Professional Documents

Culture Documents

Method Statement For Clamp Meter

Uploaded by

aldred_chezkaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Clamp Meter

Uploaded by

aldred_chezkaCopyright:

Available Formats

1.

INSPECTEST (PRIVATE) LIMITED

This method defines the procedures for calibration of Clamp Meter Digital / Analog.

1. SCOPE 2. REFERENCE STANDARD 2.1. Digital Clamp Meter with a valid certificate of calibration traceable to international standard in accordance with an industrial code or a regulation shall be used as a standard for calibration. 2.2. The reference standard shall be kept under controlled environmental conditions e.g. dust free environment and Lab. temperature 25C 2C. 3. ACCEPTANCE CRITERIA 3.1. The acceptance criteria of a specific Clamp Meter Digital / Analog shall be as per Client specifications. Other wise the Clamp Meter Digital / Analog shall be rejected if deviation is more than 2% in case of Digital Clamp Meter & 4% in case of Analog Clamp Meter. 3.2. The Clamp Meter Digital / Analog showing deviation within the Tolerance shall be accepted for calibration and deviations shall be mentioned in Calibration Certificate. 4. PRELIMINARY OPERATIONS

METHOD STATEMENT

4.1. The details of Clamp Meter Digital / For Analog received for calibration shall be entered in the calibration job form: call/001(a) 4.2. Inspection of the Clamp Meter Digital / Analog for general condition shall be carried CALIBRATION OF CLAMP METER DIGITAL/ ANALOG out. 4.3. The Clamp Meter Digital / Analog shall be inspected and marked ( ) in relevant block of equipments primary inspection section of calibration data sheet form: call / 001 (b). WARNING

Unless otherwise designated and prior to beginning the calibration process, it shall be ensured that all test equipment voltage and current out puts are set to zero (0) or turned to off where applicable, Equipment switches are set to the proper positions before making connections or applying power.

5. CALIBRATION PROCEDURE 5.1. The Clamp Meter Digital to calibrated shall be maintained at same place of standard Digital Clamp Meter for 03 hours minimum Prepared by Meter Digital / Analog shall be connected to appropriate Client'sterminal Approval 5.2 Clamp on the standard. Signature Signature 5.3 Out put of standard shall be adjusted to the proper range for Clamp Meter Digital / Name Name Analog being calibrated. 5.4 Out put of standard shall be gradually increased to each cardinal point and full scale Date Date on the test instrument. 5.5 The Standard must indicate within the manufacturer specification if known or as specified in paragraph No 3.2. 5.6 After completion of calibration the power of the standard and Clamp Meter under test shall be switched off and secure all the equipment.

Page 1 of 3

1. SCOPE This method defines the procedures for calibration of .Clamp Meter Digital / Analog 2. REFERENCE STANDARD 2.1. Digital Multi Meter Clamp Meter with a valid certificate of calibration traceable to international standard in accordance with an industrial code or a regulation shall be used as a standard for calibration. 2.2. The reference standard shall be kept under controlled environmental conditions e.g. dust free environment and Lab. temperature 25C 2C. 3. ACCEPTANCE CRITERIA 3.1. The acceptance criteria of a specific Clamp Meter Digital / Analog shall be as per Client specifications. Other wise the Clamp Meter Digital / Analog shall be rejected if deviation is more than 2% in case of Digital Multi Meter & 4% in case of Analog Multi Meter. 3.2. The Clamp Meter Digital / Analog showing deviation within the tolerance shall be accepted for calibration and deviations shall be mentioned in calibration certificate. 4. PRELIMINARY OPERATIONS 4.1. The details of Multi Meter Digital / Analog received for calibration shall be entered in the calibration job form: call/001(a) 4.2. Inspection of the Multi Meter Digital / Analog for general condition shall be carried out. 4.3. The Multi Meter Digital / Analog shall be inspected and marked ( ) in relevant block of equipments primary inspection section of calibration data sheet form: call / 001 (b). WARNING

Unless otherwise designated and prior to beginning the calibration process, it shall be ensured that all test equipment voltage and current out puts are set to zero (0) or turned to off where applicable,equipment switches are set to the proper positions before making connections or applying power.

