Professional Documents

Culture Documents

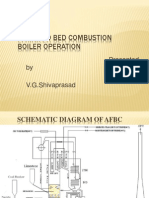

Fluidized Bed Combustion Technology

Uploaded by

Matias MancillaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluidized Bed Combustion Technology

Uploaded by

Matias MancillaCopyright:

Available Formats

Fluidized Bed Combustion Technology(2)

of the in-bed tubes immersed in the sand bed is 5-6 times higher than that of the conventional convection tube bank area. If design of boiler requires 30 m2 for convection area to generate 1000 Kg of steam per hour, we can safely take 1/6 of it or 5 m2 to generate 1000 Kg of steam from the immersed in-bed tube area. The fluidizing air enters through air distributors mounted on a flat base plate. The bed material is silica sand having a mean size of 0.9 mm (#3). Bed depth is about 400 mm.

START-UP

Start-up of the bed is achieved by the firing of an above bed distillate coal layer, which is lit by small quantity of oil at the very start. Startup is normally achieved in 45 minutes from cold status. Hot starts normally are achieved in less than 10 minutes, 6 minutes of which is needed for purging to ensure there are no pockets of ignitable gas in the boiler passes. If the bed temperature is above 600 oC no oil fuel is needed to re-start the bed. Usually bed can maintain enough heat or above 600 oC for 1-2 hours. The average bed temperature varies between 950 oC at full load to 750 oC at minimum load. In fluidised bed operation bed temperature is monitored and is in fact a better indication of combustion condition than a flame scanner used for oil burner. The major proportion of the fuel is burnt within the bed, with the remainder burning in the free board zone or disengaging space above the bed. With the injection of overfire 2nd air into the free board zone, disengaging space temperature will rise higher than the temperature of the bed. The final gas temperature leaving the furnace will be similar to the bed temperature as the elevation in temperature due to free board combustion is partially offset by the heat transfer to the uncovered portion of in-bed tubes and cooling effect of the fresh air injection. Fine coal is stored on the ground and normally flat conveyor system transport coal from the in-ground hopper to the silo mounted at the front of the boiler. The coal runs from the storage silo by gravity to the screw conveyor with variable speed gear motor, then the coal enters the furnace through an air swept spout.

BED TEMPERATURE

FREE BOARD ZONE/ OVERFIRE 2ND AIR COAL FEEDING SYSTEM

COARSE ASH REMOVAL circulating sand bed

SOOTBLOWERS

Soot blowers are not necessary to be installed as the combustion temperature of the fluidized bed is controlled at well below the ash fusion temperature and fly-ash entrained in the gases entering the convection tube banks are dry and non-adhering and possess a selfcleaning action. Coarse ash which is not elutriated from the bed must be removed. This material is removed continuously by means of circulating sand bed. We call this system as CIRCULATING BED. Air nozzles are screwed in to the multiple air distribution pipes instead of base plate which was used before. Because of this air distribution pipes, coarse ash can fall below the pipe level travelling downward in between the pipes and those materials will be discharged from the rotary valve below together with the silica sand onto the vibrating screen which will segregate those coarse ash and other foreign materials from the pure silica sand. Then the pure silica sand will be returned to the furnace

You might also like

- CFBC Boiler DescriptionDocument9 pagesCFBC Boiler Descriptioncmani_bweNo ratings yet

- Hamada Boiler Catalogue Page 14 FBC 2Document1 pageHamada Boiler Catalogue Page 14 FBC 2Matias MancillaNo ratings yet

- Fluidised Bed Combustion For Clean Energy (Contents)Document22 pagesFluidised Bed Combustion For Clean Energy (Contents)Manas Kumar SamantarayNo ratings yet

- Energy Auditors 2 6 FBC BoilerDocument13 pagesEnergy Auditors 2 6 FBC Boilervij2009100% (1)

