings yet

- MDOF CW Report - Drafting - 2Document9 pagesMDOF CW Report - Drafting - 2johnNo ratings yet

- Start: Static Input Data (Beltanalyst™)Document8 pagesStart: Static Input Data (Beltanalyst™)Erlan OlveiraNo ratings yet

- 622 E3 Addendum 1Document7 pages622 E3 Addendum 1WildanNo ratings yet

- 12155Document25 pages12155NobodyNo ratings yet

- TCD Az PSWDocument22 pagesTCD Az PSWfotonengineNo ratings yet

- How To Design A Safe and Economical PC & RC Isolated FootingsDocument4 pagesHow To Design A Safe and Economical PC & RC Isolated FootingsMagdy BakryNo ratings yet

- Economic and Financial Modelling with EViews: A Guide for Students and ProfessionalsFrom EverandEconomic and Financial Modelling with EViews: A Guide for Students and ProfessionalsNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- PCBDocument1 pagePCBchompink6900No ratings yet

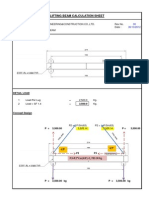

- Lifting Beam Cal 4Document1 pageLifting Beam Cal 4dd6077No ratings yet

- LicenseDocument1 pageLicensechompink6900No ratings yet

- 83e EnclrevDocument1 page83e Enclrevchompink6900No ratings yet

- Lifting Beam Calculation SheetDocument1 pageLifting Beam Calculation Sheetchompink6900No ratings yet

- CCK QuotationRev01Document3 pagesCCK QuotationRev01chompink6900No ratings yet

- Cal Stru Case 1Document12 pagesCal Stru Case 1chompink6900No ratings yet

- Lifting Beam Calculation SheetDocument1 pageLifting Beam Calculation Sheetchompink6900No ratings yet

- 1Document1 page1chompink6900No ratings yet

- BR 1887Document8 pagesBR 1887chompink6900No ratings yet

- 83e EnclrevDocument1 page83e Enclrevchompink6900No ratings yet

- Readme 1 STDocument1 pageReadme 1 STchompink6900No ratings yet

- KLSDFNKLDocument1 pageKLSDFNKLShIvaleela ChoudaryNo ratings yet

- The Ultimate Bee Gees (CD 1)Document1 pageThe Ultimate Bee Gees (CD 1)chompink6900No ratings yet

- Maintain TeklaStructures Form Request Improve WorkDocument1 pageMaintain TeklaStructures Form Request Improve Workchompink6900No ratings yet

- DEF File DescriptionDocument5 pagesDEF File Descriptionchompink6900No ratings yet

- Maintenance RequestDocument1 pageMaintenance RequestAlex Estacio CNo ratings yet

- Drop Down ListDocument4 pagesDrop Down Listduazo2009No ratings yet

- Model Basics ComponentsDocument1 pageModel Basics Componentsdd6077No ratings yet

- DROsDocument1 pageDROschompink6900No ratings yet

- LiabilityDocument1 pageLiabilitychompink6900No ratings yet

- SN 3Document1 pageSN 3chompink6900No ratings yet

- ButtonsDocument1 pageButtonsDebbie MoleNo ratings yet

- Cover Letter SHEETDocument1 pageCover Letter SHEETchompink6900No ratings yet

- Whats NewDocument2 pagesWhats Newchompink6900No ratings yet

- Cover PlateDocument1 pageCover Platechompink6900No ratings yet

- KFT OfficeDocument20 pagesKFT Officechompink6900No ratings yet

- SN 3Document1 pageSN 3chompink6900No ratings yet

- SN 5Document1 pageSN 5chompink6900No ratings yet

- Insulate Walls to Meet Building CodesDocument18 pagesInsulate Walls to Meet Building CodesAlberto LeónNo ratings yet

- Covalent Bonding in ElementsDocument31 pagesCovalent Bonding in ElementsOsmany Madrigal100% (1)

- Astm D5963-04Document9 pagesAstm D5963-04Sampath WeragodaNo ratings yet

- Flow Diagram SymbolsDocument5 pagesFlow Diagram SymbolshussainNo ratings yet

- Insulation system thermal classesDocument2 pagesInsulation system thermal classesVictor Hutahaean100% (1)

- Service Manual Samsung Nexus I9023Document79 pagesService Manual Samsung Nexus I9023htrinca100% (1)

- Almex Light Weight BrochureDocument16 pagesAlmex Light Weight BrochureGijoNo ratings yet

- Synthesis of LiCoO2 Prepared by Sol-Gel MethodDocument4 pagesSynthesis of LiCoO2 Prepared by Sol-Gel Methodمصطفى محمودNo ratings yet

- Research Report - Land PollutionDocument9 pagesResearch Report - Land PollutionMisbah GroupNo ratings yet

- GS Yuasa Battery Europe Ltd. Safety Data SheetDocument11 pagesGS Yuasa Battery Europe Ltd. Safety Data SheetVioleta MitićNo ratings yet

- Pcw-Ts-Pcs Design Process 2017Document89 pagesPcw-Ts-Pcs Design Process 2017Marlon ReonicoNo ratings yet

- L&T M30Document2 pagesL&T M30Kannan GnanaprakasamNo ratings yet

- Astm D 6184Document3 pagesAstm D 6184김인식No ratings yet

- Dickella Premakumara Final Best Practices PDFDocument36 pagesDickella Premakumara Final Best Practices PDFjune dela cernaNo ratings yet

- DC 163Document2 pagesDC 163manox007No ratings yet

- Corporate Image enDocument8 pagesCorporate Image enDanfert PinedoNo ratings yet

- 423-Renolin CLP-1Document1 page423-Renolin CLP-1Moutaz IsmailNo ratings yet

- ExhibitorsDocument6 pagesExhibitorsamanprajapati488No ratings yet

- Zero Waste Europe Policy-Briefing Waste Prevention Framework enDocument12 pagesZero Waste Europe Policy-Briefing Waste Prevention Framework enFernanda BenedettiNo ratings yet