Professional Documents

Culture Documents

Transport Laying Compaction 0 PDF

Uploaded by

morrisioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transport Laying Compaction 0 PDF

Uploaded by

morrisioCopyright:

Available Formats

B5 Transport, Laying & Compaction

The methods of transporting, laying and compacting bituminous mixtures are defined in British (BS) Standards. The BS EN Standards for bituminous mixtures only apply to the mixture in the delivery vehicle. They do not specify how the mixtures are to be used. This Topic page gives details of: Transport and delivery Tack coat and bond coat Laying in adverse conditions Hand laying Joints Compaction Layer thickness Delivery and rolling temperatures Rates of spread.

The BS requirements and guidance can be considered as best practice for all road surfacing work, including pedestrian areas and car parks. The Specification for Highway Works (SHW) uses the BS requirements as the basis of its clauses. Full details are given in: Standard: BS 594987, Asphalt for roads and other paved areas. Specification for transport, laying and compaction and design protocols

BS 594987 replaced: BS 594-2, Hot rolled asphalt for roads and other paved areas. Specification for transport, laying and compaction of hot rolled asphalt and BS 4987-2, Coated macadam (asphalt concrete) for roads and other paved areas. Specification for transport, laying and compaction. Transport and delivery Bituminous mixtures are transported in insulated and sheeted vehicles to prevent an excessive drop in temperature and protect against adverse weather. The vehicles must be loaded in a way that minimises segregation. Diesel oil, kerosene and other substances that can soften the mixture must not be used on the floor of the vehicle to aid discharge. A minimum amount of sealing grit, sand, soap solution or proprietary release agent is generally permitted. The mixture should be delivered at a temperature that allows sufficient time for it to be properly laid and compacted before the layer cools. Tack coat and bond coat Tack coats and bond coats are used to promote adhesion between layers in new construction and to bond a new layer to the existing surface in resurfacing works. It is now understood that tack coat and bond coat make a very important contribution to the long-life of a road structure.

B5 Transport, Laying & Compaction - 1 / 4

The Standard requires that a tack coat or bond coat must be applied before a new surface course is laid. Other specifications, including SHW, often require a tack or bond coat to be used between the other layers in the road structure. A tack coat is a simple sprayed layer of bitumen emulsion complying with: BS EN 13808, Bitumen and bituminous binders. Framework for specifying cationic bituminous emulsions Class C40 B4 or Class C40 B3

Bond coats are specialist proprietary emulsion materials, usually made with polymer modified bitumen. Bond coats are often used as part of a thin surface course system, because they can help to resist the higher stress imposed by heavy traffic. The Standard contains five tables that specify the amount of (residual) bitumen that must remain on the surface once the emulsion has broken. The amount depends upon the binder content of the new mixture and the condition of the layer it is to be laid on. Bitumen emulsion used as tack coat and bond coat must be applied at a uniform rate. It should be allowed to break (turn from brown to black) and not be allowed to collect in hollows. Cold, wet weather and standing water can slow down or prevent the break of the tack coat or bond coat. Laying in adverse conditions Bituminous mixtures must not be laid if standing water, ice or snow is present on the surface to be covered. Cold weather will reduce the amount of time available for proper compaction, but layer thickness and wind speed are also important. Thick layers loose heat more slowly than thin layers. Layers less that 40 mm thick require particular care. Hand laying Hand laying is often used when small quantities have to be laid in private drives and pedestrian areas. It is important to protect the delivered mixture from heat loss and adverse weather. Mixtures tipped into a heap must be sheeted. The Standard requires that the mixture is spread in a layer of uniform thickness with an even texture. It must be thoroughly compacted immediately. Joints Well-made joints make a very important contribution to the long-life of a road structure. Badly sealed joints allow water to enter and break the bond between the layers. The standard requires all joints to be made in a way that ensures adequate compaction and bonding to adjacent surfaces. For surface course layers, all joints must be made by cutting back the edges to a vertical face that exposes the full thickness of the layer. The loosened material is discarded and the vertical face is painted with a thin and uniform coating of hot bitumen (or specified alternative).

