Professional Documents

Culture Documents

APQP

Uploaded by

Amit Kumar SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APQP

Uploaded by

Amit Kumar SharmaCopyright:

Available Formats

Core Tools Advanced Product Quality Planning (APQP) Production Part Approval Process (PPAP) Failure Mode Effects

Analysis (FMEA) Measurement Systems Analysis (MSA) Statistical Process Control (SPC) and Root Cause Analysis and Reporting Methods 2-Day Risk Management using FMEA

MMTC trainers strive to stay on top of the latest versions of the Core Tools and interpret the requirements for practical deployment. Training sessions are offered in open enrollment format or onsite for employees. Each attendee receives a copy of the latest reference manual issued by AIAG. MMTC offers Core Tools training in APQP, FMEA and PPAP combination, SPC, MSA, Root Cause Analysis and Reporting Methods. Core Tools: APQP, FMEA and PPAP (2-Day Training) CEU Credits: 1.4

(Outline) MMTC offers this combination class to train companies in the planning, launch and validation of a new automotive product or process. The course blends three powerful tools to guide participants through all steps of the launch process. With an emphasis on contextual learning, attendees will use actual production parts in all phases of training.

Advanced Product Quality Planning (APQP) is applied to our injection molding process, which produces several different components that are assembled later. Participants use blueprint drawings for the parts as they learn project management skills in planning the sequence, selecting the gages, inspection points in the process, floor layout, and generating the control plan. Content includes: TS 16949 requirements Product design and development Planning and defining the program

Validation of product and process APQP team dynamics Control plan methodology

Failure Mode Effects Analysis (FMEA) During day two of the training, participants apply the latest version of FMEA to the plastic parts to determine what can go wrong with the parts and the process. Content includes: What is FMEA; how does it fit into APQP Robust design concepts (DFMEA) Quality system requirements Design and process FMEA objectives Recommended FMEA process sequence

Production Part Approval Process (PPAP) As the PPAP process is introduced; it is applied to the parts produced. Actual measurements are taken and are used to complete the various test sheets of PPAP. Content includes: When is PPAP required (applicability) Dimensional, material and test results Process requirements Floor layout (single process flow)

Offered on-site or in an open enrollment format the remaining Core Tools are delivered in one day sessions. Statistical Process Control (SPC) (1-day class) CEU Credits: 0.7

(Outline) Basic SPC is applied using the parts produced in the MMTC factory. Participants run a group of sequentially produced parts and then measure them to determine average, range and sigma. Control

limits are calculated using these same parts and additional samples are measured and plotted to determine where the process is going and why. Interpretations of results are part of this course as well as capability study exercises. Concepts of SPC detection vs. prevention Basic fundamentals Improving the process (attacking waste) Gathering data and preparing charts The 7 statistical tools X bar and R charts (setting control limits) Measurement System Analysis (MSA) (1-day class) CEU Credits: 0.7

(Outline) If measurements are used to guide decisions, then it follows logically that the more error there is in the measurements, the more error there will be in the decisions based on those measurements. The purpose of Measurement System Analysis is to qualify a measurement system for use by quantifying its accuracy, precision, and stability. Content includes: Over-correction/tampering Understanding your measurement system Basic concepts of gage analysis Problem Solving, Root Cause Analysis and Reporting Methods (1-day class) CEU Credits: 0.7

(Outline) Root cause analysis and problem-solving tools are presented and demonstrated in this session. Both internal (yield issues) and external (warranty, field failure, customer complaint) problems are introduced in the manner they are typically encountered. Teams use these tools to identify, analyze and solve the issues and determine root cause. Understanding is gained through practical hands-on exercises using the tools listed below. Problems are introduced to demonstrate the typical formats for reporting the findings, applying solutions and corrections such as Global 8-D. Tools covered include: 5-Whys

Brainstorming Cause and effect Process mapping and analysis Scatter diagram Risk Management Using FMEA (2-day class) CEU Credits: 1.4

(Outline)

This training will orient participants to the steps of Risk Management using the tool of Failure Mode Effects Analysis (FMEA) to define, manage, and reduce risks. Processes also used in this training include brainstorming, creating SIPOCs, and creating Process Flowcharts to help in the understanding, and analasys of the process. The training addresses each step of doing a FMEA, with exercises designed to ensure maximum understanding of both Design FMEA and Process FMEA. The first day of this program includes training on tools used when doing an FMEA, how to do an FMEA, and exercises to re-inforce understanding. Day two involves having each company select a process to do a PFMEA on with instructed guidance. The processes selected are taken through the process taught, beginning with SIPOC and flowchart, sharing each phase with the group. In this environment, each companys FMEA is partially finished by the end of the second day.

