Professional Documents

Culture Documents

Actuador Air Torque At401

Uploaded by

dcarunchioOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Actuador Air Torque At401

Uploaded by

dcarunchioCopyright:

Available Formats

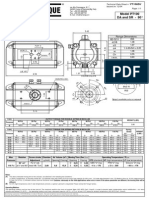

AIR TORQUE S.p.A.

S.p.A

Technical Data Sheet n AT401DM

Issued on: 06/04

Page: 1/1

via Alla Campagna, N1

24060 Costa di Mezzate(Bg) Italy

Tel.: +39 035 682299

Fax: +39 035 687791

E-mail: info@airtorque.it

Model AT401

DA and SR - 90

D im e nsio ns in m m

Available flange:

F10

F07 + F10

Flange Dimensions

ISO 5211

F07

F10

55

70

d2 f8

70

102

d3

M8x12 M10x15

d4

55

70

H

22

22

27

Ch

24

24

29

I min.

1,5

1,5

h min.

2,5

2

h1

Position Indicator for

Z = 65

proximity

Pressure connection

B2

Ancillary At tachment

AA 2

F10

F07 + F10

Spigot available only on request

TYPE

OUTPUT TORQUE FOR DOUBLE ACTING IN Nm

Pressure

2,5 bar

0

90

3 bar

0

90

3,5 bar

0

90

4 bar

0

90

4,2 bar

0

90

4,5 bar

0

90

5 bar

0

90

5,5 bar

0

90

6 bar

0

90

7 bar

0

90

8 bar

0

90

138

166

194

222

233

249

277

305

332

388

443

2,5 bar

3 bar

3,5 bar

4 bar

6 bar

7 bar

8 bar

TYPE

Pressure

S 05

S 06

S 07

S 08

S 09

S 10

S 11

S 12

Max.

Pressure

8 bar

OUTPUT TORQUE FOR SPRING RETURN IN Nm

90

90

4,2 bar

4,5 bar

5 bar

90

90

90

90

169

139

180

150

197

167

224

195

252

159

148

123

106

170

159

134

117

186

176

150

134

214

203

178

162

242

231

138 89,7 149 101 165 117 193

71,7 17,9 99,4 45,6 127 73,3 138 84,3 155 101 182

88,9 29,1 #### 56,8 #### 67,9 144 84,5 172

#### 40,3 #### 51,4 #### 68,0 161

#### 51,5 ####

145

221

90

86 56,1 114 83,8 141 111

75,5 39,6 103 67,3 131 95

65,0 23,1 92,7 50,8 120 78,5

82,2 34,3 110 62

129

210

112 200

95,7 189

79,2 179

10,2

Spring

5,5 bar

WEIGHT (Kg)

90

90

90

90

stroke

90

0

End Start

222 #### #### 335,3 #### #### #### 82,4 52,5

206 #### #### 324,8 #### #### #### 98,9 63

189 259 217 314,3 #### #### #### 115 73,5

173 248 201 304 256 #### #### 132 84

156

140

238

227

184

168

293

283

239

223

349

338

295

278

148 94,5

165 105

123

107

217

151

206

135

272

262

206

190

328

317

262

245

181

198

116

126

WEIGHT

(Kg)

11,0

11,1

11,3

11,5

11,6

11,8

11,9

12,1

Rotation

Screw stroke Chamber Air Volume (L) Moving Time (Sec.) ( A )

Operating Temperature (C) ( B )

Closing STD (standard) HT (high temperature) LT (low temperature)

Adjustment

(mm) Opening Closing Opening

For 1 adj.

D

D

NBR "O" ring

FPM "O" ring

Silicone "O" ring

90 4

0,9

1,1

at 0 and 90 need 1/4 Turn

S

S

125

1,54

2,34

1,2

1,4

- 20 to + 80

- 15 to + 150

- 40 to + 80

Notes:

(A) The above indicated moving time of the actuator, are obtained in the following test conditions:

(1) Room Temperature, (2) Actuator Stroke 90, (3) Solenoid Valve with Orifice Of 4 mm and a flow capacity Qn 400 L/min., (4) Inside pipe diameter 8 mm, (5) Medium clean air, (6) Air supply pressure

5,5 bar (79,75 Psi), (7) Actuator without external resistance load. Cautions: obviously on the field applications when one or more of the above parameter are different, the moving time will be

different.