5. CALIBRATION PROCEDURE 5.1. The Multi Meter Digital to calibrated shall be maintained at same place of standard Digital Multi Meter for 03 hours minimum 5.2. Multi Meter Digital / Analog shall be connected to appropriate terminal on the standard. 5.3. Out put of standard shall be adjusted to the proper range for Multi Meter Digital / Analog being calibrated. 5.4. Out put of standard shall be gradually increased to each cardinal point upto full scale of under test instrument. 5.5. The readings of Clamp Meter Digital / Analog shall be recorded in observed value column against the standard readings in set value column of calibration data sheet form call/001 (b). 5.6. The relevant section of calibration data sheet form: cal/001(b). shall be marked.

Page 2 of 3

5.7. The instrument under test must indicate within the manufacturer specification if known or as specified in paragraph No 3.2. 5.8. After completion of calibration the power of the standard and Multi Meter under test shall be switched off equipment.shall be secured 5.9. Calibration certificate form: call/002 shall be issued for calibrated Clamp Meter Digital / Analog as per calibration data sheet form: call/001 (b) record. 5.10. A calibration sticker call / 003 containing/ having following information shall be affixed on the calibrated Clamp Meter Digital / Analog. (a) Item code (b) Calibrated on (c) Next calibration date

6. APPENDICES

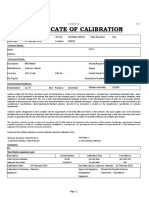

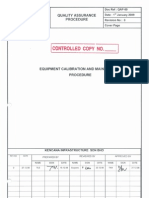

Calibration Job Form Calibration Data Sheet Form Certificate of Calibration

Call/001 (a) Call/001 (b) Call/002

Page 3 of 3

You might also like

- Calibrating Lead Gauge StandardsDocument3 pagesCalibrating Lead Gauge StandardsJohn Dolan100% (1)

- Method Statement For Conductivity MeterDocument2 pagesMethod Statement For Conductivity MeterMuhamed RasheedNo ratings yet

- Calibration ProcedureDocument2 pagesCalibration ProcedureRathnakrajaNo ratings yet

- Calibration of Thermal Process EquipmentsDocument3 pagesCalibration of Thermal Process EquipmentsAmar SinghNo ratings yet

- Procedure For Calibration of Machines Welding PDFDocument3 pagesProcedure For Calibration of Machines Welding PDFravi00098100% (1)

- 003-Megger - Insulation TesterDocument4 pages003-Megger - Insulation TesterAjlan KhanNo ratings yet

- Lead Gauge Cal 7Document2 pagesLead Gauge Cal 7John Dolan100% (3)

- CERTIFICATE NO 2 Electric Welding MachineDocument2 pagesCERTIFICATE NO 2 Electric Welding MachineOwais MalikNo ratings yet

- Method of Statement NDTDocument11 pagesMethod of Statement NDTAhmed Iraky0% (1)

- NIMT-CNL-SP No. 601 Standard Procedure for Calibration of Pressure Measuring Instruments Hydraulic TypeDocument18 pagesNIMT-CNL-SP No. 601 Standard Procedure for Calibration of Pressure Measuring Instruments Hydraulic Typeamelchan_tiqueNo ratings yet

- Calibrate Outside MicrometersDocument2 pagesCalibrate Outside MicrometerserharsinghNo ratings yet

- Dial Indicator Calibration Procedure TS-0051Document3 pagesDial Indicator Calibration Procedure TS-0051alexrferreiraNo ratings yet

- Insulation Tester 1 CI 02 I2Document13 pagesInsulation Tester 1 CI 02 I2ebbasinghNo ratings yet

- Calibration Certificate - Gas Coriolis - Unit#1Document2 pagesCalibration Certificate - Gas Coriolis - Unit#1Said100% (1)

- 03 - Oven Calibration ProcedureDocument4 pages03 - Oven Calibration ProcedureSankar Muka0% (1)

- Calibration Procedure PDFDocument10 pagesCalibration Procedure PDFmira100% (1)

- Comparison Method Calibration For HydrometerDocument12 pagesComparison Method Calibration For HydrometerHi Tech Calibration ServicesNo ratings yet

