Professional Documents

Culture Documents

Biodiesel Kinetics

Uploaded by

nizar ahmadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biodiesel Kinetics

Uploaded by

nizar ahmadCopyright:

Available Formats

This spreadsheet is used to study reaction kinetics of Biodiesel Production.

The

kinetic model used in this spreadsheet is Komer's Model (2002) which is extended by

Timothy Lawrence (2005) to include the effect of temperature to the the rate

constants. The description of the Komer's Model is provided in sheet 'Model

Description'.

All calculations are done in sheet 'Main Calculations'. They consists of 5 sequential

steps as follows:

1. User supplies operating temperature of the reaction. This spreadsheet will estimate

the normalized rate constants using Arhenius Equation based on Activation Energies

(Ea) and Arhenius Pre factors (A) provided in sheet 'Data of Ea&A'.

2. User then needs to supply their own p, n, and desired E (p is initial molar ratio of

catalyst to TG (Triglycerides), n is initial molar ratio of alcohol to TG, and E is end

product normalized concentration of alkyl ester which is the biodiesel product). This

spreadsheet is then able to estimate end product normalized concentrations of TG,

DG (Diglycerides), MG (Monoglycerides), G (Glycerol), ROH (alcohol), OH

(catalyst), and A (soap).

3. User then supplies the properties of their reactants (rho_TG, MW_TG, rho_ROH,

and MW_ROH) to let this spreadsheet to calculate the required reactant and catalyst

concentrations.

4. This spreadsheet will then calculate time of reaction (time when equilibrium is

reached) based on calculated normalized TG using formula in sheet 'Data of Ea&A'.

5. The last step is the calculation of end product actual concentrations based on

calculated normalized concentrations.

References:

1. Ishchuk, S.Yu et al (1992), “Kinetics of saponification of hydrogenated castor oil

by lithium hydroxide”, Chemistry and Technology of Fuels and Oils, 28(1-2): 48-50.

2. Komers, K. et al (2002), “Kinetics and mechanism of the KOH - catalyzed

methanolysis of rapeseed oil for biodiesel production”, European Journal of Lipid

Science and Technology, 104(11): 728-737.

3. Noureddini, H. and Zhu, D. (1997), “Kinetics of transesterification of soybean oil”,

Journal of the American Oil Chemists Society, 74(11): 1457-1463.

4. TURNER, TIMOTHY LAWRENCE (2005). "Modeling and Simulation of

Reaction Kinetics for Biodiesel Production". Graduate Faculty of North Carolina

State University.

Prepared by : Muhamad Nizar

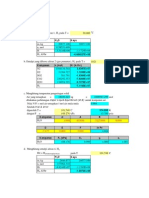

1. Calculation of rate constants based on specified operating temperature (T)

R (cal/mol/K) T (oC) T (K)

1.987215583 22.75 295.9 1. Input data in yellow cells

2. Calculated data are in green cells

Rate constants Value

k2' 5.9489 L/mol s

k2r' 2.9800 L/mol s

k4' 9.3991 L/mol s

k4r' 7.3110 L/mol s

k6' 15.1800 L/mol s

k6r' 0.6982 L/mol s

k8 0.0133 L/mol s

k9 0.3436 L/mol s

k10 0.7474 L/mol s

k11 0.4654 L/mol s

2. Calculation of end product normalized concentrations (unitless)

Komers normalizes the remaining species by the initial concentrations of triglyceride

and alcohol, as follows:

TG = [TG]/a

a = [TG]o

DG = [DG]/a

MG = [MG]/a

G = [G]/a

A = [A]/a

OH = [OH-]/a

W = [H2O]/a

ROH = [ROH]/b

b = [ROH]o

E = [E]/b

The following balance equations also apply:

TG + DG + MG + G = 1

ROH + E = 1

OH + A = p

p = [OH-]o / [TG]o

nE + 3TG + 2DG + MG + A = 3

n = [ROH]o / [TG]o

Using equilibrium relations, Komers was able to develop an algebraic solution for the end product

concentrations.