- CFB BoilerDocument12 pagesCFB Boiler95113309No ratings yet

- Boiler NotesDocument34 pagesBoiler NotesRakesh Singh BhadoriyaNo ratings yet

- Fluidized Bed CombustionDocument23 pagesFluidized Bed CombustionHawk EyeNo ratings yet

- Fluidized Bed Combustion: A Viable Alternative for Low Grade CoalDocument25 pagesFluidized Bed Combustion: A Viable Alternative for Low Grade CoalJayam KondanNo ratings yet

- FBC Boilers: Syllabus FBC Boilers: Introduction, Mechanism of Fluidized Bed Combustion, AdvantagesDocument12 pagesFBC Boilers: Syllabus FBC Boilers: Introduction, Mechanism of Fluidized Bed Combustion, AdvantagesTejas T S TejasNo ratings yet

- FBC Boilers in Power PlantDocument20 pagesFBC Boilers in Power PlantVenkatesan SundaramNo ratings yet

- Boilers Training Topic Nov 2021Document24 pagesBoilers Training Topic Nov 2021mizharmuisstNo ratings yet

- An Overview of FBC Boiler: Compiled BY S.S.AcharyaDocument56 pagesAn Overview of FBC Boiler: Compiled BY S.S.AcharyaMusycal Fynnc100% (1)

- Principles of Fluidized Bed BoilersDocument27 pagesPrinciples of Fluidized Bed BoilersssNo ratings yet

- Boiler Introduction: Steam To ProcessDocument89 pagesBoiler Introduction: Steam To ProcessEngr M S MinhasNo ratings yet

- Boiler TypesDocument14 pagesBoiler Typesaecsuresh35No ratings yet

- Stoker Vs FBC PDFDocument11 pagesStoker Vs FBC PDFAsghar MirzaNo ratings yet

- CFBC DesignDocument28 pagesCFBC DesignThanga Kalyana Sundaravel100% (2)

- Fluidized Bed Combustion: Advantages of FBC Boilers Over Pulverized Coal Fired BoilersDocument41 pagesFluidized Bed Combustion: Advantages of FBC Boilers Over Pulverized Coal Fired Boilersashishmathew0% (1)

- Circulating Fluidised Bed Combustion 1Document4 pagesCirculating Fluidised Bed Combustion 1Prasaanna MoniNo ratings yet

- Metallurgical Industrial Furnaces 3Document6 pagesMetallurgical Industrial Furnaces 3Mining ReviewNo ratings yet

- 1.1 Salient Features of CFBC BoilerDocument17 pages1.1 Salient Features of CFBC BoilerJAY PARIKHNo ratings yet

- Flurized Bed CombustionDocument8 pagesFlurized Bed CombustionshpalyNo ratings yet

- Chap 15Document14 pagesChap 15nelson escuderoNo ratings yet

- Efficient AFBC boiler cold start up and compartment transfer procedureDocument4 pagesEfficient AFBC boiler cold start up and compartment transfer procedureManimaran Guna100% (1)

- Fluidized Bed CombustionDocument2 pagesFluidized Bed Combustionlaila salahNo ratings yet

- FBC Operation II OperationDocument21 pagesFBC Operation II Operationanbesivam87No ratings yet

- Fluidized Bed BoilerDocument5 pagesFluidized Bed BoilerSavita GuptaNo ratings yet

- Unit 2: Applied Thermodynamics-1Document175 pagesUnit 2: Applied Thermodynamics-1Riddhesh NawgajeNo ratings yet

- Thermal Power Plant Training OverviewDocument192 pagesThermal Power Plant Training OverviewManoj PaneriNo ratings yet

- 25.boiler Water Chemistry R1 26.06.2017Document312 pages25.boiler Water Chemistry R1 26.06.2017VINOTHINI R B.EdNo ratings yet

- Production of DBMDocument2 pagesProduction of DBMengr kazamNo ratings yet

- Multiple Hearth Furnaces B3Document3 pagesMultiple Hearth Furnaces B3Ossy DewintaNo ratings yet