(B) For HT (high temperature) and LT (low temperature) services, a special Lubricant is requested. Please contact Air Torque factory.

Operating Medium:

The operating medium must be free of dust and oil. The maximum particle size must not exceed 30m (ISO 8573 Part1, Class5). In order to prevent water condensation and/or solidification (ice, when

actuator work below 0C), the operating medium must have a dew point equal to 20C or, at least 10C below the ambient temperature (ISO 8573 Part1, Class3).

This data sheet is property of AIR TORQUE S.p.A. Costa di Mezzate - Italy and all rights of use and reproduction are reserved.

This data sheet is general in nature and manufacturer reserves the right to alter materials or to make other improvements from time to time

You might also like

- Take PG 13Document196 pagesTake PG 13RamkumarNo ratings yet

- Tipo - Type CP50/130: Electrobombas Centrífugas Serie CP en MonoblocDocument1 pageTipo - Type CP50/130: Electrobombas Centrífugas Serie CP en MonoblocretiradoNo ratings yet

- Emisiones Pablo de La Vega Dresser Rand A Siemens Business V1Document31 pagesEmisiones Pablo de La Vega Dresser Rand A Siemens Business V1Jose Lorenzo ToralNo ratings yet

- Emerald Sea ImperialDocument4 pagesEmerald Sea Imperialdpv248438No ratings yet

- Boge Air Compressors - Leakage MonitorDocument2 pagesBoge Air Compressors - Leakage MonitorAir Repair, LLCNo ratings yet

- Catalog IDSI TYCODocument226 pagesCatalog IDSI TYCOAdrian OprisanNo ratings yet

- ERS M22 PC4 FerryDocument2 pagesERS M22 PC4 FerryouakgoodNo ratings yet

- Ffianra: Existing ModificationDocument128 pagesFfianra: Existing ModificationGary ChanNo ratings yet

- Impa Store CatalogDocument71 pagesImpa Store CatalogrecutuNo ratings yet

- Fire-Fighting NetworkDocument73 pagesFire-Fighting NetworkyutNo ratings yet

- Spec C32 746kW@1800rpmDocument15 pagesSpec C32 746kW@1800rpmPhuc DcNo ratings yet

- Nef M280Document9 pagesNef M280husan shah100% (1)

- Autronica Op PNL Bs200Document2 pagesAutronica Op PNL Bs200redvalorNo ratings yet

- Emd00099en JWP26CDocument4 pagesEmd00099en JWP26CLupu Ane MarieNo ratings yet

- 99REF004B REF Pump Identification LoRDocument8 pages99REF004B REF Pump Identification LoRfrank rodriguezNo ratings yet

- c32 Cylinder HeadDocument5 pagesc32 Cylinder HeadHaidar SareeniNo ratings yet

- MXH Pump Data SheetDocument12 pagesMXH Pump Data SheetAnonymous wIPMQ5rhNo ratings yet

- CR, CRN High Pressure: Grundfos Product GuideDocument48 pagesCR, CRN High Pressure: Grundfos Product Guiderodriguez.gaytanNo ratings yet

- Eng SPJ PDFDocument8 pagesEng SPJ PDFwizz33No ratings yet

- GC80 - 85 Compact GyroDocument112 pagesGC80 - 85 Compact GyrojaliltaghdarehNo ratings yet

- Nodriza ViDocument453 pagesNodriza Vimichael pachecoNo ratings yet

- Sew Eurodrive PDFDocument116 pagesSew Eurodrive PDFLeonardo Vinicio Olarte CarrilloNo ratings yet

- Product Doc 1 en 180Document6 pagesProduct Doc 1 en 180Fredy Mauricio Diaz VargasNo ratings yet

- Sebp7383 PDFDocument617 pagesSebp7383 PDFKadir Koray BozyelNo ratings yet

- Parts Catalog Cummins, NT855G6 - ESN 25324276 & 25324885 - CPL 1381Document118 pagesParts Catalog Cummins, NT855G6 - ESN 25324276 & 25324885 - CPL 1381Ari100% (3)

- Cat C32 ACERT Spec Sheet - CommercialDocument13 pagesCat C32 ACERT Spec Sheet - CommercialMario Godoy100% (1)

