Professional Documents

Culture Documents

TEC 08 - Bunkering Operations Checklist PDF

Uploaded by

nmospanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TEC 08 - Bunkering Operations Checklist PDF

Uploaded by

nmospanCopyright:

Available Formats

V.

SHIPS MANAGEMENT SYSTEM (VMS)

TEC 08: BUNKERING OPERATIONS CHECKLIST

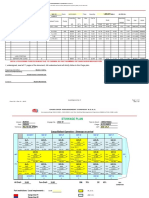

Port________________________________Date___________________________________ Ship________________________________Barge__________________________________ Master______________________________ Barge Master____________________________ Bunkers to be Transferred

Grade Fuel Oil Gasoil/Diesel LO in bulk Tonnes Vol at Load temp Load Temp Max Transfer Rate Max Line Pressure Topping Off Rate

Bunker Tanks to be loaded

Tank No Grade Vol of Tank@ 95 % Vol of oil in Tank before loading Available Volume Volume to be loaded Total Volumes Grade Expected sounding on completion

Checks prior arrival of bunkering barge or arrival at bunkering facility

Bunkering Ship Barge Code Remarks

1 2 3 4 5 6

Has barge obtained necessary permission for going alongside? Have fenders been checked, are they in good order? Adequate insulating means are in place in the barge to ship connection? All bunker hoses are in good condition and are appropriate to the service intended? Have bunker tanks onboard barge or facility tanks

been sounded?

Has bunkering plan been prepared and does it include contingency measures and sampling requirements?

The Bunker Plan is to be approved by the CE and signed by all persons involved in the bunkering operation.

Have bunker tank High level alarms been tested?

Alarm level %______ Sounding__________

8 9 10

Has transfer of fuel to minimise mixing of old fuel with new been completed? Have bunker tanks onboard the receiving vessel been sounded? Are all staff involved in bunkering familiar with the

Page 1 of 5 Created: October 2007

TEC 08 Bunkering Operations Checklist File Ref: Master & Ch. Eng: Log Entry Revision Number: 03

V.SHIPS MANAGEMENT SYSTEM (VMS)

11 12 13 14 15 16 17

ships bunkering system? Is the bunker line drip sampler clean, fitted correctly and in working order? Is the oil spill equipment ready? Is fire fighting equipment ready on barge and ship? Are all scuppers plugged? Have all drip trays/containment been verified and all air vents checked? Have bunker lines been visually inspected and found in good order? Have bunker lines where expansion joint couplings are fitted been pressure tested within last three months? Have the procedures regarding smoking areas and naked lights been enforced? Nominated smoking rooms:Vessel Barge.

18

A, R

19 20 21

Are fixed VHF/UHF transceivers and AIS equipment on low power mode or switched off? Are main radio transmitter(MF/HF) aerials earthed and radars switched off? Overboard valves connected to the cargo system, engine room bilges and bunker lines closed and sealed?

After Arrival of Bunkering Barge But Prior to Transfer

22 23 24 Is the receiving vessel securely moored If bunkering from a barge, is the barge securely moored? Has method and clarity of communications been established between responsible officers?

Primary system: Backup system: Emergency Stop Signal:

R R A, R

(VHF/UHF Ch)

25 26 27 28 29 30 31

Has delivery documentation including delivery notes and MSDS been checked and found satisfactory? Have bunker hoses been identified with grade of oil? Have drip trays been provided under hose couplings? Are hose couplings properly connected with all flange bolts fitted? Has initial bunker line up been checked and all unused manifolds blanked and fully bolted? Has a visual inspection been made of oil to check for a frothy or bubbly mixture? If frothy or bubbly mixture discovered has a TEC 08 Bunkering Operations Checklist File Ref: Master & Ch. Eng: Log Entry Revision Number: 03

Page 2 of 5 Created: October 2007

V.SHIPS MANAGEMENT SYSTEM (VMS)

note of protest been issued to barge and management office advised? Is there a safe means of access between barge and ship? All external doors and ports in the accommodation closed? Has a maximum rate or back pressure been agreed with the bunker supplier?

