Professional Documents

Culture Documents

DEE 3323.02 Pengenalan PLC

Uploaded by

nabilo20Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DEE 3323.02 Pengenalan PLC

Uploaded by

nabilo20Copyright:

Available Formats

EN.

MUHAMAD NABIL BIN MANSOR

pengenalan

Sejarah PLC

Apa itu PLC?

Litar kawalan relay

Relay

Panel Kawalan Sistem Relay

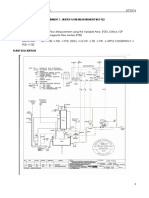

Litar kawalan relay

Panel Kawalan Sistem Relay

Relay terminal

Litar kawalan relay

Litar Kawalan Relay

Gantian kepada Relay

Simbol Contact

Simbol Coil

Gantian kepada Relay

Relays

PLC

Timers & Counters

Gantian kepada Relay

Litar Kawalan Relay

Rajah Tetangga

Gantian kepada Relay

PLC

+ x /

Operasi Aritmetik

Reject

Prod AA BB CC

Pass 33 27 43

4 3 8

2 1

4 5

Kendalian Data

Isyarat Analog

Kelebihan Menggunakan PLC

Kelebihan Menggunakan PLC

PLC vs. Relay

When I first started programming PLCs it was still questionable if a PLC was necessary over just relay control. With PLC prices going down, size shrinking, and performance of PLCs improving over the years this has become less of a battle. Yet the designer has to ask themselves if a PLC is really overkill for their application. Some questions should be asked. Is there a need for flexibility in control logic changes? Will there be frequent control logic changes? Will there be a need for rapid modification? A lot companies believe they will never change a design but more often then not ideas and goals do change and modifications will need to be made. Do you want to do that in hardware (relays) or software (PLC)? Must similar control logic be used on different machines? It's so much easier to download a program then build another panel.

PLC vs. Relay

Is there a need for future growth? A PLC can easily accept a new module in a slot or get an expansion base. Is there a need for high reliability? PLCs are seen as more robust over indiidual components. Is downtime a concern? Any change or troubleshooting on a relay system means the system might have to go offline. Changes in a PLC can often be made online with no downtime. Are space requirements important? Based on the number of relays a PLC can be a real space saver. Are increased capability and output required? PLCs can be faster then their mechanical counterparts. Are there data collection and communications required? Only possible with a PLC or computer. What are the overall costs? There's a certain price

PLC vs. Dedicated Controller

A dedicated controller is a single instrument that is dedicated to controlling one parameter such as a PID controller measuring a temperature for heating control. They have the advantages of an all in one package, typically with display and buttons. This can be a very good thing to use in simple applications. A PLC these days can compete price wise and functionally with these controllers especially if more than one controller is needed. PLCs offer a greater degree of flexibility too because the can be programmed to handle all sorts of different scenarios.

PLC vs. PC (Personal Computers)

The PLC vs. PC debate has been going on for years and I'm not going to attempt to give the definitive answer. They both have their pros and cons. What often happens is that the two are used for their strengths in different parts of the factory.

PLC vs. PC (Personal Computers)

PLC vs. PC (Personal Computers)

Pengeluar PLC

Pengeluar PLC

Jenis-jenis PLC

Nano Brick Style

ZEN

Expandable to 44 I/O Low Cost Model 20 I/O max

Compact PLC Series

CP1H The all in one PLC

CPM1A Compact & economical

CPM2A The universal small machine controller

CPM2B Brick Style Micro Controller Board Package

CPM2C The versatile slim-line controller

Modular PLC Series

CQM1H

The original backplane-less modular PLC

CJ1

The entry-level modular PLC with a big potential

Rack PLC Series

CS1

CS1D

Suitable for any job: the rack-based PLC with over 200 types of I/O units

The dual-redundant PLC system for never-fail control

Bagaimana Memilih PLC

Bagaimana Memilih PLC

Apa yang boleh PLC lakukan

Apa yang boleh PLC lakukan

Flow Rate

Float Level

Oxygen Level

Apa yang boleh PLC lakukan

Motor pump

Valve

Mixer

You might also like

- Using Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Document20 pagesUsing Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Chrisdian FaraniNo ratings yet