B5 Transport, Laying & Compaction - 2 / 4

The requirement to cut and paint joints applies to transverse joints, joints abutting the existing surface and any longitudinal joints. It also applies to transverse joints in lower layers. The vertical face of chamber covers, gully tops, kerbs, channels and other projections must also be coated with hot bitumen (or specified alternative). The position of longitudinal joints should be planned so as ensure that they are offset at least 300mm from any parallel joints in the layer below. The practice of applying bitumen to the upper surface of a finished joint is discouraged. There is a risk of skidding and slipping, particularly in wet weather.

Compaction The Standard covers a wide range of bituminous mixtures used in a variety of ways. It also covers sampling and testing to assess the proportion of air voids in the compacted layer. Full details are given in the Standard. Laying operations should not commence until the rollers are ready to start compaction. Compaction should start as soon as the rollers can travel without causing undue displacement of the laid mixture or surface cracking. When complete, there should be no distinct roller marks on the surface. Rollers should not stand on the compacted layer if it is still warm.

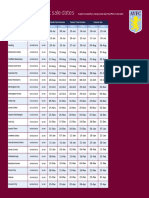

Layer thickness The Standard specifies the nominal and minimum compacted layer thickness for bituminous mixtures. The specified thickness for routinely used mixtures is: Mixture Asphalt concrete (AC) Dense surface course Close-graded surface course Dense binder course Dense base Hot rolled asphalt (HRA) Surface course (sand carpet) Regulating course Surface course Stone mastic asphalt (SMA) Surface course 6 10 14 20 to 40 25 to 50 35 to 50 15 20 30 0/2 15/10 30/14 25 30 40 20 25 35 6 10 20 32 20 to 30 30 to 40 50 to 100 70 to 150 15 25 40 55 Size, mm Nominal layer thickness, mm Minimum thickness, mm

B5 Transport, Laying & Compaction - 3 / 4

Delivery and rolling temperatures The Standard gives guidance on the minimum temperature on arrival. The temperatures are intended to allow sufficient time for laying and compaction. However, delivery temperatures are often difficult to measure in a safe way. Guidance on minimum rolling temperatures is also given. The temperatures are related to the visco-elastic properties of the grade of bitumen used in the mixture. They ensure that the mixture is still sufficiently workable to be properly compacted. Simplified guidance is: Bitumen grade, pen 40/60 100/150 160/220 Minimum arrival temperature, C 130 120 110 Minimum rolling temperature, C 100 95 85

The actual guide temperatures for some mixtures may be slightly different to this table. Refer to the Standard for full details. Rates of spread The actual rate of spread that can be achieved using a particular bituminous mixture at the specified thickness depends upon the density and grading of the aggregate, the condition of the layer (substrate) below and the degree of compaction. The guidance in Annex B of the Standard can be simplified as: Average compacted thickness, mm 25 30 35 40 50 60 80 100 Approximate rate of spread, m/tonne 16 (15 to 18) 13 (12 to 15) 11 (10 to 13) 10 (9 to 11) 8 (7 to 9) 7 (6 to 8) 5 (4 to 6) 4.5 (4 to 5)

The Standard gives slightly different values for different types of mixture. See the Standard for further details. Quality management The SHW requires road surfacing works to be carried out in accordance with: Quality Management in Highway Works, Sector Scheme 16 Sector Scheme Document for the Laying of Asphalt Mixes. The sector scheme details how a quality management system (QMS) complying with BS EN 9001 can developed and maintained with by a road surfacing contractor. The sector scheme includes specific requirements about the training and competence of the contractors employees. Sector scheme documents are published by UKAS. Copies can be downloaded from: www.ukas.com. Click on the UKAS Publications (M4) list under Information Centre. Then scroll down to the list of Sector Schemes in the section about publications related to certification body accreditation.