Max rate = Max back pressure =

32 33 34

R R A

35

Has the notice period been agreed for reducing the rate for topping off / completion? Have procedures for changing over tanks, including any stoppages, been agreed?

Notice_____Minutes State Ship or Shore stop notification

36

Pre-Commencement Declaration We have checked, where appropriate jointly, the items of the checklist in accordance with the instructions and have satisfied ourselves that the entries made are correct to the best of our knowledge. Items coded A signify mutual agreement has been reached between vessel and supplier. We have also made arrangements to carry out repetitive checks as necessary and agreed that the items coded R in the checklist should be rechecked at intervals not exceeding..hours If, to our knowledge, the status of any item changes, we will immediately inform the other party.

For Ship Name Rank Signature Date Time Name Rank Signature Date

For Barge

Time

Page 3 of 5 Created: October 2007

TEC 08 Bunkering Operations Checklist File Ref: Master & Ch. Eng: Log Entry Revision Number: 03

V.SHIPS MANAGEMENT SYSTEM (VMS)

During Bunkering

37 38 39 40 41 Are all ships bunker tanks being checked at regular intervals? Bunker hoses and lines checked for leakage? Are drip samples being collected over the whole bunkering period? Is there an effective watch on board the barge and on the vessel maintained at the bunker connection and roving watch to detect spills? Testing for toxic gas emissions carried out appropriate to MSDS sheet? A, R R R R R

H2S content. Benzene Content.. At intervals not exceeding minutes

42 43

Has the receiving rate been calculated and is the supplier being updated with the rate and estimated time for topping off and completion? Has the communications between the ship and supplier been tested?

R R

Record of repetitive checks

Date: Time: Initials for Ship: Initials for Barge:

Page 4 of 5 Created: October 2007

TEC 08 Bunkering Operations Checklist File Ref: Master & Ch. Eng: Log Entry Revision Number: 03

V.SHIPS MANAGEMENT SYSTEM (VMS)

After Completion of Bunkering

44 45 46 47 48 49 50 51 52 Have all ship barge or bunkering facility tanks been sounded and delivery quantity verified? Has bunker receipt been signed by the Chief Engineer and Master for volume only and not for weight? Have all lines been drained? Have bunker hoses been disconnected and manifolds blanked? Have drip trays been drained? Have the contents of drip sample container been stirred before transfer to sample bottles? Have the samples been sealed and signed by suppliers representative? Has MARPOL VI sample been taken, sealed and seal number recorded and number updated in Annex VI register and the BDN? Have the samples been despatched to the nearest VPS or other fuel testing programme laboratory within 24 hours? Has the sampling and sealing of the suppliers sample been personally witnessed and carried out in accordance with VPS or other testing programme procedures?

NB: VShips to be advised of the reasons if this is not possible

53

Closing Declaration

We have checked, where appropriate jointly, the items of the checklist in accordance with the instructions and have satisfied ourselves that the entries made are correct to the best of our knowledge.

For Ship Name Rank Signature Date Time Name Rank Signature Date

For Barge

Time

Page 5 of 5 Created: October 2007

TEC 08 Bunkering Operations Checklist File Ref: Master & Ch. Eng: Log Entry Revision Number: 03

You might also like

- Tech 32c MSC Manya S PlakidaDocument24 pagesTech 32c MSC Manya S PlakidajudesonNo ratings yet

- D-3 - Status of CertificatesDocument4 pagesD-3 - Status of Certificatesmaxuya2001No ratings yet

- Applicable Bunkering ChecklistDocument1 pageApplicable Bunkering ChecklistM SundaramNo ratings yet

- Allianz Middle East Ship Management LLC: 500 Meter ChecklistDocument3 pagesAllianz Middle East Ship Management LLC: 500 Meter ChecklistJeet SinghNo ratings yet

- Loading PlanDocument6 pagesLoading PlanIordache Dumitru100% (1)