Assuming that all reactions have reached equilibrium, we calculate equilibrium constants:

K2' 1.9963

K4' 1.2856

K6' 21.7417

Define

p 0.1225

n 2.0883

E 0.7687

We obtain

<-- this value is adjusted

TG 0.2982 until value of balance ~ 1

DG 0.1791

MG 0.0693

G 0.4533

balance 1

We then also obtain based on balance equations:

A 0.0725

ROH 0.2313

OH 0.0500

3. Calculation of required reactant and catalyst concentrations

Specify:

rho_TG 0.925 g/ml <-- this value is depended on type of oil/fat used

MW_TG 882.82 g/mol <-- this value is depended on type of oil/fat used

rho_ROH 0.791 g/ml <-- this value is depended on type of alcohol used

MW_ROH 32.04 g/mol <-- this value is depended on type of alcohol used

We then calculate:

[TG]_pure 1.0478 mol/L

[ROH]_pure 24.6879 mol/L

[TG]o = a 0.9625 mol/L

[ROH]o = b 2.0099 mol/L

[OH-]o 0.1179 mol/L <--- this is the concentration of required catalyst

4. Calculation of time of reaction based on calculated normalized TG

time of reaction 142.3101 s 2.3718 min

5. Calculation of end product actual concentrations based on calculated normalized

concentrations

[TG] 0.2870 mol/L

[DG] 0.1724 mol/L

[MG] 0.0667 mol/L

[G] 0.4363 mol/L

[A] 0.0698 mol/L

[OH-] 0.0481 mol/L

[ROH] 0.4649 mol/L

<-- this is calculated using the same approach as

[H2O] 55.4939 mol/L [TG]_pure is calcucated

[E] 1.5450 mol/L <-- this is the Biodiesel

You might also like

- Strength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07MettkDocument287 pagesStrength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07Mettkluis morales100% (2)

- Magnetism Workhsheet Siap EditDocument10 pagesMagnetism Workhsheet Siap EditMamberamo ClassNo ratings yet

- Bridge Design Report - Docx 150Document17 pagesBridge Design Report - Docx 150nephembaniNo ratings yet

- Chemical Formulas and Equations PDFDocument14 pagesChemical Formulas and Equations PDFJomarie Cabuello100% (1)

- Chapter 7 Chemical Energetics ExerciseDocument5 pagesChapter 7 Chemical Energetics ExerciseAri Adiantari100% (1)

- S P I C e J e T Q U e S T I o N SDocument43 pagesS P I C e J e T Q U e S T I o N SDharavGosaliaNo ratings yet

- Energy BalanceDocument19 pagesEnergy Balancekamran AhmadNo ratings yet

- Calculation Procedure For Determination of Approach To Equilibrium For The Methane Reforming ReactionDocument11 pagesCalculation Procedure For Determination of Approach To Equilibrium For The Methane Reforming ReactionmadhunaNo ratings yet

- Designing Urea ReactorDocument20 pagesDesigning Urea ReactordcobasbNo ratings yet

- Heat CalcDocument7 pagesHeat CalcasdfghjkNo ratings yet

- Heat Balance of Rotary DryerDocument2 pagesHeat Balance of Rotary Dryernizar ahmadNo ratings yet

- Boiler efficiency and flue gas analysis calculationsDocument50 pagesBoiler efficiency and flue gas analysis calculationsDilip MishraNo ratings yet

- Design of Rotary DryerDocument2 pagesDesign of Rotary Dryernizar ahmad57% (7)

- Calculate Boiler Efficiency Using Direct MethodDocument53 pagesCalculate Boiler Efficiency Using Direct Methoddineshkbunker08No ratings yet

- Hydrogen Production TechnologiesFrom EverandHydrogen Production TechnologiesMehmet SankirNo ratings yet

- Boy's Gas Calorimeter Lab Report Group 5Document5 pagesBoy's Gas Calorimeter Lab Report Group 5Aavvas AsgharNo ratings yet