You might also like

- Automated Software Testing Interview Questions You'll Most Likely Be Asked: Job Interview Questions SeriesFrom EverandAutomated Software Testing Interview Questions You'll Most Likely Be Asked: Job Interview Questions SeriesNo ratings yet

- Book Series Increasing Productivity of Software Development, Part 2: Management Model, Cost Estimation and KPI ImprovementFrom EverandBook Series Increasing Productivity of Software Development, Part 2: Management Model, Cost Estimation and KPI ImprovementNo ratings yet

- Core Tools Training: APQP, FMEA, PPAP (2-Day) & SPC, MSA, Root Cause (1-DayDocument4 pagesCore Tools Training: APQP, FMEA, PPAP (2-Day) & SPC, MSA, Root Cause (1-Dayraghusanth007No ratings yet

- Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)Document6 pagesCore Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)Rob Willestone100% (1)

- Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)Document2 pagesCore Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)skluxNo ratings yet

- APQP Core ToolsDocument5 pagesAPQP Core ToolsbbaskaranNo ratings yet

- Quality Core Tools APQP FMEA MSA SPC PPAPDocument14 pagesQuality Core Tools APQP FMEA MSA SPC PPAPالعاب الاطفال- jeux enfantsNo ratings yet

- APQP Process GuideDocument35 pagesAPQP Process GuideThuận HoàngNo ratings yet

- Introduction To Advanced Product Quality PlanningDocument14 pagesIntroduction To Advanced Product Quality PlanningAbraham GuerraNo ratings yet

- Are The Tools That Help Us Greatly Reduce Quality Problems in The Launch of New Products Apqp & CP, Amef, Control Plan, SPC, R & R and PpapDocument4 pagesAre The Tools That Help Us Greatly Reduce Quality Problems in The Launch of New Products Apqp & CP, Amef, Control Plan, SPC, R & R and PpapSergio Cristobal Bonilla CegadorNo ratings yet

- Experiment No 7 MEMDocument11 pagesExperiment No 7 MEMImdad JalaliNo ratings yet

- Core Tools PDFDocument3 pagesCore Tools PDFR.BalasubramaniNo ratings yet

- The 5 Core Quality Tools ExplainedDocument17 pagesThe 5 Core Quality Tools ExplainedRajesh GhoshNo ratings yet

- The 5 Core ToolDocument17 pagesThe 5 Core ToolRajesh GhoshNo ratings yet

- Software Defect PreventionDocument6 pagesSoftware Defect Preventionjoin luckyNo ratings yet

- DMAIC Process: D-Define M-Measure A-Analyse I-Improve C-ControlDocument18 pagesDMAIC Process: D-Define M-Measure A-Analyse I-Improve C-ControlPujitha GarapatiNo ratings yet

- Process FmeaDocument8 pagesProcess Fmeaanirudha samalNo ratings yet

- DAY-3 Agile Scrum Method STLC Bug Life CycleDocument16 pagesDAY-3 Agile Scrum Method STLC Bug Life CycleRishabh KumarNo ratings yet

- Publisher Namespringer, London Print Isbn978-1-84882-471-3 Online Isbn978-1-84882-472-0 Ebook PackagesDocument3 pagesPublisher Namespringer, London Print Isbn978-1-84882-471-3 Online Isbn978-1-84882-472-0 Ebook PackagesEva WatiNo ratings yet

- ISWE Assignment QuestionDocument5 pagesISWE Assignment QuestionUzt ReyNo ratings yet

- Development of Quality System For Engine AssemblyDocument55 pagesDevelopment of Quality System For Engine AssemblysvrbchaudhariNo ratings yet

- FMEADocument5 pagesFMEAAkanksha KumariNo ratings yet

- APQPDocument62 pagesAPQPYogaditya ModukuriNo ratings yet

- Basic Concepts of FMEA and FMECADocument2 pagesBasic Concepts of FMEA and FMECAalyalexNo ratings yet

- Report On Software Development Life CycleDocument12 pagesReport On Software Development Life CycleShailu SinghNo ratings yet

