Professional Documents

Culture Documents

Portable M295 WilsonHardness

Uploaded by

Khoa Bui AnhOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Portable M295 WilsonHardness

Uploaded by

Khoa Bui AnhCopyright:

Available Formats

M295 Portable Hardness Tester

The completely new generation of portable Wilson Hardness Leeb type M Series testers offer the most affordable but accurate testing solution for on-site testing in workshops and in field operation for quality assurance. Any metal product with a minimum solid mass of 1,5 kg or more can be tested in any hardness scale. Test results appear immediately on backlit display. To maximize friendly use of the instruments on site, the M Series are featured with standard batteries and internal memory with RS-232 output. Seven different impact devices and various support rings allow for testing on a wide variety of part geometries. **This item is not available in the Americas

MODELS

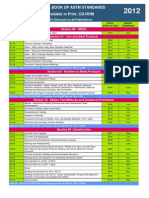

Materials versus range for impact device D (HLD 200-900)

Material

HRC

HRB

HRA

HB

HV

HS

Steel & cast steel

20-68

60-100

59-86

80-650 80-940 32-100

Coldwork tool steel

20-68

80-940

Stainless steel

20-62

46-100

80-650 80-800

Grey cast iron

90-380

Nodular cast iron

90-380

Aluminium alloy

20-160

Brass

40-170

Bronze

60-290

Copper

45-315

SPECIFICATIONS

Technical Specifications

Hardness Scales

HL(X), HRC, HRB, HV, HB, HS

Tensile strength UTS range (steel only)

From 370 to 2000 (106 N/mm2)

Display dimensions

128 x 64 LCD with back light function

Display functions

Hardness scale, Hardness value, Limits, Times,Average, Impact direction, Type device, Memory

Accuracy

Within 0.5% (at HRD = 800) on solid parts

Statistics

Average value

Memory

500 average readings, date

Output

RS232

Impact device

Any type

Workpiece max. hardness value

940HV

Work piece radius (convex/concave)

Rmin = 50 mm (with support ring Rmin = 10 mm)

Work piece minimum weight

1.5 kg on solid support (0.1 kg with couplant paste)

Work piece min. thickness when coupled

3 mm

Work piece min. case hardened depth

0.8 mm

Power

2 x AA battery 1.5V (low bat. warning)

Operating temperature

5 to 50 C

Overall dimensions (H x W x D)

132 mm x 76 mm x 31 mm

Weight

345 g

ACCESSORIES

Impact Device D Universal Standard unit. Perfect for the majority of hardness testing assignments.

Impact Device DC Extremely short impact device. Spring loaded with a special loading stick. Otherwise as for type D. Ideal in very confined spaces, e.g. in holes, cylinders or for internal measurements on assembled machines.

Impact Device D+15 Particularly slim front section and with measuring coil moved back. For hardness measurements in grooves and on recessed surfaces.

Impact Device DL Needle front section diameter 4.2 mm, length 50 mm. Perfect for measurements in extremely confined spaces.

Impact Device C Reduced impact energy (approximately of that for type D). Ideal for surface hardened components, coatings, thin walled or impact sensitive components (small measuring indentations).

Impact Device G Enlarged test tip, increased impact energy (approximately 9 times that of type D). Low demands on measuring surface finish. For measurements in the Brinel range only (max. 650 HB). Ideal for Solid components, e.g. heavy castings and forgings.

Impact Device E

Synthetic diamond test tip (approximately 5000 HV). For measurements in the extremely high hardness range (always in excess of 50 HRC/650 HV). Tool steels with high carbide content inclusions. For measurements up to 1200 HV.