- 1204-Barge 2 Tech SpecsDocument13 pages1204-Barge 2 Tech SpecsmardiradNo ratings yet

- Calpeda MXHL Stainless Steel Horizontal Multistage PumpDocument4 pagesCalpeda MXHL Stainless Steel Horizontal Multistage PumpWayne SeamanNo ratings yet

- 2015 Price ListDocument164 pages2015 Price ListGalang100% (1)

- Maintenance Interval Schedule: Operation and Maintenance ManualDocument4 pagesMaintenance Interval Schedule: Operation and Maintenance ManualAgus Dani100% (1)

- Desalt JWP 26 C Series PDFDocument4 pagesDesalt JWP 26 C Series PDFRavindar AnandanNo ratings yet

- Fire Pump EnginesDocument2 pagesFire Pump Enginessugax00No ratings yet

- 3516 516de4a 50HZ 6300Document6 pages3516 516de4a 50HZ 6300sinliongNo ratings yet

- SC550 50HZ Cummins Generator STAMFORDDocument4 pagesSC550 50HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- Ingersoll RandDocument2 pagesIngersoll Randvijayps.mech0% (1)

- Caterpillar c32 Marine Engine (001 300)Document300 pagesCaterpillar c32 Marine Engine (001 300)mala1972No ratings yet

- Copeland ZR125KC-TF5-950 Scroll Compressor - Carrier HVACDocument3 pagesCopeland ZR125KC-TF5-950 Scroll Compressor - Carrier HVACjacc42No ratings yet

- Product Guide o e w26 PDFDocument228 pagesProduct Guide o e w26 PDFa03041998No ratings yet

- LW Sparepart Lw450eDocument59 pagesLW Sparepart Lw450eMatthew100% (1)

- Marine Generator Set: 30.0 Ekw (60 HZ) at 1800 RPM 24.5 Ekw (50 HZ) at 1500 RPMDocument2 pagesMarine Generator Set: 30.0 Ekw (60 HZ) at 1800 RPM 24.5 Ekw (50 HZ) at 1500 RPMByron CheleNo ratings yet

- RSV Series BookletDocument24 pagesRSV Series BookletmajidNo ratings yet

- 3516C Marine Propulsion Engines PDFDocument3 pages3516C Marine Propulsion Engines PDFJose RoaNo ratings yet

- Caterpillar ElectronicDocument10 pagesCaterpillar ElectronicНиколай БелыйNo ratings yet

- GTA38 Service Parts With Images (Oil Heater Pp13y14)Document36 pagesGTA38 Service Parts With Images (Oil Heater Pp13y14)foroNo ratings yet

- WAF30 GU Part ListDocument5 pagesWAF30 GU Part ListChia PeterNo ratings yet

- AC&M Power TransducersDocument2 pagesAC&M Power TransducersLare LenangNo ratings yet

- PIM130B1 - Daihatsu DT Series Archived JUN PDFDocument5 pagesPIM130B1 - Daihatsu DT Series Archived JUN PDFAnonymous XGsiY6rNo ratings yet

- Azcue Multistage PumpsDocument16 pagesAzcue Multistage PumpsJun Bryan JuenNo ratings yet

- Weidmuller Analog Signal ConditionersDocument65 pagesWeidmuller Analog Signal ConditionersCem AlpaslanNo ratings yet

- Bitzer DataDocument27 pagesBitzer Databookslover1No ratings yet

- B3.3 Series: Diesel Generator SetDocument4 pagesB3.3 Series: Diesel Generator SetCarlos PerezNo ratings yet

- PERKÿNS SABRE 6TG2AM AYRDIMCI MOTORDocument2 pagesPERKÿNS SABRE 6TG2AM AYRDIMCI MOTORRiki Akbar100% (1)

- Pt100du Air TorqueDocument1 pagePt100du Air TorqueAurelio SuarezNo ratings yet

- Ac PDFDocument95 pagesAc PDFCarlos TorresNo ratings yet

- HiNo DutRo Fuel Injection Pump DiagramDocument8 pagesHiNo DutRo Fuel Injection Pump Diagramjoe88% (16)

- SMC Neumatic CatalogDocument98 pagesSMC Neumatic CataloganderssonpcNo ratings yet