- ReportDocument28 pagesReportDipanshu KumarNo ratings yet

- Improve Limestone Processing with Horizontal Rotary Cascade PreheatersDocument3 pagesImprove Limestone Processing with Horizontal Rotary Cascade PreheatersD S VenkateshNo ratings yet

- Ball and Tube Mill OperationDocument5 pagesBall and Tube Mill OperationRakesh KiranNo ratings yet

- UNIT VDocument23 pagesUNIT VDhilsanth SLNo ratings yet

- Production and Generation of Sulfonated ProductsDocument15 pagesProduction and Generation of Sulfonated ProductsAbraham wisdomNo ratings yet

- Cold Cyclone CFBC BoilerDocument2 pagesCold Cyclone CFBC BoilerVirendra PatilNo ratings yet

- How CFB Boilers WorkDocument3 pagesHow CFB Boilers Workazeemmet9924No ratings yet

- CFBC CatalogueDocument4 pagesCFBC CatalogueD NageshNo ratings yet

- A Diagnostic Study in A Husk Fired Boiler For A Power PlantDocument44 pagesA Diagnostic Study in A Husk Fired Boiler For A Power Plantparthi20065768No ratings yet

- Coal Mill ManualDocument8 pagesCoal Mill Manualanupraja100% (1)

- Blast Furnace ProcessDocument4 pagesBlast Furnace ProcessmohommedaamirNo ratings yet

- CupolaDocument19 pagesCupolaFIREREALM66No ratings yet

- Coal Mill Safety K ChandaDocument12 pagesCoal Mill Safety K Chandanarasimhamurthy414No ratings yet

- AFBC Boiler Cold Start-Up ProcedureDocument3 pagesAFBC Boiler Cold Start-Up ProcedurekiranNo ratings yet

- Pulverised Coal Firing SystemDocument20 pagesPulverised Coal Firing Systemmurthykeshava100% (3)

- Factors That Affect CFBC Panel Erosion by K.K.Parthiban PDFDocument34 pagesFactors That Affect CFBC Panel Erosion by K.K.Parthiban PDFparthi20065768100% (1)

- Factors That Affect CFBC Panel Erosion by K.K.parthibanDocument34 pagesFactors That Affect CFBC Panel Erosion by K.K.parthibanparthi20065768100% (2)

- 11 Steam Generators 3-2Document26 pages11 Steam Generators 3-2Omar AhmedNo ratings yet

- Thermodynamic Cycles:: Unit I Thermal Power PlantsDocument33 pagesThermodynamic Cycles:: Unit I Thermal Power PlantsbernabasNo ratings yet

- A Solution For Preventing Fouling in CFBC Boiler by K.K.parthibanDocument30 pagesA Solution For Preventing Fouling in CFBC Boiler by K.K.parthibanparthi20065768100% (2)

- Boiler Construction N19Document16 pagesBoiler Construction N191907nirmal100% (1)

- Circulating Fluidised Bed CombustionDocument1 pageCirculating Fluidised Bed CombustionAmitav MishraNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Chimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemFrom EverandChimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemNo ratings yet

- Catalago Resumen de ValvulasDocument21 pagesCatalago Resumen de ValvulasMatias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 56 Heavy Duty Chain GrateDocument1 pageHamada Boiler Catalogue Page 56 Heavy Duty Chain GrateMatias MancillaNo ratings yet

- Amca Publication 11-03: Certified Ratings Program Operating ManualDocument30 pagesAmca Publication 11-03: Certified Ratings Program Operating ManualMatias MancillaNo ratings yet

- Amca Publication 11-03: Certified Ratings Program Operating ManualDocument30 pagesAmca Publication 11-03: Certified Ratings Program Operating ManualMatias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 57 Coalmac 1Document1 pageHamada Boiler Catalogue Page 57 Coalmac 1Matias MancillaNo ratings yet

