Professional Documents

Culture Documents

Fab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FS

Uploaded by

abidaliabid1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FS

Uploaded by

abidaliabid1Copyright:

Available Formats

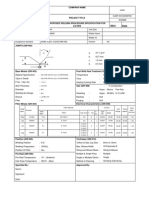

Doc No: QA/QC-FRM-002 Rev: 00

WELDING PROCEDURE SPECIFICATION

Welding Procedure Specification no. Supporting PQR No.(s) Manufacturer: Welding Process (es): CODE: FAB-WPS-002 FAB-PQR-002 FABCON DESIGN & ENGINEERING (Pvt) LTD. GTAW+SMAW ASME IX Type (s) * Manual Revision No. Date: 00 3/Sep/12

Date: Dec 04, 2009 Page: 1 of 2 Date: 3/Sep/12

* (Automatic, Manual, Machine or Semi-Auto)

JOINTS (QW-402)

Joint Design Backing (Yes) As per Drawing GTAW:With Or Without SMAW-With only Backing Material (Type) Base Metal : Weld Metal 2 ~ 4 mm N/A

Root Spacing :

Rtainers (Yes / No) (Refer to both backing and retainers)

Bevel Preparation:- Flame cut, Machining / Grinding

BASE METALS (QW-403)

P.No. S.No. OR Specification type and grade to specification type and grade OR Chem. Analysis and Mech. Prop. to Chem. Analysis and Mech. Prop. Thickness Range : Base Metal : Pipe Dia Range: Other Groove Groove 5 ~ 50 mm All Fillet : Fillet : All All N.A

SA 335 Gr-P22 SA 335 Gr-P22

5A

Group No. Group No.

1 to S.No.

to P.No.

5A Group No.

Group No.

* REPAIR FOR ALL MENTION THICKNESS (FAB-QC-PR-002)

FILLER METALS (QW-404)

Spec. No. (SFA) AWS No. (Class) F. No. A.No. Size of Electrode/Filler Wire Filler Metal Product Type Deposited Weld Metal: Thickness Range : Groove Fillet Flux Electrode-Flux (Class) Flux Trade Name Consumable Insert Brand *

Root 5.28 ER 90S-B3 6 3 2.4 mm Lincoln 12 mm (Max)

Filling / Capping 5.5 E 9018 B3 4 3 2.5, 3.25, 4.00 mm Fortrex 75 mm (Max)

upto 10 mm All NA NA NA None BOC / LION UK

upto 50 mm All NA 8 NA None BOC / LION UK

* Trade Name : Bohler, Metrode, ESAB, Lincoln, Kobe Steel or Equivalent.

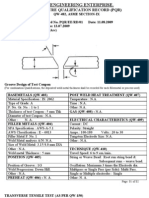

Doc No: QA/QC-FRM-002 Rev: 00

WELDING PROCEDURE SPECIFICATION

Rev: 00

Date: Dec 04, 2009 Page: 1 of 2 WPS No: FAB-WPS-001

POSITIONS (QW-405)

Position(s) of Groove Welding Progression : Uphill All

POST WELD HEAT TREATMENT (QW-407)

Temperature Range SoakingTime Rate of Heating 700~745 C

2 Hours Min (1 hour/25mm THK) 200oC/Hour 200 C/Hour Upto 250oC

o

Downhill

Position(s) of Fillet

All

Rate of Cooling

PREHEAT (QW-406)

Preheat Temp Min. Interpass Temp Max. Preheat Maintenance Others : 200 C 350 C 300 C ~ 400 C Post Heating

o o o o

GAS (QW-408) Composition Gas(es) Shielding Trailing Backing Argon Argon Mixture %

99.99% Flow rate(l/min) 6 ~ 15

None

99.99% 6 ~ 15

ELECTRICAL CHARACTERISTICS (QW-409) Current AC or DC Amps (Range) DC See Table below Polarity Volts (Range) GTAW : EN / SMAW : EP See Table below

(Amps and volts range should be recorded for each electrode size, position, and thickness, etc. This information may be listed in a tabular form similar to that shown below.) Pulsing NO 2 , 2.4 mm, Tungsten Electrode 2% Thoriated (Pure Tungsten, E WTh2) Tungsten electrode Size and Type

