Professional Documents

Culture Documents

BS 476-3 1975

Uploaded by

Wan MahiramCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BS 476-3 1975

Uploaded by

Wan MahiramCopyright:

Available Formats

British Standard

A single copy of this British Standard is licensed to Giorgio Cavalieri on November 16, 2000

This is an uncontrolled copy. Ensure use of the most current version of this standard by searching British Standards Online at bsonline.techindex.co.uk

BRITISH STANDARD

BS 476-3:1975

Fire tests on building materials and structures

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

Part 3: External fire exposure roof test

UDC 614.841.322:620.1:699.81:69.024

BS 476-3:1975

Co-operating organizations

The Petroleum Equipment Industry Standards Committee, under whose supervision this British Standard was prepared, consists of representatives from the following Government department and scientific and industrial organization: British Gas Corporation British Mechanical Engineering Confederation British Rubber Manufacturers Association Ltd. British Steel industry* Council of British Manufacturers of Petroleum Equipment* Department of Energy Oil Companies Materials Association* The Industrial organization marked with an asterisk in the above list, together with the following, were directly represented on the Committee entrusted with the preparation of this standard: Association of Hydraulic Equipment Manufacturers British Chemical Engineering Contractors Association British Industrial Measuring and Control Apparatus Manufacturers Association British Plastics Federation British Ship Research Association British Valve Manufacturers Association Engineering Equipment Users Association Steel Castings Association

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

This British Standard, having been approved by the Petroleum Equipment Industry Standards Committee, was published under the authority of the Executive Board on 28 November 1975 BSI 01-1999 First published, June 1952 First revision, March 1960 Second revision, November 1975 The following BSI references relate to the work on this standard: Committee reference PEE/1 Draft for comment 74/74150 DC ISBN 0 580 08817 0

Amendments issued since publication Amd. No. Date of issue Comments

BS 476-3:1975

Contents

Co-operating organizations General foreword Foreword 1 2 3 4 5 6 7 8 Scope References Definitions Test specimen Test equipment Test procedure Expression of results Test report Page Inside front cover ii iii 1 1 1 1 1 4 5 5 6 2 3 5

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

Appendix A Copper asbestos disc radiometer Figure 1 Diagram showing radiation intensities at nine positions on plan of specimen for calibration Figure 2 Typical roof test apparatus Figure 3 Path of travel of pilot flame Publication referred to

Inside back cover

BSI 01-1999

BS 476-3:1975

General foreword

BS 476 was published as a single volume in 1932. A later revision expanded the standard into three Parts: Part 1:1953, Fire tests on building materials and structures; Part 2:1955, Flammability test for thin flexible materials; Part 3:1958, External fire exposure roof tests. In the present revision the three sections of Part 1:1953 have been revised and published as new and separate Parts in the BS 476 series. Thus the three sections of Part 1 are replaced respectively by: Part 4:1970, Non-combustibility test for materials; Part 7:1971, Surface spread of flame tests for materials; Part 8:1972, Test methods and criteria for the fire resistance of elements of building construction. In addition, during the present revision new Parts have been added to the series as follows: Part 5:1968, Ignitability test for materials; Part 6:1968, Fire propagation test for materials. Part 2:1955 has been withdrawn and replaced by BS 2782 Methods of testing plastics, Part 5 Miscellaneous methods. This British Standard replaces Part 3:1958 which is withdrawn. At present the BS 476 series comprises Parts 3 to 8 inclusive; other tests are, however, under consideration. DD 36 Fire tests on building materials and structures: measurement of the optical density of smoke produced by small specimens of materials has been published as a Draft for Development. This test was originally prepared with the intention of issuing it as BS 476-9, but since it was considered that insufficient tests have so far been carried out to establish reproducibility between laboratories, it has been decided that the method cannot yet be given the full status of a British Standard in the BS 476 series. The need for a glossary covering terms used in BS 476 has been established and this has been published as BS 4422 Glossary of terms associated with fire, with the following Parts: Part 1: The phenomenon of fire; Part 2: Building materials and structures; Part 3: Means of escape; Part 4: Fire protection equipment; Part 5: Miscellaneous terms (in course of preparation).

