Professional Documents

Culture Documents

Application Note: Sentry Spiral Tube Heat Exchanger Vent Condenser Application

Uploaded by

raritylimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application Note: Sentry Spiral Tube Heat Exchanger Vent Condenser Application

Uploaded by

raritylimCopyright:

Available Formats

SPD 12.1.10 Rev.

0 6/00

Application Note

Sentry Spiral Tube Heat Exchanger Vent Condenser Application

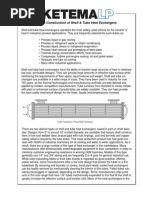

Many fluids are contained in atmospheric or low pressure tanks. Regulatory agencies have compiled a growing list of fluids with limits on the amount of vapors which can be exhausted into the environment. Whenever a tank is filled or the temperature of the tank increases either the pressure within the tank increases or gases will exit the tank. Exiting gases will be saturated with vapor from the tank contents. Reducing emissions from the tank will require condensing of the vapors prior to exhaust of the gas. A Sentry spiral heat exchanger can be mounted either in the piping exiting the tank or within the tank at the outlet connection. Circulating a cold fluid through the tubes of the heat exchanger will cool the exiting gas and condense some of the vapors on the tube wall. When the exchanger is mounted within the tank this condensate can drip off of the tubes back into the tank and reduce the vapor content of the discharge gas. If tube side condensing is needed, a reverse upflow manifold arrangement on the spiral can be used which allows for the condensate to drain back to the tank. This style is also used when special material requirements make tube side condensing more economic. See figs. 1 & 2. Sentry Spiral tube heat exchangers are ideally suited for this service because: 1. The compact design of the spiral tube heat exchanger allows it to frequently fit within the existing tank opening. 2. Moderate gas flow can be handled with cross flow with very low gas side pressure drop 3. Corrosion resistant materials are frequently needed for tubing material. Computerized heat transfer calculation and model selection insures a satisfactory exchanger for the desired service. This is particularly important in vapor condensing since many times multi-component fluids are present and the condensing calculations can be complex. Sentry's flexible manufacturing processes allow optimization of the exchanger design; including tube diameter, number of tubes, tube length and spacing.

Fig. 1

Because of our special manufacturing techniques and multi-product usage of stainless steel tubing, Sentry offers the unique ability to provide a welded 304 stainless steel spiral tube bundle for the same price as our competitor's brazed copper tube bundle in lower pressure/temperature applications where copper would typically be used because of cost. This provides the user with greater heat exchanger life and expanded heat exchanger flexibility with no appreciable loss in heat transfer. Additionally, we specialize in spiral tube heat exchangers with 316L stainless steel and a variety of exotic alloy materials including Hastelloy , Inconel , Incoly and specialty stainless steels to name just a few. Fig . 2 Sentry Spiral tube heat exchangers are available in either bolted or all welded shell construction. All welded units provide a significantly lower cost than bolted units when shell side inspection or cleaning is not essential or economic. Standard shell construction utilizes carbon steel with NPT pipe thread connections. Other available materials and connections including flanged, socket weld, butt weld or specialty connectors are available. ASME Section VIII Division 1 stamped heat exchangers are available upon request

Sentry Equipment Corp PO Box 127 Oconomowoc, WI 53066 Phone: 262-567-7256 Fax: 262-567-4523 E-mail: sales@sentry-equip.com Web Site: http://www.sentry-equip.com

You might also like

- Basic Construction of Shell & Tube Heat ExchangersDocument12 pagesBasic Construction of Shell & Tube Heat ExchangerslatshareNo ratings yet

- Chapter No.6: Design of Heat ExchangerDocument35 pagesChapter No.6: Design of Heat ExchangerGlacier RamkissoonNo ratings yet

- Boiler Pressure PartsDocument3 pagesBoiler Pressure PartsBedabyas DehuryNo ratings yet