- CA3000A Dodge BearingDocument708 pagesCA3000A Dodge BearingSuphi YükselNo ratings yet

- Envirenmental EngineeringDocument87 pagesEnvirenmental Engineering4919404No ratings yet

- p-100 Vol2 1935 Part5Document132 pagesp-100 Vol2 1935 Part5Matias MancillaNo ratings yet

- Refractories For Heat Treating: Industrial CeramicsDocument6 pagesRefractories For Heat Treating: Industrial CeramicsMatias MancillaNo ratings yet

- Carter Variator CatDocument40 pagesCarter Variator CatMatias MancillaNo ratings yet

- CA3000A Dodge BearingDocument708 pagesCA3000A Dodge BearingSuphi YükselNo ratings yet

- Hamada Boiler Catalogue Page 58 Coalmac 2Document1 pageHamada Boiler Catalogue Page 58 Coalmac 2Matias MancillaNo ratings yet

- Chapter 21Document25 pagesChapter 21Matias MancillaNo ratings yet

- CA3000A Dodge BearingDocument708 pagesCA3000A Dodge BearingSuphi YükselNo ratings yet

- Technical Documents of The BoilerDocument20 pagesTechnical Documents of The BoilerMatias Mancilla0% (1)

- Hamada Boiler Catalogue Page 47 Rotary Furnace For AMPDocument1 pageHamada Boiler Catalogue Page 47 Rotary Furnace For AMPMatias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 60 Coalmac 4Document1 pageHamada Boiler Catalogue Page 60 Coalmac 4Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 22 Coal Storage and PLC ControlDocument1 pageHamada Boiler Catalogue Page 22 Coal Storage and PLC ControlMatias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 62 Rice Husk Firing Boiler 1Document1 pageHamada Boiler Catalogue Page 62 Rice Husk Firing Boiler 1Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 61 EFB Palm Waste FiringDocument1 pageHamada Boiler Catalogue Page 61 EFB Palm Waste FiringMatias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 60 Coalmac 4Document1 pageHamada Boiler Catalogue Page 60 Coalmac 4Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 59 Coalmac 3Document1 pageHamada Boiler Catalogue Page 59 Coalmac 3Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 59 Coalmac 3Document1 pageHamada Boiler Catalogue Page 59 Coalmac 3Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 63 Rice Husk Firing Boiler 2Document1 pageHamada Boiler Catalogue Page 63 Rice Husk Firing Boiler 2Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 65 Rice Husk Firing Boiler 4Document1 pageHamada Boiler Catalogue Page 65 Rice Husk Firing Boiler 4Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 64 Rice Husk Firing Boiler 3Document1 pageHamada Boiler Catalogue Page 64 Rice Husk Firing Boiler 3Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 67 TVTB 3Document1 pageHamada Boiler Catalogue Page 67 TVTB 3Matias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 8 Model DF Series General ViewDocument1 pageHamada Boiler Catalogue Page 8 Model DF Series General ViewMatias MancillaNo ratings yet

- Solid Fuel Combustion On Water-Cooled Vibrating Grate: Plant Equipment and ComponentsDocument2 pagesSolid Fuel Combustion On Water-Cooled Vibrating Grate: Plant Equipment and ComponentsMatias MancillaNo ratings yet

- Hamada Boiler Catalogue Page 7 Fluidizing Fire and Biomass FuelDocument1 pageHamada Boiler Catalogue Page 7 Fluidizing Fire and Biomass FuelMatias MancillaNo ratings yet

- Correspondence LetterDocument5 pagesCorrespondence LetterVesheto HesuhNo ratings yet

- BAOLSSDocument3 pagesBAOLSSJahidur RahmanNo ratings yet

- Emsa Isps June July 2014Document102 pagesEmsa Isps June July 2014gusyahri001No ratings yet

- Bangladesh CAAB Personal Licensing HandbookDocument278 pagesBangladesh CAAB Personal Licensing Handbooks ramanNo ratings yet