- Basics of PLC Workshop - Day 1 AgendaDocument119 pagesBasics of PLC Workshop - Day 1 AgendaOwais Khan100% (2)

- Volvo EW145B Wheeled ExcavatorDocument48 pagesVolvo EW145B Wheeled ExcavatorHai Van100% (9)

- Drying Shrinkage of ConcreteDocument6 pagesDrying Shrinkage of Concretecrownguard100% (1)

- Industrial AC MotorsDocument86 pagesIndustrial AC Motorsandry wibowoNo ratings yet

- Soalan Pentaksiran Praktikal 3Document8 pagesSoalan Pentaksiran Praktikal 3Muhamad ReduanNo ratings yet

- Programmable Logic Controller (PLC)Document57 pagesProgrammable Logic Controller (PLC)Sumanta Gupta100% (1)

- Audio Visual Testing ProceduresDocument10 pagesAudio Visual Testing ProceduresneddylalolaNo ratings yet

- Programmable Logic Controller (PLC) - Industrial Wiki - ODESIE® by Technology TransferDocument41 pagesProgrammable Logic Controller (PLC) - Industrial Wiki - ODESIE® by Technology TransferAbhishek SinghNo ratings yet

- PLC Workshop 1-2 DayDocument120 pagesPLC Workshop 1-2 DayHamza Khan Khattak100% (1)

- Nota Praktikal 4-DBDocument9 pagesNota Praktikal 4-DBilyasak halimNo ratings yet

- AUDIO VIDEO TESTINGDocument16 pagesAUDIO VIDEO TESTINGneddylalolaNo ratings yet

- Industrial Automation Drawing BOMDocument6 pagesIndustrial Automation Drawing BOMHanif RikuNo ratings yet

- Comparison WCPU and ACSUDocument1 pageComparison WCPU and ACSUKhay SaadNo ratings yet

- Motor Spec - IPOWER Rev01Document4 pagesMotor Spec - IPOWER Rev01GAGANNo ratings yet

- Total Water Management in Thermal Power StationsDocument8 pagesTotal Water Management in Thermal Power StationsSarah FrazierNo ratings yet

- Nota Kursus M&E - K4Document9 pagesNota Kursus M&E - K4Mckenzie Calixtus0% (1)

- Soalan Ujian HidraulikDocument8 pagesSoalan Ujian HidraulikDilla AfzanNo ratings yet

- Cranes, Rigging and BanksmanDocument61 pagesCranes, Rigging and BanksmanAdelCh100% (3)

- TJJWDocument57 pagesTJJWAdam MusavvirNo ratings yet

- Experimental Mechanics Laboratory ManualDocument76 pagesExperimental Mechanics Laboratory Manualprabhaakar100% (1)

- Nota Kuliah 2Document17 pagesNota Kuliah 2Jason Maldonado100% (1)

- 08 SpreaderDocument58 pages08 SpreaderMartin Vargas Pedro100% (1)

- Cominox SterilClave 18-24 - User and Maintenance ManualDocument68 pagesCominox SterilClave 18-24 - User and Maintenance ManualJose Tavares100% (2)

- RSL Etn 2023Document3 pagesRSL Etn 2023Masila IsmailNo ratings yet

- Table Arus Maksima 1Document1 pageTable Arus Maksima 1Haezzah NasibNo ratings yet

- Soalan Ujian HidraulikDocument9 pagesSoalan Ujian HidraulikDilla AfzanNo ratings yet

- K1-Nota Kuliah OSHADocument8 pagesK1-Nota Kuliah OSHAMuhamad Ismail Mohd JamilNo ratings yet

- Lab Sheet Teknologi Elektrik No 1-Rev1Document11 pagesLab Sheet Teknologi Elektrik No 1-Rev1semi2542No ratings yet

- JKR 4.4 TABC - Air Cooled Package SystemDocument22 pagesJKR 4.4 TABC - Air Cooled Package SystemAniq AimanNo ratings yet

- Jadual Peratusan Masa C02 6.8Document6 pagesJadual Peratusan Masa C02 6.8Cucu MaAtok MeseiryNo ratings yet

- Temperature Controlled Fan ReportDocument85 pagesTemperature Controlled Fan ReportyrikkiNo ratings yet

