Professional Documents

Culture Documents

Help Qthread en

Uploaded by

emaster1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Help Qthread en

Uploaded by

emaster1Copyright:

Available Formats

QMSys Threads and Gauges QMSys Threads

Software for Determining the Parameters Of Threaded Products and Gauges

Threads and Gauges - User Manual

Table of Contents

Introduction......................................................................................................................................... 3 Software Licensing ............................................................................................................................... 3 Software description ............................................................................................................................. 4 Surface Finishing.................................................................................................................................. 5 Pitch Diameter Measuring over Wires or Balls ......................................................................................... 5 Software Application............................................................................................................................. 6 Software Settings ................................................................................................................................. 6 Printout, Templates .............................................................................................................................. 7 Metric Thread according to ISO 68-1, ISO 965-1, DIN 13, ASME 1.13M..................................................... 8 Metric Thread MJ-Profile according to ISO 5855-1:1999........................................................................... 8 Metric Thread with large clearance according to DIN 2510-2:1971............................................................ 8 Metric galvanized Thread according to ISO 965-4, to ISO 965-5 ............................................................... 8 Unified Thread UN, UNR according to ANSI/ASME B1.1:2003 ..................................................................10 Unified Thread UNJ-Profile according to ASME B1.15:1995......................................................................10 Parallel Whitworth Thread according to BS 84:2007 ...............................................................................12 Class 5 interference-fit thread according to ANSI/ASME B1.12:1987.........................................................13 Parallel Pipe Thread according to ISO 228-1: 2003 .................................................................................14 Taper Pipe Thread according to ISO 7-1:1994........................................................................................15 ANSI Pipe Threads according to ANSI B1.20.1, ANSI B1.20.3, ANSI B1.20.5, ANSI B1.20.7, NFPA 1963......16 ANSI Aeronautical pipe threads according to SAE AS71051:2008 .............................................................18 ISO Trapezoidal Thread according to ISO 2901:1993, DIN 103-1:1993 ....................................................19 ISO Stub Metric Trapezoidal Thread according to DIN 380:1995..............................................................19 ACME Trapezoidal Thread according to ANSI/ASME B1.5:1997 ................................................................20 ACME STUB Trapezoidal Thread according to ANSI/ASME B1.8:1988 .......................................................20 Metric Miniature Thread according to ISO 1501, DIN 14 .........................................................................21 Unified Miniature Thread UNM according to ANSI/ASME B1.10:2004 ........................................................22 BA Miniature Thread according to BS 93:2008 .......................................................................................22 B.S.C. Cycle-Thread according to B.S. 811:1950.....................................................................................23 Metric Buttress Thread 33 according to DIN 513:1985 ..........................................................................24 Metric Buttress Thread 45 according to DIN 2781:1990.........................................................................24 ASME Buttress Thread according to ASME B1.9:1973..............................................................................25 B.S. Buttress Thread according to BS 1657, ASME B1.9:1973 ..................................................................25 Knuckle Thread according to DIN 405:1997 ...........................................................................................26 Knuckle Thread with large depth according to DIN 20400:1990...............................................................26 Knuckle thread for lifting hooks according to DIN 15403:1969.................................................................26 Steel Conduit Thread (DIN 40430:1971)................................................................................................27 API Pipe Threads according to API Spec. 5B:2008 ..................................................................................27 STI Metric Thread according to DIN 8140, BS 4377, SAE MA1567............................................................28 STI Inch Thread UN, UNJ according to NASM 33537, BS 3409.................................................................29 STI Parallel Whitworth Thread according to ANSI/ASME BS 84:2007 ........................................................30 STI Parallel Pipe Thread according to ISO 228-1: 2003 ...........................................................................30 STI Taper Pipe Thread according to ISO 7-1:1994..................................................................................31 STI ANSI Pipe Threads according to ANSI B1.20.1, SAE AS71051:2008....................................................31 Non-standard and Special threads ........................................................................................................32

Threads and Gauges - User Manual

Introduction

The software product QMSys Threads and Gauges (QMSys Threads) is designed for engineers, quality control managers, mechanics, etc., with the purpose to save time and prevent human errors during the process of determining rated and boundary thread parameters. The program is especially useful in the manufacture and control of threaded products and tools by saving time and costs for calculations and supplying standards. The calculated results are based on international standards and comprise information about values and tolerances of threaded products, working gauges, plug and ring gauges, as well as check gauges. QMSys Threads and Gauges (QMSys Threads) software assists users in the following activities: Thread measurement and control determining the rated and limiting values of parameters of external and internal threads Inspection of working and check gauges determining the rated and limiting values of parameters of thread check gauges Product design selection of threaded joints The software comprises data base and methods for calculating the rated and limiting values of the following types of threads: Metric screw thread M, MJ Unified inch screw thread UN, UNR, UNJ Whitworth screw thread Metric miniature screw thread, unified miniature screw thread ISO, ANSI and API straight and taper pipe threads Metric and ACME trapezoidal threads Metric and ACME buttress screw threads Knuckle threads Steel conduit thread Gauges for non-standard and special threads Thread sizes which are not listed in the standards Automatic corrections for coatings, statistic and arithmetic tolerance computation For determining the pitch diameter during measurement by the 3 wire/ball method, the rated and limiting values of the outcome from measuring by the method described in the publication EA 10/10 are additionally calculated. Calculated results can be saved in a file or copied in another program. Note: All numerical values of tolerances and deviations relate to parts with dimensions specified at 20C.

Software Licensing

We deliver the QMSys Software installed and licensed on USB Memory stick. The advantages of this method are: - The software can be used on any computer, which the USB Memory stick is connected to. - Nothing will be installed on the computer. Therefore considerations for possible computer damages are not relevant. - You dont need to unlock the software for any computer. - In case you replace your computer, you dont need to reinstall the software. You can receive further information on our web site: www.qsyst.com. Free trial unlock keys QMSYS software is available as a free trial for 30 days. Upon expiration of the trial period, the user can open the software in demonstration mode only. You can request a trial unlock key by sending an email to sales@qsyst.com or qualisyst@qsyst.com, including your contact details (Name and Organization) and product names (or product license keys), and you will have the full version for a 30-day evaluation period.

Threads and Gauges - User Manual

Software description

The list of type of thread selection and standard for the computation of the gauges are in the upper range of the program window. The parameters for determining the thread are set in the Basic parameters window. Depending on the type of thread selected, different types of parameters are shown. The following data is positioned on separate pages: Additional parameters of the thread Basic profile and limit sizes of the workpiece Thread working gauges for checking threaded products Setting gauges Checking gauges or Hi-Lo setting plugs Tolerances, parameters for the computation of the gauges In the lower range of the window, the status line with the used units can be found.

Program menu and button bar

Calculation Calculation of thread parameters. Print Print of computed results. Copy Copy of thread parameters in the clipboard. [mm]-[in] Unit mm - inch switch. Settings Calls a window for setting the program. Figure Shows drawings from the relevant standards. Help Calls Help in the program. Exit An exit from the program Field for selection or entry of nominal size, pitch and other parameters. Selection of standard thread sizes.

Software settings New Enters a new diameter of wires, respectively balls. Delete Deletes a chosen line from the table.

Threads and Gauges - User Manual

Surface Finishing

Surface finishing is a broad range of industrial processes that alter the surface of a manufactured item to achieve a certain property. Finishing processes may be employed to: improve appearance, adhesion or wettability, solderability, corrosion resistance, chemical resistance, wear resistance, hardness. Following kinds of finishing are considered automatically in the computation: Adding or altering finishing change of the mass is positive. Examples: anodizing, electroplating, galvanizing Removing or reshaping finishing change of the mass is negative. Examples: polishing, electrochemical polishing, superfinishing Minimum and maximum plating thicknesses (change of the mass) are entered. The computation of the corrections can take place arithmetically or statistically. The most often method used is the arithmetic one, sometimes called the maximum - minimum calculation method. This method guarantees full assembly and working interchangeability of components. However, due to the demand of higher accuracy of the closed component, it results in too limited tolerances of partial components and therefore high manufacturing costs. The arithmetic method is therefore suitable for calculating dimensional circuits with a small number of components or in case that broader tolerance of the resulting dimension is acceptable. It is most often used in piece or small-lot production. Statistical methods of calculation of dimensional chains are based on the calculus of probability. These methods assume that in a random selection of components during assembly, the limit values of deviations occur with more partial components simultaneously rarely, as is the case of combined probability. The probability of the occurrence of limit value of deviations in manufacturing individual dimensions on one component will be similarly small. With a certain, pre-selected risk of rejection of some components, the tolerances of partial components in the dimensional chain can be increased. The statistical method guarantees only partial assembly interchangeability, with a low percentage of unfavourable cases (spoilage). With respect to larger tolerances of partial dimensions, however, it results in a decrease in manufacturing costs. It is mainly used in mass and large-lot production, where savings in manufacturing costs outbalance increased assembly and operating costs resulting from incomplete assembly interchangeability of components. Example: Thread M10x1,5 6g and coating thickness 0,05-0,06mm, 0,05-0,07mm and 0,05-0,08mm. Tolerance for: Pitch diameter after plating Major diameter after plating Plating Pitch diameter before plating Major diameter before plating Arithm. Method Stat. Method Arithm. Stat. Method Method 0,132 mm 0,236 mm 0,01 mm 0,092 mm 0,126 mm 0,216 mm 0,235 mm 0,02 mm 0,052 mm 0,105 mm 0,196 mm 0,233 mm 0,03 mm 0,012 mm 0,055 mm 0,176 mm 0,228 mm Arithm. Method Stat. Method