- Blancaflor, Vann Luis Z. - 12proscogreas - 3rdgrading - Contemporary ArtsDocument3 pagesBlancaflor, Vann Luis Z. - 12proscogreas - 3rdgrading - Contemporary ArtsMadelyn MacahipayNo ratings yet

- Acer Aspire V5-132P Angel - CY 12313-1Document102 pagesAcer Aspire V5-132P Angel - CY 12313-1Aphe TaiasuNo ratings yet

- Anum's Project DraftDocument32 pagesAnum's Project DraftAreebaRaoNo ratings yet

- Meritor Serie 160 164Document69 pagesMeritor Serie 160 164Manuel RojasNo ratings yet

- Out Going LettersDocument461 pagesOut Going LettersHemn Rafiq TofiqNo ratings yet

- GSM-R SR20Document375 pagesGSM-R SR20kepscoNo ratings yet

- BHEL Enquiry for Ballscrew Rod SupplyDocument8 pagesBHEL Enquiry for Ballscrew Rod SupplyGohilakrishnan ThiagarajanNo ratings yet

- February 2016Document17 pagesFebruary 2016Pumper TraderNo ratings yet

- Petrol Pump DelhiDocument33 pagesPetrol Pump DelhikunalggnNo ratings yet

- Survey, Design, Preparation of DPR of Multi-Village Scheme Under Jal Jeevan Mission (Rajasthan State)Document10 pagesSurvey, Design, Preparation of DPR of Multi-Village Scheme Under Jal Jeevan Mission (Rajasthan State)prabhjot26No ratings yet

- Capability Codes and Capability Statements 2016 Bi-Sc Nu0083Document403 pagesCapability Codes and Capability Statements 2016 Bi-Sc Nu0083Stan Iulian87% (15)

- Northwest NewsprintDocument6 pagesNorthwest NewsprintSamantha HazellNo ratings yet

- Car NappingDocument3 pagesCar NappingiamnoelNo ratings yet

- Effect of Airline Choice and Temporality On - 2020 - Journal of Air Transport MDocument19 pagesEffect of Airline Choice and Temporality On - 2020 - Journal of Air Transport MFernanda RojasNo ratings yet

- VWT Xc20 Jigging Web 1Document11 pagesVWT Xc20 Jigging Web 1Carlos Ernesto Flores Albino100% (1)

- 4 - Stair Case - Dead LoadsDocument4 pages4 - Stair Case - Dead Loadsraghav abudhabiNo ratings yet

- Brand New Boeing 747 Scrapped After 16 FlightsDocument9 pagesBrand New Boeing 747 Scrapped After 16 FlightsIrvan IrvanNo ratings yet

- Life Cycle Assessment of Packaging Materials For Milk and Dairy ProductsDocument12 pagesLife Cycle Assessment of Packaging Materials For Milk and Dairy Productsmanisha maniNo ratings yet

- ADB Toolkit For Highway PPP ProjectsDocument260 pagesADB Toolkit For Highway PPP ProjectsSmart Government InstituteNo ratings yet

- 38Document9 pages38anon_981731217No ratings yet

- Bombay Provincial Municipal Corporations Act SummaryDocument418 pagesBombay Provincial Municipal Corporations Act SummaryVarsha Arya100% (1)

- SAMP CHatlogDocument35 pagesSAMP CHatlogredNo ratings yet

- ABS Rules and StandardsDocument5 pagesABS Rules and StandardsrbdelosNo ratings yet

- AfCFTADocument2 pagesAfCFTAeltonNo ratings yet

- Boiling PointDocument3 pagesBoiling PointaeneNo ratings yet

- A Forecasting System For Car Fuel Consumption Using A Radial Basis Function Neural Network PDFDocument6 pagesA Forecasting System For Car Fuel Consumption Using A Radial Basis Function Neural Network PDFiitgn007No ratings yet