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

ii

BSI 01-1999

BS 476-3:1975

Foreword

A fire may create a hazard to neighbouring property. The extent of the hazard depends on the distance separating a building from the fire, the size and severity of the fire and the amount of the heat received on a building. The chief danger arises from radiated heat combined with the burning embers (flying brands) thrown off from the fire. The tests described in this Part of BS 476 are designed to give information on the ability of a roof covering and its supporting deck or supports to act as a protective barrier against a fire in a nearby building and on the extent of any surface ignition. Provision is also made for the testing of rooflights, domelights and similar components. Whilst the test has been designed to give information on the performance of a roof to external fire exposure in a building situation, the results obtained do not necessarily show how the roof will behave in any particular fire and therefore should not be considered as an overall indication of the potential fire hazard. No information is obtained from the test on the performance of the roof when subjected to conditions of an internal fire. When subjected to the performance test the specimen is exposed to radiant heat which can be regarded as, for example, the intensity incident on a roof 7.5 m above ground level from a fire 13.5 m away in a building with a facade of 15 m 15 m and 50 % window openings. A gas flame is employed in the test to represent flying brands falling on the roof. In this revision of the standard the following modifications have been made. a) The separate spread of flame test has been dropped and in its place a measurement of the extent of surface ignition is made at the same time as the penetration test using the same level of radiation intensity. This change also avoids confusion with the surface spread of flame test now covered in Part 7 which relates to the characteristics of wall and ceiling linings under internal fire conditions. b) The requirements for suction under the roof specimen for the purposes of simulating the effects of a wind on the upper surface of a roof has been omitted. The requirement was found to interfere with observation of the underside of the specimen due to the presence of smoke within the enclosed specimen holder. c) To extend the field of application of the test, provision has been made for increasing its duration if required. d) The penetration of fire and surface ignition measurements being combined in one test reduce the number of specimens to be tested. The specimen size has been increased to 1.5 m 1.2 m to provide a sufficient area for measurement of surface ignition and at the same time permit a more representative construction to be tested. e) The previous method required the test flame to be applied only once during the early part of the exposure. This was considered to be unrealistic and in the revised method the test flame is applied at intervals during the test. f) The performance of the specimen was previously expressed in terms of definite designations. These designations are replaced by the actual performance data. The above mentioned designations were used for the purposes of building control by grouping certain performance classifications in relation to type of buildings and distance from the boundary.

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

BSI 01-1999

iii

BS 476-3:1975

The following table shows examples of the relationship between existing groupings and the new method of expressing a similar performance for penetration. Part 3:1958 AA, AB, AC BA, BB, BC AD, BD, CA CB, CC, CD Unclassifiable

a

Part 3:1975 P60a P30

P15

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

P5

P60 means that the specimen passed the preliminary test (see 6.2) and that fire penetration (see 6.3) did not occur in less than 1 h.

Extent of surface ignition characteristics are not included in the new designations given in the above table. In some situations it may be necessary additionally to control these characteristics for which the test report provides full details.

NOTE The category designations used in the previous edition of this standard were two letters. The first letter referred to penetration times of the specimen, where penetration had occurred in A for not less than 1 h, B for not less than 30 min, C for less than 30 min and D during the preliminary flame test. The second letter referred to spread of flame of the specimen which occurred, A none, B for not more than 21 in (533.4 mm), C for more than 21 in (533.4 mm) and D which continued to burn for 5 min after withdrawal of the test flame or spread more than 15 in (381 mm) across the region of burning in the preliminary test. Suffix X to category designations denoted dripping from the underside of the specimen tested, and this is now included as a part of the test report.