- Hindle 4.2.2 Torque Characteristics PDFDocument6 pagesHindle 4.2.2 Torque Characteristics PDFpandit1010No ratings yet

- Cirkulac Pumpe BUHLER De370001Document8 pagesCirkulac Pumpe BUHLER De370001sealion72100% (1)

- GDI DENSO InjectorsDocument19 pagesGDI DENSO InjectorsPāvels SmilgaNo ratings yet

- SD 14 eDocument12 pagesSD 14 eseaqu3stNo ratings yet

- Gas Separator Iso ViewDocument1 pageGas Separator Iso ViewdcarunchioNo ratings yet

- Gas Separator General ViewDocument1 pageGas Separator General ViewdcarunchioNo ratings yet

- Gas Separator View 1Document1 pageGas Separator View 1dcarunchioNo ratings yet

- Pipe LineDocument1 pagePipe LinedcarunchioNo ratings yet

- ManifoldDocument1 pageManifolddcarunchioNo ratings yet

- Asme TK Lateral SectionDocument1 pageAsme TK Lateral SectiondcarunchioNo ratings yet

- Asme TK MODELDocument1 pageAsme TK MODELdcarunchioNo ratings yet

- Gas Separator Top ViewDocument1 pageGas Separator Top ViewdcarunchioNo ratings yet

- BujiasDocument1 pageBujiasdcarunchioNo ratings yet

- DrainDocument1 pageDraindcarunchioNo ratings yet

- Awwa SpoolDocument1 pageAwwa SpooldcarunchioNo ratings yet

- Recipient EDocument1 pageRecipient EdcarunchioNo ratings yet

- Crude Oil Piping Isometric ViewDocument1 pageCrude Oil Piping Isometric ViewdcarunchioNo ratings yet

- Crude Oil PipingDocument1 pageCrude Oil PipingdcarunchioNo ratings yet

- Asme TK Plant SectionDocument1 pageAsme TK Plant SectiondcarunchioNo ratings yet

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Document9 pagesTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioNo ratings yet

- Aisi 347 CaracteristicasDocument2 pagesAisi 347 CaracteristicasdcarunchioNo ratings yet

- Piping SolidworksDocument1 pagePiping SolidworksdcarunchioNo ratings yet

- Performance LogDocument1 pagePerformance LogdcarunchioNo ratings yet

- BELIMO LM24 ActuadorDocument2 pagesBELIMO LM24 ActuadordcarunchioNo ratings yet

- 7800 - Relay Cleaver BroksDocument20 pages7800 - Relay Cleaver Broksrubl770622No ratings yet

- PipeDocument8 pagesPipedcarunchioNo ratings yet

- Maxon 5500 InstructionsDocument8 pagesMaxon 5500 InstructionsdcarunchioNo ratings yet

- Display Honeywell s7999 Controlinks DisplayDocument12 pagesDisplay Honeywell s7999 Controlinks DisplaydcarunchioNo ratings yet

- Bomba Dosificadora Flyer DMH 2.2 - 3000 LTS-HDocument2 pagesBomba Dosificadora Flyer DMH 2.2 - 3000 LTS-HdcarunchioNo ratings yet

- Mediciones CEMS - ZZ-025-0802EDocument4 pagesMediciones CEMS - ZZ-025-0802EdcarunchioNo ratings yet

- Maxon 5550 BulletinDocument4 pagesMaxon 5550 BulletindcarunchioNo ratings yet

- Maxon 5500 InstructionsDocument8 pagesMaxon 5500 InstructionsdcarunchioNo ratings yet

- Actuador Honeywell ML 7999 B - Ds - 65-0264Document12 pagesActuador Honeywell ML 7999 B - Ds - 65-0264dcarunchioNo ratings yet

- Dogs - Pink Floyd chords and tabsDocument2 pagesDogs - Pink Floyd chords and tabsdcarunchioNo ratings yet

- Form-Q - Application For Quarry PermitDocument1 pageForm-Q - Application For Quarry PermitDebasish PradhanNo ratings yet

- Action Research HandoutDocument2 pagesAction Research HandoutgeethamadhuNo ratings yet

- Assessment of Electronic Collection Development in Nigerian University LibrariesDocument24 pagesAssessment of Electronic Collection Development in Nigerian University Librariesmohamed hassanNo ratings yet