- Silibus Sem 1 - Sem 3 A17Document139 pagesSilibus Sem 1 - Sem 3 A17Hariq Hann0% (1)

- Pneumatic Circuit Diagram Interpretation and Component Function CheckDocument16 pagesPneumatic Circuit Diagram Interpretation and Component Function CheckFairos ZakariahNo ratings yet

- Peralatan-Peralatan Aircond: InstallationDocument4 pagesPeralatan-Peralatan Aircond: Installationamir ashriNo ratings yet

- Bahan Luak Untuk PNP Jle 1A & 1B & Jle4 2013Document8 pagesBahan Luak Untuk PNP Jle 1A & 1B & Jle4 2013Leo OelNo ratings yet

- Lab Sheet 5 - Lukisan Mesin Elektrik - 2Document8 pagesLab Sheet 5 - Lukisan Mesin Elektrik - 2Amirul WanNo ratings yet

- STORDocument14 pagesSTORMohd KhidirNo ratings yet

- Mini Dryer Project ProposalDocument24 pagesMini Dryer Project ProposalImfarosha Emma100% (1)

- Nota Praktikal 5 (Inspect - Testing) - EditDocument11 pagesNota Praktikal 5 (Inspect - Testing) - EditMuhammad Ilyasak Abdul HalimNo ratings yet

- Core Abilities Tahap 3 Modul 1Document19 pagesCore Abilities Tahap 3 Modul 1Intan Farhana100% (2)

- Chapter 4 - ProgrammingDocument58 pagesChapter 4 - ProgrammingMOHD SABREENo ratings yet

- 11-Shoes Dryer With Keypad TimerDocument1 page11-Shoes Dryer With Keypad TimerzulNo ratings yet

- Bab Elektrik: Suatu PengenalanDocument82 pagesBab Elektrik: Suatu PengenalanSeindahNyaNo ratings yet

- Acson Inverter UnitDocument1 pageAcson Inverter UnitRizwan RanaNo ratings yet

- 25 Barcode ShopcartDocument1 page25 Barcode ShopcartzulNo ratings yet

- Core Abilities Tahap 3Document5 pagesCore Abilities Tahap 3Intan Farhana100% (1)

- (MTK DVM 1) 01. Struktur DMB Teknologi Kimpalan Sem 1Document9 pages(MTK DVM 1) 01. Struktur DMB Teknologi Kimpalan Sem 1Noor Fadlan0% (1)

- Arduino Robotics Workshop NotesDocument17 pagesArduino Robotics Workshop Notesvinilants0% (1)

- Process Instrumentation & Control BTK374: Experiment 1: Water Flow Measurement WLF 922 ObjectivesDocument4 pagesProcess Instrumentation & Control BTK374: Experiment 1: Water Flow Measurement WLF 922 ObjectivesKH200 73NG LIHUANo ratings yet

- InternshipDocument26 pagesInternshipfawwaz sazalliNo ratings yet

- Control System Design and PLC Programming NotesDocument94 pagesControl System Design and PLC Programming NotesMohd Shufi Abd RahimNo ratings yet

- JSPB Lengkap Dea 3333Document10 pagesJSPB Lengkap Dea 3333Roger JohnNo ratings yet

- EarthingDocument65 pagesEarthingAzura Abu100% (1)

- Course Outline - DEA 2313Document11 pagesCourse Outline - DEA 2313Roger JohnNo ratings yet

- K5-Nota Kuliah OSHADocument9 pagesK5-Nota Kuliah OSHAMuhamad Ismail Mohd JamilNo ratings yet

- 5 - Plan Mengajar AmaliDocument8 pages5 - Plan Mengajar AmaliNur Zaidan100% (1)

- Pentaksiran Teori-Assignment (k1)Document8 pagesPentaksiran Teori-Assignment (k1)adibNo ratings yet

- Cocu 1 - Three Phase DrawingDocument11 pagesCocu 1 - Three Phase DrawingHardiySarawakNo ratings yet

- Function GeneratorDocument15 pagesFunction GeneratorAngelina0% (1)

- Chapter 7: Electricity and MagnetismDocument2 pagesChapter 7: Electricity and MagnetismPauling ChiaNo ratings yet