Support rings On curved surfaces having a radius of under 30mm, effective positioning on the component is facilitated by the use of support rings. This ring can be screwed on front of the impact device. Set of 7 rings: Convex: 10-15mm, 14.5-30mm, 25-50mm Concave: 11-13mm, 12.5-17mm, 16.5-30mm Universal: one model

Printer Thermal printer for M295

You might also like

- Metal BenderDocument6 pagesMetal Benderbula10100% (1)

- Chelsea Filter Reactions Gem Stone Study 1Document3 pagesChelsea Filter Reactions Gem Stone Study 1Georgegeorgeb100% (1)

- ISO 3755 Cast-Carbon-Steel-General-Engineering-PurposesDocument9 pagesISO 3755 Cast-Carbon-Steel-General-Engineering-PurposesLe Van TamNo ratings yet

- Elizabeth Mayne - The Rose of LorraineDocument255 pagesElizabeth Mayne - The Rose of LorrainenardossNo ratings yet

- Geology of GemstoneDocument34 pagesGeology of GemstoneSaravanan RasayaNo ratings yet

- DinanderieDocument356 pagesDinanderieArannoHossain100% (1)

- Lost Stars - A Star Wars TaleDocument386 pagesLost Stars - A Star Wars TaleRobert Trnka100% (7)

- Iso 2819 1980Document8 pagesIso 2819 1980RobertoNo ratings yet

- De BeersDocument5 pagesDe Beerssanjeev_soni725951No ratings yet

- Diamond Spec Guide 2014Document438 pagesDiamond Spec Guide 2014user1-3No ratings yet

- Hi - Temp 900Document5 pagesHi - Temp 900bhavesh solankiNo ratings yet

- A Toy To Be LovedDocument28 pagesA Toy To Be LovedShyam BhatNo ratings yet

- Seiko Watch Corporation - Moving UpmarketDocument42 pagesSeiko Watch Corporation - Moving UpmarketMilitsa100% (1)

- Evaluating Coatings For High Temperature Service: Standard Test Methods ForDocument3 pagesEvaluating Coatings For High Temperature Service: Standard Test Methods ForFernando Berrospi Garay100% (1)

- Maleable Cast IronsDocument0 pagesMaleable Cast IronsGilang Miky Pratama AlwianNo ratings yet

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDocument2 pagesAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987No ratings yet

- Trim Material Valve PlugDocument4 pagesTrim Material Valve Plugalexmontell100% (1)

- MitrugpaDocument12 pagesMitrugpaAyur MontsuregiNo ratings yet

- Dedh Ishqiya - Draft 1Document79 pagesDedh Ishqiya - Draft 1moifightclub88% (8)

- Astm D792-20Document6 pagesAstm D792-20Александр ЛNo ratings yet

- Comparison of BS and BSEN For Steel Simplified VersionDocument28 pagesComparison of BS and BSEN For Steel Simplified VersiondpkguptNo ratings yet

- BS en 10002-2-1992Document15 pagesBS en 10002-2-1992Unes JrdNo ratings yet

- 50 Songs From The CharyagitiDocument20 pages50 Songs From The CharyagitiriechersmNo ratings yet

- Iso 21809 2 2007 en FR PDFDocument11 pagesIso 21809 2 2007 en FR PDFmsaremiNo ratings yet

- Implications of NORSOK M-650 Standard in The OffshoreDocument27 pagesImplications of NORSOK M-650 Standard in The OffshoreJoherNo ratings yet

- Se 1316Document46 pagesSe 1316leonciomavarezNo ratings yet

- 25CrMo4Document1 page25CrMo4Hans GoetheNo ratings yet

- Seamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForDocument3 pagesSeamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification Forandrea assanelli100% (1)

- Abrasion TaberDocument2 pagesAbrasion TaberDiego Fernado AvendañoNo ratings yet

- Astm E10 2001 PDFDocument9 pagesAstm E10 2001 PDFSofiaJabadanEspulgarNo ratings yet

- Surface Comparator Chart Sa 2 5Document5 pagesSurface Comparator Chart Sa 2 5Vebryan SyahNo ratings yet

- 16-GB-T 8162-1999-Seamless Steel Tubes For Structural PurposesDocument30 pages16-GB-T 8162-1999-Seamless Steel Tubes For Structural PurposesWellington AnaluisaNo ratings yet

- Iso 7452 2013 en PDFDocument8 pagesIso 7452 2013 en PDFfahmi aballiNo ratings yet

- Polythionic Acid Stress Corrosion CrackingDocument3 pagesPolythionic Acid Stress Corrosion Crackingvajidqc100% (1)