- PHE Method StatementDocument3 pagesPHE Method Statementzampacaanas0% (1)

- WIKA Calibration Certificate for Process CalibratorDocument3 pagesWIKA Calibration Certificate for Process CalibratorBalaji BobadeNo ratings yet

- STS EDAC WELD REPAIR PROCEDUREDocument51 pagesSTS EDAC WELD REPAIR PROCEDUREmohd as shahiddin jafriNo ratings yet

- Standard Densitometer Calibration ProcedureDocument4 pagesStandard Densitometer Calibration ProcedureAjlan Khan100% (2)

- Standard Procedure For Calibration of GaugesDocument12 pagesStandard Procedure For Calibration of Gaugessharif sayyid al mahdalyNo ratings yet

- Certificate of CalibrationDocument2 pagesCertificate of CalibrationMiguel Angel Pacahuala CristobalNo ratings yet

- GE Mentor EM Weld BrochureDocument6 pagesGE Mentor EM Weld BrochuredimachampionNo ratings yet

- Free Digital Multimeter Calibration ProcedureDocument12 pagesFree Digital Multimeter Calibration ProcedurejoaoNo ratings yet

- Methodology On Technical Inspection: Equipment NDT Procedure Inspection DevicesDocument1 pageMethodology On Technical Inspection: Equipment NDT Procedure Inspection DevicesEphraim John Tangelon AquinoNo ratings yet

- Temperature Controllers: Installation and MaintenanceDocument5 pagesTemperature Controllers: Installation and MaintenanceJose Uriel Ortega LeonNo ratings yet

- Hydrostatic Test Report: Form No.: JFC-F-QC-06, Form Rev. No.: 0, Form Released Date: 01-Jan-17 Page 1 of 1Document1 pageHydrostatic Test Report: Form No.: JFC-F-QC-06, Form Rev. No.: 0, Form Released Date: 01-Jan-17 Page 1 of 1Dhaval ChitreNo ratings yet

- Thermocouple Calibration FurnaceDocument4 pagesThermocouple Calibration FurnaceAHMAD YAGHINo ratings yet

- Calibrate BTU Meter CertificateDocument1 pageCalibrate BTU Meter CertificateEby JoyNo ratings yet

- Job Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Outside Micrometer Calibration Procedure: 1.0 Standards and EquipmentDocument2 pagesOutside Micrometer Calibration Procedure: 1.0 Standards and EquipmentCoop StElzearNo ratings yet

- CalibrationDocument45 pagesCalibrationDeb RoyNo ratings yet

- Calibrate Metal Tapes Using Standard Tape MethodDocument12 pagesCalibrate Metal Tapes Using Standard Tape Methodhaharamesh100% (1)

- EPA Thermometer Calibration ProceduresDocument7 pagesEPA Thermometer Calibration ProceduresGilberto Andrés Jurado100% (1)

- 02-Calibration & Control of Measuring & Monitoring DevicesDocument1 page02-Calibration & Control of Measuring & Monitoring DeviceskitekNo ratings yet

- Pro PWHT 006 Rev 1 - Procedure For PWHTDocument6 pagesPro PWHT 006 Rev 1 - Procedure For PWHTsugumar100% (1)

- Calibration Procedure for Equipment at 370MW Power ProjectDocument5 pagesCalibration Procedure for Equipment at 370MW Power ProjectAkhilesh KumarNo ratings yet

- Leak Test ReportDocument1 pageLeak Test ReportTiffany Vance100% (1)

- Ultrasonic Fuel Sensor Data Sheet UF202Document7 pagesUltrasonic Fuel Sensor Data Sheet UF202Rahul AroraNo ratings yet

- 01 Pressure Gauge CalibrationDocument3 pages01 Pressure Gauge CalibrationSantosh Odiyar0% (1)

- Gloss Meter Operating ProcedureDocument2 pagesGloss Meter Operating ProcedureM Jawad Ali100% (1)

- EURAMET Cg-8 V 2 1 Calibration of ThermocouplesDocument19 pagesEURAMET Cg-8 V 2 1 Calibration of ThermocouplesOmerNo ratings yet