- Chemistry The Molecular Science 5th Edition Moore Solutions Manual 1Document36 pagesChemistry The Molecular Science 5th Edition Moore Solutions Manual 1josephandersonxqwbynfjzk100% (27)

- Chemistry The Molecular Science 5Th Edition Moore Solutions Manual Full Chapter PDFDocument36 pagesChemistry The Molecular Science 5Th Edition Moore Solutions Manual Full Chapter PDFsusan.robleto221100% (11)

- By J. Gutow 8/2007 Fuel ValuesDocument2 pagesBy J. Gutow 8/2007 Fuel ValuesMiriam TorreNo ratings yet

- Non Reacting MixtureDocument17 pagesNon Reacting MixtureAmmarul NafikNo ratings yet

- 11 Stoichiometry Calculations Based On Chemical EquationsDocument38 pages11 Stoichiometry Calculations Based On Chemical EquationsMohamed TarekNo ratings yet

- Posobie Teplovoj Raschet 1 1Document95 pagesPosobie Teplovoj Raschet 1 1abbeyNo ratings yet

- I. The Gross Calorific Value of The Fuel: KJ/KGDocument2 pagesI. The Gross Calorific Value of The Fuel: KJ/KGAhmed SharaawyNo ratings yet

- Gibbs Free Energy PP Key - TaggedDocument1 pageGibbs Free Energy PP Key - Tagged天石No ratings yet

- Hydrogen Peroxide Determination by Redox TitrationDocument6 pagesHydrogen Peroxide Determination by Redox Titrationdaniel_12No ratings yet

- Gas Plant 1Document90 pagesGas Plant 1Murali MuthuNo ratings yet

- Thermodynamics Lab SolutionsDocument4 pagesThermodynamics Lab SolutionsVictor ApazaNo ratings yet

- Lec2New Microsoft Office PowerPoint PresentationDocument36 pagesLec2New Microsoft Office PowerPoint PresentationMeroNarutoNo ratings yet

- Kinetic Operational Mechanism To AutotheDocument15 pagesKinetic Operational Mechanism To AutothenogiyNo ratings yet

- 2-Heat Chemistry ProjectDocument6 pages2-Heat Chemistry ProjectMuhammad shehryar wainNo ratings yet

- Fundamentals of Petroleum Lec. 8Document8 pagesFundamentals of Petroleum Lec. 8abyNo ratings yet

- Mol. Gas Const.Document4 pagesMol. Gas Const.Shiju Kp.No ratings yet

- 1 s2.0 S1385894721019550 mmc1Document20 pages1 s2.0 S1385894721019550 mmc1sripantNo ratings yet

- Internal Lab 2018Document16 pagesInternal Lab 2018MahmoudKamalElshazlyNo ratings yet

- S2012 ChE234 S Exam - 2Document6 pagesS2012 ChE234 S Exam - 2jrobs314No ratings yet

- Date of Submission: 5 MAY 2022Document11 pagesDate of Submission: 5 MAY 2022RUANGLADDA LIMPONGSAWATNo ratings yet

- Catalyzed Decomposition of Hydrogen PeroxideDocument5 pagesCatalyzed Decomposition of Hydrogen PeroxideDennis WrinNo ratings yet

- Lec 3 Material Balance For Reactive Processes Ver 002Document67 pagesLec 3 Material Balance For Reactive Processes Ver 002Mark Pleak Nourgh HidalgoNo ratings yet

- ME354-Tut11sol w07 PDFDocument7 pagesME354-Tut11sol w07 PDFKen ToyNo ratings yet

- Sheet (6) ThermoDocument6 pagesSheet (6) ThermoAhmed A. TaimaNo ratings yet

- Esercizi Tipo Esame 13-01-2022Document15 pagesEsercizi Tipo Esame 13-01-2022armanjeffryNo ratings yet