g) A simulated gutter is positioned at the front end of the specimen to collect any molten materials which may flow from the surface of the specimen during a test. h) An additional section gives the minimum information that should be included in a test report. Attention is drawn to the Health and Safety at Work etc. Act 1974, and the need to ensure that the methods of test specified in this standard are carried out under suitable environmental conditions to provide adequate protection to personnel against the risk of fire, inhalation of smoke and/or toxic products of combustion. BSI has established OC/10, Co-ordinating committee on fire tests, and as a result of the work of this committee it may be necessary to amend this standard at a future date. This standard is expressed in metric terms. A British Standard does not purport to include all the necessary provisions of a contract. Users of British Standards are responsible for their correct application. Compliance with a British Standard does not of itself confer immunity from legal obligations.

Summary of pages This document comprises a front cover, an inside front cover, pages i to iv, pages 1 to 6, an inside back cover and a back cover. This standard has been updated (see copyright date) and may have had amendments incorporated. This will be indicated in the amendment table on the inside front cover. iv

BSI 01-1999

BS 476-3:1975

1 Scope

This Part of this British Standard specifies tests which are designed to measure: a) the ability of a representative section of a roof, rooflight, domelight and similar components to resist penetration by fire when the external surface is exposed to heat radiation and flame; b) the extent of surface ignition of the upper surface with and without supporting radiation.

4 Test specimen

4.1 Construction of specimens. The test specimen shall be representative of the roof construction including at least one example of each joint, if any used, in each of the materials employed in the construction. Any joints in the roof construction shall be so arranged to occur in the central part of the specimen. The specimen edges shall be sealed with strips of a non-combustible material such as 12 mm thick asbestos board, the tops of the strips being flush with the upper surface of the specimen.

NOTE If information is required on the behaviour of the specimen with eaves or verges, these may be included in the construction.

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

2 References

The title of the British Standard referred to in this standard is given on the inside back cover.

3 Definitions

For the purposes of this British Standard the following definitions and those given in BS 4422 apply. 3.1 specimen of roof construction all constituents comprising the roof covering (including any associated membrane or insulating materials fixed above the supporting members) together with the roof slab or decking in contact therewith and the supports thereto but excluding any ceiling or soffit beneath such decking or supporting members

NOTE Where the roof covering is intended to be used in conjunction with a stressed skin deck construction the decking shall be a representative section comprising the top skin together with any joist or similar supports.

4.2 Size of specimens. The overall size of the specimen, excluding the sealing strips, shall be not less than 1.5 m 1.2 m (see Figure 1). If the specimen is a rooflight or similar component which is only available in a size other than specified, the next smaller component shall be tested and properly fitted in accordance with 4.1 into the centre of a panel 1.5 m 1.2 m of an appropriate non-combustible roof construction. 4.3 Number of specimens. Four specimens shall be provided. 4.4 Conditioning of the specimens. The specimens shall be conditioned to equilibrium in an atmosphere at a temperature of 10 C to 21 C and 55 % to 65 % relative humidity. They shall be tested as soon as possible after leaving the conditioned atmosphere; the interval between removal from this atmosphere and testing shall not exceed 4 h.

3.2 penetration time the time at which glowing or flaming appears on the underside surface of the specimen or the time at which the formation of holes or fissures or collapse of specimen occurs, whichever is the earliest. For this purpose a hole or fissure includes any aperture through which the test flame can be observed from the underside when it is applied to the upper surface 3.3 extent of surface ignition the maximum distance of lateral flame spread on the upper surface

5 Test equipment

5.1 Test environment. The test equipment shall be located in a draught-free atmosphere. In order to maintain the calibration of the equipment during the course of a test it is recommended that the volume of the test enclosure be not less than 1 300 m3 and the floor to ceiling height be not less than 5 m. 5.2 Heating panel. The heating panel shall consist of four 300 5 mm2 radiant heaters mounted on a steel flamework so that their centres occur at the corners of a square having 480 mm sides. The heating panel assembly shall be capable of movement between a position 10 to 45 to the horizontal.