- Sample Qap For NpcilDocument2 pagesSample Qap For NpcilSuKHjiT SiNGhNo ratings yet

- Astm A240 Uns S32205Document3 pagesAstm A240 Uns S32205Mintone Sajayah BekabekaNo ratings yet

- Din en 1172 e 2010-07Document16 pagesDin en 1172 e 2010-07Niko Zurabishvili100% (1)

- 1.4404 enDocument5 pages1.4404 enyraju88No ratings yet

- D1414-22 9.02 Standard Test Methods For Rubber O-RingsDocument24 pagesD1414-22 9.02 Standard Test Methods For Rubber O-RingsHamidreza AraghianNo ratings yet

- Coating Thickness Meter Data SheetDocument2 pagesCoating Thickness Meter Data SheetMohamed ZainNo ratings yet

- Drop Weight Tear Testing of High Toughness Pipeline MaterialDocument8 pagesDrop Weight Tear Testing of High Toughness Pipeline MaterialKK SinghNo ratings yet

- En 10029Document5 pagesEn 10029PHAMTOAINo ratings yet

- 521+technical Data Sheet V-6Document2 pages521+technical Data Sheet V-6TeenTeen GaMingNo ratings yet

- Astm A423 A423m-95Document3 pagesAstm A423 A423m-95FeteneNo ratings yet

- Quality HandbookDocument8 pagesQuality HandbookGuillermo Guerrero VacasNo ratings yet

- 11.03 Iso-6272-1-2011Document9 pages11.03 Iso-6272-1-2011hoanvuNo ratings yet

- Metz Lab Presentation: First Floor, Thangavel Nagar, Walajabad Main Road, Mannivakkam-600048Document20 pagesMetz Lab Presentation: First Floor, Thangavel Nagar, Walajabad Main Road, Mannivakkam-600048sevugarajanNo ratings yet

- Tinius Olsen - Ref 30 - 60000lb Cal Super L - B117GDocument8 pagesTinius Olsen - Ref 30 - 60000lb Cal Super L - B117Gjr_satish6965No ratings yet

- Nfa 49 310 Grade Tu 52 B Tubes PDFDocument1 pageNfa 49 310 Grade Tu 52 B Tubes PDFMitul MehtaNo ratings yet

- Material Data Sheet en Aw 6082 Almgsi1Document1 pageMaterial Data Sheet en Aw 6082 Almgsi1pankajrs.mechengineer4502No ratings yet

- Righton LTD - Copper and Copper Alloys CC492K LG4 - 379 PDFDocument1 pageRighton LTD - Copper and Copper Alloys CC492K LG4 - 379 PDFjenishjsNo ratings yet

- Application for Certification according to DIN 18800-7Document9 pagesApplication for Certification according to DIN 18800-7gorgika papandNo ratings yet

- MSU Copper Casting Alloys 2011 PDFDocument10 pagesMSU Copper Casting Alloys 2011 PDFVahid SarfarazNo ratings yet

- NDT of helically welded pipesDocument13 pagesNDT of helically welded pipes_ARCUL_No ratings yet

- GB-T 232-2010 Metallic Materials-Bend TestDocument14 pagesGB-T 232-2010 Metallic Materials-Bend TestH. Camer E.No ratings yet

- Jis D0205 1987 PDFDocument52 pagesJis D0205 1987 PDFAMUL VEKARIANo ratings yet

- Chromium nickel martensitic stainless steel propertiesDocument2 pagesChromium nickel martensitic stainless steel propertiesZeljko68No ratings yet

- MIL-STD-193L Painting Procedures and Marking For Vehicles, Construction Equipment, Material Handling Equipment, and Spare PartsDocument47 pagesMIL-STD-193L Painting Procedures and Marking For Vehicles, Construction Equipment, Material Handling Equipment, and Spare PartsCemalNo ratings yet

- WPQR TIG Fillet Welding ProcedureDocument3 pagesWPQR TIG Fillet Welding ProcedureDimitris NikouNo ratings yet