- Repot PLCDocument7 pagesRepot PLCkupirzz88No ratings yet

- Pemarkahan Ujian Amali 2DDocument4 pagesPemarkahan Ujian Amali 2DPAUL KENNY TSHONGNo ratings yet

- Senarai Kursus Yang Ditawarkan Bagi Program Latihan Kemahiran CIDB Bagi Belia Dan Personel Binaan Adalah Seperti BerikutDocument1 pageSenarai Kursus Yang Ditawarkan Bagi Program Latihan Kemahiran CIDB Bagi Belia Dan Personel Binaan Adalah Seperti BerikutIlya YusopNo ratings yet

- Report Final ProjekDocument42 pagesReport Final ProjekMuhammad Zainul Abidin50% (2)

- Nota Kuliah (4) PREPARE PRODUCT REPORTDocument26 pagesNota Kuliah (4) PREPARE PRODUCT REPORTAdrian SamuelNo ratings yet

- AD Click Versus Programmable Relays and Timers White PaperDocument8 pagesAD Click Versus Programmable Relays and Timers White PaperAsan MasrafNo ratings yet

- PLC1aDocument71 pagesPLC1aSymon Justine SañoNo ratings yet

- What Is A Programmable Logic Controller (PLC) ?: Products by Size by Series Customized EnclosuresDocument11 pagesWhat Is A Programmable Logic Controller (PLC) ?: Products by Size by Series Customized EnclosuresTrisha SambranoNo ratings yet

- L12!05!06.01 Pengenalan Drive SystemDocument43 pagesL12!05!06.01 Pengenalan Drive Systemnabilo20No ratings yet

- DEE 3323.05 Programming Console PDFDocument23 pagesDEE 3323.05 Programming Console PDFnabilo20No ratings yet

- Cj1W-Oc/Oa/Od: A Wide Range of Basic Output Units For High Speed Output and Different ApplicationsDocument36 pagesCj1W-Oc/Oa/Od: A Wide Range of Basic Output Units For High Speed Output and Different Applicationsnabilo20No ratings yet

- Cj1W-Id/Ia: A Wide Range of Basic Input Units For High Speed Input and Different ApplicationsDocument25 pagesCj1W-Id/Ia: A Wide Range of Basic Input Units For High Speed Input and Different ApplicationsJerry PrasathNo ratings yet

- DEE 3323.03 Teori OperasiDocument27 pagesDEE 3323.03 Teori Operasinabilo20No ratings yet

- DEE 3323.11 RelayDocument11 pagesDEE 3323.11 Relaynabilo20No ratings yet

- Servomotor y DriverDocument326 pagesServomotor y DriverCanek UnoNo ratings yet

- Digital Logic GatesDocument11 pagesDigital Logic Gatesnabilo20No ratings yet

- May 2002 Q BrochureDocument31 pagesMay 2002 Q Brochurenabilo20No ratings yet

- DEE 3323.08 Basic CommandDocument18 pagesDEE 3323.08 Basic Commandnabilo20No ratings yet

- DEE 3323.13 Sensor2Document88 pagesDEE 3323.13 Sensor2nabilo20No ratings yet

- Pertandingan Myskills Ke-7 Electronics CompetitionDocument11 pagesPertandingan Myskills Ke-7 Electronics Competitionnabilo20No ratings yet

- Servomotor y DriverDocument326 pagesServomotor y DriverCanek UnoNo ratings yet

- Dee 3323.10 PLC WiringDocument28 pagesDee 3323.10 PLC Wiringnabilo20No ratings yet

- DEE 3323.07 CX ProgrammerDocument20 pagesDEE 3323.07 CX Programmernabilo20No ratings yet

- Dee 3323.04 Cqm1h PLCDocument17 pagesDee 3323.04 Cqm1h PLCnabilo20No ratings yet

- Solid State RelayDocument5 pagesSolid State Relaynabilo20No ratings yet

- Praktikal PRA MySkills 2013 - ElectronicsDocument13 pagesPraktikal PRA MySkills 2013 - Electronicsnabilo20No ratings yet

- 4066Document25 pages4066nabilo20No ratings yet

- Bode PlotDocument7 pagesBode Plotnabilo20No ratings yet

- Soalan Praktikal Myskills 2013 Electronics - AkhirDocument14 pagesSoalan Praktikal Myskills 2013 Electronics - Akhirnabilo20No ratings yet