- Gas Cooling Systems For Steam Reforming PlantsDocument12 pagesGas Cooling Systems For Steam Reforming Plantsrajaramc100% (1)

- Comparing Plate-Fin and Coil-Wound Heat ExchangersDocument16 pagesComparing Plate-Fin and Coil-Wound Heat Exchangerscapricorno4694No ratings yet

- 1 PBDocument12 pages1 PBscata1117No ratings yet

- Designing AND Optimization OF A Shell and Tube Heat ExchangerDocument8 pagesDesigning AND Optimization OF A Shell and Tube Heat ExchangerAyush SinghNo ratings yet

- 112.09 Heat Exchangers BrochureDocument4 pages112.09 Heat Exchangers BrochureAlexandru DinaNo ratings yet

- Boiler Components: Super HeaterDocument2 pagesBoiler Components: Super Heaterponnivalavans_994423No ratings yet

- Air Cooled Heat Exchangers - GEA BrochureDocument16 pagesAir Cooled Heat Exchangers - GEA BrochurenorthstarleoNo ratings yet

- 01 - Chemetics Gas-Gas Heat Exchanger InfoSheetDocument2 pages01 - Chemetics Gas-Gas Heat Exchanger InfoSheetWeb LogueandoNo ratings yet

- Air-Cooled Heat Exchangers Fin-Fan: by M.M.SorourDocument64 pagesAir-Cooled Heat Exchangers Fin-Fan: by M.M.SorourNader GaafarNo ratings yet

- Surface Condenser: Applications of Surface Condensers and Requirement of Surface CondenserDocument17 pagesSurface Condenser: Applications of Surface Condensers and Requirement of Surface Condenserdroffilcz27100% (1)

- DX Evaporator CoilsDocument3 pagesDX Evaporator CoilsSME CoilsNo ratings yet

- Boiler Types and Components OverviewDocument48 pagesBoiler Types and Components OverviewSubramanian Ravishankar100% (1)

- Heat Exchange TubesDocument34 pagesHeat Exchange Tubesgabattupro99No ratings yet

- How To Select Shell and Tube HEDocument10 pagesHow To Select Shell and Tube HEgigihpradana100% (1)

- Cooling Technology for ElectronicsDocument29 pagesCooling Technology for ElectronicsNikhil ShahNo ratings yet

- Use of ExchangersDocument21 pagesUse of Exchangerssteepa22No ratings yet

- Heat Exchanger Design: Table of ContentDocument18 pagesHeat Exchanger Design: Table of ContenthellopaNo ratings yet

- Heat ExchangerDocument37 pagesHeat Exchangerdhairya1725100% (5)

- Engineering Letter: IndustrialsteamheatingsystemsDocument8 pagesEngineering Letter: Industrialsteamheatingsystemsmontie3No ratings yet

- 500mwboilermahagenco 140115124304 Phpapp02Document38 pages500mwboilermahagenco 140115124304 Phpapp02Lakshmi NarayanNo ratings yet

- Guide to Shell and Tube Heat Exchangers Layout and DesignDocument23 pagesGuide to Shell and Tube Heat Exchangers Layout and DesignMurugan VeluNo ratings yet

- Coil Catalog Version 09 - 01ADocument28 pagesCoil Catalog Version 09 - 01AblindjaxxNo ratings yet

- Heat Recovery From Exhaust GasesDocument6 pagesHeat Recovery From Exhaust GasesnaveenNo ratings yet

- Jumpover Hose Installation Jumpover Leak ReportDocument1 pageJumpover Hose Installation Jumpover Leak ReportSA1No ratings yet

- Surface CondenserDocument33 pagesSurface CondensershivvaramNo ratings yet

- 3.1 Heat ExchangersDocument76 pages3.1 Heat Exchangersraghu_iictNo ratings yet

- Evaporator and Condenser CoilsDocument3 pagesEvaporator and Condenser CoilsSME CoilsNo ratings yet