- Table of Shipboard Working ArrangementsDocument2 pagesTable of Shipboard Working ArrangementsKunal SinghNo ratings yet

- TEC 08a - Washing State Bunker Procedure List PDFDocument2 pagesTEC 08a - Washing State Bunker Procedure List PDFnmospanNo ratings yet

- S-18 - Bunkering ChecklistDocument3 pagesS-18 - Bunkering Checklistmaxuya2001No ratings yet

- Rsq-0560 Vms 6.1 ReleaseDocument4 pagesRsq-0560 Vms 6.1 ReleaseIgor PetrovNo ratings yet

- F0603 Deck Senior Officers Handing Over FormDocument3 pagesF0603 Deck Senior Officers Handing Over FormIhwan AsrulNo ratings yet

- Famirlirisatio Card s3.14f PDFDocument2 pagesFamirlirisatio Card s3.14f PDFNaNNo ratings yet

- A. Checklist Cargo Ops OKDocument44 pagesA. Checklist Cargo Ops OKIhwan Asrul100% (1)

- Deck FormsDocument81 pagesDeck FormsRose AriantiNo ratings yet

- MV. Pekan Fajar PRELIME SURVEY REPORTDocument5 pagesMV. Pekan Fajar PRELIME SURVEY REPORTintan nNo ratings yet

- Cargo Loading/Discharge PlanDocument14 pagesCargo Loading/Discharge Planعبدالله الشحيNo ratings yet

- Superintendent Visit Report Ob LSBL ViiiDocument7 pagesSuperintendent Visit Report Ob LSBL ViiialsitorNo ratings yet

- SBS-417 Bunker PlanDocument2 pagesSBS-417 Bunker PlanalberioNo ratings yet

- MT Alexia - SpecificatieDocument18 pagesMT Alexia - SpecificatiecpîndaruNo ratings yet

- Pms Monthly ReportDocument2 pagesPms Monthly ReportKunal SinghNo ratings yet

- Disch Plan VOY 89 Disch at Sendai, Japan - 20 KLDocument17 pagesDisch Plan VOY 89 Disch at Sendai, Japan - 20 KLRahul GuptaNo ratings yet

- Voy 038D Callao - TalaraDocument35 pagesVoy 038D Callao - TalaraHendra TambunanNo ratings yet

- SQE MARINE Cargo Shifting 2018-07-1Document2 pagesSQE MARINE Cargo Shifting 2018-07-1MeysamGholizadeh100% (1)

- CS 209 Form MasterlistDocument13 pagesCS 209 Form MasterlistDiwakar Singh100% (1)

- Store Forepeak STBDDocument1 pageStore Forepeak STBDalsitorNo ratings yet

- Shipboard Safety MeetingDocument2 pagesShipboard Safety MeetingKunal SinghNo ratings yet

- Maintenance Plan Bg. TaisirDocument12 pagesMaintenance Plan Bg. TaisiralsitorNo ratings yet

- CONTAINER CARGO OPERATIONS AND SECURING GUIDELINESDocument15 pagesCONTAINER CARGO OPERATIONS AND SECURING GUIDELINESintan nNo ratings yet

- Tanker Inspection Report SummaryDocument15 pagesTanker Inspection Report SummaryMalik Badi Uz Zaman100% (1)

- F06-12 Chief Engineer Briefing AshoreDocument3 pagesF06-12 Chief Engineer Briefing AshoreIhwan AsrulNo ratings yet

- Master's SMS Review Report SummaryDocument3 pagesMaster's SMS Review Report Summaryoto saviour100% (1)

- 4.7 Cargo Sampling ProcedureDocument7 pages4.7 Cargo Sampling ProcedureHasan CosalevNo ratings yet

- M.V. Spar Virgo at Tuticorin Off Hire Bunker ConditionDocument15 pagesM.V. Spar Virgo at Tuticorin Off Hire Bunker ConditionVikkiVikiNo ratings yet

- G138 Shipboard WorkingDocument3 pagesG138 Shipboard WorkingJeet SinghNo ratings yet