- Eftalia Marin Eng 2018 1948Document2 pagesEftalia Marin Eng 2018 1948Alina Mariana NicaNo ratings yet

- OHIO SCHOOL MILK AUCTION COLLUSIONDocument21 pagesOHIO SCHOOL MILK AUCTION COLLUSIONmhafner88No ratings yet

- ASTMH Exam Brochure 18 FNLDocument17 pagesASTMH Exam Brochure 18 FNLNgô Khánh HuyềnNo ratings yet

- StompIO-1 User ManualDocument92 pagesStompIO-1 User ManualFederico Maccarone50% (2)

- Borang Permohonan Pinjaman Pendidikan FMM Tunku Tan Sri Mohamed Study Loan Application FormDocument10 pagesBorang Permohonan Pinjaman Pendidikan FMM Tunku Tan Sri Mohamed Study Loan Application FormJom StadiNo ratings yet

- Efficient Three Phase X3-Max Inverters from SolaX for Industrial and Residential UseDocument2 pagesEfficient Three Phase X3-Max Inverters from SolaX for Industrial and Residential UseMuhammad FaruqNo ratings yet

- Marty Schwartz Blues TipsDocument25 pagesMarty Schwartz Blues TipsEuCelNouNo ratings yet

- Aurora Diesel Engine Driven FP SelectionDocument48 pagesAurora Diesel Engine Driven FP Selectionsyed mustafa aliNo ratings yet

- Lesson 2 - The RPA Business Analyst - Role, Skills and ChallengesDocument5 pagesLesson 2 - The RPA Business Analyst - Role, Skills and ChallengesjayarajanNo ratings yet

- Paradeep Refinery Project: A Sunrise Project For A Sunshine FutureDocument35 pagesParadeep Refinery Project: A Sunrise Project For A Sunshine Futuremujeebtalib80% (5)

- Aug. 25 Hendersonville City Council Meeting PacketDocument27 pagesAug. 25 Hendersonville City Council Meeting PacketLurahNo ratings yet

- Jan 2012Document40 pagesJan 2012Daneshwer Verma100% (1)

- The Cucumber Book Behaviour-Driven Development For Testers and DevelopersDocument28 pagesThe Cucumber Book Behaviour-Driven Development For Testers and DevelopersGursharan AulakhNo ratings yet

- PNMT (Pasolink) Operation ManualDocument52 pagesPNMT (Pasolink) Operation ManualAsrar Zaffar50% (2)

- Occurrence of Black Soldier Fly HermetiaDocument2 pagesOccurrence of Black Soldier Fly HermetiaMarcelo Geraldo TeixeiraNo ratings yet

- Flyrock Prediction FormulaeDocument5 pagesFlyrock Prediction FormulaeAmy LatawanNo ratings yet

- OBURE Understanding How Reits Market WorksDocument3 pagesOBURE Understanding How Reits Market WorksJohn evansNo ratings yet

- Drinking Water StandardDocument2 pagesDrinking Water StandardNoorul Mufas Mn100% (1)

- Hydrostatic Test ReportsDocument3 pagesHydrostatic Test ReportsHanuman RaoNo ratings yet

- Field Attachment Report Format For All Third Year Students - Final For Use by StudentsDocument2 pagesField Attachment Report Format For All Third Year Students - Final For Use by StudentsJoseph Kayima50% (2)

- 1 ComplaintDocument6 pages1 ComplaintIvy PazNo ratings yet

- Manual D00125190 1 PDFDocument114 pagesManual D00125190 1 PDFnimish_845588906No ratings yet

- Difference Between Offer and Invitation To TreatDocument5 pagesDifference Between Offer and Invitation To TreatBrian Okuku Owinoh100% (2)

- ATTDocument3 pagesATTforu_kkkNo ratings yet

- Guerrero vs. CA - DigestDocument2 pagesGuerrero vs. CA - DigestMarionnie SabadoNo ratings yet

- Danh sách đ tài Đ c nglunvăn ề ề ươ ậ HK1/19-20Document47 pagesDanh sách đ tài Đ c nglunvăn ề ề ươ ậ HK1/19-20LONG Trương MinhNo ratings yet

- A Future For The World's Children?: The Numbers That CountDocument20 pagesA Future For The World's Children?: The Numbers That CountCarmen PalimariuNo ratings yet