Pitch Diameter Measuring over Wires or Balls

Indicated values and pitch diameters are determined using measuring wires or balls by Berndts iteration formula from the publication "EA10/10, Guidelines on the Determination of Pitch Diameter of Parallel Thread Gauges by Mechanical Probing". The program calculates automatically the optimum diameter of wires/balls and offers a suitable probing element from the catalogue. When the probing element catalogue is not complete, the optimum diameter of wires/balls is offered. When it is necessary, another value of the diameter of wires/balls can be selected or entered. The measuring force is entered when it is known. When the check values of the pitch diameter are calculated, the deformation due to the measuring force is also taken into consideration. 5

Threads and Gauges - User Manual

Software Application

1. Select the standard for calculation of threaded products and gauges. 2. Enter nominal size and pitch or TPI. The software offers selection of thread sizes which are listed in the standards. 3. Select or enter the additional parameters: Number of grooves for multi-start thread Denotation for left-hand thread Tolerance of the external thread Tolerance of the internal thread Length of thread engagement Plating

4. With the key "Calculation", the thread workpieces and the screw gauges are computed. 5. Calculated results can be saved in a file or copied in another program. Although the software is easy to use, we would like to emphasize on the fact that it is necessary to possess a good knowledge of the concerned standards and procedures for measuring and calculating screw threads in order to interpret the results.

Software Settings

Program settings comprise: Decimal places - number of right-of-comma positions Statistical computation of the corrections for coating Specification of non-standard and special threads Material of the ball probing elements Selection of method for the pitch diameter measurement perpendicular to the thread axis (3wires/balls) or inclined towards the thread axis (2 wires/balls) Diameters of the set of measurement wires Diameters of the set of ball probing elements

Threads and Gauges - User Manual

Printout, Templates

Printout in the program is made by configurable templates in text format (*.RTF, *.TXT) with coded fields, e.g. $FA01#. Types of coded fields $FA01# - individual field $C0118# - field name The user can provide or adapt the report by using the codings of the fields from the standard report. The RTF - template can contain pictures (e.g. Company Logo). The following rules must be however fulfilled: The marking of a field consists of: " $" + " Fieldname" + " #" Coded fields must be with the same font - e.g. $FA01# is correct, $FA01# is wrong. The sequence of the individual fields or tables can be changed. Print options The dialog window can be called through menu "Edit \ Print \ Templates. Templates are adjusted separately for each thread. In the field Name" enter the designation of the report, in the field "File" select the template file. Several templates per thread type can be selected. Add template Delete template Set template as default Open template Standard template Standard template Standard template Selection of file for new template. Deletes the setting for the selected template; the file will be not deleted. Marks the selected template as default. Opens the selected template for redaction. Opens the standard template with all coded fields; field names are shown with code and text. Opens the standard template with all coded fields; field names are shown with text. Opens the standard template with all coded fields; field names are shown with code.

Threads and Gauges - User Manual

Metric Thread according to ISO 68-1, ISO 965-1, DIN 13, ASME 1.13M Metric Thread MJ-Profile according to ISO 5855-1:1999 Metric Thread with large clearance according to DIN 2510-2:1971 Metric galvanized Thread according to ISO 965-4, to ISO 965-5

Basic parameters Input of the thread parameters select a standard thread according to ISO 261:1999, ISO 5855-1:1999 or DIN 2510 select a major diameter and pitch according to ISO 261:1998, for diameters from 300 mm to 1000 mm, DIN 13 up to 3rd row it is necessary to take into account the recommendations of the standards how to select the pitch depending on the nominal size option for entering a non-standardized thread from 1 up to 1000 [mm] enter the number of grooves for multi-start thread denotation for left-hand thread The lead of the thread and the normal length of engagement are determined automatically. Additional parameters Thread tolerances tolerance of the pitch diameter and the major diameter of the external thread tolerance of the pitch diameter and the minor diameter of the internal thread option for specifying non-standardized tolerances select a basic deviation and enter the tolerance in [m] The program sets the standard tolerances by default: M-Profile External thread Internal thread MJ-Profile External thread Internal thread Pitch diameter 4h 4H Major diameter 6h Minor diameter D<= 5mm - 6H D> 5mm - 5H Major diameter up to 1,4 mm 6h 5H Major diameter over 1,4 mm 6g 6H

Metric Thread with large clearance Pitch diameter External thread 6e mod. Internal thread 6H Metric galvanized Thread ISO 965-4 External thread 6az Internal thread 6H

Major diameter 6e mod. -

Minor diameter 6H

ISO 965-4 6h 6AZ

Length of thread engagement Select the denotation of the length of engagement for external and internal thread S small length N normal length L large length The limit values for the length of engagement N" are represented within the upper range of the window.

Threads and Gauges - User Manual

Gauges according to 1502:1996 Working gauges GO Screw ring and snap gauge NOT GO Screw ring and snap gauge GO Screw plug gauge NOT GO Screw plug gauge GO Ring and snap gauge for major diameter NOT GO Ring and snap gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Note: For adjustable ring and snap gauges the limit values are not fixed for the pitch diameter, since the screw gauge is adjusted with its setting plugs. Setting gauges Setting plug for GO Screw ring gauge Setting plug for NOT GO Screw ring gauge Setting plug for GO Screw snap gauge Setting plug for NOT GO Screw snap gauge Thread setting plug for indicating gauges according to DIN 2241:2005 Thread setting ring for indicating gauges according to DIN 2241:2005 Checking gauges GO Checking plug for GO Screw ring gauge NOT GO Checking plug for GO Screw ring gauge Wear Checking plug for GO Screw ring gauge GO Checking plug for NOT GO Screw ring gauge NOT GO Checking plug for NOT GO Screw ring gauge Wear Checking plug for NOT GO Screw ring gauge GO Checking plug for GO Ring gauge for minor diameter NOT GO Checking plug for NOT GO Ring gauge for minor diameter Wear Checking plug for GO Ring gauge for minor diameter Gauges according to ANSI/ASME B1.16M:1984 Working gauges GO Screw ring and snap gauge - X and W gauge tolerances NOT GO Screw ring and snap gauge - X and W gauge tolerances GO Screw plug gauge - X and W gauge tolerances NOT GO Screw plug gauge - X and W gauge tolerances GO Ring gauge for major diameter - Z gauge tolerance NOT GO Ring gauge for major diameter - Z gauge tolerance GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance Setting gauges Setting plug for GO Screw ring gauge - X and W gauge tolerances Setting plug for NOT GO Screw ring gauge - X and W gauge tolerances GO Thread setting ring for indicating gauges - W gauge tolerance NOT GO Thread setting ring for indicating gauges - W gauge tolerance Hi-Lo setting plugs Hi-Lo setting plug Hi-Lo setting plug Hi-Lo setting plug Hi-Lo setting plug for for for for GO Screw ring gauge X tolerance GO Screw ring gauge W tolerance NOT GO Screw ring gauge X tolerance NOT GO Screw ring gauge W tolerance

Threads and Gauges - User Manual

Unified Thread UN, UNR according to ANSI/ASME B1.1:2003 Unified Thread UNJ-Profile according to ASME B1.15:1995