- Doc 6 Encryption Key FormulaDocument1 pageDoc 6 Encryption Key Formulanabilo20No ratings yet

- B12NS5V2Document2 pagesB12NS5V2nabilo20No ratings yet

- The Omnidirectional Writobot Presentation 2Document28 pagesThe Omnidirectional Writobot Presentation 2nabilo20No ratings yet

- WritobotDocument9 pagesWritobotnabilo20No ratings yet

- Tajuk: Pengesan Kapasitif: Ciri-Ciri Pengesan Cara-Cara Ia Berfungsi Fungsi Setiap Blok Data Teknikal PenggunaanDocument25 pagesTajuk: Pengesan Kapasitif: Ciri-Ciri Pengesan Cara-Cara Ia Berfungsi Fungsi Setiap Blok Data Teknikal Penggunaannabilo20No ratings yet

- Fire CraftDocument28 pagesFire CraftLooi Kok HuaNo ratings yet

- Astm B622Document6 pagesAstm B622Ramón GarcíaNo ratings yet

- Milling Speed & Feed Calculator - Inch To MetricDocument16 pagesMilling Speed & Feed Calculator - Inch To MetricAdnan MehmoodNo ratings yet

- Soil Stabilization ASSIGNMENTDocument31 pagesSoil Stabilization ASSIGNMENTvishnu_2008No ratings yet

- Enzo Nicolai T. Teves High School 1st Periodical Test in Automotive ServicingDocument4 pagesEnzo Nicolai T. Teves High School 1st Periodical Test in Automotive ServicingSylvia Aguilar RizaldoNo ratings yet

- Load Calculation and Distribution for Amal Camp FacilitiesDocument4 pagesLoad Calculation and Distribution for Amal Camp FacilitiesnikunjNo ratings yet

- Material SpecificationDocument9 pagesMaterial SpecificationMuthu GaneshNo ratings yet

- Aibel PDF 18 Advanced MethodsDocument34 pagesAibel PDF 18 Advanced Methodsbaiju79No ratings yet

- I-Series GC 600G36 GB WW 1016-3Document40 pagesI-Series GC 600G36 GB WW 1016-3Erick AvNo ratings yet

- Mine VentilationDocument3 pagesMine VentilationAbl EdwrNo ratings yet

- 6063 Aluminium Alloy - WikipediaDocument3 pages6063 Aluminium Alloy - WikipediaNinad PawarNo ratings yet

- Accgun Ins 11Document1 pageAccgun Ins 11pulakjaiswal85No ratings yet

- A Guide To Subfloors Used Under Wood Flooring - Wood Floor Business MagazineDocument20 pagesA Guide To Subfloors Used Under Wood Flooring - Wood Floor Business MagazinecarlvpNo ratings yet

- Aral Catalouge June 2017 0Document242 pagesAral Catalouge June 2017 0beboo KhamisNo ratings yet

- Vulcan LIBS Analyser For QA QC - 2Document6 pagesVulcan LIBS Analyser For QA QC - 2Trần Văn LộcNo ratings yet

- Concrete Pavements in Canada - Usage and PerformanceDocument22 pagesConcrete Pavements in Canada - Usage and PerformanceNo DisponibleNo ratings yet

- VT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & CirculatorsDocument4 pagesVT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & Circulatorshamdi gshNo ratings yet

- Multi-turn Actuator and Gear Reducer SpecificationsDocument10 pagesMulti-turn Actuator and Gear Reducer SpecificationspaulNo ratings yet

- CCCC - Direct Buried 1200 mm2 132 KV Double Circuits (Filling 1.5 K.M-W)Document10 pagesCCCC - Direct Buried 1200 mm2 132 KV Double Circuits (Filling 1.5 K.M-W)ManafNo ratings yet

- SAB Flexible Cables C1Document20 pagesSAB Flexible Cables C1Carlos OzaetaNo ratings yet

- Lecture 10 - Recovery Recrystallication and Grain GrowthDocument22 pagesLecture 10 - Recovery Recrystallication and Grain GrowthsimNo ratings yet