- Subjective CSQADocument46 pagesSubjective CSQAAdam TuckerNo ratings yet

- Six Sigma DMAIC Methodology ExplainedDocument3 pagesSix Sigma DMAIC Methodology Explainedrajee1010% (1)

- Tcs InterviewDocument10 pagesTcs InterviewYogi GowdaNo ratings yet

- An Application of Overall Equipment Effectiveness (OEE) For Minimizing The Bottleneck Process in Semiconductor IndustryDocument8 pagesAn Application of Overall Equipment Effectiveness (OEE) For Minimizing The Bottleneck Process in Semiconductor IndustryDrRasha Abo ShoShaNo ratings yet

- Analyze Product Failures with FMEADocument7 pagesAnalyze Product Failures with FMEAAhmed M. HashimNo ratings yet

- Software Engineering Practice: - SriniDocument53 pagesSoftware Engineering Practice: - Srinimadhusudhan reddyNo ratings yet

- FMEA Failure Modes & Effects AnalysisDocument32 pagesFMEA Failure Modes & Effects AnalysisSherif Eltoukhi100% (7)

- Overview of Software TestingDocument12 pagesOverview of Software TestingBhagyashree SahooNo ratings yet

- Lean Six SigmaDocument2 pagesLean Six SigmaAkash RathodNo ratings yet

- Seminar Report - Atharva - Sanglikar - 19121236Document22 pagesSeminar Report - Atharva - Sanglikar - 19121236Atharva SanglikarNo ratings yet

- Design, Structural Analysis and D-FMEA of Automobile Manual Transmission Gear-BoxDocument32 pagesDesign, Structural Analysis and D-FMEA of Automobile Manual Transmission Gear-BoxAtul DahiyaNo ratings yet

- Total Quality ManagementDocument5 pagesTotal Quality Managementshweta15marNo ratings yet

- TEST AUTOMATION BENEFITS AND PROCESSDocument15 pagesTEST AUTOMATION BENEFITS AND PROCESSShalin SanghviNo ratings yet

- Core Tools (Apqp, Dfmea, Pfmea, Control Plans, Ppap, SPC, Msa) 5 Days TrainingDocument2 pagesCore Tools (Apqp, Dfmea, Pfmea, Control Plans, Ppap, SPC, Msa) 5 Days TrainingAnkur DhirNo ratings yet

- Failure Mode and Effect AnalysisDocument9 pagesFailure Mode and Effect AnalysisameliaNo ratings yet

- Failure Mode and Effect AnalysisDocument21 pagesFailure Mode and Effect AnalysisAnkita SinhaNo ratings yet

- Software Testing Life CycleDocument9 pagesSoftware Testing Life Cyclemadhu_devu9837No ratings yet

- The Basics of Healthcare Failure Mode and Effect AnalysisDocument10 pagesThe Basics of Healthcare Failure Mode and Effect Analysisالمعتزبالله جاب اللهNo ratings yet

- Termpaper Synopsis OF CSE-302 (SAD) : Submitted To: Submitted By: Miss. Neha Gaurav Khara Mam RJ1802 A15Document6 pagesTermpaper Synopsis OF CSE-302 (SAD) : Submitted To: Submitted By: Miss. Neha Gaurav Khara Mam RJ1802 A15Harpreet SinghNo ratings yet

- The Value of Value Stream Mapping To StudentsDocument12 pagesThe Value of Value Stream Mapping To StudentsTanuj BhattacharyyaNo ratings yet

- DMAIC Six Sigma Improves Yarn QualityDocument34 pagesDMAIC Six Sigma Improves Yarn Qualitymanan hudeNo ratings yet

- Software Development Life Cycle: 2 WeeksDocument8 pagesSoftware Development Life Cycle: 2 WeeksmaheshpandyanNo ratings yet

- Basic Concepts of FMEA and FMECADocument5 pagesBasic Concepts of FMEA and FMECARob WillestoneNo ratings yet

- PDCADocument6 pagesPDCAHshs hsHshahsNo ratings yet

- 100 QuestionsDocument112 pages100 QuestionsPiyush YadavNo ratings yet

- Software Testing Lifecycle Practice: Yujuan dou (窦玉娟)Document29 pagesSoftware Testing Lifecycle Practice: Yujuan dou (窦玉娟)Ramesh KodaliNo ratings yet

- System and Technical DocumentationDocument8 pagesSystem and Technical DocumentationAffo AlexNo ratings yet