Basic parameters Input of the thread parameters select a standard thread according to ANSI/ASME B1.1:2003, ASME B1.15:1995 select a major diameter and TPI according to ANSI/ASME B1.1:2003 option for entering a non-standardized thread from 0,06 up to 40 [in] enter the number of grooves for multi-start thread denotation for left-hand thread The pitch, the lead and the normal length of engagement of the thread are determined automatically. Additional parameters Thread tolerances tolerance of the external thread tolerance of the internal thread The program sets the standard tolerances by default: UN, UNR UNJ External thread 2A 3A Internal thread 2B 3B Length of thread engagement The UN thread form specification uses "length of engagement" as a parameter in determining the tolerance of pitch diameters. The limit values for normal length of engagement are represented within the upper range of the window. Gauges according to ANSI/ASME B1.2:1983 Working gauges GO Screw ring and snap gauge - X and W gauge tolerances NOT GO Screw ring and snap gauge - X and W gauge tolerances GO Screw plug gauge - X and W gauge tolerances NOT GO Screw plug gauge - X and W gauge tolerances GO Ring gauge for major diameter - Z gauge tolerance NOT GO Ring gauge for major diameter - Z gauge tolerance GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance Setting gauges Setting plug for GO Screw ring gauge - X and W gauge tolerances Setting plug for NOT GO Screw ring gauge - X and W gauge tolerances GO Thread setting ring for indicating gauges - W gauge tolerance NOT GO Thread setting ring for indicating gauges - W gauge tolerance Hi-Lo setting plugs Hi-Lo setting plug for GO Screw ring gauges X and W tolerance Hi-Lo setting plug for NOT GO Screw ring gauges X and W tolerance Gauges according to ISO 1502:1996 Working gauges GO Screw ring and snap gauge NOT GO Screw ring and snap gauge GO Screw plug gauge NOT GO Screw plug gauge GO Ring and snap gauge for major diameter NOT GO Ring and snap gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter

10

Threads and Gauges - User Manual

Setting gauges Setting plug for GO Screw ring gauge Setting plug for NOT GO Screw ring gauge Setting plug for GO Screw snap gauge Setting plug for NOT GO Screw snap gauge Thread setting plug for indicating gauges according to DIN 2241:2005 Thread setting ring for indicating gauges according to DIN 2241:2005 Checking gauges GO Checking plug for GO Screw ring gauge NOT GO Checking plug for GO Screw ring gauge Wear Checking plug for GO Screw ring gauge GO Checking plug for NOT GO Screw ring gauge NOT GO Checking plug for NOT GO Screw ring gauge Wear Checking plug for NOT GO Screw ring gauge GO Checking plug for GO Ring gauge for major diameter NOT GO Checking plug for NOT GO Ring gauge for major diameter Wear Checking plug for GO Ring gauge for major diameter Gauges according to BS 919-1:2007 Working gauges Solid GO Screw ring gauge Solid NOT GO Screw ring gauge Adjustable GO Screw ring and snap gauge Adjustable NOT GO Screw ring and snap gauge GO Screw plug gauge NOT GO Screw plug gauge - low addendum NOT GO Screw plug gauge - high addendum GO Ring and snap gauge for major diameter NOT GO Ring and snap gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Note: For adjustable ring and snap gauges the limit values are not fixed for the pitch diameter, since the screw gauge is adjusted with its setting plugs. Setting gauges Setting plug Setting plug Setting plug Setting plug for for for for GO Screw ring gauge NOT GO Screw ring gauge GO Screw snap gauge NOT GO Screw snap gauge

Checking gauges GO Checking plug for GO Screw ring gauge NOT GO Checking plug for GO Screw ring gauge Wear Checking plug for GO Screw ring gauge GO Checking plug for NOT GO Screw ring gauge NOT GO Checking plug for NOT GO Screw ring gauge GO Checking plug for GO Ring gauge for minor diameter NOT GO Checking plug for GO Ring gauge for minor diameter GO Checking plug for NOT GO Ring gauge for minor diameter NOT GO Checking plug for NOT GO Ring gauge for minor diameter

11

Threads and Gauges - User Manual

Parallel Whitworth Thread according to BS 84:2007

Basic parameters Input of the thread parameters select a standard thread according to BS 84:2007 select a TPI according to BS 84:2007 option for entering a non-standardized thread from 0,06 up to 40 [in] enter the number of grooves for multi-start thread denotation for left-hand thread The pitch, the lead and the normal length of engagement of the thread are determined automatically. Additional parameters Thread tolerances tolerance of the external thread - "medium" by default tolerance of the internal thread - "medium" by default option for truncated form threads with flat crests Gauges according to BS 919-2:2007 Working gauges GO Screw ring gauge - General for tolerances "medium" and "free", Reference for tolerance "close" NOT GO Screw ring gauge GO Screw calliper gauge - General for tolerances "medium" and "free", Reference for tolerance "close" NOT GO Screw calliper gauge GO Screw plug gauge - General for tolerances "medium" and "normal", Reference for tolerance "close" NOT GO Screw plug gauge GO Ring gauge for major diameter NOT GO Ring gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Setting gauges Setting plug for GO Screw ring and calliper gauges Setting plug for NOT GO Screw ring and calliper gauges Reference gauges Reference GO Screw plug gauge Reference setting plug for GO Screw ring and calliper gauges

12

Threads and Gauges - User Manual

Class 5 interference-fit thread according to ANSI/ASME B1.12:1987

Basic parameters Input of the thread parameters select a standard thread according to ANSI/ASME B1.12:1987 type of thread materials denotation for left-hand thread Thread materials HF External thread, hard ferrous material with Brinell hardness over 160 HB CSF External thread, copper alloy and soft ferrous material with Brinell hardness of 160 HB or less NF External thread, nonferrous material IF Internal thread, ferrous material INF Internal thread, nonferrous material Gauges according to ANSI/ASME B1.12:1987 Working gauges GO Screw ring and snap gauge - X tolerance NOT GO Screw ring and snap gauge - X tolerance GO Screw plug gauge - X tolerance NOT GO Screw plug gauge - X tolerance GO Ring gauge for major diameter - Z gauge tolerance NOT GO Ring gauge for major diameter - Z gauge tolerance GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance Setting gauges Setting plug for GO Screw ring gauge - W gauge tolerance Setting plug for NOT GO Screw ring gauge - W gauge tolerance GO Thread setting ring for indicating gauges - W gauge tolerance NOT GO Thread setting ring for indicating gauges - W gauge tolerance

13

Threads and Gauges - User Manual

Parallel Pipe Thread according to ISO 228-1: 2003

Basic parameters The defining parameters of pipe thread according to ISO 228-1:2003 are: nominal size of the thread denotation for left-hand thread The number of threads per inch and the pitch are automatically determined. Additional parameters Thread tolerances select the tolerance class of the external thread it is "A" by default Gauges according to ISO 228-2:1987 Working gauges GO Screw ring gauge NOT GO Screw ring gauge GO Screw plug gauge NOT GO Screw plug gauge Checking gauges GO Checking plug for GO Screw ring gauge NOT GO Checking plug for GO Screw ring gauge Wear Checking plug for GO Screw ring gauge GO Checking plug for NOT GO Screw ring gauge NOT GO Checking plug for NOT GO Screw ring gauge Wear Checking plug for NOT GO Screw ring gauge

14

Threads and Gauges - User Manual

Taper Pipe Thread according to ISO 7-1:1994

Basic parameters The defining parameters of pipe thread according to ISO 7-1994 are: nominal size of the thread denotation for left-hand thread The number of threads per inch and the pitch are automatically determined. Additional parameters Type of internal thread Rp - parallel internal thread Rc - taper internal thread. Gauges according to ISO 7-2:2000, EN 10266-3:2005 Working gauges Taper full form threaded plug gauge (Gauge No. 1) Taper full form threaded plug gauge with relief (Gauge No. 2) Parallel full form threaded ring gauge (Gauge No. 3) Taper plain ring gauge (Gauge No. 4) Checking gauges Taper modified thread form check plug gauge (Gauge No. 5) Parallel modified thread form check ring gauge (Gauge No. 6) Gauges according to DIN 2999 Working gauges Cylindrical GO/NOT-GO Screw ring gauge Tapered GO/NOT-GO Screw plug gauge Checking gauges Tapered checking screw plug gauge Gauges according to BS 21:1985 Working gauges, System A Tapered GO/NOT-GO Screw ring gauge Tapered GO/NOT-GO Screw plug gauge Working gauges, System B Tapered GO/NOT-GO Screw ring gauge Tapered GO/NOT-GO Screw plug gauge Tapered GO/NOT-GO Plain ring gauge Tapered GO/NOT-GO Plain plug gauge

15

Threads and Gauges - User Manual

ANSI Pipe Threads according to ANSI B1.20.1, ANSI B1.20.3, ANSI B1.20.5, ANSI B1.20.7, NFPA 1963