- PROCESS DESIGN OF MALEIC ANHYDRIDE PLANTDocument45 pagesPROCESS DESIGN OF MALEIC ANHYDRIDE PLANTRolandianurNo ratings yet

- Numerical ModelDocument61 pagesNumerical ModelAlbert AguileraNo ratings yet

- Final Memo 2Document12 pagesFinal Memo 2SaidNo ratings yet

- Yağız Bayazit Berfu Elçin Ceylan - PETE218 - HW2Document15 pagesYağız Bayazit Berfu Elçin Ceylan - PETE218 - HW2Emir MazlumNo ratings yet

- Thermo HWDocument6 pagesThermo HWMuhammad Fawwad ObaidaNo ratings yet

- Muzami Thahir / 04211741000029/ Marine Engineering Ship Performance & Energy Efficiency TaskDocument5 pagesMuzami Thahir / 04211741000029/ Marine Engineering Ship Performance & Energy Efficiency TaskMuzami ThahirNo ratings yet

- M N M M N MDocument2 pagesM N M M N MabhiNo ratings yet

- Material Balances: Dr. M. ColeyDocument28 pagesMaterial Balances: Dr. M. ColeyToanique HeadmanNo ratings yet

- Enthalpy WKST KEYDocument4 pagesEnthalpy WKST KEYمحمد گراوندNo ratings yet

- Lab Report 1Document12 pagesLab Report 1Felix JoshuaNo ratings yet

- Lecture 3 StoichiometryDocument45 pagesLecture 3 StoichiometryAndrew LeungNo ratings yet

- Treybal DistDocument5 pagesTreybal DistJay CeeNo ratings yet

- Calorimetry LabDocument3 pagesCalorimetry LabJesse PattonNo ratings yet

- Thermodynamics ReportDocument6 pagesThermodynamics ReportHarsh Vora100% (1)

- Solution #9Document7 pagesSolution #9KinnonPangNo ratings yet

- A Fixed Quantity of Gas at 21Document8 pagesA Fixed Quantity of Gas at 21nonoytagupa3No ratings yet

- Lecture 10xx 2Document66 pagesLecture 10xx 2King Cyruz PabloNo ratings yet

- Chem Basic FB Answer Key CH 17 (06.14.16)Document6 pagesChem Basic FB Answer Key CH 17 (06.14.16)Tessa KodraNo ratings yet

- Chap3lect 2020Document62 pagesChap3lect 2020Anonymous wt2BA7uNo ratings yet

- Energy Balance InsightsDocument13 pagesEnergy Balance InsightsIan GuerreroNo ratings yet

- Gas StoichiometryDocument12 pagesGas StoichiometryAhmed Ali SomosaNo ratings yet

- PreburnerDocument2 pagesPreburnerHuzaifa Bin ZahidNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Environmental Consultant CVDocument3 pagesEnvironmental Consultant CVnizar ahmadNo ratings yet

- Muhamad Nizar - CVDocument12 pagesMuhamad Nizar - CVnizar ahmadNo ratings yet

- Muhamad Nizar ProfileDocument13 pagesMuhamad Nizar Profilenizar ahmadNo ratings yet

- Sounds of EquipmentsDocument3 pagesSounds of Equipmentsnizar ahmadNo ratings yet

- Implementation Report SMTMLK3 Berbasis KomputerDocument13 pagesImplementation Report SMTMLK3 Berbasis Komputernizar ahmadNo ratings yet

- EFs For MiningDocument5 pagesEFs For Miningnizar ahmadNo ratings yet

- Vvsizing: Prepared By: Muhamad NizarDocument4 pagesVvsizing: Prepared By: Muhamad Nizarnizar ahmadNo ratings yet

- Sheet 'Intro' of Biomass HydrolysisDocument1 pageSheet 'Intro' of Biomass Hydrolysisnizar ahmadNo ratings yet

- Sheet 'H+ Estimation' of Biomass HydrolysisDocument1 pageSheet 'H+ Estimation' of Biomass Hydrolysisnizar ahmadNo ratings yet