- Vessel Name: TB SADP XXX Date Position Description Tested by Sensor AlarmDocument4 pagesVessel Name: TB SADP XXX Date Position Description Tested by Sensor AlarmalsitorNo ratings yet

- Sire InspectionDocument8 pagesSire InspectionAnil yucebasNo ratings yet

- P-010 Crew Change Confirmation Form Rev 00Document1 pageP-010 Crew Change Confirmation Form Rev 00Ihwan AsrulNo ratings yet

- BRG & DK Procedures Checklist FormsDocument17 pagesBRG & DK Procedures Checklist FormsMeraz AhmedNo ratings yet

- Tanker Survey QuestionnaireDocument4 pagesTanker Survey Questionnairerays100% (1)

- C.E Abstract LogDocument5 pagesC.E Abstract LogAri SetiawanNo ratings yet

- 25 ISM System Familiarization ChecklistDocument1 page25 ISM System Familiarization ChecklistJeet SinghNo ratings yet

- Guidelines For Ism AuditDocument6 pagesGuidelines For Ism AuditUmang Gabba100% (1)

- Blank Vessel Safety Inspection Report - NPO FunctionDocument13 pagesBlank Vessel Safety Inspection Report - NPO FunctioncaptafuentesNo ratings yet

- ENV-09A - Fuel Change-Over Procedure Rev 0Document15 pagesENV-09A - Fuel Change-Over Procedure Rev 0Filip NikolevskiNo ratings yet

- Checklist Pms ObDocument3 pagesChecklist Pms ObalsitorNo ratings yet

- Bridge / Deck DPT Filing List: As PerDocument5 pagesBridge / Deck DPT Filing List: As Persailor21316No ratings yet

- 407.001 Main Engine Performance ReportDocument1 page407.001 Main Engine Performance ReportCelal BozdoganNo ratings yet

- Main Engine Running Hours ReportDocument1 pageMain Engine Running Hours ReportIhwan AsrulNo ratings yet

- Vessel Discharging AgreementDocument2 pagesVessel Discharging Agreementantopaul2100% (3)

- Shipboard education formDocument1 pageShipboard education formalsitorNo ratings yet

- On-Off Hire SurveyDocument1 pageOn-Off Hire SurveyAditya PrasadNo ratings yet

- Hospital Medicine Inventory OctDocument8 pagesHospital Medicine Inventory OctJeet SinghNo ratings yet

- Vetting Close Out 3Document4 pagesVetting Close Out 3Muhammad Fajri FahmiNo ratings yet

- Guidelines For Supt - EngineersDocument2 pagesGuidelines For Supt - EngineersjoreyvilNo ratings yet

- Dampskibsselskabet "NORDENDocument1 pageDampskibsselskabet "NORDENopytnymoryakNo ratings yet

- 22 Free Port To Mussafah Esnaad Base 01sepDocument3 pages22 Free Port To Mussafah Esnaad Base 01sepJeet SinghNo ratings yet

- Appendix 1 868 Ballast Water Reporting FormDocument1 pageAppendix 1 868 Ballast Water Reporting Formapi-26251207100% (1)

- Certificate Validity Issued by Convention: MARPOL Annex V (Ships 400 GT / Less When Carrying More Than 15 Passengers)Document5 pagesCertificate Validity Issued by Convention: MARPOL Annex V (Ships 400 GT / Less When Carrying More Than 15 Passengers)Dhanam Vijaya Kumar ChellapalliNo ratings yet

- Ship/Shore Safety Check List: Company Forms and Check ListsDocument3 pagesShip/Shore Safety Check List: Company Forms and Check ListsopytnymoryakNo ratings yet

- ECL6 Bunkering Safety ChecklistDocument3 pagesECL6 Bunkering Safety Checklistyvonne22No ratings yet

- Ahmad Ridzuan Ibrahim (CD 5103)Document24 pagesAhmad Ridzuan Ibrahim (CD 5103)Kabil RajNo ratings yet

- Request Documents or InfoDocument6 pagesRequest Documents or InfoRashika RampalNo ratings yet