B5 Transport, Laying & Compaction - 4 / 4

You might also like

- Sensitive Earthwork Rates DivisionDocument2 pagesSensitive Earthwork Rates DivisionmorrisioNo ratings yet

- Ineffective Risk Management - That's RiskyDocument10 pagesIneffective Risk Management - That's RiskymorrisioNo ratings yet

- ROM Notes - Green CanopyDocument5 pagesROM Notes - Green CanopymorrisioNo ratings yet

- General Damages For Delay - Capped, or Uncapped - White & Case LLPDocument4 pagesGeneral Damages For Delay - Capped, or Uncapped - White & Case LLPmorrisioNo ratings yet

- Ramskill Martin Programmes Progress Monitoring and ReportingDocument8 pagesRamskill Martin Programmes Progress Monitoring and ReportingmorrisioNo ratings yet

- Road Marking & PaintingDocument12 pagesRoad Marking & PaintingmorrisioNo ratings yet

- Building - Comment - Addressing The Crisis in The Professional Indemnity (PI) Insurance Market, 19 February 2020Document3 pagesBuilding - Comment - Addressing The Crisis in The Professional Indemnity (PI) Insurance Market, 19 February 2020morrisioNo ratings yet

- Civil Code ClausesDocument9 pagesCivil Code ClausesmorrisioNo ratings yet

- Construction-Essay - PHP: Challengesofwater - Quality PDFDocument1 pageConstruction-Essay - PHP: Challengesofwater - Quality PDFmorrisioNo ratings yet

- The Nature of Construction ContractsDocument17 pagesThe Nature of Construction ContractsmorrisioNo ratings yet

- Kick-Starting Construction With Minor Works - Comment - BuildingDocument3 pagesKick-Starting Construction With Minor Works - Comment - BuildingmorrisioNo ratings yet

- Manage your monthly budget with this plannerDocument3 pagesManage your monthly budget with this plannermorrisioNo ratings yet

- Reading ListDocument1 pageReading ListmorrisioNo ratings yet

- Outline of The Law of ObligationsDocument18 pagesOutline of The Law of ObligationsmorrisioNo ratings yet

- TMA - ExerciseDocument3 pagesTMA - ExercisemorrisioNo ratings yet

- Savings Interest Calculator: Savings Plan Inputs Summary of ResultsDocument7 pagesSavings Interest Calculator: Savings Plan Inputs Summary of ResultsmorrisioNo ratings yet

- Damac Hills - Apartment PricesDocument3 pagesDamac Hills - Apartment PricesmorrisioNo ratings yet

- Contract Subcontractor ForecastDocument1 pageContract Subcontractor ForecastmorrisioNo ratings yet

- Final EssayDocument8 pagesFinal EssaymorrisioNo ratings yet

- Insurance - Dates - of ClaimDocument1 pageInsurance - Dates - of ClaimmorrisioNo ratings yet

- Rent, utility, and furniture expenses for new apartmentDocument1 pageRent, utility, and furniture expenses for new apartmentmorrisioNo ratings yet

- Guide to Preparing Comprehensive Extension of Time ClaimsDocument9 pagesGuide to Preparing Comprehensive Extension of Time Claimsgrtuna100% (1)

- LEED, Its Efficacy and FallacyDocument12 pagesLEED, Its Efficacy and FallacymorrisioNo ratings yet

- Prior Move Month 1 2/11/2017 Rental Deposit Agency Fees Dewa Hijari KitchenDocument3 pagesPrior Move Month 1 2/11/2017 Rental Deposit Agency Fees Dewa Hijari KitchenmorrisioNo ratings yet

- Credit Card SpendingDocument2 pagesCredit Card SpendingmorrisioNo ratings yet

- Subcontractor Management Schedule - 01Document2 pagesSubcontractor Management Schedule - 01morrisioNo ratings yet

- Sustained by Science The LEEDDocument1 pageSustained by Science The LEEDmorrisioNo ratings yet

- Invoice No Invoice Date Agreement No Invoice Period Remark BillDocument6 pagesInvoice No Invoice Date Agreement No Invoice Period Remark BillmorrisioNo ratings yet

- Game On Sale Tables 1819Document2 pagesGame On Sale Tables 1819morrisioNo ratings yet

- 2017 Leave PlanDocument1 page2017 Leave PlanmorrisioNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- TRA of Radiography EKLDocument3 pagesTRA of Radiography EKLSanjeet SinghNo ratings yet

- Data Teknis Kapal Isap Produksi (Kip) Permis: A. Dredge SuctionDocument2 pagesData Teknis Kapal Isap Produksi (Kip) Permis: A. Dredge SuctionYulian Fauzi AldiNo ratings yet

- Energy Savings with Reversible Thyristor Controlled RectifierDocument7 pagesEnergy Savings with Reversible Thyristor Controlled RectifierLaurence MichaelNo ratings yet