BSI 01-1999

BS 476-3:1975

Before a test the heating panel shall be controlled to provide a maximum incident radiation intensity of 14.6 0.5 kW/m2 at the centre of the surface of the specimen measured by a radiometer. The apparatus shall be calibrated to give the distribution of radiation intensity in the plane of the upper surface of the specimen at nine positions as shown in Figure 1. These intensities shall be measured without a specimen being in place. The monitoring of radiation intensity before a test shall be by means of four radiometers placed symmetrically in front of the radiant heaters at the corners of a square of 610 mm side. A suitable method is to use copper asbestos disc radiometers, as described in appendix A, placed at a distance of 125 mm in front of the radiant heaters. 5.3 Test flame. The test flame shall consist of a luminous coal (simulated town) gas or natural gas flame 200 mm to 250 mm long issuing from a tube when held in a vertical position with an orifice of 9 0.5 mm diameter (see note). The tube shall be provided with a flexible length of pipe so that the test flame can be moved over the surface of the specimen.

NOTE It has been found that this can be achieved when using coal (simulated town) gas (calorific value 4 450 kcal/m3) at a flow rate of approximately 3 730 cm3/min or natural gas (calorific value 10 730 kcal/m3) at a flow rate of approximately 1 550 cm3/min.

5.4 Specimen holder (see Figure 2). The specimen shall be supported by a metal framework that allows an unobstructed view of the underside of the specimen and does not restrict its thermal movement. The frame shall be provided with means of adjustment for the height of the specimen and its angle of inclination from 1 to 45 to the horizontal. The specimen on its frame shall be capable of movement from an unexposed position to the test position within 5 s. A metal gutter extending the full width of the specimen shall be fitted to the front of the frame, located about 50 mm below the front edge.

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

Figure 1 Diagram showing radiation intensities at nine positions on plan of specimen for calibration

BSI 01-1999

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

BSI 01-1999

Figure 2 Typical roof test apparatus

BS 476-3:1975

BS 476-3:1975

6 Test procedure

6.1 Mounting of specimens. Each specimen shall be mounted with its upper surface at an angle of 45 to the horizontal. If the specimen represents a construction which is intended to be used at a lesser angle, then the appropriate slope shall be used in the test with a minimum slope of 1. 6.2 Preliminary ignition test. One specimen shall be supported as specified in 5.4 and the test flame, specified in 5.3, shall be applied to its upper surface without incident heat radiation. The orifice through which the flame is issuing shall be held 5 mm to 10 mm from the surface at the centre of the specimen with the tube held at an angle to enable the flame to maintain contact with the upper surface. The flame shall be removed 1 min after application and observations made of any continued flaming on the upper surface and fire penetration to the underside. If penetration occurs the subsequent tests shall not be carried out. 6.3 Fire penetration and surface ignition test 6.3.1 Three specimens shall be tested. The heating panels shall be stabilized to provide the radiation intensity on the upper surface of the specimen as specified in 5.2. This is normally achieved at a distance of 580 5 mm from the plane forming the radiant heaters, the distance being measured at right-angles to the centre of the specimen. 6.3.2 The specimen shall be moved from the unexposed position to the test position within 5 s. The test starts at the moment the specimen is in the test position. The test shall be of at least 60 min duration, unless penetration occurs earlier. The test period may be extended beyond 60 min to a maximum of 90 min.