- Loyalty Program Description PDFDocument7 pagesLoyalty Program Description PDFJayjay latiNo ratings yet

- Strategic Control ProcessDocument18 pagesStrategic Control ProcessMudassir IslamNo ratings yet

- Usb Modem 2Document4 pagesUsb Modem 2emadNo ratings yet

- Table of Specification (Automated) v1Document1 pageTable of Specification (Automated) v1Ar WinNo ratings yet

- Chapter 19 - Managing Personal CommunicationDocument37 pagesChapter 19 - Managing Personal CommunicationAmit Thapa100% (2)

- Physics 05-01 Fluids and DensityDocument2 pagesPhysics 05-01 Fluids and DensityRocelin E. MolabolaNo ratings yet

- 12 585 Rov Latches Brochure v3 Web 1 PDFDocument8 pages12 585 Rov Latches Brochure v3 Web 1 PDFIZayvenkoNo ratings yet

- A Day in The Life of A Proactive Maintenance TechnicianDocument6 pagesA Day in The Life of A Proactive Maintenance TechnicianAshraf Al KirkuklyNo ratings yet

- Engineering Technical Report of The v12 Engine and Related Assignments at Tipco IncDocument36 pagesEngineering Technical Report of The v12 Engine and Related Assignments at Tipco Incapi-244817040No ratings yet

- Bio BatteryDocument29 pagesBio BatteryDileepChowdary100% (1)

- Orace Rac TafDocument4 pagesOrace Rac TafNst TnagarNo ratings yet

- Ficha Tecnica Viking PDFDocument11 pagesFicha Tecnica Viking PDFRichie ChicolNo ratings yet

- Evaluating SWOT's Value in Creating Actionable, Strategic IntelligenceDocument94 pagesEvaluating SWOT's Value in Creating Actionable, Strategic IntelligenceMJFinnegan4100% (4)

- Eee342 hw3 PDFDocument2 pagesEee342 hw3 PDFRedion XhepaNo ratings yet

- W6 ReadmeDocument15 pagesW6 ReadmewerewNo ratings yet

- Sda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Document1 pageSda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Himani PatelNo ratings yet

- Approved List of Manufacturers: Line Pipes (Carbon/Alloy Steel)Document4 pagesApproved List of Manufacturers: Line Pipes (Carbon/Alloy Steel)Sourav Kumar GuptaNo ratings yet

- UA Checkliste VPD Verfahren enDocument3 pagesUA Checkliste VPD Verfahren enBharadwaja ReddyNo ratings yet

- Barangay Profile: (BP DCF No. 1 S. 2022)Document4 pagesBarangay Profile: (BP DCF No. 1 S. 2022)AiMae BaobaoenNo ratings yet

- Bhopal Gas Tragedy Case StudyDocument10 pagesBhopal Gas Tragedy Case StudyAbhijith MadabhushiNo ratings yet

- Screw Conveyor O&M ManualDocument20 pagesScrew Conveyor O&M Manualjay b100% (1)

- Class PDF 516 QuestionDocument80 pagesClass PDF 516 QuestionRahul KashyapNo ratings yet

- 2019 Planning OverviewDocument7 pages2019 Planning Overviewapi-323922022No ratings yet

- Finaldc 2Document10 pagesFinaldc 2Noel BactonNo ratings yet

- IWWA Directory-2020-2021Document72 pagesIWWA Directory-2020-2021venkatesh19701No ratings yet

- Ladybug5 DatasheetDocument2 pagesLadybug5 DatasheetEloy Ricardo Franco FigueiraNo ratings yet

- Fast, Fast VP : FAST: Features, Drawbacks, Applications and Some QuestionsDocument13 pagesFast, Fast VP : FAST: Features, Drawbacks, Applications and Some QuestionsSraVanKuMarThadakamallaNo ratings yet

- Spokane County Sheriff's Internal Communication PlanDocument11 pagesSpokane County Sheriff's Internal Communication Planjmcgrath208100% (1)