TECHNIQUE (QW-410)

String or Weave bead Orifice or Gas Cup Size Initial and Interpass Cleaning (Brushing, Grinding etc.) Method of Back Gouging Oscillation Multiple or Single Pass (per side) Multiple or Single Electrodes Travel Speed (Range) Peening Other Root: (String), Filling / Capping:Both (Weaving 4 times of Electrode dia max.) 6~12 mm Wire brushing, Grinding / Chipping BY Air arc Gouging,Grinding etc. N.A Multiple Single 4 ~ 5 CM/Min For GTAW , 6 ~ 7 CM/Min FOR SMAW NA Back welding may be done after grinding of sound metal

Sr. No. 1 2 3 4

Weld Layer (s) ROOT HOT FILL CAP

Filler Metal Process Class GTAW GTAW SMAW SMAW ER 90S-B3 ER 90S-B3 E 9018 B3 E 7018 Dia. 2.4 mm 2.4 mm 4.0 mm 3.25 mm Type DCEN DCEN DCEN DCEN

Current Amp. Range 85-100 80-150 120-180 90-160

Volt Range 13-15 13-15 20-30 20-30

PREPARED BY

NAME. : SIGN : DATE : Junaid Arif NAME. : SIGN : DATE :

APPROVED BY

MUHAMMAD fahim sadiq NAME. : SIGN : 9/3/2012 DATE :

REVIEWED BY

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- WPS FormatDocument1 pageWPS FormatAbdullah AnsariNo ratings yet

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- AWS A5.21-A5.21 M - 2011 SPC For Electrods & Rodes For SurfacingDocument12 pagesAWS A5.21-A5.21 M - 2011 SPC For Electrods & Rodes For Surfacingkdalavadi390550% (2)

- ISO Standards On WeldingDocument22 pagesISO Standards On Weldingmoxshyde100% (1)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Start-Up Sample BPDocument54 pagesStart-Up Sample BPsteven100% (1)

- BK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldDocument2 pagesBK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldHarkesh RajputNo ratings yet

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Prof. Dr. Ismail A. AbdallahDocument3 pagesProf. Dr. Ismail A. Abdallahabidaliabid167% (3)

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- Welding Terms and Definitions PDFDocument6 pagesWelding Terms and Definitions PDFtomj9104No ratings yet

- WELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111Document15 pagesWELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111surya1960No ratings yet

- Operating FactorDocument9 pagesOperating Factormekhman mekhtyNo ratings yet

- WPS For Structure Mild Steel Fillet WeldDocument2 pagesWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- MANUFACTURING PROCESS WELDING OVERVIEWDocument70 pagesMANUFACTURING PROCESS WELDING OVERVIEWAzmeer Mohamed100% (1)

- WPSDocument2 pagesWPSJuli Agus50% (2)

- Loading Unloading Temperature Welding ProgressionDocument5 pagesLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- PQR-WPS-WPQR XXX Rev 0Document6 pagesPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- AWS 2007 standards library color codesDocument12 pagesAWS 2007 standards library color codesWagnerTarossiNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- MRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDocument5 pagesMRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDeepak100% (1)

- Welding Terms & Definitions GuideDocument42 pagesWelding Terms & Definitions GuidepchakkrapaniNo ratings yet

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- GIS 18-012 Procurement, Storage, and Control of Welding ConsumablesDocument12 pagesGIS 18-012 Procurement, Storage, and Control of Welding ConsumablesDinesh NadarNo ratings yet

- Lecture 13 - HEAT FLOW AND HEAT BALANCE IN WELDINGDocument10 pagesLecture 13 - HEAT FLOW AND HEAT BALANCE IN WELDINGVINAYAK SHARMANo ratings yet

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Interview Questions and AnswersDocument8 pagesInterview Questions and AnswersMahendra Prasad100% (4)

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- BS EN 196-Part1Document29 pagesBS EN 196-Part1abidaliabid167% (3)