- DMAICDocument3 pagesDMAICADAM BEN SALAHNo ratings yet

- ASAP MethodologyDocument14 pagesASAP MethodologyTiffany HughesNo ratings yet

- STLCDocument6 pagesSTLCAgung WibawaNo ratings yet

- TMap NEXT Poster (En)Document1 pageTMap NEXT Poster (En)mieqieNo ratings yet

- GE8077 Total Quality Management QBDocument10 pagesGE8077 Total Quality Management QBRahulNo ratings yet

- Failure Modes and Effects Analysis (FMEA) 1Document18 pagesFailure Modes and Effects Analysis (FMEA) 1Muhamad Fauzi100% (4)

- Quality Improvement Processes and ToolsDocument11 pagesQuality Improvement Processes and ToolsErwin BenitezNo ratings yet

- FMEA BasicsDocument23 pagesFMEA Basicsashwin jacksonNo ratings yet

- (Report) Storage Tanks (Japan)Document179 pages(Report) Storage Tanks (Japan)RAJENDRA PRASADNo ratings yet

- Wt. of RackDocument3 pagesWt. of RackAmit Kumar SharmaNo ratings yet

- Hoofdstuk1 ContentDocument184 pagesHoofdstuk1 ContentAmit Kumar SharmaNo ratings yet

- General Arrengment of Evaporator Body 3000sq. MTR 2 - 1-ModelDocument1 pageGeneral Arrengment of Evaporator Body 3000sq. MTR 2 - 1-ModelAmit Kumar SharmaNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductAmit Kumar SharmaNo ratings yet

- PPF CalculatorDocument8 pagesPPF CalculatormenitinsharmaNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductAmit Kumar SharmaNo ratings yet

- 304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFDocument16 pages304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFAndressa EgerNo ratings yet

- Detail of Tube Plate For Evaporator BodyDocument1 pageDetail of Tube Plate For Evaporator BodyAmit Kumar SharmaNo ratings yet

- Product Release Letter AVEVA PDMS 12.0.SP4.8 Partial Fix Release 51906 Windows 2000 and XPDocument5 pagesProduct Release Letter AVEVA PDMS 12.0.SP4.8 Partial Fix Release 51906 Windows 2000 and XPAmit Kumar SharmaNo ratings yet

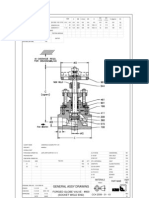

- #800 Globe SWDocument1 page#800 Globe SWAmit Kumar SharmaNo ratings yet

- Product Release Latest Update AVEVA PDMS 12.0.SP4.8 Partial Fix Release 51906Document1 pageProduct Release Latest Update AVEVA PDMS 12.0.SP4.8 Partial Fix Release 51906Amit Kumar SharmaNo ratings yet

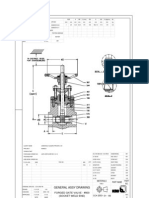

- #800 Gate SWDocument1 page#800 Gate SWAmit Kumar SharmaNo ratings yet

- Sensor Installation GuideDocument96 pagesSensor Installation GuideAmit Kumar SharmaNo ratings yet

- PDF Processed With Cutepdf Evaluation EditionDocument1 pagePDF Processed With Cutepdf Evaluation EditionAmit Kumar SharmaNo ratings yet

- CareersDocument35 pagesCareersAmit Kumar SharmaNo ratings yet

- Arrangement of Batch Type Raw Centrifugal Machine-ModelDocument1 pageArrangement of Batch Type Raw Centrifugal Machine-ModelAmit Kumar SharmaNo ratings yet

- BOM Sheet Details Weight QuantitiesDocument2 pagesBOM Sheet Details Weight QuantitiesAmit Kumar SharmaNo ratings yet

- Hudson Swafford LIV Player Participation Agreement REDACTEDDocument11 pagesHudson Swafford LIV Player Participation Agreement REDACTEDRyan BallengeeNo ratings yet

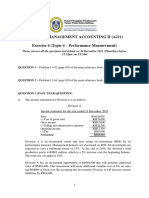

- A211 MA2 EXERCISE 4 (TOPIC 4 Performance Measurement) - Questions - Upoladed 18 Dec 2021Document3 pagesA211 MA2 EXERCISE 4 (TOPIC 4 Performance Measurement) - Questions - Upoladed 18 Dec 2021Amirul Hakim Nor AzmanNo ratings yet