- Heat Ex Changer Model Selection TypeDocument10 pagesHeat Ex Changer Model Selection TypenoxleekNo ratings yet

- Heat ExchangersDocument8 pagesHeat ExchangersLiyan Fajar GintaraNo ratings yet

- Get Profile 1 PDFDocument24 pagesGet Profile 1 PDFحمودي معزNo ratings yet

- Heat ExchangerDocument6 pagesHeat ExchangeralokbdasNo ratings yet

- Cryogenic Piping DesignDocument19 pagesCryogenic Piping Designsatishchemeng80% (10)

- Heat Exchanger Options: Confidential Marketing GuideDocument12 pagesHeat Exchanger Options: Confidential Marketing GuideEmerson PenaforteNo ratings yet

- Power plant condensers: types, working principle and advantagesDocument7 pagesPower plant condensers: types, working principle and advantagesMustafam98No ratings yet

- Steam Turbine Condenser: How it Works and TypesDocument33 pagesSteam Turbine Condenser: How it Works and TypesSatyam KumarNo ratings yet

- ABC 200 Heat ExchangerDocument200 pagesABC 200 Heat Exchanger전상문100% (2)

- Vacuum SystemDocument49 pagesVacuum Systemssmith2007100% (3)

- Heat Exchanger Design - ProcessDocument42 pagesHeat Exchanger Design - Processalokbdas100% (1)

- Air-Cooled Heat Exchangers: LectureDocument39 pagesAir-Cooled Heat Exchangers: LectureBaraa Shurbaji No 111No ratings yet

- Shell and Tube Ref - AnandDocument6 pagesShell and Tube Ref - Anand7761430No ratings yet

- Shell and Tube Heat Exchanger Design ConsiderationsDocument55 pagesShell and Tube Heat Exchanger Design ConsiderationsCc12 22tNo ratings yet

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDocument18 pageseBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xNo ratings yet

- Tube Still HeaterDocument7 pagesTube Still HeaterStalinNarayanasamyNo ratings yet

- Basic Boiler ConstructionDocument37 pagesBasic Boiler ConstructionSudarmarine SudharNo ratings yet

- Waste-heat recovery environmental factorsDocument7 pagesWaste-heat recovery environmental factorsrvnesariNo ratings yet

- CalorifierDocument12 pagesCalorifierNay Myo OoNo ratings yet

- Types of Heat Exchangers ClassificationDocument13 pagesTypes of Heat Exchangers ClassificationAbhijit NathNo ratings yet

- Design and Experimental Analysis of Spiral Tube Heat ExchangerDocument6 pagesDesign and Experimental Analysis of Spiral Tube Heat ExchangergpcshfNo ratings yet

- SEC Spiral Heat Exchangers BrochureDocument4 pagesSEC Spiral Heat Exchangers BrochureShrikant Nimbalkar100% (1)

- Document 1Document4 pagesDocument 1SAMARTHNo ratings yet

- Shell and Tube Heat Exchanger BasicsDocument12 pagesShell and Tube Heat Exchanger BasicsSachin KumarNo ratings yet

- Heating With Coils and Jackets - Spirax SarcoDocument14 pagesHeating With Coils and Jackets - Spirax SarcoWEN GIE KONGNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Seismic Capacity of Buildings in Singapore Designed Primarily For Gravity LoadsDocument11 pagesSeismic Capacity of Buildings in Singapore Designed Primarily For Gravity LoadsraritylimNo ratings yet

- Earthquake DesignDocument13 pagesEarthquake DesignraritylimNo ratings yet

- Equator Principles Governance Rules December 2013Document27 pagesEquator Principles Governance Rules December 2013raritylimNo ratings yet

- 11Document25 pages11raritylimNo ratings yet

- Excerpts From TNO Purple BookDocument6 pagesExcerpts From TNO Purple BookraritylimNo ratings yet