6.3.3 The test flame shall be applied over the upper surface of the specimen for a period of 1 min, the first application being at 5 min from the start of the test. Throughout the duration of the test successive applications shall be made at 5, 10, 15, 30, 45 and 75 min from the start of the test unless the test has been terminated at an earlier time. The test flame shall be directed towards the top edge of the specimen (see Figure 1) with the orifice 5 mm to 10 mm from the surface of the specimen and the tube held at an angle to enable the flame to maintain contact. At each application of the test flame it shall traverse the specimen from one side edge to the other at least once, in a direction parallel to the XX axis (see Figure 1) and so as to pass over the central area of the specimen. Where rooflights are incorporated the path of the pilot flame should be as shown in Figure 3. The test flame shall be moved slowly over the surface at an average speed of 2 m/min covering joints and other positions which appear susceptible to flaming; it may be held at any point for up to 15 s if ignition of the surface seems imminent. 6.3.4 Immediately following the application of the flame to the surface of the specimen the test flame shall if required be applied to any molten material collecting in the gutter. 6.4 Test observations. The following observations shall be recorded in respect of each specimen. a) The time and occurrence of any flaming on the upper surface and its duration. Where sporadic or intermittent flaming occurs without a measurable progression of the flame front, it shall be recorded under other observation [see clause 8 e)]. b) The time at which glowing or flaming appears on the underside. c) The time of development of holes or fissures, or collapse. d) Visual changes in appearance. e) Any fall of molten materials into the gutter at the front or from the underside of the specimen and any flaming of the molten material. f) Behaviour at eaves when these are incorporated. g) The maximum distance of lateral flame spread on the upper surface which has occurred at any time during the test shall be measured to the nearest 25 mm, as follows: 1) maximum spread in any direction in the preliminary ignition test (see 6.2); 2) maximum spread measured along the XX axis (see Figure 1) in the fire penetration and surface ignition test (see 6.3).

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

BSI 01-1999

BS 476-3:1975

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

Figure 3 Path of travel of pilot flame 6.5 Test results 6.5.1 Preliminary ignition test. If the duration of flaming exceeds 5 min after the withdrawal of the test flame or if the maximum distance of flaming in any direction exceeds 370 mm, the performance of the specimen shall be expressed by the letter X. If the duration of flaming after the withdrawal of the test flame is less than 5 min or if the maximum distance of flaming does not exceed 370 mm, the performance shall be expressed by the letter P. If penetration of fire occurs in this test the penetration time for the whole sample shall be reported as 1 min. 6.5.2 Fire penetration and surface ignition test. The penetration time to the nearest minute shall be given for each specimen. If no penetration has occurred, the time shall be taken as the maximum duration of the test. The extent of surface ignition shall be given for the three specimens at 60 min or at the time of penetration to the nearest 25 mm.

7 Expression of results

The results obtained for each roof specimen tested shall be given as follows. a) Inclination of the roof. b) Performance in the preliminary ignition test. c) The penetration time in minutes. d) The extent of surface ignition in millimetres.

8 Test report

The test report on the specimens shall include the following information. a) Name of testing laboratory. b) Name of sponsor. c) Date of test. d) Complete description of construction and conditioning of test specimens. e) Test results, as specified in clause 7 including any observations under 6.4.

BSI 01-1999

BS 476-3:1975

Appendix A Copper asbestos disc radiometer

The copper asbestos disc radiometer is constructed from a copper disc, 0.376 mm thick and 25.4 mm diameter, to which is soldered chromel and constantan thermocouple wires, 0.719 mm diameter. Discs of asbestos paper, 0.254 mm thick, 32 mm diameter and with a mass per unit area of 175 g/m2, are secured to both sides of the copper disc by sodium silicate adhesive. The sodium silicate adhesive consists of an aqueous syrup of composition between Na2O:3.2SiO2 and Na2O:3.4SiO2, having a relative density between 1.41 and 1.43. The thermocouple wires are soldered to the copper disc at diametrically opposite points near the edge using a high melting point solder (750 C). After soldering, the disc is thoroughly cleaned on both sides by dipping in a cleaning mixture consisting of concentrated sulphuric acid and chromic acid or sodium dichromate in the ratio 4 to 1 by volume.