- Job Specification and Job Description of Nestle Bangladesh - PREPARED FOR ASSIGNMENT ON JOB DESCRIPTION AND JOB Tamanna Parveen Eva (TPE Senior Lecturer - Course Hero PDFDocument12 pagesJob Specification and Job Description of Nestle Bangladesh - PREPARED FOR ASSIGNMENT ON JOB DESCRIPTION AND JOB Tamanna Parveen Eva (TPE Senior Lecturer - Course Hero PDFHumayun JavedNo ratings yet

- CavinKare's Case Study on Sustaining Growth and Expanding BusinessDocument20 pagesCavinKare's Case Study on Sustaining Growth and Expanding BusinessDhanun JayNo ratings yet

- BS 476-24-1987Document25 pagesBS 476-24-1987Hadi Iz'aanNo ratings yet

- Taxbanter Special Topic MaterialsDocument84 pagesTaxbanter Special Topic MaterialsJessica YuNo ratings yet

- MoneyWorks Proposal38yoDocument5 pagesMoneyWorks Proposal38yoMorg ActusNo ratings yet

- Sap SDocument3 pagesSap SMiaNo ratings yet

- Topic 1 - Introduction To Economics (Week1)Document30 pagesTopic 1 - Introduction To Economics (Week1)Wei SongNo ratings yet

- Government Budget ExplainedDocument2 pagesGovernment Budget ExplainedParth NataniNo ratings yet

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document2 pagesTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Devan ShahNo ratings yet

- Credit Card Processing System UML Use Case DiagramDocument2 pagesCredit Card Processing System UML Use Case DiagramTushar TariNo ratings yet

- IADC Associate WebDocument8 pagesIADC Associate WebCarlos ChiNo ratings yet

- Nigeria 4Document34 pagesNigeria 4CHÂU TRỊNH MINHNo ratings yet

- Customer Hierarchy in SAPDocument4 pagesCustomer Hierarchy in SAPumesh.soni100% (5)

- Diabetes Essay ConclusionDocument6 pagesDiabetes Essay Conclusiond3h7qfpr100% (2)

- Package Handler ResumeDocument6 pagesPackage Handler Resumegbfcseajd100% (2)

- HRM Assignment 02Document13 pagesHRM Assignment 02meketedeguale12No ratings yet

- Bill of Quantity (BOQ) : General Contractor and TradingDocument2 pagesBill of Quantity (BOQ) : General Contractor and TradingApriliaNo ratings yet

- KFUPM ISE-534 Advanced Quality ControlDocument3 pagesKFUPM ISE-534 Advanced Quality ControlNoman Ullah ChoudharyNo ratings yet

- Productivity Improvement in Construction Industry: Sneha Jamadagni, Prof.B.V.BirajdarDocument5 pagesProductivity Improvement in Construction Industry: Sneha Jamadagni, Prof.B.V.BirajdarShaklain NarmawalaNo ratings yet

- Hannes Meyer's biographical essay explores the architect's workDocument52 pagesHannes Meyer's biographical essay explores the architect's worknisivocciaNo ratings yet

- Jawaban 10 - Accounting For PensionDocument2 pagesJawaban 10 - Accounting For PensionBie SapuluhNo ratings yet

- Assignment 1 13032021 121200pmDocument9 pagesAssignment 1 13032021 121200pmSagar SinghNo ratings yet

- BUSM4185B Assignment 2 - Case StudyDocument8 pagesBUSM4185B Assignment 2 - Case Studytrần huyNo ratings yet

- Login to e-employmentnews.co.in for nutritional status of women and children in North East IndiaDocument32 pagesLogin to e-employmentnews.co.in for nutritional status of women and children in North East IndiaSandeepNo ratings yet

- Limited Partnership Formation and Characteristics (Art. 1843-1867Document13 pagesLimited Partnership Formation and Characteristics (Art. 1843-1867Alia Arnz-DragonNo ratings yet

- E Commerce Notes PDF Lecture Notes University LevelDocument64 pagesE Commerce Notes PDF Lecture Notes University LevelAbhishek aggarwalNo ratings yet

- FETTY CAKE LTDDocument3 pagesFETTY CAKE LTDNGONIDZASHE G MUBAYIWANo ratings yet

- Basics of Banking Question BankDocument54 pagesBasics of Banking Question BankRashmi Ranjana100% (1)