- Non-Oriented Fully Process Electrical Steel - ASTMDocument28 pagesNon-Oriented Fully Process Electrical Steel - ASTMhpham2005No ratings yet

- Spe 76-222 Dec 2012Document10 pagesSpe 76-222 Dec 2012akashdruva892No ratings yet

- Astm2012 PDFDocument3 pagesAstm2012 PDFRiyas UdheenNo ratings yet

- EN 1043-2 Micro Hardness TestDocument13 pagesEN 1043-2 Micro Hardness TestMadley RockNo ratings yet

- Abrasion (Mechanical)Document29 pagesAbrasion (Mechanical)stallone21No ratings yet

- A571 PDFDocument6 pagesA571 PDFMahendra PatilNo ratings yet

- Hardness Tester PortableDocument2 pagesHardness Tester Portablealfachemy100% (1)

- DP 300 Portable Hardness TesterDocument2 pagesDP 300 Portable Hardness Testerviller_lpNo ratings yet

- Portable hardness tester - Thiết bị đo độ cứng cầm tay- Liên hệ: 0989653832Document15 pagesPortable hardness tester - Thiết bị đo độ cứng cầm tay- Liên hệ: 0989653832Đặng Đình TuấnNo ratings yet

- Why Check Hardness? Understanding Material Properties and Testing MethodsDocument58 pagesWhy Check Hardness? Understanding Material Properties and Testing MethodsVishal MandlikNo ratings yet

- Why Check Hardness? Key Factors of Hardness TestingDocument58 pagesWhy Check Hardness? Key Factors of Hardness TestingTim NguyenNo ratings yet

- HLN-11A Leeb Portable Hardness TesterDocument2 pagesHLN-11A Leeb Portable Hardness TesterRaden RoyNo ratings yet

- Universal 930 WilsonHardnessREV3Document2 pagesUniversal 930 WilsonHardnessREV3Khoa Bui AnhNo ratings yet

- Universal UH250 WilsonHardness en LoresDocument2 pagesUniversal UH250 WilsonHardness en LoresKhoa Bui AnhNo ratings yet

- Universal 930 WilsonHardness en LoresDocument2 pagesUniversal 930 WilsonHardness en LoresKhoa Bui AnhNo ratings yet

- Universal UH250 WilsonHardnessDocument2 pagesUniversal UH250 WilsonHardnessKhoa Bui AnhNo ratings yet

- Universal POD UH751-3001 WilsonHardness 0313Document2 pagesUniversal POD UH751-3001 WilsonHardness 0313Khoa Bui AnhNo ratings yet

- ROCKWELL 2000 WilsonHardnessDocument2 pagesROCKWELL 2000 WilsonHardnessKhoa Bui AnhNo ratings yet

- ROCKWELL POD BriorR WilsonHardness LoresDocument2 pagesROCKWELL POD BriorR WilsonHardness LoresKhoa Bui AnhNo ratings yet

- ROCKWELL POD 2000 WilsonHardness LoresDocument2 pagesROCKWELL POD 2000 WilsonHardness LoresKhoa Bui AnhNo ratings yet

- ROCKWELL POD 574 WilsonHardness LoresDocument2 pagesROCKWELL POD 574 WilsonHardness LoresKhoa Bui AnhNo ratings yet

- Universal POD UH753-3003 WilsonHardness 0313Document2 pagesUniversal POD UH753-3003 WilsonHardness 0313Khoa Bui AnhNo ratings yet

- Portable POD M495 WilsonHardness LoresDocument2 pagesPortable POD M495 WilsonHardness LoresKhoa Bui AnhNo ratings yet

- ROCKWELL 574 WilsonHardnessDocument2 pagesROCKWELL 574 WilsonHardnessKhoa Bui Anh0% (1)

- Knoop - Vickers KV KL4Document2 pagesKnoop - Vickers KV KL4Khoa Bui AnhNo ratings yet

- Knoop - Vicker Tukon2500 en LoresDocument2 pagesKnoop - Vicker Tukon2500 en LoresKhoa Bui AnhNo ratings yet

- Knoop - Vicker Tukon3100 0412Document2 pagesKnoop - Vicker Tukon3100 0412Khoa Bui AnhNo ratings yet