- Modeling and Understanding BLEVEsDocument27 pagesModeling and Understanding BLEVEssen_iimNo ratings yet

- Intumescent PaintDocument11 pagesIntumescent Paintraritylim100% (1)

- EarthquakeDocument10 pagesEarthquakeraritylimNo ratings yet

- 1 Butene Pressure Surge Calculator - PrelimDocument1 page1 Butene Pressure Surge Calculator - PrelimraritylimNo ratings yet

- 1 Butene Pressure Surge Calculator - PrelimDocument1 page1 Butene Pressure Surge Calculator - PrelimraritylimNo ratings yet

- Excerpt Guidelines For Developing Quantitative Safety Risk Criteria - WileyDocument2 pagesExcerpt Guidelines For Developing Quantitative Safety Risk Criteria - WileyraritylimNo ratings yet

- Gastech 2005 LPG Paper Rev3Document8 pagesGastech 2005 LPG Paper Rev3raritylimNo ratings yet

- Modeling and Understanding BLEVEsDocument27 pagesModeling and Understanding BLEVEssen_iimNo ratings yet

- Emco B0300 eDocument2 pagesEmco B0300 eraritylimNo ratings yet

- Wi Reless Vga & Hdmi Real-Ti Me VI Deo and Data Presentati OnDocument1 pageWi Reless Vga & Hdmi Real-Ti Me VI Deo and Data Presentati OnraritylimNo ratings yet

- OT FestivalsDocument3 pagesOT FestivalsraritylimNo ratings yet

- Implementation of Eurocodes in Malaysia - A View Point From Consulting Engineer (Iem)Document45 pagesImplementation of Eurocodes in Malaysia - A View Point From Consulting Engineer (Iem)raritylimNo ratings yet

- Gdflo 497Document9 pagesGdflo 497raritylimNo ratings yet

- NFPA Diamond Health Flammability ReacitivityDocument64 pagesNFPA Diamond Health Flammability ReacitivityraritylimNo ratings yet

- Gdflo 497Document9 pagesGdflo 497raritylimNo ratings yet

- Glycol 2000Document209 pagesGlycol 2000raritylimNo ratings yet

- IEOM166Document6 pagesIEOM166raritylimNo ratings yet

- Chapter 5 Existing Environment - Rev03 - Latest Wave HeightDocument3 pagesChapter 5 Existing Environment - Rev03 - Latest Wave HeightraritylimNo ratings yet

- OECD SIDS Profile for CitralDocument113 pagesOECD SIDS Profile for CitralraritylimNo ratings yet

- BL 2701Document35 pagesBL 2701raritylimNo ratings yet

- ISO Standards Collection - CranesDocument4 pagesISO Standards Collection - CranesJosé Rezende0% (1)

- Storage TanksDocument62 pagesStorage Tankstoychom2013No ratings yet

- Safety Coupling Prevents Driveaway SpillsDocument1 pageSafety Coupling Prevents Driveaway SpillsraritylimNo ratings yet

- Be Thou My Vision - CompleteDocument8 pagesBe Thou My Vision - Completeraritylim100% (1)

- Case Study: The Chinese Fireworks IndustryDocument37 pagesCase Study: The Chinese Fireworks IndustryPham Xuan Son100% (1)

- BlockStack Top 21 Trends in Web3 1676290935Document9 pagesBlockStack Top 21 Trends in Web3 1676290935Ahmed BachaNo ratings yet

- AVD 370 Installation Manual WEBDocument72 pagesAVD 370 Installation Manual WEBLuis Anselmo CastilloNo ratings yet

- Fire Exit Doors SizeDocument3 pagesFire Exit Doors SizeBerlin Andrew SionNo ratings yet

- Political Education and Voting Behaviour in Nigeria: A Case Study of Ogbadibo Local Government Area of Benue StateDocument24 pagesPolitical Education and Voting Behaviour in Nigeria: A Case Study of Ogbadibo Local Government Area of Benue StateMohd Noor FakhrullahNo ratings yet