- Instrument Calibration ProcedureDocument10 pagesInstrument Calibration ProcedureMohammad Nurayzat JohariNo ratings yet

- Calibration Procedure FOR Calipers General: Technical ManualDocument8 pagesCalibration Procedure FOR Calipers General: Technical ManualrcmetrologyNo ratings yet

- LPT Written ProcedureDocument8 pagesLPT Written ProcedureManikantaSumanthNo ratings yet

- Calibration, American Laboratory: FlijkeDocument3 pagesCalibration, American Laboratory: FlijkeAMINE MEDDAHINo ratings yet

- Method Statement For PH MeterDocument2 pagesMethod Statement For PH MeterMuhamed RasheedNo ratings yet

- STD-InSP-0005 (Plate Inspection Procedure)Document3 pagesSTD-InSP-0005 (Plate Inspection Procedure)airbroomNo ratings yet

- ASME SEC IX Article Iii, Welding Performance QualificationsDocument11 pagesASME SEC IX Article Iii, Welding Performance QualificationsTeoxNo ratings yet

- Procedure For Caliper Calibration (Rev.1)Document10 pagesProcedure For Caliper Calibration (Rev.1)syisyi87No ratings yet

- Calibration of AnemometerDocument4 pagesCalibration of AnemometerAhmet ŞenNo ratings yet

- NIST Stopwatch & Timer Calibrations 2009Document82 pagesNIST Stopwatch & Timer Calibrations 2009ririmonir100% (1)

- Calibrate Vernier Calipers ProcedureDocument2 pagesCalibrate Vernier Calipers Proceduregiamillia100% (2)

- Calibrate Measuring Tape CertificateDocument2 pagesCalibrate Measuring Tape CertificateKiranNo ratings yet

- Method Statement of Calibration Field Instrument: Rantu Dedap Geothermal Power Plant Project Capacity 220 MWDocument8 pagesMethod Statement of Calibration Field Instrument: Rantu Dedap Geothermal Power Plant Project Capacity 220 MWsugeng wahyudiNo ratings yet

- RadarTank Gauging (D 28)Document13 pagesRadarTank Gauging (D 28)Elias EliasNo ratings yet

- Calibration of Dial Temperature Gauges Digital Temparature Indicators ControllersDocument5 pagesCalibration of Dial Temperature Gauges Digital Temparature Indicators ControllersCharlie Dela RosaNo ratings yet

- Method Statement For Instrument CalibrationDocument14 pagesMethod Statement For Instrument CalibrationFredric Tun100% (2)

- QAP-09 Equipment CalibrationDocument20 pagesQAP-09 Equipment Calibrationnaseema1100% (5)

- Project Number:: Commodore Contracting Co L.L.CDocument1 pageProject Number:: Commodore Contracting Co L.L.Caldred_chezkaNo ratings yet

- BITUSTICK - XL-Tecnical Data SheetDocument2 pagesBITUSTICK - XL-Tecnical Data Sheetaldred_chezka100% (1)

- Fosroc Renderoc CS PuneDocument2 pagesFosroc Renderoc CS Punealdred_chezkaNo ratings yet

- Bitustick - XL-Material Safety Data SheetDocument2 pagesBitustick - XL-Material Safety Data Sheetaldred_chezka100% (1)

- Bitustick XLDocument2 pagesBitustick XLaldred_chezkaNo ratings yet

- Puncture ResistanceDocument1 pagePuncture Resistancealdred_chezkaNo ratings yet

- The Critical Need For Software Engineering EducationDocument5 pagesThe Critical Need For Software Engineering EducationGaurang TandonNo ratings yet

- CFLM1 Chapter 1Document24 pagesCFLM1 Chapter 1Jonathan TawagNo ratings yet

- Crafting and Executing StrategyDocument33 pagesCrafting and Executing Strategyamoore2505No ratings yet

- UN Habitat UPCL Myanmar TranslationDocument254 pagesUN Habitat UPCL Myanmar TranslationzayyarNo ratings yet

- Vega Plus 69Document3 pagesVega Plus 69yashNo ratings yet

- 199-Article Text-434-1-10-20200626Document11 pages199-Article Text-434-1-10-20200626ryan renaldiNo ratings yet