Basic parameters The defining parameters of pipe thread according to ANSI B1.20.1, ANSI B1.20.3, ANSI B1.20.5, ANSI B1.20.7, NFPA 1963 are: nominal size of the thread denotation for left-hand thread The number of threads per inch and the pitch are automatically determined. NPT, NPSC, NPTR general pipe thread, Gauges according to ANSI/ASME B1.20.1 Working gauges Taper threaded plug gauge Taper threaded ring gauge Master gauges Taper threaded check plug gauge Taper threaded check ring gauge NPSM, NPSL general pipe thread, Gauges according to ANSI/ASME B1.2 Working gauges GO Screw ring and snap gauge - X and W gauge tolerances NOT GO Screw ring and snap gauge - X and W gauge tolerances GO Screw plug gauge - X and W gauge tolerances NOT GO Screw plug gauge - X and W gauge tolerances GO Ring gauge for major diameter - Z gauge tolerance NOT GO Ring gauge for major diameter - Z gauge tolerance GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance Setting gauges Setting plug for GO Screw ring gauge - X and W gauge tolerances Setting plug for NOT GO Screw ring gauge - X and W gauge tolerances Thread setting plug for indicating gauges - W gauge tolerance Thread setting ring for indicating gauges - W gauge tolerance NPTF, F-PTF Dryseal pipe thread, Gauges according to ANSI/ASME B1.20.5 Working gauges L1 Taper thread plug gauge - basic step, 3 and 4 step L3 Taper thread plug gauge - basic step, 3 and 4 step Crest check plug gauge 6 step Root check plug gauge 6 step L1 Taper thread ring gauge - basic step, 3 and 4 step L2 Taper thread ring gauge - basic step, 3 and 4 step Crest check ring gauge 6 step Root check ring gauge 6 step Master gauges Master plug gauge for L1 and L2 working ring gauges Master ring gauge for L1 and L3 working plug gauges Master plug gauge for 6-step working crest ring gauge Master plug gauge for 6-step working root ring gauge Master ring gauge for 6-step working crest plug gauge Master ring gauge for 6-step working root plug gauge

16

Threads and Gauges - User Manual

PTF-SAE Short Dryseal pipe thread, Gauges according to ANSI/ASME B1.20.5 Working gauges L1 Short Taper L3 Short Taper L1 Short Taper L2 Short Taper thread thread thread thread plug gauge - 3 step plug gauge - 3 step ring gauge - 3 step ring gauge - 3 step

Master gauges Master plug gauge for L1 and L2 working ring gauges Master ring gauge for L1 and L3 working plug gauges NPSF, NPSI Dryseal pipe thread, Gauges according to ANSI/ASME B1.20.5 Working gauges NPSF L1 Short Taper thread plug gauge - 3 step NPSI L1 Taper thread plug gauge - 3 step Master gauges Master plug gauge for L1 and L2 working ring gauges Master ring gauge for L1 and L3 working plug gauges NPSH, NH Hose coupling thread, Gauges according to ANSI/ASME B1.20.5, ANSI/ASME B1.2 Working gauges GO Screw ring and snap gauge - X gauge tolerances NOT GO Screw ring and snap gauge - X gauge tolerances GO Screw plug gauge - X gauge tolerances NOT GO Screw plug gauge - X gauge tolerances GO Ring gauge for major diameter - Z gauge tolerance NOT GO Ring gauge for major diameter - Z gauge tolerance GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance Setting gauges Setting plug for GO Screw ring gauge - X gauge tolerances Setting plug for NOT GO Screw ring gauge - X gauge tolerances NFPA Fire-hose coupling thread, Gauges according to NFPA 1963, ANSI/ASME B1.2 Working gauges GO Screw ring and snap gauge - X gauge tolerances NOT GO Screw ring and snap gauge - X gauge tolerances GO Screw plug gauge - X gauge tolerances NOT GO Screw plug gauge - X gauge tolerances GO Ring gauge for major diameter - Z gauge tolerance NOT GO Ring gauge for major diameter - Z gauge tolerance GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance Setting gauges Setting plug for GO Screw ring gauge - X gauge tolerances Setting plug for NOT GO Screw ring gauge - X gauge tolerances

17

Threads and Gauges - User Manual

ANSI Aeronautical pipe threads according to SAE AS71051:2008

Basic parameters The defining parameters of pipe thread according to SAE AS71051, MIL-P-7105B are: nominal size of the thread denotation for left-hand thread The number of threads per inch and the pitch are automatically determined. Working gauges L1 Taper thread plug gauge - 3 step L3 Taper thread plug gauge - 3 step Crest check plug gauge 6 step L1 Taper thread ring gauge - 3 step L2 Taper thread ring gauge - 3 step Crest check ring gauge 6 step

18

Threads and Gauges - User Manual

ISO Trapezoidal Thread according to ISO 2901:1993, DIN 103-1:1993 ISO Stub Metric Trapezoidal Thread according to DIN 380:1995

Basic parameters Input of the thread parameters select a standard thread according to ISO 2901:1993 or DIN 380:1995 select a major diameter and a pitch according to ISO 2901:1993 it is necessary to take into account the recommendations of the standards how to select the pitch depending on the nominal size option for entering a non-standardized thread from 1 up to 1000 [mm] enter the number of grooves for multi-start thread The lead of the thread and the normal length of engagement are determined automatically. Additional parameters Thread tolerances tolerance of the pitch diameter and the minor diameter of the external thread tolerance of the pitch diameter of the internal thread option for specifying non-standardized tolerances select a basic deviation and enter the tolerance in [m] The program sets the standard tolerances by default: Pitch diameter Major diameter Minor diameter External thread 7e 4h 7h Internal thread 7H 4H

Length of thread engagement Select the denotation of the length of engagement for external and internal thread N normal length L large length The limit values for length of engagement N" are represented within the upper range of the window. Gauges according to DIN 103:1993 Working gauges GO Screw ring and snap gauge NOT GO Screw ring and snap gauge GO Screw plug gauge NOT GO Screw plug gauge GO Ring and snap gauge for major diameter NOT GO Ring and snap gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Note: For adjustable ring and snap gauges the limit values are not fixed for the pitch diameter, since the screw gauge is adjusted with its setting plugs. Setting gauges Setting plug for GO Screw snap gauge Setting plug for NOT GO Screw snap gauge Checking gauges GO Checking plug for GO Screw ring gauge NOT GO Checking plug for GO Screw ring gauge Wear Checking plug for GO Screw ring gauge GO Checking plug for NOT GO Screw ring gauge NOT GO Checking plug for NOT GO Screw ring gauge Wear Checking plug for NOT GO Screw ring gauge

19

Threads and Gauges - User Manual

ACME Trapezoidal Thread according to ANSI/ASME B1.5:1997 ACME STUB Trapezoidal Thread according to ANSI/ASME B1.8:1988

Basic parameters Input of the thread parameters select a standard thread according to ANSI/ASME B1.5:1997 or ANSI/ASME B1.8:1988 select a major diameter and a TPI according to ANSI/ASME B1.5:1997 option for entering a non-standardized thread from 0,06 up to 40 [in] enter the number of grooves for multi-start thread denotation for left-hand thread The lead of the thread and the normal length of engagement are determined automatically. Additional parameters Thread tolerances application of ACME thread (General Purpose, Centralizing) profile of STUB ACME thread (Standard, Modified Form 1, Modified Form 2) tolerance of the external thread tolerance of the internal thread The program sets the standard tolerances by default: ACME - General Purpose ACME - Centralizing STUB ACME thread 2G 2C (5C) 2G Length of thread engagement The ACME thread form specification uses "length of engagement" as a parameter in determining the allowance of pitch diameters. The limit value for normal length of engagement is represented within the upper range of the window. Gauges for ACME - General Purpose and STUB ACME threads Working gauges GO Screw ring and snap gauge NOT GO Screw ring and snap gauge GO Screw plug gauge NOT GO Screw plug gauge GO Ring and snap gauge for major diameter NOT GO Ring and snap gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Setting gauges Setting plug for GO Screw snap gauge Setting plug for NOT GO Screw snap gauge Gauges for ACME - Centralizing threads Working gauges GO Screw ring and snap gauge NOT GO Screw ring and snap gauge GO Screw plug gauge for Pitch diameter NOT GO Screw plug gauge for Pitch diameter GO Screw plug gauge for Major diameter NOT GO Screw plug gauge for Major diameter GO Ring and snap gauge for major diameter NOT GO Ring and snap gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Setting gauges Setting plug for GO Screw snap gauge Setting plug for NOT GO Screw snap gauge

20

Threads and Gauges - User Manual

Metric Miniature Thread according to ISO 1501, DIN 14

Basic parameters Input of the thread parameters select the major diameter and pitch according to ISO/R 1501, DIN 14 Additional parameters Thread tolerances tolerance of the pitch diameter and the minor diameter of the internal thread The program sets the standard tolerances 4H 5H by default. Length of thread engagement Select the denotation of the length of engagement for external and internal thread S small length N normal length L large length The limit values for the length of engagement N" are represented within the upper range of the window. Gauges according to 1502:1996 Working gauges GO Screw ring and snap gauge NOT GO Screw ring and snap gauge GO Screw plug gauge NOT GO Screw plug gauge GO Ring and snap gauge for major diameter NOT GO Ring and snap gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Note: For adjustable ring and snap gauges the limit values are not fixed for the pitch diameter, since the screw gauge is adjusted with its setting plugs. Gauges according to ANSI/ASME B1.16M:1984 Working gauges GO Screw ring and snap gauge - X and W gauge tolerances NOT GO Screw ring and snap gauge - X and W gauge tolerances GO Screw plug gauge - X and W gauge tolerances NOT GO Screw plug gauge - X and W gauge tolerances GO Ring gauge for major diameter - Z gauge tolerance NOT GO Ring gauge for major diameter - Z gauge tolerance GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance

21

Threads and Gauges - User Manual

Unified Miniature Thread UNM according to ANSI/ASME B1.10:2004

Basic parameters Input of the thread parameters select a major diameter and pitch according to ANSI/ASME B1.10:2004 The number of threads per inch and the normal length of engagement of the thread are determined automatically. Additional parameters Length of thread engagement The limit values for the normal length of engagement are represented within the upper range of the window. Gauges according to ANSI/ASME B1.16M:1984 Working gauges GO Screw plug gauge - X and W gauge tolerances NOT GO Screw plug gauge - X and W gauge tolerances GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance Gauges according to 1502:1996 Working gauges GO Screw plug gauge NOT GO Screw plug gauge GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter

BA Miniature Thread according to BS 93:2008

Basic parameters Input of the thread parameters select a major diameter according to BS 93:2008 The number of threads per inch and the pitch are determined automatically. Gauges according to BS 919-2:2007 Working gauges GO Screw ring gauge NOT GO Screw ring gauge GO Screw calliper gauge NOT GO Screw calliper gauge GO Screw plug gauge NOT GO Screw plug gauge GO Ring gauge for major diameter NOT GO Ring gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Setting gauges Setting plug for GO Screw ring and calliper gauges Setting plug for NOT GO Screw ring and calliper gauges Reference gauges Reference GO Screw plug gauge Reference setting plug for GO Screw ring and calliper gauges

22

Threads and Gauges - User Manual

B.S.C. Cycle-Thread according to B.S. 811:1950

Basic parameters The defining parameters of pipe thread according to B.S. 811 are: thread type nominal size of the thread Thread types according to B.S. 811: Bolts and nuts Spokes and nupples Special applications The number of threads per inch and the pitch are automatically determined. Additional parameters Thread tolerances tolerance of the external thread - "medium" by default tolerance of the internal thread - "medium" by default Gauges according to BS 919-2:2007 Working gauges GO Screw ring gauge - General for tolerances "medium" and "free", Reference for tolerance "close" NOT GO Screw ring gauge GO Screw calliper gauge - General for tolerances "medium" and "free", Reference for tolerance "close" NOT GO Screw calliper gauge GO Screw plug gauge - General for tolerances "medium" and "normal", Reference for tolerance "close" NOT GO Screw plug gauge GO Ring gauge for major diameter NOT GO Ring gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Setting gauges Setting plug for GO Screw ring and calliper gauges Setting plug for NOT GO Screw ring and calliper gauges Reference gauges Reference GO Screw plug gauge Reference setting plug for GO Screw ring and calliper gauges

23

Threads and Gauges - User Manual

Metric Buttress Thread 33 according to DIN 513:1985 Metric Buttress Thread 45 according to DIN 2781:1990

Basic parameters Input of the thread parameters select a standard thread according to DIN 513-2:1985 or DIN 2781:1990 select a major diameter and a pitch according to DIN 513-2:1985 or DIN 2781:1990 it is necessary to take into account the recommendations of the standards how to select the pitch depending on the nominal size option for entering a non-standardized thread from 1 up to 1250 [mm] enter the number of grooves for multi-start thread The lead of the thread and the normal length of engagement are determined automatically. Additional parameters Thread tolerances tolerance of the pitch diameter and the minor diameter of the external thread tolerance of the pitch diameter of the internal thread The program sets the standard tolerances by default: Metric Buttress thread according to DIN 513:1985 Pitch diameter Major diameter Minor diameter External thread 7e h9 (ISO 286-2) 7h Internal thread 7H H10 (ISO 286-2) 4H Metric Buttress thread according to DIN 513:1985 Pitch diameter Major diameter Minor diameter External thread 7e e8 (ISO 286-2) 7h Internal thread 7H H8 (ISO 286-2) 4H Length of thread engagement Select the denotation of the length of engagement for external and internal thread N normal length L large length The limit values for length of engagement N" are represented within the upper range of the window. Gauges according to ISO 1502:1996 or DIN 103:1993 Working gauges GO Screw ring and snap gauge NOT GO Screw ring and snap gauge GO Screw plug gauge NOT GO Screw plug gauge GO Ring and snap gauge for major diameter NOT GO Ring and snap gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Note: For adjustable ring and snap gauges the limit values are not fixed for the pitch diameter, since the screw gauge is adjusted with its setting plugs. Setting gauges Setting plug for GO Screw snap gauge Setting plug for NOT GO Screw snap gauge Checking gauges GO Checking plug for GO Screw ring gauge NOT GO Checking plug for GO Screw ring gauge Wear Checking plug for GO Screw ring gauge GO Checking plug for NOT GO Screw ring gauge NOT GO Checking plug for NOT GO Screw ring gauge Wear Checking plug for NOT GO Screw ring gauge

24

Threads and Gauges - User Manual

ASME Buttress Thread according to ASME B1.9:1973 B.S. Buttress Thread according to BS 1657, ASME B1.9:1973

Basic parameters Input of the thread parameters select a standard thread according to ASME B1.9 ASME profile with thread engagement height 0.6P or B.S. profile with thread engagement height 0.4P option for entering a non-standardized thread from 0,06 up to 40 [in] enter the number of grooves for multi-start thread denotation for left-hand thread The pitch, the lead and the normal length of engagement of the thread are determined automatically. Additional parameters Thread tolerances tolerance of the external thread tolerance of the internal thread The program sets the standard tolerances by default: ASME profile B.S. profile External thread 2A medium Internal thread 2B medium Length of thread engagement The UN thread form specification uses "length of engagement" as a parameter in determining the tolerance of pitch diameters. The limit values for normal length of engagement are represented within the upper range of the window. Gauges according to ASME B1.9:1973 Working gauges GO Screw ring and snap gauge - X gauge tolerances NOT GO Screw ring and snap gauge - X gauge tolerances GO Screw plug gauge - X gauge tolerances NOT GO Screw plug gauge - X gauge tolerances GO Ring gauge for major diameter - Z gauge tolerance NOT GO Ring gauge for major diameter - Z gauge tolerance GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance Setting gauges Setting plug for GO Screw ring gauge - W gauge tolerances Setting plug for NOT GO Screw ring gauge - W gauge tolerances

25

Threads and Gauges - User Manual

Knuckle Thread according to DIN 405:1997 Knuckle Thread with large depth according to DIN 20400:1990 Knuckle thread for lifting hooks according to DIN 15403:1969

Basic parameters Input of the thread parameters select standard thread according to DIN 405-1, DIN 20400 or DIN 15403 select major diameter and TPI (pitch) according to DIN 405-1, DIN 20400 or DIN 15403 option for entering of a non-standardized thread from 1 up to 1000 [mm] enter number of grooves for multi-start thread denotation for left-hand thread The lead of the thread and the normal length of engagement are determined automatically. Additional parameters Thread tolerances according to DIN 405-1:1997 tolerance of the pitch and major diameter of external thread tolerance of the pitch and minor diameter of internal thread The program sets the standard tolerances by default: Pitch diameter Major diameter Minor diameter External thread 7h 6h 7h Internal thread 7H 6H Knuckle thread according to DIN 15403 Enter the maximum axial clearance; the diameter tolerance can be calculated arithmetically or statistically. Length of thread engagement Enter the length of engagement for external and internal thread. The limit values of the length of engagement N" are represented within the upper range of the window. Gauges according to DIN 405-3:1997 Working gauges GO Screw ring gauge NOT GO Screw ring gauge GO Screw plug gauge NOT GO Screw plug gauge GO Screw snap gauge for minor diameter of external thread NOT GO Screw snap gauge for minor diameter of external thread GO Screw plug gauge for major diameter of internal thread GO Ring and snap gauge for major diameter NOT GO Ring and snap gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Setting gauges for screw snap gauge for minor diameter of external thread Setting plug for GO Screw snap gauge Setting plug for NOT GO Screw snap gauge Checking gauges GO Checking plug for GO Screw ring gauge NOT GO Checking plug for GO Screw ring gauge Wear Checking plug for GO Screw ring gauge GO Checking plug for NOT GO Screw ring gauge NOT GO Checking plug for NOT GO Screw ring gauge Wear Checking plug for NOT GO Screw ring gauge GO Checking plug for GO Ring gauge for major diameter NOT GO Checking plug for NOT GO Ring gauge for major diameter Wear Checking plug for GO Ring gauge for major diameter