After washing and drying the disc, care being taken not to handle the surface of the copper with the fingers, a drop of silicate adhesive is applied to the centre of the disc from a 6 mm diameter rod that has been immersed to a depth of 30 mm in the silicate adhesive. The asbestos disc is then placed on top and worked round with the finger spreading the adhesive over its surface until it becomes tacky. The disc is then centralized and pressed down firmly. This process is repeated for the other side of the disc, care being taken to ensure that the asbestos paper is pressed down firmly round the thermocouple wires and is well sealed round the edge. The completed copper asbestos disc radiometer should be used with the thermocouples side facing the source of radiation. The output, in millivolts, from the radiometers is obtained from the following relationship: 4.187 E2 + 79.56E 100I = 0 where E is the e.m.f. (mV); I is the intensity of radiation (kW/m2).

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

BSI 01-1999

BS 476-3:1975

Publication referred to

This standard makes reference to the following British Standard: BS 4422, Glossary of terms associated with fire.

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

BSI 01-1999

BSI 389 Chiswick High Road London W4 4AL

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

BSI British Standards Institution

BSI is the independent national body responsible for preparing British Standards. It presents the UK view on standards in Europe and at the international level. It is incorporated by Royal Charter. Revisions British Standards are updated by amendment or revision. Users of British Standards should make sure that they possess the latest amendments or editions. It is the constant aim of BSI to improve the quality of our products and services. We would be grateful if anyone finding an inaccuracy or ambiguity while using this British Standard would inform the Secretary of the technical committee responsible, the identity of which can be found on the inside front cover. Tel: 020 8996 9000. Fax: 020 8996 7400. BSI offers members an individual updating service called PLUS which ensures that subscribers automatically receive the latest editions of standards. Buying standards Orders for all BSI, international and foreign standards publications should be addressed to Customer Services. Tel: 020 8996 9001. Fax: 020 8996 7001. In response to orders for international standards, it is BSI policy to supply the BSI implementation of those that have been published as British Standards, unless otherwise requested. Information on standards BSI provides a wide range of information on national, European and international standards through its Library and its Technical Help to Exporters Service. Various BSI electronic information services are also available which give details on all its products and services. Contact the Information Centre. Tel: 020 8996 7111. Fax: 020 8996 7048. Subscribing members of BSI are kept up to date with standards developments and receive substantial discounts on the purchase price of standards. For details of these and other benefits contact Membership Administration. Tel: 020 8996 7002. Fax: 020 8996 7001. Copyright Copyright subsists in all BSI publications. BSI also holds the copyright, in the UK, of the publications of the international standardization bodies. Except as permitted under the Copyright, Designs and Patents Act 1988 no extract may be reproduced, stored in a retrieval system or transmitted in any form or by any means electronic, photocopying, recording or otherwise without prior written permission from BSI. This does not preclude the free use, in the course of implementing the standard, of necessary details such as symbols, and size, type or grade designations. If these details are to be used for any other purpose than implementation then the prior written permission of BSI must be obtained. If permission is granted, the terms may include royalty payments or a licensing agreement. Details and advice can be obtained from the Copyright Manager. Tel: 020 8996 7070.

Licensed Copy: Giorgio Cavalieri, none, 16-Nov-00, Uncontrolled Copy. BSI

You might also like

- GPT CalculationDocument2 pagesGPT CalculationWan MahiramNo ratings yet

- GPT OgiDocument2 pagesGPT OgiWan MahiramNo ratings yet

- The Installation Process of HDPE Sewer Pipes and Actual Site ConditionsDocument12 pagesThe Installation Process of HDPE Sewer Pipes and Actual Site ConditionsSK NGNo ratings yet

- Spiral Hdpe Flat GatesDocument2 pagesSpiral Hdpe Flat GatesWan MahiramNo ratings yet