- Brochure Roll Bonded Clad Plates EDocument36 pagesBrochure Roll Bonded Clad Plates EAries MarteNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- SS312 Type310Document4 pagesSS312 Type310Vimin PrakashNo ratings yet

- New IELTS Writing Answer SheetDocument4 pagesNew IELTS Writing Answer Sheetraaj2240% (5)

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingFrom EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNo ratings yet

- WPS Indosol 001 (ASME) RDocument2 pagesWPS Indosol 001 (ASME) RDoni HardiNo ratings yet

- Welding Procedure Specification-1Document8 pagesWelding Procedure Specification-1Suresh Rathod100% (1)

- Everything You Need to Know About Stainless Steel Welding Procedure SpecificationDocument6 pagesEverything You Need to Know About Stainless Steel Welding Procedure SpecificationDanem HalasNo ratings yet

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Document24 pagesPrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNo ratings yet

- Ami-003 WPSDocument2 pagesAmi-003 WPSBenjamin BrownNo ratings yet

- Welding Variables for Qualification of Base Metals and Filler MetalsDocument3 pagesWelding Variables for Qualification of Base Metals and Filler MetalsAdilMunirNo ratings yet

- Plates ASTM-A240 Gr 304LDocument6 pagesPlates ASTM-A240 Gr 304Labhishek198327No ratings yet

- Astm A53-A53m-12Document23 pagesAstm A53-A53m-12abidaliabid1100% (2)

- QW 483Document2 pagesQW 483delta lab sangliNo ratings yet

- MIl W 8611.PDF Rev ADocument10 pagesMIl W 8611.PDF Rev ABryan MartinezNo ratings yet

- WPS TITLEDocument2 pagesWPS TITLERichard Periyanayagam86% (14)

- (EW-471) - Gas Metal Arc Welding (2012 - 1998, Hobart Institute of Welding Technology)Document9 pages(EW-471) - Gas Metal Arc Welding (2012 - 1998, Hobart Institute of Welding Technology)Juan Diego AlvarezNo ratings yet

- Groove DesignDocument4 pagesGroove DesignElizabeth SpenceNo ratings yet

- p22MNVMB MN Gtaw+Smaw (Pipe)Document2 pagesp22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1No ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Des QC 8505 Ab 08Document3 pagesDes QC 8505 Ab 08Touseef RafiqueNo ratings yet

- 2005-05 - WPS & PQR C5Document6 pages2005-05 - WPS & PQR C5misthahNo ratings yet

- Nit 2019 20 56 Wps 1569579575Document16 pagesNit 2019 20 56 Wps 1569579575vijayachiduNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document2 pagesQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Interiew Stuff Adfasd Adf Asdfafads FaDocument46 pagesInteriew Stuff Adfasd Adf Asdfafads Faabidaliabid1No ratings yet

- The Sssessential List of Microsoft Outlook Keyboard ShortcutsDocument3 pagesThe Sssessential List of Microsoft Outlook Keyboard Shortcutsabidaliabid1No ratings yet

- Ultramag Sg3: Mild Steel Solid WireDocument1 pageUltramag Sg3: Mild Steel Solid Wireabidaliabid1No ratings yet

- Business Plan Fill in Form PDFDocument12 pagesBusiness Plan Fill in Form PDFabidaliabid1No ratings yet

- November 2021, March 2022, and July 2022: API 653 Exam Administration - Publications Effectivity SheetDocument1 pageNovember 2021, March 2022, and July 2022: API 653 Exam Administration - Publications Effectivity SheetBala KrishnanNo ratings yet

- Codes and Standard LinksDocument1 pageCodes and Standard Linksabidaliabid1No ratings yet

- Ifs 2002PVDocument3 pagesIfs 2002PVdowNo ratings yet

- Pressure Conversion TableDocument1 pagePressure Conversion Tableabidaliabid1No ratings yet

- Benefits of Dot Gazing and Simple ExercisesDocument22 pagesBenefits of Dot Gazing and Simple Exercisesabidaliabid1No ratings yet

- National Law Provisions Concerning International Taxation: Training Material HRM Wing (FBR) - GizDocument22 pagesNational Law Provisions Concerning International Taxation: Training Material HRM Wing (FBR) - GizMuhammad MoizNo ratings yet