26

Threads and Gauges - User Manual

Steel Conduit Thread (DIN 40430:1971)

Basic parameters Input of the thread parameters select a standard thread according to DIN 40430:1971 The lead of the thread and the normal length of engagement are determined automatically. Gauges according to DIN 40431:1970 Working gauges GO Screw ring gauge GO Screw plug gauge NOT GO Ring and snap gauge for major diameter NOT GO Plug gauge for minor diameter

API Pipe Threads according to API Spec. 5B:2008

Basic parameters The defining parameters of pipe thread according to API Spec. 5B:2008 are: select the thread type select the nominal size of the thread Thread types according to API Spec. 5B:2008: LP - Line Pipe Thread CSG - Casing Short Round Thread LCSG - Casing Long Round Thread TBG - Non-upset Tubing Round Thread UP TBG - External-upset Tubing Round Thread UP LTBG - External-upset Long Tubing Round Thread IJ TBG - Integral Joint Tubing Round Thread BCSG - Casing Buttress Thread XCSG - Extreme-Line Casing Thread LTC - Enhanced Leak Resistance Thread The number of threads per inch and the pitch are automatically determined. Gauge parameter calculation Thread workpiece and the following screw gauge are automatically computed: Working gauges Taper threaded plug gauge Taper threaded ring gauge Master gauges Reference master plug gauge Reference master ring gauge

27

Threads and Gauges - User Manual

STI Metric Thread according to DIN 8140, BS 4377, SAE MA1567

Basic parameters Input of the thread parameters select a standard thread according to DIN 8140, BS 4377, SAE MA1567 enter a major diameter and a pitch of a non-standardized thread denotation for MJ-profile denotation for left-hand thread Additional parameters Length of thread engagement from 0.5d up to 3.0d Tolerance class 5H (4H5H), 6H (5H) or 6G (5G) Gauges according to 1502:1996 Working gauges GO Screw plug gauge NOT GO Screw plug gauge GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Setting gauges Thread setting ring for indicating gauges according to DIN 2241:2005 Gauges according to ANSI/ASME B1.16M:1984 Working gauges GO Screw plug gauge - X and W gauge tolerances NOT GO Screw plug gauge - X and W gauge tolerances GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance Setting gauges GO Thread setting ring for indicating gauges - W gauge tolerance NOT GO Thread setting ring for indicating gauges - W gauge tolerance

28

Threads and Gauges - User Manual

STI Inch Thread UN, UNJ according to NASM 33537, BS 3409

Basic parameters Input of the thread parameters select a standard thread according to NASM 33537, BS 3409 enter a major diameter and a pitch of a non-standardized thread denotation for UNJ-profile denotation for left-hand thread Additional parameters Length of thread engagement from 0.5d up to 3.0d Tolerance class 2B or 3B Gauges according to ANSI/ASME B1.2:1983 Working gauges GO Screw plug gauge - X and W gauge tolerances NOT GO Screw plug gauge - X and W gauge tolerances GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance Setting gauges GO Thread setting ring for indicating gauges - W gauge tolerance NOT GO Thread setting ring for indicating gauges - W gauge tolerance Gauges according to ISO 1502:1996 Working gauges GO Screw plug gauge NOT GO Screw plug gauge GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Setting gauges Thread setting ring for indicating gauges according to DIN 2241:2005 Gauges according to BS 919-1:2007 Working gauges GO Screw plug gauge NOT GO Screw plug gauge - low addendum NOT GO Screw plug gauge - high addendum GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter

29

Threads and Gauges - User Manual

STI Parallel Whitworth Thread according to ANSI/ASME BS 84:2007

Basic parameters Input of the thread parameters select a standard thread according to BS 84:2007 select a TPI according to BS 84:2007 option for entering non-standardized thread from 0,06 up to 40 [in] denotation for left-hand thread Pitch, lead and normal length of engagement of the thread are determined automatically. Additional parameters Thread tolerances Length of thread engagement from 0.5d up to 3.0d tolerance of the internal thread - "close" by default Gauges according to BS 919-2:2007 Working gauges GO Screw plug gauge - General for tolerance "medium" , Reference for tolerance "close" NOT GO Screw plug gauge GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Reference gauges Reference GO Screw plug gauge

STI Parallel Pipe Thread according to ISO 228-1: 2003

Basic parameters The defining parameters of pipe thread according to ISO 228-1:2003 are: select the nominal size of the thread denotation for left-hand thread The number of threads per inch and the pitch are automatically determined. Additional parameters Length of thread engagement from 0.5d up to 3.0d Gauges according to ISO 228-2:1987 Working gauges GO Screw plug gauge NOT GO Screw plug gauge

30

Threads and Gauges - User Manual

STI Taper Pipe Thread according to ISO 7-1:1994

Basic parameters The defining parameters of pipe thread according to ISO 7-1994 are: select the nominal size of the thread denotation for left-hand thread The number of threads per inch and the pitch are automatically determined. Additional parameters Length of thread engagement from 0.5d up to 3.0d Type of internal thread Rp - parallel internal thread Rc - taper internal thread. Gauges according to ISO 7-2:2000, EN 10266-3:2005 Working gauges Taper full form threaded plug gauge (Gauge No. 1) Taper full form threaded plug gauge with relief (Gauge No. 2) Gauges according to DIN 2999 Working gauges Tapered GO/NOT-GO Screw plug gauge Gauges according to BS 21:1985 Working gauges, System A Tapered GO/NOT-GO Screw plug gauge Working gauges, System B Tapered GO/NOT-GO Screw plug gauge Tapered GO/NOT-GO Plain plug gauge

STI ANSI Pipe Threads according to ANSI B1.20.1, SAE AS71051:2008

Basic parameters The defining parameters of pipe thread according to ANSI B1.20.1, SAE AS71051:2008 are: nominal size of the thread denotation for left-hand thread The number of threads per inch and the pitch are automatically determined. NPT, NPSC Working gauges Taper threaded plug gauge ANPT Working gauges L1 Taper thread plug gauge - 3 step L3 Taper thread plug gauge - 3 step

31

Threads and Gauges - User Manual

Non-standard and Special threads

Basic parameters Input of the thread parameters enter nominal size up to 1000 [mm]; 40 [in] , pitch or threads per inch option for entering of a nonstandardized thread from 1 enter number of grooves for multi-start thread Additional parameters Thread diameters and tolerances thread designation nominal and limit sizes of the major, pitch and minor diameter root and crest radius Gauges according to 1502:1996 Working gauges GO Screw ring and snap gauge NOT GO Screw ring and snap gauge GO Screw plug gauge NOT GO Screw plug gauge GO Ring and snap gauge for major diameter NOT GO Ring and snap gauge for major diameter GO Plug gauge for minor diameter NOT GO Plug gauge for minor diameter Note: For adjustable ring and snap gauges the limit values are not fixed for the pitch diameter, since the screw gauge is adjusted with its setting plugs. Setting gauges Setting plug for GO Screw ring gauge Setting plug for NOT GO Screw ring gauge Setting plug for GO Screw snap gauge Setting plug for NOT GO Screw snap gauge Thread setting plug for indicating gauges according to DIN 2241:2005 Thread setting ring for indicating gauges according to DIN 2241:2005 Checking gauges GO Checking plug for GO Screw ring gauge NOT GO Checking plug for GO Screw ring gauge Wear Checking plug for GO Screw ring gauge GO Checking plug for NOT GO Screw ring gauge NOT GO Checking plug for NOT GO Screw ring gauge Wear Checking plug for NOT GO Screw ring gauge GO Checking plug for GO Ring gauge for minor diameter NOT GO Checking plug for NOT GO Ring gauge for minor diameter Wear Checking plug for GO Ring gauge for minor diameter Gauges according to ANSI/ASME B1.16M:1984 Working gauges GO Screw ring and snap gauge - X and W gauge tolerances NOT GO Screw ring and snap gauge - X and W gauge tolerances GO Screw plug gauge - X and W gauge tolerances NOT GO Screw plug gauge - X and W gauge tolerances GO Ring gauge for major diameter - Z gauge tolerance NOT GO Ring gauge for major diameter - Z gauge tolerance GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance

32

Threads and Gauges - User Manual

Setting gauges Setting plug for GO Screw ring gauge - X and W gauge tolerances Setting plug for NOT GO Screw ring gauge - X and W gauge tolerances GO Thread setting ring for indicating gauges - W gauge tolerance NOT GO Thread setting ring for indicating gauges - W gauge tolerance Hi-Lo setting plugs Hi-Lo setting plug Hi-Lo setting plug Hi-Lo setting plug Hi-Lo setting plug for for for for GO Screw ring gauge X tolerance GO Screw ring gauge W tolerance NOT GO Screw ring gauge X tolerance NOT GO Screw ring gauge W tolerance