- Authorities Approval Status (25!09!16)Document12 pagesAuthorities Approval Status (25!09!16)Wan MahiramNo ratings yet

- EarthworkDocument26 pagesEarthworkWan MahiramNo ratings yet

- BS ListDocument7 pagesBS ListWan Mahiram100% (1)

- Excel:earthwork Manual SpreadsheetDocument14 pagesExcel:earthwork Manual SpreadsheetWan MahiramNo ratings yet

- ResintechHDPEsewerpipe-superiormaterialforsewerconstructionDocument14 pagesResintechHDPEsewerpipe-superiormaterialforsewerconstructionJonNo ratings yet

- AGRD06-10 Guide To Road Design Part 6 Roadside Design Safety and BarriersDocument266 pagesAGRD06-10 Guide To Road Design Part 6 Roadside Design Safety and BarriersRamadan DurakuNo ratings yet

- New Sewerage Works Approval Procedures For Low RiskDocument19 pagesNew Sewerage Works Approval Procedures For Low RiskWan Mahiram100% (1)

- Sports Personal Accident InsuranceDocument6 pagesSports Personal Accident InsuranceWan MahiramNo ratings yet

- Austroads: Guide To Road Design Part 3 Geometric DesignDocument374 pagesAustroads: Guide To Road Design Part 3 Geometric Design268586660% (5)

- Notification For Connection To Public SewerDocument3 pagesNotification For Connection To Public SewerMohamad AmirulbaharudinNo ratings yet

- Measurement and Earthwork CalculationDocument5 pagesMeasurement and Earthwork CalculationGawesha DissanayakeNo ratings yet

- Lysaght Bondek User GuideDocument12 pagesLysaght Bondek User GuideSiu SiuNo ratings yet

- Sewer Hydraulic CalculationDocument3 pagesSewer Hydraulic CalculationWan Mahiram100% (3)

- Sports PA BrochureF AD B11 V13Document16 pagesSports PA BrochureF AD B11 V13Wan MahiramNo ratings yet

- Osd 1Document4 pagesOsd 1Wan Mahiram100% (1)

- Drainage Inspection Checklist ProjectDocument1 pageDrainage Inspection Checklist ProjectWan Mahiram100% (3)

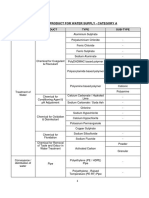

- Product Grouping Under Category A For Water Supply ProductDocument6 pagesProduct Grouping Under Category A For Water Supply ProductWan MahiramNo ratings yet

- Infraworks Colouring For SubmissionDocument7 pagesInfraworks Colouring For SubmissionWan MahiramNo ratings yet

- REPORT Earthworks PDFDocument7 pagesREPORT Earthworks PDFWan MahiramNo ratings yet

- AUTHORITY SUBMISSION GUIDEDocument3 pagesAUTHORITY SUBMISSION GUIDEWan Mahiram100% (4)

- Need Statement Guide JKRDocument89 pagesNeed Statement Guide JKRKhairuddin Ismail67% (12)

- Civil 3d Best PracticesDocument210 pagesCivil 3d Best Practicescosty2882100% (1)

- L-Shape Wall Mar13Document2 pagesL-Shape Wall Mar13Wan MahiramNo ratings yet

- Cas Sambungan TNBDocument11 pagesCas Sambungan TNBsofyanshahNo ratings yet

- DR Quek Time Area KL - MSMA2Document5 pagesDR Quek Time Area KL - MSMA2Wan MahiramNo ratings yet

- U Shape Drain Mar13Document4 pagesU Shape Drain Mar13Wan MahiramNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Denny Darmawan Diredja: Professional Attributes / Skills ExperiencesDocument2 pagesDenny Darmawan Diredja: Professional Attributes / Skills ExperiencesIntan WidyawatiNo ratings yet

- C15 DiagranmaDocument2 pagesC15 Diagranmajose manuel100% (1)