- MPD Alibaba Group8 SectionBDocument4 pagesMPD Alibaba Group8 SectionBRajeev P TibarewalNo ratings yet

- Resume Under 40 CharactersDocument4 pagesResume Under 40 CharactersChirag KothiyaNo ratings yet

- Gasketed Plate Heat Exchangers Equipment DesignDocument8 pagesGasketed Plate Heat Exchangers Equipment DesignAldren Delina RiveraNo ratings yet

- Competitive Exams: Allotropes of Carbon: AllotropyDocument3 pagesCompetitive Exams: Allotropes of Carbon: AllotropySwati MishraNo ratings yet

- Chapter 1 - IntroductionDocument53 pagesChapter 1 - IntroductionSiraj MohammedNo ratings yet

- Corning Recommended Fiber Optic Test Guidelines - LAN-1561-AEN - PAGE 1Document12 pagesCorning Recommended Fiber Optic Test Guidelines - LAN-1561-AEN - PAGE 1Karthikeyan RNo ratings yet

- PCS AutomationDocument6 pagesPCS Automationsandmike_83No ratings yet

- Update On The Latest SCDF Fire Code PDFDocument55 pagesUpdate On The Latest SCDF Fire Code PDFMaung AyeNo ratings yet

- Data Alamat Dan Nomor Telephone IIFPG 1419 Up DatedDocument28 pagesData Alamat Dan Nomor Telephone IIFPG 1419 Up DatedRahmat Nofiardi83% (6)

- Report On The Dangers of Cellphone Use While DrivingDocument6 pagesReport On The Dangers of Cellphone Use While DrivingMitchell JacksonNo ratings yet

- Read Online Here: Atx Power Supply ServiceDocument3 pagesRead Online Here: Atx Power Supply ServiceErroz RosadiNo ratings yet

- Tybca SlipsDocument8 pagesTybca SlipsJobin JosephNo ratings yet

- Severe Cyclic Conditions - ASME B31.3Document2 pagesSevere Cyclic Conditions - ASME B31.3aap1No ratings yet

- Caterpillar Cat 245B SERIES II EXCAVATOR (Prefix 6MF) Service Repair Manual (6MF00513 and Up)Document27 pagesCaterpillar Cat 245B SERIES II EXCAVATOR (Prefix 6MF) Service Repair Manual (6MF00513 and Up)rpoy9396615No ratings yet

- CookiesDocument44 pagesCookiesDavid LopezNo ratings yet

- 32 Page in DesignDocument17 pages32 Page in DesignChaley fufaNo ratings yet

- Vendor Selection MatrixDocument5 pagesVendor Selection MatrixGaurav BansalNo ratings yet

- 2005-021 MotwaniDocument6 pages2005-021 Motwanialexander100% (1)

- Basement Floor Drainage & Sump Plan - 30-6-20Document1 pageBasement Floor Drainage & Sump Plan - 30-6-20arjun 11No ratings yet

- WA Electrical Requirements SummaryDocument68 pagesWA Electrical Requirements SummaryYe KyawNo ratings yet

- Performance of Schools Real Estate BrokerDocument33 pagesPerformance of Schools Real Estate BrokerTheSummitExpressNo ratings yet

- Values Are Displayed As NAn On InTouchViewApp in Some of The Remote Connections.Document1 pageValues Are Displayed As NAn On InTouchViewApp in Some of The Remote Connections.JTNo ratings yet

- Democracy and Government Test AnswersDocument1 pageDemocracy and Government Test AnswersMarlynNo ratings yet

- Industrial SalesmenDocument9 pagesIndustrial Salesmenmaher76No ratings yet

- Time Delay Relays Time Delay Relays (Continued)Document1 pageTime Delay Relays Time Delay Relays (Continued)Hamza KefayahNo ratings yet

- Curiculum Vite Mansi Hans: Mansi - Agrawal@yahoo - Co.inDocument6 pagesCuriculum Vite Mansi Hans: Mansi - Agrawal@yahoo - Co.inmansiagrawalNo ratings yet

- CSCw32 Sys Eng1Document746 pagesCSCw32 Sys Eng1Don Predrag Simic83% (6)