Gauges according to ANSI/ASME B1.2:1983 Working gauges GO Screw ring and snap gauge - X and W gauge tolerances NOT GO Screw ring and snap gauge - X and W gauge tolerances GO Screw plug gauge - X and W gauge tolerances NOT GO Screw plug gauge - X and W gauge tolerances GO Ring gauge for major diameter - Z gauge tolerance NOT GO Ring gauge for major diameter - Z gauge tolerance GO Plug gauge for minor diameter - Z gauge tolerance NOT GO Plug gauge for minor diameter - Z gauge tolerance Setting gauges Setting plug for GO Screw ring gauge - X and W gauge tolerances Setting plug for NOT GO Screw ring gauge - X and W gauge tolerances GO Thread setting ring for indicating gauges - W gauge tolerance NOT GO Thread setting ring for indicating gauges - W gauge tolerance Hi-Lo setting plugs Hi-Lo setting plug for GO Screw ring gauges X and W tolerance Hi-Lo setting plug for NOT GO Screw ring gauges X and W tolerance

33

You might also like

- Amca 803 PDFDocument98 pagesAmca 803 PDFVILLANUEVA_DANIEL2064No ratings yet

- Precision Gage Solutions: Thread Check IncDocument51 pagesPrecision Gage Solutions: Thread Check IncAngel Alvarez CarrilloNo ratings yet

- Asme B1.3-2007 (2017)Document24 pagesAsme B1.3-2007 (2017)jamie courney100% (1)

- Norm Asme PTC 18-2002Document89 pagesNorm Asme PTC 18-2002Juan Julian Jesus Huaroto Sevilla100% (1)

- Asme B 89.7.6 2019Document24 pagesAsme B 89.7.6 2019مرکز پژوهش متالورژی رازی RMRCNo ratings yet

- Asme B1.3-2007 (R2017)Document24 pagesAsme B1.3-2007 (R2017)lucasNo ratings yet

- ASME B89.1.13-2013 (Content)Document4 pagesASME B89.1.13-2013 (Content)Jorge Cota AcostaNo ratings yet

- HB 86.2-1998 A Guide To The Selection Care Calibration and Checking of Measuring Instruments in Industry SimpDocument5 pagesHB 86.2-1998 A Guide To The Selection Care Calibration and Checking of Measuring Instruments in Industry SimpSAI Global - APACNo ratings yet

- B16-47 Edtn 2006Document111 pagesB16-47 Edtn 2006MustafaNo ratings yet

- B16-3 Edtn 2006Document47 pagesB16-3 Edtn 2006MustafaNo ratings yet

- Asme B16.38-2012 (2017) - 2Document20 pagesAsme B16.38-2012 (2017) - 2Emi Ruiz0% (1)

- Pipe PVC Pressure PipeDocument90 pagesPipe PVC Pressure PipeZoidberg12No ratings yet

- Manual Tecnico ENG-E-sCAiODocument84 pagesManual Tecnico ENG-E-sCAiOJose Luis SaldiasNo ratings yet

- Rec 670Document658 pagesRec 670José MariñoNo ratings yet

- Asme B18.24-2020Document190 pagesAsme B18.24-2020윤규섭0% (1)

- Wrought Gopper An-D: (RevisionDocument24 pagesWrought Gopper An-D: (RevisionIlka RaffaelliNo ratings yet

- NR-13 Brazilian Standard For Boiler and Pressure VesselDocument21 pagesNR-13 Brazilian Standard For Boiler and Pressure VesselWilly SastraleksanaNo ratings yet

- Relion 670 Series Reg670Document830 pagesRelion 670 Series Reg670CuevaMariaServerNo ratings yet

- Tristar 3000 Operators Manual v6.08Document335 pagesTristar 3000 Operators Manual v6.08Adrian Paz RamosNo ratings yet

- Asme B18.8.1 Clvis PinsDocument4 pagesAsme B18.8.1 Clvis Pinsquality0% (2)

- Case Version 6.5 Service ManualDocument276 pagesCase Version 6.5 Service ManualFauza Aryagus80% (5)

- B16.44 2012Document24 pagesB16.44 2012Edwin MariacaNo ratings yet

- DocumentDocument20 pagesDocumentfayceal25% (4)

- Actix OverviewDocument76 pagesActix OverviewKapil MathurNo ratings yet

- Australian Standard: Pipe Threads of Whitworth Form Part 1: Sealing Pipe Threads (Metric Units)Document7 pagesAustralian Standard: Pipe Threads of Whitworth Form Part 1: Sealing Pipe Threads (Metric Units)SancbNo ratings yet

- Amca 803Document98 pagesAmca 803insult2injury100% (1)

- ASME B16.11-2021 Forged Fittings, Socket-Welding and ThreadedDocument34 pagesASME B16.11-2021 Forged Fittings, Socket-Welding and ThreadedCristhian Portocarrero100% (4)

- General Instructions: ASME PTC 1-2015Document4 pagesGeneral Instructions: ASME PTC 1-2015saryNo ratings yet

- Amca 201 PDFDocument80 pagesAmca 201 PDFfuwad84No ratings yet

- Micrium User ManualDocument182 pagesMicrium User Manualfreddy brigstoneNo ratings yet

- Previews Amca 201 R2011 PreDocument17 pagesPreviews Amca 201 R2011 PreBilly MoerdaniNo ratings yet

- PDVSA k-302Document55 pagesPDVSA k-302protecciones100% (2)

- Application Manual Line Differential Protection RED670 Version 2.2 IECDocument996 pagesApplication Manual Line Differential Protection RED670 Version 2.2 IECJavier Valencia MurilloNo ratings yet

- Relion 670 SeriesDocument944 pagesRelion 670 SeriesashokNo ratings yet

- Lit 1201753Document26 pagesLit 1201753Eden SilveiraNo ratings yet

- Commander SK QsDocument82 pagesCommander SK Qsthanh_cdt01No ratings yet

- B16-4 Edtn 2006Document31 pagesB16-4 Edtn 2006MustafaNo ratings yet

- Previews 2088495 PreDocument12 pagesPreviews 2088495 PreJuan Leon100% (1)

- BECS-C18 Computerized Embroidery Machine Owner's ManualDocument206 pagesBECS-C18 Computerized Embroidery Machine Owner's ManualSayantan RahaNo ratings yet

- Publication 201-02 (R2007)Document80 pagesPublication 201-02 (R2007)Joebo Comia100% (1)

- Systimax Scs Powersum and Gigaspeed XL Cabling Design GuidelinesDocument29 pagesSystimax Scs Powersum and Gigaspeed XL Cabling Design Guidelinesgerman12No ratings yet

- Of The Nuclear Safety Standards Commission (KTA)Document161 pagesOf The Nuclear Safety Standards Commission (KTA)pradeepajadhavNo ratings yet

- Calculation Software A6V13696649 - enDocument63 pagesCalculation Software A6V13696649 - envld20082No ratings yet

- Quality Control Procedure (Sectra-Branded) - Philips MicroDose L30 SW 8.4 8.4P1Document66 pagesQuality Control Procedure (Sectra-Branded) - Philips MicroDose L30 SW 8.4 8.4P1vasiliy_gromikNo ratings yet

- Hspice MosmodDocument792 pagesHspice MosmodprashantvlsiNo ratings yet

- Subsea Production Guide Aug18Document111 pagesSubsea Production Guide Aug18Jay JayNo ratings yet

- Edsa PaladinDocument89 pagesEdsa PaladinIulian PârjoleanuNo ratings yet

- Asme B18.24-2004 PDFDocument156 pagesAsme B18.24-2004 PDFlofej5755550% (2)

- Manual Bordadora Feia Becs-216 InglesDocument149 pagesManual Bordadora Feia Becs-216 InglesJose Newlook PedrazaNo ratings yet

- Asme B31G-2023Document82 pagesAsme B31G-2023gerencia100% (2)

- Allen BradleyDocument36 pagesAllen BradleywvwintersNo ratings yet

- Pressure Systems 9000 ManualDocument169 pagesPressure Systems 9000 ManualJonNo ratings yet

- Anixter Installation Pocket Reference Guide enDocument86 pagesAnixter Installation Pocket Reference Guide enShakeel AslamNo ratings yet

- Practical Modern SCADA Protocols: DNP3, 60870.5 and Related SystemsFrom EverandPractical Modern SCADA Protocols: DNP3, 60870.5 and Related SystemsRating: 5 out of 5 stars5/5 (6)