- Syllabus: Android Training Course: 1. JAVA ConceptsDocument6 pagesSyllabus: Android Training Course: 1. JAVA ConceptsVenkata Rao GudeNo ratings yet

- Saturn Engine Compression Test GuideDocument7 pagesSaturn Engine Compression Test GuideManuel IzquierdoNo ratings yet

- Iso 9117-3 2010Document10 pagesIso 9117-3 2010havalNo ratings yet

- Physical GEOGRAPHY - TIEDocument432 pagesPhysical GEOGRAPHY - TIEnassorussi9No ratings yet

- Web Servers ExplainedDocument15 pagesWeb Servers ExplainedIman AJNo ratings yet

- 10 Questions About Independent ReadingDocument4 pages10 Questions About Independent ReadingdewiNo ratings yet

- Micro810 Allen Bradley User ManualDocument120 pagesMicro810 Allen Bradley User ManualStefano MontiNo ratings yet

- Mo Handbook Fbimnci Apr 18, 2019Document296 pagesMo Handbook Fbimnci Apr 18, 2019Prakash Thakulla100% (1)

- Gas Turbine MaintenanceDocument146 pagesGas Turbine MaintenanceMamoun1969100% (8)

- Neem Oil Insect Repellent FormulationDocument12 pagesNeem Oil Insect Repellent FormulationnityaNo ratings yet

- A Light Sculling Training Boat PDFDocument8 pagesA Light Sculling Training Boat PDFLuis BraulinoNo ratings yet

- Regenerative Braking System: An Efficient Way to Conserve EnergyDocument31 pagesRegenerative Braking System: An Efficient Way to Conserve EnergyPRAVIN KUMAR NNo ratings yet

- Sample COBOL ProgramsDocument35 pagesSample COBOL Programsrahul tejNo ratings yet

- Bleed Fan SelectionDocument4 pagesBleed Fan Selectionomar abdullahNo ratings yet

- Strategies and Methods For Cloud MigrationDocument10 pagesStrategies and Methods For Cloud MigrationVel_stNo ratings yet

- The Government-Created Subprime Mortgage Meltdown by Thomas DiLorenzoDocument3 pagesThe Government-Created Subprime Mortgage Meltdown by Thomas DiLorenzodavid rockNo ratings yet

- BLDG TECH Juson Assignment Lecture 1Document23 pagesBLDG TECH Juson Assignment Lecture 1Ma. Janelle GoNo ratings yet

- Complaint FTC V SkechersDocument60 pagesComplaint FTC V SkechersLara PearsonNo ratings yet

- Ticket Frankfurt Berlin 3076810836Document2 pagesTicket Frankfurt Berlin 3076810836farzad kohestaniNo ratings yet

- SteroidsDocument2 pagesSteroidsShawn FreemanNo ratings yet

- Grand Central Terminal Mep Handbook 180323Document84 pagesGrand Central Terminal Mep Handbook 180323Pete A100% (1)

- Myo Cny 2023 MenuDocument12 pagesMyo Cny 2023 Menulihanyong17No ratings yet

- Examen 03 Aula - F PostgradoDocument5 pagesExamen 03 Aula - F PostgradodiegoNo ratings yet

- Cost Accounting DQ - Midterms - AnswersDocument10 pagesCost Accounting DQ - Midterms - AnswersKurt dela TorreNo ratings yet

- Slimline: Switch Disconnector Fuse, SR 63-630 ADocument46 pagesSlimline: Switch Disconnector Fuse, SR 63-630 AЕвгений МатвеевNo ratings yet

- WBLFFDocument10 pagesWBLFFMohd IzatNo ratings yet

- Chapter 2 EnglishDocument9 pagesChapter 2 Englishdgdhdh_66No ratings yet

- PESU BTech Jan2017 6thsemCourseInfoDocument51 pagesPESU BTech Jan2017 6thsemCourseInforakshithrajNo ratings yet