- IONE-Binder LabelDocument13 pagesIONE-Binder Labelabidaliabid1No ratings yet

- Article Writing With PlaigiarismaDocument5 pagesArticle Writing With Plaigiarismaabidaliabid1No ratings yet

- Thomas Fahasd Fasfjda Lkas Fjklfjalkfj AklfDocument2 pagesThomas Fahasd Fasfjda Lkas Fjklfjalkfj Aklfabidaliabid1No ratings yet

- Haarp Class Presentation Reprents New Knowledge in Technology and ScienceDocument40 pagesHaarp Class Presentation Reprents New Knowledge in Technology and Scienceabidaliabid1No ratings yet

- Instructions HP 61Document2 pagesInstructions HP 61Nabil Mambailong DolmatNo ratings yet

- Exam Flashcards: by Jonathan DonadoDocument157 pagesExam Flashcards: by Jonathan Donadoabidaliabid1No ratings yet

- Instructions HP 61Document2 pagesInstructions HP 61Nabil Mambailong DolmatNo ratings yet

- Standards & Codes Quick Reference LinksDocument1 pageStandards & Codes Quick Reference Linksabidaliabid1No ratings yet

- Flow ChartDocument3 pagesFlow Chartnitin235No ratings yet

- Do Not Copy This Sample: Career EpisodeDocument6 pagesDo Not Copy This Sample: Career Episodeabidaliabid1No ratings yet

- Mohamed Younies: QC Welding Engineer/InspectorDocument1 pageMohamed Younies: QC Welding Engineer/Inspectorabidaliabid1No ratings yet

- Welding Details - Night ShiftDocument3 pagesWelding Details - Night Shiftabidaliabid1No ratings yet

- Chintan Raval - Welding Engineer with Over 15 Years ExperienceDocument3 pagesChintan Raval - Welding Engineer with Over 15 Years Experienceabidaliabid1No ratings yet

- ASME Guides WeldCanadaDocument3 pagesASME Guides WeldCanadaSubhan50No ratings yet

- ISO 9001 2000 OverviewDocument47 pagesISO 9001 2000 Overviewjesmon_ajNo ratings yet

- Av Catalogo Completo 2005Document20 pagesAv Catalogo Completo 2005Marin LaurentiuNo ratings yet

- European Standards For Destructive Test MethodsDocument6 pagesEuropean Standards For Destructive Test MethodsAdil HasanovNo ratings yet

- Procedure Qualification Records (PQR)Document2 pagesProcedure Qualification Records (PQR)amine algNo ratings yet

- Factors in Selection of Filler Metals in WeldingDocument2 pagesFactors in Selection of Filler Metals in WeldingBalakumarNo ratings yet

- Umicore BrazeTec Principles of BrazingDocument28 pagesUmicore BrazeTec Principles of BrazingsboergertNo ratings yet

- TK Schweisszusatzwerkstoffe GB PDFDocument132 pagesTK Schweisszusatzwerkstoffe GB PDFMohammed Ady GanjarNo ratings yet

- Is - Ihb.1969-Arc Welding MethidsDocument163 pagesIs - Ihb.1969-Arc Welding Methidssuresh kumarNo ratings yet

- Rke PQR 01Document2 pagesRke PQR 01Satish KeskarNo ratings yet

- GTAW Tigfil 70S-2 Triple Deoxidized Copper Coated C-Mn Steel Filler RodDocument1 pageGTAW Tigfil 70S-2 Triple Deoxidized Copper Coated C-Mn Steel Filler RodSureshNo ratings yet

- Materials System SpecificationDocument9 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- Ship and Boat Building and Repair-2Document5 pagesShip and Boat Building and Repair-2navalmamunNo ratings yet

- Welding SymbolsDocument12 pagesWelding SymbolsrsrtnjNo ratings yet

- Guidance On The Welding of Weathering SteelsDocument0 pagesGuidance On The Welding of Weathering Steelsinfinity_178No ratings yet

- Standard For Brazing Procedure and Performance QualificationDocument5 pagesStandard For Brazing Procedure and Performance QualificationvaibraineaterNo ratings yet