- Mock DataDocument56 pagesMock DataAnonymous O2bvbOuNo ratings yet

- J05720020120134026Functions and GraphsDocument14 pagesJ05720020120134026Functions and GraphsmuglersaurusNo ratings yet

- Admission:Discharge Criteria in Speech-Language Pathology - ASHADocument16 pagesAdmission:Discharge Criteria in Speech-Language Pathology - ASHANádia MarquesNo ratings yet

- The UFO Book Encyclopedia of The Extraterrestrial (PDFDrive)Document756 pagesThe UFO Book Encyclopedia of The Extraterrestrial (PDFDrive)James Lee Fallin100% (2)

- Gentle Classical Nature Sample - Units1 and 2Document129 pagesGentle Classical Nature Sample - Units1 and 2Carita HemsleyNo ratings yet

- An Introduction To Community DevelopmentDocument21 pagesAn Introduction To Community DevelopmentThuyAnh NgnNo ratings yet

- Demand Performa For Annual DemandDocument10 pagesDemand Performa For Annual DemandpushpNo ratings yet

- Travel Agency ManagementDocument47 pagesTravel Agency ManagementKatherine BarretoNo ratings yet

- Tomas Del Rosario College: Department: EDUCATIONDocument12 pagesTomas Del Rosario College: Department: EDUCATIONveehneeNo ratings yet

- Alaris 8210 and 8220 SpO2 Module Service ManualDocument63 pagesAlaris 8210 and 8220 SpO2 Module Service ManualNaveen Kumar TiwaryNo ratings yet

- Abiding LonelinessDocument9 pagesAbiding Lonelinessgrupodelectura04No ratings yet

- TCBE - Conversation Skills TemplateDocument10 pagesTCBE - Conversation Skills TemplateAryoma GoswamiNo ratings yet

- It 7sem Unit Ii IotDocument10 pagesIt 7sem Unit Ii IotMaitrayee SuleNo ratings yet

- Materials For Oxygen ServicesDocument4 pagesMaterials For Oxygen Services陳文鴻No ratings yet

- 1 s2.0 S1747938X21000142 MainDocument33 pages1 s2.0 S1747938X21000142 MainAzmil XinanNo ratings yet

- CROCI Focus Intellectual CapitalDocument35 pagesCROCI Focus Intellectual CapitalcarminatNo ratings yet

- MST 2 ReviewerDocument4 pagesMST 2 ReviewerAizha NarioNo ratings yet

- Brochure Troysperse+CD1+Brochure+ (TB0112)Document8 pagesBrochure Troysperse+CD1+Brochure+ (TB0112)mario3312No ratings yet

- Plenaristas León 2022xDocument6 pagesPlenaristas León 2022xGloria MontielNo ratings yet

- Lecture 6-Design For ShearDocument14 pagesLecture 6-Design For ShearMarkos DanielNo ratings yet

- Best Mesl StudoDocument15 pagesBest Mesl StudoJoenielNo ratings yet

- Chemistry 101 - The Complete Notes - Joliet Junior College (PDFDrive)Document226 pagesChemistry 101 - The Complete Notes - Joliet Junior College (PDFDrive)Kabwela MwapeNo ratings yet

- Pricelist Hardware Jayacom Disember 2018Document2 pagesPricelist Hardware Jayacom Disember 2018ContempGamelan PerformingGroupNo ratings yet

- Unit 5 - Assessment of One'S Teaching Practice: Universidad de ManilaDocument15 pagesUnit 5 - Assessment of One'S Teaching Practice: Universidad de ManilaDoc Joey100% (3)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessFrom EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNo ratings yet

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Electrical Principles and Technology for EngineeringFrom EverandElectrical Principles and Technology for EngineeringRating: 4 out of 5 stars4/5 (4)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Basic Electric Circuit Theory: A One-Semester TextFrom EverandBasic Electric Circuit Theory: A One-Semester TextRating: 1.5 out of 5 stars1.5/5 (2)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsFrom EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsNo ratings yet

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesFrom EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesNo ratings yet