- Principles of Clinical Chemistry Automation and Point-of-Care TestingDocument27 pagesPrinciples of Clinical Chemistry Automation and Point-of-Care TestingMalliga SundareshanNo ratings yet

- GUIDE FOR ROOM EXAMINER - 2023-05 Revised (CSE-Pen & Paper Test) - ModifiedDocument14 pagesGUIDE FOR ROOM EXAMINER - 2023-05 Revised (CSE-Pen & Paper Test) - ModifiedLeilani BacayNo ratings yet

- Chapter 2Document20 pagesChapter 2Saman Brookhim100% (4)

- Training Manual W Appendix 3-20-14 RsDocument193 pagesTraining Manual W Appendix 3-20-14 RsZakir Ullah100% (5)

- Complex Number Exercise Book PDFDocument26 pagesComplex Number Exercise Book PDFRitik KumarNo ratings yet

- Lecture Nsche Engr Mafe SIWESDocument38 pagesLecture Nsche Engr Mafe SIWESoluomo1No ratings yet

- Cotton-Top Tamarin - Husbandry - ManualDocument98 pagesCotton-Top Tamarin - Husbandry - Manualjoaquin chan100% (1)

- Sally Su-Ac96e320a429130Document5 pagesSally Su-Ac96e320a429130marlys justiceNo ratings yet

- Test Booklet Primary-1 PDFDocument53 pagesTest Booklet Primary-1 PDFReynold Morales Libato100% (1)

- College of Home Economics, Azimpur, Dhaka-1205.: Seat Plan, Group:-ScienceDocument3 pagesCollege of Home Economics, Azimpur, Dhaka-1205.: Seat Plan, Group:-Sciencesormy_lopaNo ratings yet

- Speaking Topics b1Document3 pagesSpeaking Topics b1Do HoaNo ratings yet

- Mechanical Properties of Rna NanowiresDocument4 pagesMechanical Properties of Rna NanowiresIJAR JOURNALNo ratings yet

- Recombinant Protein Production in E.coliDocument23 pagesRecombinant Protein Production in E.coliSanjay KumarNo ratings yet

- Under DronesDocument336 pagesUnder DronesRobert LewisNo ratings yet

- Falcon Nir Online AnalyzerDocument4 pagesFalcon Nir Online AnalyzerCesc MezaNo ratings yet

- Study Guide For Kawabata's "Of Birds and Beasts"Document3 pagesStudy Guide For Kawabata's "Of Birds and Beasts"BeholdmyswarthyfaceNo ratings yet

- Rail Section As Per IrsDocument6 pagesRail Section As Per IrskarnagaNo ratings yet

- Nipas Act, Ipra, LGC - Atty. Mayo-AndaDocument131 pagesNipas Act, Ipra, LGC - Atty. Mayo-AndaKing Bangngay100% (1)

- 1.fish and Fisheries of IndiaDocument36 pages1.fish and Fisheries of Indiazozo torzoNo ratings yet

- BIO125 Syllabus Spring 2020Document3 pagesBIO125 Syllabus Spring 2020Joncarlo EsquivelNo ratings yet

- Slides Iso 17021 Be LacDocument117 pagesSlides Iso 17021 Be Lacjorge.s1943No ratings yet

- Metamorphic differentiation explainedDocument2 pagesMetamorphic differentiation explainedDanis Khan100% (1)

- Enclosure No. 6.7: Parental ConsentDocument3 pagesEnclosure No. 6.7: Parental ConsentRhea CarinoNo ratings yet

- Validate Analytical MethodsDocument9 pagesValidate Analytical MethodsFernando Silva BetimNo ratings yet

- Reflection Paper About Educational Administration (Ivy M. Peralta)Document1 pageReflection Paper About Educational Administration (Ivy M. Peralta)Ivy peraltaNo ratings yet