- Sheet 'Main Calculations' of Biomass HydrolysisDocument2 pagesSheet 'Main Calculations' of Biomass Hydrolysisnizar ahmadNo ratings yet

- AW Meter Aqualab PREDocument2 pagesAW Meter Aqualab PREDebrina ANo ratings yet

- Topic 4 - Probability (Old Notes)Document22 pagesTopic 4 - Probability (Old Notes)Pradeep100% (1)

- F1223 1479757-1Document9 pagesF1223 1479757-1Thaweekarn ChangthongNo ratings yet

- DMCR Detection Measurement Control RelayDocument5 pagesDMCR Detection Measurement Control RelayMuhammad AbuzarNo ratings yet

- Improve Steel Quality with Electromagnetic StirrersDocument4 pagesImprove Steel Quality with Electromagnetic Stirrerst_pradipNo ratings yet

- Open Stent Design: Craig Bonsignore NDC 47533 Westinghouse Drive Fremont, CA, 94566Document93 pagesOpen Stent Design: Craig Bonsignore NDC 47533 Westinghouse Drive Fremont, CA, 94566akire_aicragNo ratings yet

- Dosing Pump Innovata Drive ConceptDocument5 pagesDosing Pump Innovata Drive ConceptgarpNo ratings yet

- GE Lighting Systems Brevard Series Spec Sheet 12-74Document2 pagesGE Lighting Systems Brevard Series Spec Sheet 12-74Alan MastersNo ratings yet

- E-CAPS-28 - For CoE (XI) - Chemistry - (Que. - Answer Key)Document3 pagesE-CAPS-28 - For CoE (XI) - Chemistry - (Que. - Answer Key)darling deanNo ratings yet

- General Physics 1 1st Quarter Module 1 ActivitiesDocument16 pagesGeneral Physics 1 1st Quarter Module 1 ActivitiesMica LopezNo ratings yet

- Unit Hydrograph DerivationDocument7 pagesUnit Hydrograph DerivationSudharsananPRSNo ratings yet

- Curriculum-Of Mathematics Government College Women University, SialkotDocument119 pagesCurriculum-Of Mathematics Government College Women University, SialkotHuzaifa GurmaniNo ratings yet

- Bradford AssayDocument2 pagesBradford AssayCNo ratings yet

- Energy in Somaliland Novia Thesis - Editing PDFDocument25 pagesEnergy in Somaliland Novia Thesis - Editing PDFAbdirahmanNo ratings yet

- Numerical Analysis 1Document21 pagesNumerical Analysis 1Maged Mohammad Hassan100% (1)

- LaminateDocument154 pagesLaminateAbhishek VaggarNo ratings yet

- Metrology AssignmentDocument31 pagesMetrology AssignmentKailas Sree Chandran100% (1)

- Topic 1Document17 pagesTopic 1Trịnh Tuấn HiềnNo ratings yet

- 2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical ApplicationsDocument6 pages2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical Applicationsultrasonic81No ratings yet

- Measuring Elastic Modulus of Beams Using Deflection MethodDocument14 pagesMeasuring Elastic Modulus of Beams Using Deflection MethodHaziq PazliNo ratings yet

- 1117 1 M-Ary Signals PART 1Document11 pages1117 1 M-Ary Signals PART 1PARKSANGWOOKNo ratings yet

- The Statistical Imagination: Chapter 7. Using Probability Theory To Produce Sampling DistributionsDocument18 pagesThe Statistical Imagination: Chapter 7. Using Probability Theory To Produce Sampling DistributionsVictoria LiendoNo ratings yet

- Cup Making MachineDocument3 pagesCup Making MachineJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Abdel Jawad 2005Document8 pagesAbdel Jawad 2005Alberto Tupa OrtizNo ratings yet

- BHEL Haridwar Block 2 Heavy Fabrication, Training ReportDocument53 pagesBHEL Haridwar Block 2 Heavy Fabrication, Training ReportUdit Soni100% (5)