- CNC Machining Handbook: Building, Programming, and ImplementationFrom EverandCNC Machining Handbook: Building, Programming, and ImplementationNo ratings yet

- Network Processors: Architecture, Programming, and ImplementationFrom EverandNetwork Processors: Architecture, Programming, and ImplementationNo ratings yet

- Deploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideFrom EverandDeploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideRating: 5 out of 5 stars5/5 (2)

- HP PCL 5 Manual Do Usuario Part 1Document394 pagesHP PCL 5 Manual Do Usuario Part 1Marcello MelloNo ratings yet

- VGA Connector PDFDocument4 pagesVGA Connector PDFAnuraNo ratings yet

- Key Way DimensionsDocument1 pageKey Way DimensionsMuckromin MulyaNo ratings yet

- D-Code-list: Cad and Cam SpecificationsDocument1 pageD-Code-list: Cad and Cam Specificationsemaster1No ratings yet

- Font ManlDocument129 pagesFont Manlemaster1100% (1)

- Tạm lệnhDocument7 pagesTạm lệnhemaster1No ratings yet

- Tooth Thickness Measurement With Pins or BallsDocument5 pagesTooth Thickness Measurement With Pins or Ballsemaster1No ratings yet

- M License Mcam9Document6 pagesM License Mcam9emaster1No ratings yet

- Cấu hình máy cho phần mềm inventorDocument4 pagesCấu hình máy cho phần mềm inventoremaster1No ratings yet

- Cấu Hình Máy Cho Phần Mềm InventorDocument4 pagesCấu Hình Máy Cho Phần Mềm Inventoremaster1No ratings yet

- SPCBD Presentation Rev.EDocument14 pagesSPCBD Presentation Rev.Eemaster1No ratings yet

- SPCBD Presentation Rev.EDocument14 pagesSPCBD Presentation Rev.Eemaster1No ratings yet

- Opto BomDocument1 pageOpto Bomemaster1No ratings yet

- Sign Blazer ManualDocument243 pagesSign Blazer ManualUSCutterNo ratings yet

- Cam TraxDocument28 pagesCam Traxemaster1No ratings yet

- PCB Artist Library TutorialDocument54 pagesPCB Artist Library TutorialLúcio Di LoretoNo ratings yet

- 05/04/2013 4:59:29 PM E:/Thi/Mach Dien Tu/linh Tinh/Motor/Diver Step/BOB/bob - Thi/mod - Thi - SCH (Sheet: 1/1)Document1 page05/04/2013 4:59:29 PM E:/Thi/Mach Dien Tu/linh Tinh/Motor/Diver Step/BOB/bob - Thi/mod - Thi - SCH (Sheet: 1/1)emaster1No ratings yet

- Noi Dung Boot Ini FileDocument1 pageNoi Dung Boot Ini Fileemaster1No ratings yet

- 1BOB TU VE Sai ChanDocument1 page1BOB TU VE Sai Chanemaster1No ratings yet

- Using Your MouseDocument15 pagesUsing Your MouseV A Prem KumarNo ratings yet

- 06/04/2013 1:34:47 PM E:/Thi/Mach Dien Tu/linh Tinh/Motor/Diver Step/BOB/bob - Thi/bob - Thi - Vden - BRDDocument1 page06/04/2013 1:34:47 PM E:/Thi/Mach Dien Tu/linh Tinh/Motor/Diver Step/BOB/bob - Thi/bob - Thi - Vden - BRDemaster1No ratings yet

- Readme of Make The CutDocument1 pageReadme of Make The Cutemaster1No ratings yet

- TIPOFDAYDocument1 pageTIPOFDAYemaster1No ratings yet

- Named Colors LythonDocument2 pagesNamed Colors Lythonemaster1No ratings yet

- Able Extract ProfessionalDocument5 pagesAble Extract ProfessionalBribaldo da SilvaNo ratings yet

- WinAVR User ManualDocument23 pagesWinAVR User ManualMohan Raj GuptaNo ratings yet

- Material DataDocument1 pageMaterial Dataemaster1No ratings yet

- Cam Trax 98Document27 pagesCam Trax 98emaster1No ratings yet

- Last Design RunDocument1 pageLast Design Runemaster1No ratings yet

- Different Types of Thread Data ChartDocument233 pagesDifferent Types of Thread Data Chartrankx001No ratings yet

- Slotted Countersunk Flat Head Screws (Head Style) - : CommonDocument10 pagesSlotted Countersunk Flat Head Screws (Head Style) - : Commonkumar QANo ratings yet

- Model Met-C1 Cde (D148/D149/D150) Parts CatalogDocument266 pagesModel Met-C1 Cde (D148/D149/D150) Parts CatalogRoberto BernardiNo ratings yet

- Lot 3 - Bom - Anchor BoltDocument7 pagesLot 3 - Bom - Anchor BoltHongducBuiNo ratings yet

- E92 M3 Clutch ServiceDocument52 pagesE92 M3 Clutch ServiceJonas Alberto Ochoa CastilloNo ratings yet

- Mechanical Thread TablesDocument38 pagesMechanical Thread TablesbarcristianNo ratings yet

- AppendixDocument21 pagesAppendixEcho CanyonNo ratings yet

- Wirethread TablesDocument3 pagesWirethread TablesN.PalaniappanNo ratings yet

- VARGUS General CatalogDocument420 pagesVARGUS General Catalogsaepudin 40No ratings yet

- Threading Tools: F79 To F101Document24 pagesThreading Tools: F79 To F101Peter KlassenNo ratings yet

- Superbolt Dimension-List Torque-Guidelines MT UncDocument1 pageSuperbolt Dimension-List Torque-Guidelines MT UncaputraNo ratings yet

- Acme & Stub Acme LoadDocument4 pagesAcme & Stub Acme Loadraseen pNo ratings yet

- BS en 14399-7-2007 (2010)Document24 pagesBS en 14399-7-2007 (2010)WeldedSpliceNo ratings yet

- BS 1580 3 2007Document24 pagesBS 1580 3 2007Kannan100% (1)

- 686 Rotary Harvesting Unit (103954-) North American Edition Primary Pictorial IndexDocument106 pages686 Rotary Harvesting Unit (103954-) North American Edition Primary Pictorial Indexavant comercialNo ratings yet

- AF InHex Catalogue 2013Document37 pagesAF InHex Catalogue 2013WalissonNo ratings yet

- Screw Thread TypesDocument7 pagesScrew Thread TypesVille4everNo ratings yet

- 06 Stainless Steel Hydraulic JIC Adapters To ISO 8434-2 J514Document36 pages06 Stainless Steel Hydraulic JIC Adapters To ISO 8434-2 J514Fabiano CardosoNo ratings yet

- Takamaz XC XLseriesDocument24 pagesTakamaz XC XLseriesPham LongNo ratings yet

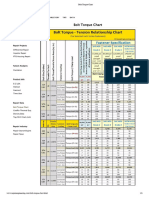

- Bolt Torque ChartDocument6 pagesBolt Torque Chart5221asri_maabNo ratings yet

- UNI 5587 - 1968thick Hexagon Nuts (Special Purpose) - ISO Metric Coarse and Fine Thread - Finish ADocument9 pagesUNI 5587 - 1968thick Hexagon Nuts (Special Purpose) - ISO Metric Coarse and Fine Thread - Finish ANarimane BentyNo ratings yet

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 pagesForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNo ratings yet

- Is.8535.1987 - 0 ANCHOR BOLTS NOMENCLATUREDocument38 pagesIs.8535.1987 - 0 ANCHOR BOLTS NOMENCLATUREamitjustamitNo ratings yet

- Internal and external boring bars and toolholdersDocument30 pagesInternal and external boring bars and toolholdersDedik HandokoNo ratings yet

- External ISO Metric Trapezoidal Screw Threads Table Chart Sizes TR8 - TR315 - Engineers EdgeDocument8 pagesExternal ISO Metric Trapezoidal Screw Threads Table Chart Sizes TR8 - TR315 - Engineers EdgeDiaconu Vlad CatalinNo ratings yet

- SL Turning Units & AV HoldersDocument20 pagesSL Turning Units & AV HoldersecarrilloNo ratings yet

- Asme B18 2 1 1996Document61 pagesAsme B18 2 1 1996Daniyal EzaziNo ratings yet

- Thread Sizes and Tap Drills METRIC PDFDocument1 pageThread Sizes and Tap Drills METRIC PDFFernando ChavezNo ratings yet

- Porca Din 439 BDocument7 pagesPorca Din 439 BFrank NunesNo ratings yet

- Gleason Nastroje Komplet - AJ PDFDocument52 pagesGleason Nastroje Komplet - AJ PDFdiegomilitojNo ratings yet