- Knoop - Vicker VH3100Document16 pagesKnoop - Vicker VH3100Khoa Bui AnhNo ratings yet

- BRINELL BH3000 - WilsonHardnessDocument2 pagesBRINELL BH3000 - WilsonHardnessKhoa Bui AnhNo ratings yet

- Knoop - Vicker POD 1202 WilsonHardness LoresDocument2 pagesKnoop - Vicker POD 1202 WilsonHardness LoresKhoa Bui AnhNo ratings yet

- Knoop - Vicker 1202 WilsonHardnessREV3Document2 pagesKnoop - Vicker 1202 WilsonHardnessREV3Khoa Bui AnhNo ratings yet

- Knoop - Vicker FN01474 Wilson VH3100Document16 pagesKnoop - Vicker FN01474 Wilson VH3100Khoa Bui AnhNo ratings yet

- Knoop - Vicker POD 432&452SVD WilsonHardness LoresDocument2 pagesKnoop - Vicker POD 432&452SVD WilsonHardness LoresKhoa Bui AnhNo ratings yet

- Knoop - Vicker 402MVD WilsonHardnessDocument2 pagesKnoop - Vicker 402MVD WilsonHardnessKhoa Bui AnhNo ratings yet

- Knoop - Vicker 402MVD WilsonHardness en LoresDocument2 pagesKnoop - Vicker 402MVD WilsonHardness en LoresKhoa Bui AnhNo ratings yet

- Answers To Chapter 3 Review QuestionsDocument3 pagesAnswers To Chapter 3 Review Questionsieltstutor100% (1)

- Gem Socketing - GM BinderDocument3 pagesGem Socketing - GM Binderantony.9No ratings yet

- Muslim Women: Hidden Jewels Shining Through Hard TimesDocument2 pagesMuslim Women: Hidden Jewels Shining Through Hard TimesfarahfaadiNo ratings yet

- Why Cats and Dogs Always Fight StoryDocument9 pagesWhy Cats and Dogs Always Fight StoryKevin Aditya SaputraNo ratings yet

- Franks Casket - Appendices - Mjolnir - The Kobelev Runic Thor's Hammer (Lolland)Document2 pagesFranks Casket - Appendices - Mjolnir - The Kobelev Runic Thor's Hammer (Lolland)john_k7408No ratings yet

- Literatur LeuciteDocument23 pagesLiteratur LeucitenindYNo ratings yet

- Types of StoneDocument2 pagesTypes of StonePushkaraj KshirsagarNo ratings yet

- ClothingDocument5 pagesClothingSharmine MalaluanNo ratings yet

- Sapphire - WikipediaDocument75 pagesSapphire - WikipediaReynaLord Rafael-sanNo ratings yet

- From, Mahesh R. Thakkar, 1201 / 1202, Antariksha, 12th FloorDocument3 pagesFrom, Mahesh R. Thakkar, 1201 / 1202, Antariksha, 12th FloorDavid JohnsonNo ratings yet

- Full Download Intermediate Accounting Volume 2 Canadian 10th Edition Kieso Test BankDocument35 pagesFull Download Intermediate Accounting Volume 2 Canadian 10th Edition Kieso Test Banklofsteadkaroluks100% (38)

- Child Labour StoriesDocument3 pagesChild Labour Storiessohalsingh1No ratings yet

- HWLREZnovDocument40 pagesHWLREZnovjackson_publishingNo ratings yet

- A Chronology of Clocks from Ancient Sumerians to the 16th CenturyDocument18 pagesA Chronology of Clocks from Ancient Sumerians to the 16th CenturyHamza BouNo ratings yet

- JewelleryDocument8 pagesJewelleryshubhangi gargNo ratings yet

- Campos Relacionados Control de Stocks ALM VTAS BCBG RM AUADocument12 pagesCampos Relacionados Control de Stocks ALM VTAS BCBG RM AUAluz pulidoNo ratings yet

- Jennies Amber BeadesDocument7 pagesJennies Amber BeadesShabrin TajNo ratings yet